In the power transmission and distribution system, busbar is the core conductive component, which is widely used in high-voltage transmission, data center, new energy, rail transportation, industrial automation and other fields. Different types of busbars have their own characteristics in terms of materials, structure, current carrying capacity, heat dissipation performance, etc. How to choose the right busbar product is directly related to the safety, energy efficiency and long-term operation stability of the system.

This guide will deeply analyze the key terms, electrical performance, industry applications and selection points of busbars to help you match your needs more accurately and optimize the design of the power supply system.

Busbar product types

-

It is an important electronic transmission axis for transmitting large flows and is used in distribution cabinets, substations and industrial distribution systems.

-

A tubular conductor made of aluminum alloy or copper, used for high current transmission, reducing skin effect and improving heat dissipation performance.

-

It is made of copper and aluminum, combining the electrical conductivity of copper and the lightweight of aluminum, and is suitable for new energy and rail transportation.

-

It adopts a multi-layer structure to reduce electromagnetic interference and improve system efficiency. It is suitable for data centers and UPS power systems.

-

Insulated Busbar

Assisted by a bonding layer, it reduces the risk of short circuits, improves safety, and is suitable for high-voltage systems.

-

It adopts multi-layer copper yarn or purple aluminum tape structure, which is suitable for dynamic power transmission environment, such as BMS battery system and industrial automation.

-

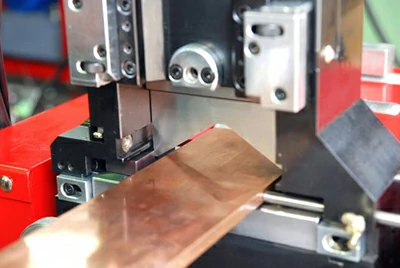

Roll Busbar / Coiled Busbar

It is suitable for flexible power distribution systems and can be installed in a flexible manner. It is suitable for power distribution cabinets, data centers, rail transit and other industries.

Busbar auxiliary support & connection product types

-

Busbar Connector

Used for the restraint and connection of busbars, including meeting the requirements of aluminum, copper and aluminum-copper cross-material connection.

-

Connecting Terminals

Used for the terminal connection between busbar and electrical equipment, suitable for conductors of different materials. Available in copper, aluminum, and copper-clad aluminum.

-

Bimetallic Connector

Solve the problem of electrochemical corrosion when connecting copper and aluminum.

-

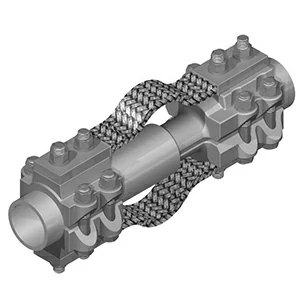

Expansion Connector

The busbar is allowed to expand and contract to cope with thermal expansion and release.

-

Busbar Duct

Protect the busbar, limit capacity, and enhance environmental adaptability.

-

Busbar Support

Used to fix the busbar, reduce vibration and mechanical loss, and improve safety.

-

Insulation Sleeves

Provides additional insulation protection for high voltage busbar systems to prevent short circuits and electrical faults.

Detailed explanation of busbar electrical performance parameters

The electrical performance of the busbar directly determines the stability and efficiency of the power supply system. In different application scenarios, the rational selection of the busbar can optimize current transmission and improve equipment reliability. The following are key electrical parameters and their optimization solutions.

Current carrying capacity

The current carrying capacity of the busbar determines its maximum carrying current. Overloading may cause the busbar to overheat, increase electrical losses, aging of the insulation layer, and even safety hazards.

Choose high conductivity materials (such as 1350 pure aluminum, C1100 pure copper) to reduce resistance.

Increase the busbar cross-sectional area, reduce the unit current density, and reduce the risk of overheating.

Adopt optimized structure, such as Buspipe, to improve heat dissipation capacity and reduce current transmission loss.

Voltage drop

The longer the busbar length, the greater the voltage loss caused by resistance, which may affect the stable operation of terminal equipment, especially in data centers, rail transit and new energy systems.

Use low resistance materials, such as high purity aluminum (1350) or copper (C1100), to reduce energy loss.

Increase busbar width or thickness to improve current carrying capacity and reduce voltage drop impact.

In high-frequency applications (such as UPS, inverter), optimize the busbar structure and improve the uniformity of current distribution.

Electrical conductivity

Conductivity affects the energy loss and heat dissipation capacity of the busbar. In applications such as high-power equipment and new energy storage systems, low conductivity will increase power loss and affect overall energy efficiency.

Choose high conductivity materials, such as 1350 pure aluminum (61% IACS) or C1100 pure copper (100% IACS), to improve transmission efficiency.

When space is limited, laminated busbars are used to optimize the current path and improve overall conductivity.

Power loss

The power loss of the busbar affects the energy efficiency of the equipment, especially in data centers, UPS systems and high-power industrial equipment, where high power loss will increase operating costs.

Choose low resistance busbar material (such as 1350 pure aluminum or C1100 pure copper) to reduce energy loss.

Adopt optimized structure (such as laminated busbar) to reduce connection loss and improve current transmission efficiency.

Busbar electromagnetic & thermal effects

In high-frequency power systems and high-power electronic equipment, the electromagnetic effect and thermal management capabilities of the bus are crucial to system stability.

Skin effect

High-frequency AC current tends to flow along the surface of the conductor, reducing the effective conductive area and causing a decrease in conductive efficiency. This has a significant impact in inverters, UPS, and power electronic equipment.

Laminated busbars are used to optimize current distribution and reduce the impact of skin effect.

Select appropriate busbar shape (such as thin-film busbar) to optimize conductive efficiency.

Eddy current loss

Eddy current losses mainly occur in high-frequency equipment (such as inverters and induction heating systems), which may cause internal circulation of current, generate additional heat, and reduce the overall efficiency of the busbar.

Laminated busbars are used to reduce magnetic flux loops, lower eddy current losses and improve energy efficiency.

Choose silver-plated or anodized busbars to optimize conductivity.

Heat dissipation

The busbar will generate heat during long-term operation. Insufficient heat dissipation capacity may cause the equipment to overheat and affect long-term stability. This problem is particularly important in high-load applications such as UPS power supply systems and electric vehicle charging stations.

Buspipe (busbar tube) is used to dissipate heat through air convection to reduce the temperature rise of the busbar.

Select busbar materials with high thermal conductivity (such as silver-plated or tin-plated busbars) to improve heat dissipation capacity.

By optimizing the installation method (such as vertically installing the busbar), the heat dissipation area can be increased and the heat exchange efficiency can be improved.

Busbar insulation and safety requirements

The insulation performance and safety of the busbar determine its applicability in scenarios such as high-voltage power supply, data centers, and industrial automation.

Insulation resistance

Insulation resistance determines the busbar's ability to resist leakage, affecting the busbar's safety and long-term reliability. If the insulation layer is damaged, it may cause a short circuit or electrical failure, especially in humid or high temperature environments (such as offshore wind power, tunnel power supply).

Select insulated busbars and use materials such as epoxy resin and polyvinyl chloride (PVC) to improve insulation performance.

In an environment with high humidity, a fully enclosed insulation process is used to prevent moisture from penetrating.

Fire resistance

The busbar may be affected by short circuits, arcs, etc. during long-term operation. If the flame retardant performance is insufficient, the risk of fire may increase. The flame retardant requirements of busbars are particularly important in the building power supply, data center, photovoltaic and wind power industries.

Choose busbars that meet UL94 V-0 flame retardant standards to improve fire safety.

Use high temperature resistant insulating coatings (such as epoxy resin and fluoroplastic coatings) to reduce the risk of busbar fire.

In closed environments (such as distribution cabinets and computer rooms), choose busbars with flame retardant certification to improve overall safety.

Industry application of busbar

Busbar products are widely used in many industries. Different types of busbars are suitable for different equipment and power supply systems. The following are the main industries and their key application areas, and corresponding busbar products are recommended for different needs.

High voltage transmission

High-voltage power transmission systems require busbars to have high conductivity, high temperature resistance, and low resistance to reduce power loss and improve power supply efficiency.

Contact us now

Application area

- Substation busbar system

- Conductive connection of high voltage transmission tower

- Switchgear and busbar bridging systems

Recommended busbar products

Data center & UPS systems

Data center and UPS power supply systems require high-efficiency, low-loss and compact busbar solutions to ensure stable equipment operation and reduce energy consumption.

Contact us now

Application area

- Data center main distribution bus

- Busbar connection for UPS battery energy storage system

- Server cabinet power supply bus

Recommended busbar products

Rail transit & metro

The rail transit power supply system requires the busbar to have high strength, corrosion resistance and good vibration resistance to ensure the safe operation of the train.

Contact us now

Application area

- Rail transit traction power supply system

- Substation busbar connection

- On-board power supply bus

Recommended busbar products

- 6082 Aluminum Busbar

- 6061 Aluminum Busbar

- Laminated busbar

EV & charging stations

New energy vehicles and charging pile systems require busbars with high conductivity, high temperature resistance and lightweight to improve charging efficiency and reduce energy loss.

Contact us now

Application area

- Charging pile busbar connection system

- New energy vehicle power battery connection busbar

- On-board DC/DC converter and inverter bus

Recommended busbar products

- 6063 Aluminum Busbar

- 6101 Aluminum Busbar

- Rolled busbar

Solar photovoltaic & Wind power

The energy industry requires busbars to be corrosion-resistant, anti-aging and highly conductive to optimize power conversion efficiency.

Contact us now

Application area

- PV inverter busbar connection

- Wind turbine busbar system

- DC busbar

Recommended busbar products

- 1350 Aluminum Busbar

- CCA busbar

- Insulated busbar

Industrial automation & robotics

Industrial automation equipment requires compact, flexible and highly reliable busbars to meet complex power supply requirements.

Contact us now

Application area

- Robot power bus

- Power supply busbar for automated production line

- Inverter power supply system

Recommended busbar products

- 6061 aluminum busbar

- Flexible busbar

- Rolled busbar

Marine & offshore engineering

Busbars in marine environments need to be resistant to corrosion, high humidity and impact to adapt to harsh operating conditions.

Contact us now

Application area

- Main busbar of ship power system

- Offshore wind power conversion station bus

- Diving equipment power supply bus

Recommended products

- 6082 aluminum busbar

- Copper clad aluminum busbar

- Insulated busbar

Busbar supplier selection guide

When purchasing busbar products, it is crucial to choose a supplier with a complete supply chain and one-stop processing capabilities. A high-quality busbar supplier should not only provide busbar products of various specifications, but also have complete processing capabilities, customized services and technical support to ensure that the busbar performs at its best in the customer's application scenarios.

Chalco Busbar – a wide selection of busbar products

Chalco offers a full range of busbar materials and specifications to meet the needs of various industries and scenarios. We supply aluminum busbars (1050, 1060, 6101, 6061, etc.), copper clad aluminum (CCA), laminated, flexible, and roll busbars, covering both conventional and high-performance applications.

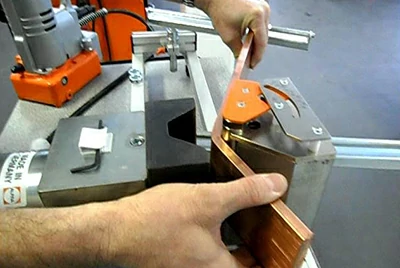

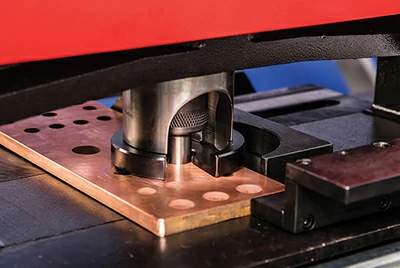

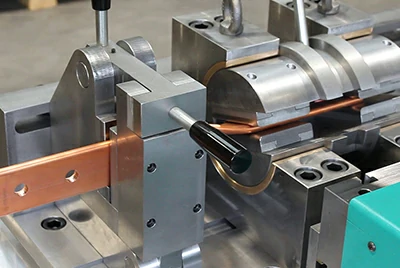

Chalco Busbar – complete processing & customization capabilities

We provide customized busbar sizes and precise processing services to meet installation needs across systems. Our capabilities include bending, punching, cutting, and terminal processing, helping customers reduce secondary processing costs and ensure easy integration.

Chalco Busbar – multiple surface treatments & composite processes

To enhance durability and performance, Chalco offers advanced surface treatments such as anodizing, silver/tin/nickel plating, and insulation coatings including epoxy, heat shrink tubing, and PVC sleeves, along with copper clad aluminum for optimized conductivity and weight.

Chalco Busbar – accessories & connector kits support

We offer a full set of accessories to ensure compatibility and stability in busbar installations, including connectors, clamps, aluminum/copper terminals, bimetallic connectors, and insulation supports, helping customers simplify procurement and improve efficiency.

Chalco Busbar – technical support & solutions

Our team provides professional support for busbar selection, system design, installation guidance, and electrical testing (e.g., conductivity, short circuit, temperature rise) to ensure safety, compliance, and optimal performance in every project.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote