Why choose Chalco 6262 aluminum bar?

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AMS 4115

ASTM B221/B221M

MIL-T-7081E

ISO 6361-2

EN 573-3

JIS H4000

KS D 7001

BS L 110

Chalco is a manufacturer with advantages and capabilities in the field of aerospace materials. The company has advanced research and development, detection and analysis instruments, which can accelerate the research and development of new products and the transformation of scientific and technological achievements.

Chalco's brand represents high quality, timely delivery and good reputation. With leading technology and globally competitive products, Chalco is committed to common development with customers.

Specification of 6262 aluminum bar

| Temper | T6 T651 T73 T74 |

| Diameter | 5.0mm-76.0mm |

| 6262 aluminum bar stock | Diameter: 5.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm, 16.0mm, 20.0mm, 25.0mm, 30.0mm, 35.0mm, etc. |

Chemical composition of 6262 aluminum bar

| Element | Composition(%) |

| Al | Bal |

| Si | 0.40/0.80 |

| Fe | 0.70 max |

| Cu | 0.15/0.40 |

| Mn | 0.15 max |

| Cr | 0.04/0.14 |

| Ti | 0.15 max |

| Mg | 0.80/1.20 |

| Zn | 0.25 max |

| Bi | 0.40-0.70 |

| Pb | 0.40-0.70 |

| Other Each | 0.05 max |

| Others Total | 0.15 max |

PLEASE NOTE:

Due to European Environmental Protection Directives

- # 2000/53/CE-ELV–For the automotive sector

- # 2002/95/CE-RoHS–For the electrical and electronics sector

This alloy has been replaced by Alloy 6026 which has a lower Lead content.

Typical material properties for 6262 aluminium bar

Material properties for 6262 T6 aluminium bar

| Tensile strength (MPa) | 440 |

| Yield strength (MPa) | 400 |

| Elongation (%) | 8 |

| Hardness (HRB) | 95 |

Material properties for 6262 T651 aluminium bar

| Tensile strength (MPa) | 455 MPa |

| Yield strength (MPa) | 410 MPa |

| Elongation (%) | 8% |

| Hardness (HRB) | 95 HRB |

What are the characteristics of 6262 aircraft aluminum bar?

High strength

Compared to ordinary aluminum alloys, 6262 aircraft aluminum bar has higher strength. After heat treatment, this material can achieve very high tensile and yield strength.

Good machinability

6262 aircraft aluminum bar is easy to machine and shape, and can be formed through cold and hot working, suitable for manufacturing various shapes and sizes.

Good corrosion resistance

6262 aircraft aluminum bar has excellent corrosion resistance, and can be used in various environments, such as high humidity, acidic and alkaline environments.

Lightweight

Compared to other metallic materials, aluminum alloys have low density, which can reduce the weight of structures, contributing to improved fuel efficiency and payload capacity of aircraft.

Recyclability

6262 aircraft aluminum bar can be fully recycled, with minimal impact on the environment, meeting the requirements of sustainable development.

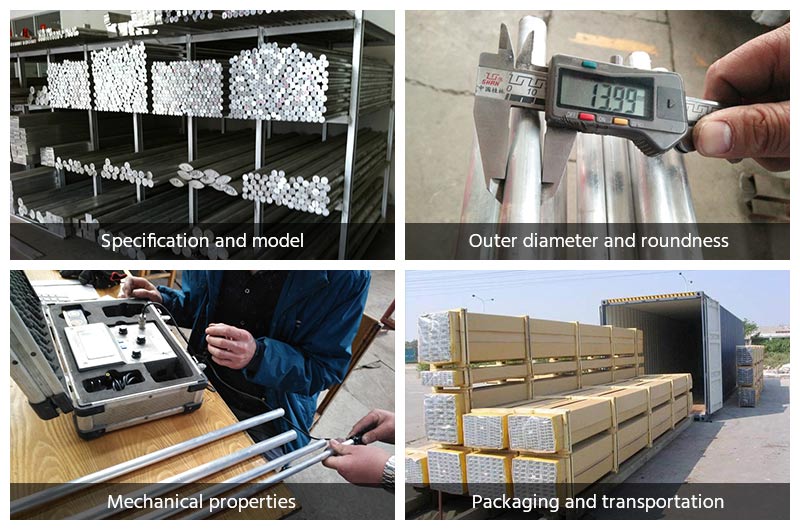

Key points for purchasing 6262 aerospace aluminum rods

Material certification: confirm whether the material meets the relevant international standards and specifications, and whether there are corresponding material certification documents.

Size and shape: confirm whether the required size and shape meet your requirements, and check whether the supplier has the corresponding processing capabilities for necessary customization.

Delivery capability: confirm the supplier's delivery capability, including delivery time, quantity, packaging, transportation, etc., to ensure that the required materials can be delivered on time.

Quality assurance: confirm whether the supplier has a corresponding quality assurance system, such as ISO 9001 quality management system certification, to ensure that the purchased materials meet the prescribed quality standards.

Price and payment method: confirm whether the price is reasonable, and understand the payment method and payment terms.

After-sales service: confirm whether the supplier provides corresponding after-sales services, such as handling of quality issues, technical support, etc.

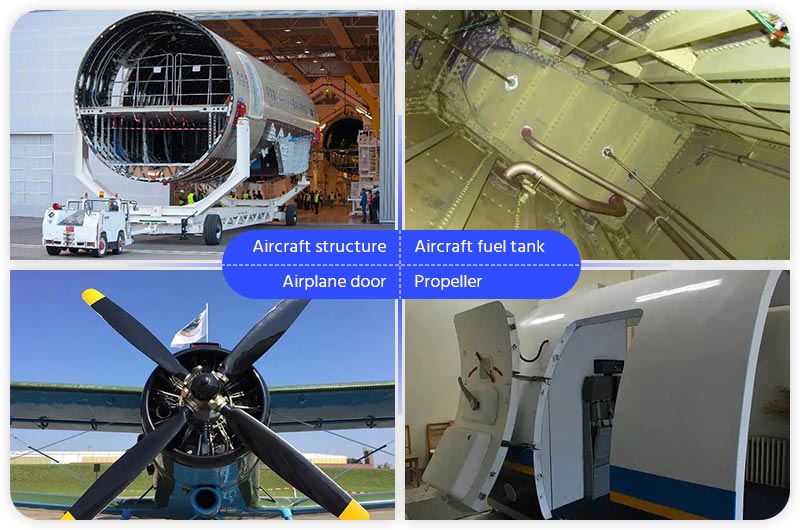

The application of 6262 aerospace aluminum rods

6262 T6 aerospace aluminum rod

The T6 temper aerospace aluminum rod has the highest strength and hardness, but it is also relatively brittle, suitable for the manufacture of components with high strength and rigidity requirements, such as aircraft body structures and support components.

6262 T651 aerospace aluminum rod

The T651 temper aerospace aluminum rod has good corrosion resistance and weldability, suitable for the manufacture of components requiring corrosion resistance and weldability, such as fuel tanks and hydraulic systems.

6262 T73/T74 aerospace aluminum rod

After heat treatment, cooling, and aging, it has high strength and hardness, suitable for the manufacture of components requiring high strength and rigidity.

- Aircraft structural parts: such as wings, wing beams, landing gear, cabin doors, and other components.

- Fuel tanks: fuel tanks in aerospace require high strength and corrosion resistance.

- Engine components: such as turbine blades, turbine discs, cylinders, and other components, which require high strength, rigidity, and good high-temperature resistance.