6066 is an aluminum-magnesium-silicon alloy belonging to the 6000 series, sharing over 98% of alloy composition similarity with 6061 aluminum. It is an aluminum alloy used for welded structural forgings and extruded components, suitable for manufacturing high-strength and lightweight components in the aerospace and structural aerospace sectors.

As a supplier of aerospace aluminum materials to companies like Collins Aerospace, Boeing, and Airbus, China Aluminium can customize products according to customer requirements, offering excellent quality and the most competitive prices.Welcome to contact

Chalco 6066 aerospace aluminum standard

AMS-QQ-A-200/10A, BS 2 L84, ASTM B221, and ASME SB221

Chalco accreditations

AS9100,OHSAS 18001,ISO14001,ISO9001,NADCAP HT,NADCAP NDT,IATP16949

The specification introduction of 6066 aviation aluminum bar

| Name | 6066 aviation aluminum bar |

| Temper | O, T4, T4510, T42, T6, T6510, T62 |

| 6066 Extruded aluminum rod diameter | 3.0-420mm |

| 6066 Cold finish aluminum rod diameter | 3.0-350mm |

| 6066 aluminum Square bar size | 10×10mm-150×150mm |

| 6066 aluminum flat bar size | Customized according to customer requirements |

| 6066 aluminum Hexagonal rods size | Customized according to customer requirements |

| Length | 1-6m, Random, Fix ; Cut Length or as per clients’requirement |

Detailed size information, you can directly contact us for customization or check the hot-selling dimensions chart for 6066 aviation aluminum bars below.Custom Alu bar

Chalco hot selling 6066 aviation aluminum rod products

6066 T6 aerospace grade aluminum bar

6066 T6 aerospace grade aluminum bar has high strength and hardness, and is mainly used in the manufacture of aviation components.

Quick Quote6066 T651 aviation aluminum rod

6066 T651 aviation aluminum rod has high strength and good crack resistance. It is mainly used in the manufacture of parts and components that require complex shape forming in the aerospace field.

Free samples6066 T6510 aviation aluminum bar

6066 T6510 aviation aluminum bar are stabilized after heat treatment and artificial aging treatment to improve stress corrosion resistance. It is mainly used in the manufacture of products requiring high strength and high corrosion resistance in the aerospace field.

Request A Quote6066 O aircraft aluminum bar

6066 O aircraft aluminum bar has high ductility and machinability, but low strength. It is mainly used in the manufacture of products requiring high plasticity, such as aluminum tubes in the aerospace field.

Custom Alu bar6066 T4 aircraft aluminum rod

6066 T4 aircraft aluminum rod has high strength and toughness. Mainly used in the manufacture of products requiring higher strength and toughness in the aerospace field.

6066 T6511 aviation aluminum rods

6066 T6511 aviation aluminum bars has high strength and excellent cutting performance. It is mainly used in the manufacture of parts and components that require complex processing in the aerospace field, such as fuselage structures, rudder surfaces, engine parts, etc.

Request A Quote

Other popular aerospace-grade aluminum bar offered by Chalco

6061 aerospace aluminum bar

5052 aerospace aluminum bar

2618A aerosapce aluminum bar

2024 aerospace aluminum bar

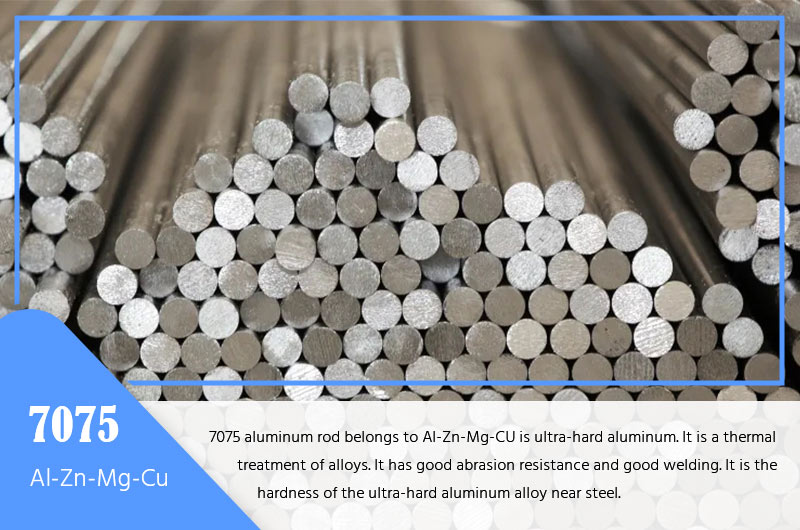

7075 aerosapce aluminum bar

7050 aerospace aluminum rod bar

The chemical composition of 6066 aircraft aluminum bar

| 6066 Alloy % | |

| Si | 0.9-1.8 |

| Fe | 0.50 |

| Cu | 0.7-1.2 |

| Mn | 0.6-1.1 |

| Mg | 0.8-1.4 |

| Cr | 0.40 |

| Zn | 0.25 |

| Ti | 0.20 |

| Other | 0.20 |

| Al | Remainder |

The mechanical properties of 6066 aircraft aluminum rod

| Physical Property | |||||

| Alloy | Temper | Dimensions /mm | Room temperature test result | ||

| Tension strength /MPa | Yield strength /MPa | Elongation/% | |||

| A50mm | |||||

| Not less than | |||||

| 6066 | O | All | 200 Max | 124 Max | 16 Min |

| T4, T4510 | All | 276 | 172 | 14 | |

| T42 | All | 276 | 165 | 14 | |

| T6, T6510 | All | 345 | 310 | 8 | |

| T62 | All | 345 | 290 | 8 | |

What are the characteristics of 6066 aviation aluminum rods?

- High strength

- Good corrosion resistance

- Good solderability

- Excellent heat treatment performance

- Good wear resistance

- Good low temperature performance Free samples

What are the advantages of Chalco?

Chalco, as one of China's leading aluminum manufacturers, offers a vast range of molds, producing a full series of 6066 Aluminum Bar to meet varying size and shape requirements. The prices are highly competitive, providing a one-stop supply to eliminate your concerns. All products are certified under quality systems such as ISO 9001, GJB 9001, AS9100, TS16949, and hold Nadcap (NonDestructive/Heat/Materials Testing) certification. Customization according to Japanese, European, American standards, and other client-specific needs is available upon request.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Chalco Hot-selling Dimensions Table for 6066 Aviation Aluminum Bars

| Hot-selling Dimensions Table for 6066 Aviation Aluminum Round Bars/mm | |||||||||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 |

| 35 | 36 | 37 | 38 | 39 | 40 | 42 | 45 | 46 | 48 |

| 50 | 52 | 55 | 57 | 58 | 60 | 62 | 65 | 70 | 75 |

| 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 |

| 130 | 135 | 140 | 145 | 150 | 155 | 160 | 165 | 170 | 175 |

| 180 | 185 | 190 | 195 | 200 | 210 | 220 | 230 | 240 | 250 |

| 260 | 270 | 280 | 290 | 300 | 310 | 320 | 330 | 340 | 350 |

| 360 | 370 | 380 | 390 | 400 | 410 | 420 | |||

| Hot-selling Dimensions Table for 6066 Aviation Aluminum Square Bars/mm | |||||||||

| 6.35×6.35 | 10×10 | 12×12 | 12.7×12.7 | 15×15 | 20×20 | 25×25 | 30×30 | 35×35 | 40×40 |

| 50×50 | 60×60 | 70×70 | 80×80 | 90×90 | 100×100 | 110×110 | 120×120 | 130×130 | 150×150 |

FAQ for purchasing 6066 aerospace aluminum rods bar

Q: What are the common specifications and sizes available for 6066 aluminum rods?

A: We offer a variety of common specifications and sizes for aluminum rods, including options for diameter, length, and specific shapes. For instance, aluminum round bars are available in diameters ranging from 5mm to 420mm, while aluminum square bars range from 10x10mm to 150x150mm. Standard lengths are typically 3m, 6m... but customization is possible according to customer requirements.

Q: How are the prices for 6066 aerospace aluminum rods determined?

A: The prices of aluminum rods depend on the selected specifications, dimensions, and order quantity. We provide competitive pricing and offer flexibility based on bulk orders and other factors. Please contact our sales team for specific quotations.

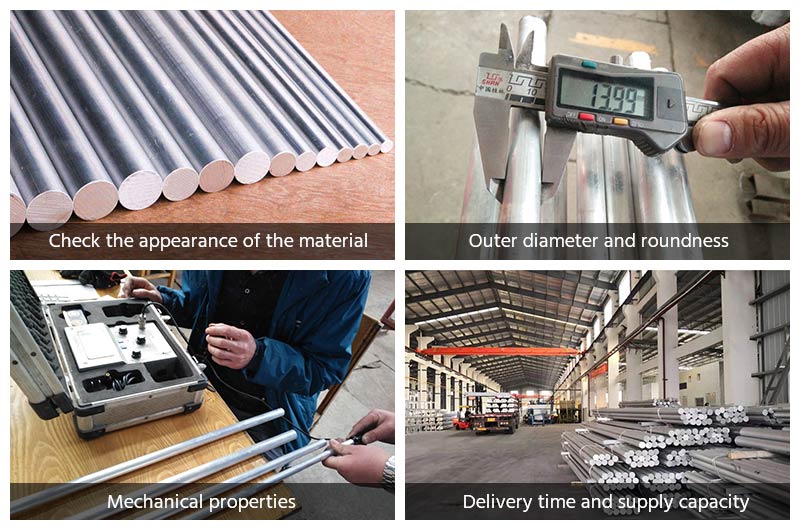

Q: How is the quality of the aluminum rods ensured?

A: We strictly control the production process using advanced technology and rigorous testing to ensure that the aluminum rods meet the required standards. Each batch undergoes strict inspection and testing to ensure stable and reliable quality. Customers can conduct on-site inspections at the factory or invite third-party inspections to confirm the quality.

Q: How long does it take for delivery after placing an order?

A: The delivery time varies depending on the order size and stock availability. Generally, aluminum rods of standard specifications are usually in stock and can be cleared for shipment within 7 days after ordering. Larger quantities or specific sizes often require customization, with delivery times typically ranging from 1 to 3 months. For specific delivery schedules, please consult our sales team.