In modern defense, balancing protection and mobility is critical. Chalco's 7039 aluminum armor plate offers the perfect solution. This high-strength Al-Zn-Mg alloy delivers superior ballistic resistance, lightweight strength, and reliable performance in harsh conditions. With excellent weldability, formability, and certified compliance with MIL-DTL-46063H, it enables lighter, more agile, and secure armored vehicles.

Instant QuoteThe specification of Chalco 7039 aluminum armor plate

| Alloy | 7039 |

| Temper | T6, T61, T64 |

| Thickness | 0.250″ – 4″ |

| Size | 72″ W × 144″ L or 48″ W × 144″ L |

Why Choose Chalco 7039 aluminum armor plate

Certified Military Grade

Our 7039 aluminum armor plates fully comply with MIL-DTL-46063H, ensuring top-tier ballistic and structural performance.

Trusted by Leading Defense Clients

We are proud partners of UKROBORONPROM, ASELSAN, HEAVY INDUSTRIES TAXILA, Raytheon, and SF Engineering, proving our expertise in critical defense projects.

Expert Support & Tailored Solutions

From alloy selection to processing advice, Chalco offers complete technical support and customized services for your armor system requirements.

Flexible Supply & Custom Options

We ensure stable inventory, fast delivery, and tailor-made dimensions to meet diverse defense manufacturing needs.

Chalco 7039 Aluminum Armor Plate: Superior Ballistic Performance

Chalco's 7039 aluminum armor plate is engineered for lightweight, high-protection demands.

It effectively resists projectiles and various forms of corrosion, and offers good weldability (where applicable), making it an ideal choice for military vehicles and protective structures.

Core Ballistic Advantages:

- Unmatched Anti-Armor Piercing (AP) Performance: Our 7039 alloy excels against armor-piercing threats, significantly outperforming 5083 aluminum to provide a higher level of protection.

- Rigorously Ballistically Tested: We strictly adhere to industry standards. Our products undergo stringent testing, including with 0.30 caliber armor-piercing rounds and 20mm fragment simulating projectiles.

Choose Chalco 7039 for a proven, high-performance ballistic solution that ensures the safety of personnel and equipment in critical missions.

Advantages of 7039 Aluminum Armor Plate

Certified ballistic protection

Complies with MIL-DTL-46063H. Proven V50 performance against bullets and fragments.

High strength-to-weight ratio

Offers strong protection with reduced vehicle weight for better mobility and payload.

Excellent corrosion resistance

Performs well in harsh environments, especially with surface treatments like anodizing.

Good weldability and formability

Easy to weld and form, supporting modular armor designs.

Stable in extreme temperatures

Retains mechanical strength in both hot and cold conditions.

Chalco 7039 Aluminum Armor Plate: Key Applications

Chalco 7039 aluminum armor plate is specifically designed to provide exceptional protection while reducing weight. With its outstanding ballistic performance, high strength-to-weight ratio, and good weldability, it is the preferred material for many demanding military and defense projects.

Instant QuoteArmored Vehicles

Used in Light Armored Vehicles (LAVs), Armored Personnel Carriers (APCs), and Infantry Fighting Vehicles (IFVs). The lightweight nature of 7039 enhances vehicle speed, mobility, and fuel efficiency while maintaining occupant safety, expanding operational range and payload capacity.

Military Shelters and Tactical Structures

Widely applied in deployable military shelters, mobile command centers, and field hospitals. Its lightweight yet strong armor effectively resists small arms fire and fragments, ensuring rapid deployment and tactical flexibility.

Naval Ships and Marine Protection

Ideal for ship superstructures, protective bulkheads, and decking, where reducing top weight improves ship stability. Its high strength and excellent corrosion resistance suit harsh marine environments.

Logistics and Ammunition Containers

Used in missile launch tubes, ammunition boxes, and other sensitive military storage units, ensuring safety during transport and storage, minimizing risks to critical payloads.

Specialized and Custom Defense Solutions

Available for custom applications such as security facility armor panels, bespoke safety barriers, and other defense components requiring specific weight and ballistic certifications.

7039 Aluminum Armor Plate vs. 5083 Aluminum Armor Plate: Choosing the Right Military Protection Solution

5083 and 7039 are two widely used aluminum armor alloys in military and defense, each meeting different US military standards and offering distinct performance features. Understanding their differences is key to selecting the optimal protective solution.

| Characteristic / Alloy | 7039 Aluminum Armor Plate | 5083 Aluminum Armor Plate |

| Military Standard | MIL-DTL-46063H | MIL-A46027F (MR) |

| Strength | High strength | Strong and tough |

| Density | Slightly higher than 5083 | Lower density |

| Armor-Piercing Ballistic Performance (AP) | Clearly superior to 5083 | Inferior to 7039 |

| Fragment Simulation Ballistic Performance (FS) | Slightly worse than 5083, especially under 1.235 inches thick | Better than 7039 |

| Weldability | Less weldable | More weldable |

| Corrosion Resistance | Prone to stress corrosion, especially after welding | More resistant to stress corrosion |

| Main Application Considerations | Prioritizes armor-piercing resistance and lightweight, ideal for high-speed, high-mobility vehicles | Focuses on overall protection and weld integrity, often used as standard stock alloy |

The 7039 Aluminum Armor Plate offers superior armor-piercing performance and high strength, making it ideal for lightweight, high-mobility armored vehicles where penetration resistance is critical. The 5083 Aluminum Armor Plate provides better weldability and corrosion resistance, suitable for applications requiring complex welded structures and durability. Choosing between them depends on specific protection requirements, manufacturing processes, and operating environments.

Chalco: Your One-Stop Military Aluminum Armor Material Solution Provider

Beyond the high-performance 7039 aluminum armor plate, Chalco offers a wide range of military-standard aluminum alloy armor solutions to meet various protection needs and engineering challenges across different applications.

Available military-grade aluminum armor materials include

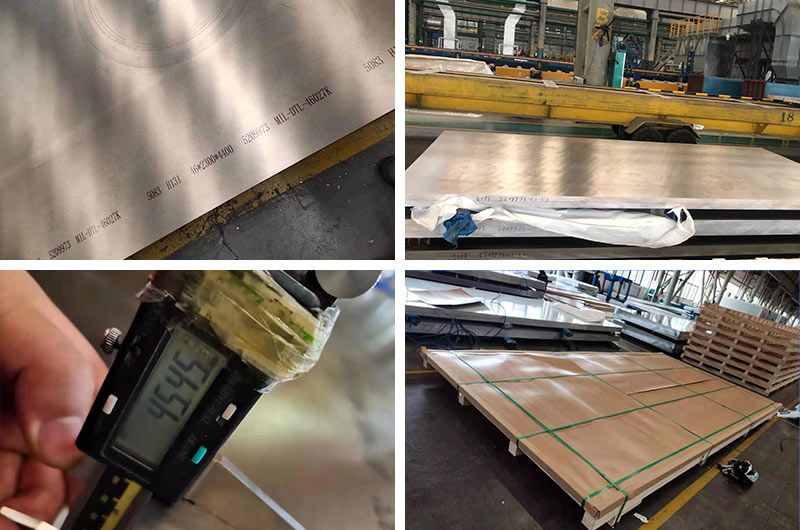

5083 / 5456 / 5059 Armor Plates

MIL-DTL-46027 / MIL-DTL-32262 certified. Widely used in military vehicles for their strength, weldability, and corrosion resistance.

Contact us now2139 / 2195 / 2060 Armor Plates

High-strength Al-Li alloys like 2139 (MIL-DTL-32341) and 2195/2060 (AMS) for lightweight and high-performance armor solutions.

Contact us now

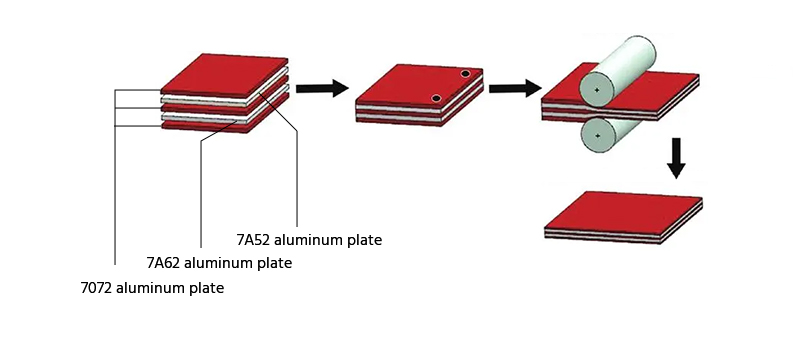

Made with 7A52/7A62 alloys using explosive welding or lamination. Offers multi-layer protection for demanding defense needs.

Contact us nowOther High-Strength Aluminum Armor Materials

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

The chemical composition of 7039 T64 aluminum armor plate

| Element | Composition (%) |

| Si | 0.30 max |

| Fe | 0.40 max |

| Cu | 0.10 max |

| Mg | 0.10–0.40 |

| Mn | 2.30–3.30 |

| Cr | 0.15–0.25 |

| Zn | 3.50–4.50 |

| Ti | 0.10 max |

| Al | Remainder |

| Remainder (total) | 0.15 max |

Physical and mechanical properties of 7039 aluminum armor plate

Physical properties

| Properties | Metric |

| Density | 2.74 g/cm3 |

| Melting point | 482–638°C |

Mechanical properties

| Properties | Metric |

| Tensile strength | 450 MPa |

| Yield strength | 380 MPa |

| Elongation at break | 13% |

| Elastic modulus | 69.6 GPa |

| Shear strength | 255 MPa |

Thickness tolerances of 7039 T64 aluminum armor plate

Thickness tolerances for production armor and ballistic test plates shall be a specified in the table below.

| Ordered Thickness, inches | Tolerance (inch) |

| Minus Plus 1/ | |

| 0.500 to 0.625,incl | 0.025 |

| 0.626 to 0.875,incl | .030 |

| 0.876 to 1.125,incl | .035 |

| 1.126 to 1.375,incl | .040 |

| 1.376 to 1.625,incl | .045 |

| 1.626 to 1.875,incl | .052 |

| 1.876 to 2.250,incl | .060 |

| 2.251 to 2.750,incl | .075 |

| 2.751 to 3.000,incl | .090 |

| 3.001 to 4.000,incl | .110 |

1/ The values for the plus column are derived from the full range of tolerances specified (for sheet and plate not specified for aerospace applications) in table 3.1 of ANSI H35.2 less the value shown in the minus column. For example, the plus tolerance on a 2.0 inch thick by a 73 inches wide plate would be as

follows:

Thickness tolerance (from ANSI H35.2) ±0.060"

Tolerance value shown in minus column 0.060"

Full tolerance less minus tolerance 0.120" - 0.060" = 0.060"

Derived plus tolerance 0.000"

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote