6060 aluminum is a widely used Al-Mg-Si alloy valued for its excellent extrusion performance, smooth surface finish, and corrosion resistance. In practical industrial supply, 6060 aluminum is most commonly delivered in extruded tube form for architectural and lightweight structural applications.

Chalco supplies 6060 aluminum tube as an extrusion-based product for global procurement, supporting custom dimensions, EN standards, and project-based quotation requirements.

Product Forms of Chalco 6060 Aluminum Tube

Seamless (ASTM B210) 6060 Aluminum Tube

Instant Quote6060 aluminum tube in seamless form features a uniform structure without welded seams, offering consistent wall thickness, smooth surface quality, and stable dimensional accuracy.

Commonly supplied for applications requiring precision tubing and reliable fabrication performance rather than heavy mechanical loading.

Cold Drawn 6060 Aluminum Tube

Instant Quote6060 aluminum tube produced by drawing from extruded tubing provides improved dimensional tolerance and enhanced surface finish.

Well suited for applications that require precise tube dimensions, smooth appearance, and consistent quality.

Extruded 6060 Aluminum Tube

Instant Quote6060 aluminum tube supplied in extruded form allows flexible dimensions and consistent hollow section geometry.

Widely used in architectural, industrial, and general fabrication applications where formability and appearance are important.

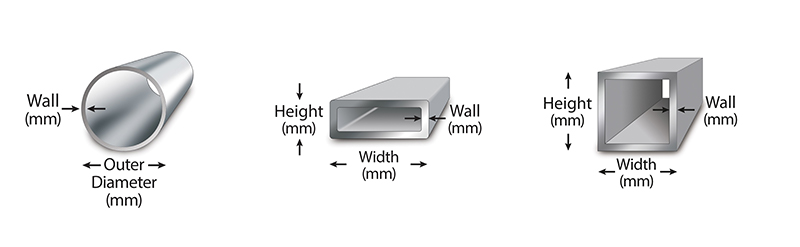

Round Section 6060 Aluminum Tube

Instant Quote6060 aluminum tube with round section offers uniform circular geometry and balanced performance for general tubing applications.

Commonly used in lightweight frames, brackets, enclosures, and architectural tube systems where dimensional consistency is required.

Square Section 6060 Aluminum Tube

Instant Quote6060 aluminum tube with square section provides stable geometry and easy assembly for framed and supported structures.

Typically applied in industrial frameworks, equipment supports, and architectural assemblies that require clean edges and consistent tube dimensions.

Rectangular Section 6060 Aluminum Tube

Instant Quote6060 aluminum tube with rectangular section combines flat surfaces with good dimensional stability for framed and supported tube applications.

Commonly used in construction components, machinery housings, and structural assemblies where shape control and fabrication efficiency are required.

R-Angle Rectangular Section 6060 Aluminum Tube

Instant Quote6060 aluminum tube with R-angle rectangular section features rounded corners to support smoother stress transition and improved fabrication appearance.

Suitable for architectural structures, decorative assemblies, and mechanical components where edge quality and visual consistency are important.

Special Shaped Sections 6060 Aluminum Tube

Instant Quote6060 aluminum tube can be supplied in special shaped hollow sections such as elliptical, tapered, or project-specific geometries.

These tube forms are typically supplied based on drawings or specifications for architectural, decorative, and equipment-related applications.

Why 6060 Aluminum Tube

6060 aluminum tube is widely selected for tubing applications where formability, surface quality, and stable dimensional control are required. This alloy is optimized for extrusion-based tube production, making it suitable for projects that prioritize consistency, appearance, and fabrication efficiency.

- Excellent extrusion performance for aluminum tubing: enables stable wall thickness control and uniform tube geometry across production batches.

- Smooth surface finish: ideal for anodized and decorative aluminum tube applications where visual quality is important.

- Good corrosion resistance: suitable for architectural and outdoor tube environments with long-term exposure requirements.

- Balanced strength-to-weight ratio: supports lightweight tube structures without unnecessary material cost or over-engineering.

These characteristics make 6060 aluminum tube suitable for applications that require reliable tube quality, clean appearance, and efficient fabrication, rather than extreme mechanical loading or heavy structural performance.

Manufacturing Method and Chalco Production Capability for 6060 Aluminum Tube

6060 aluminum tube is primarily manufactured through extrusion, a process well suited for producing long hollow sections with stable dimensional control and smooth surface quality. At Chalco, tube production is organized around extrusion-based manufacturing rather than forging, aligning with the alloy's formability characteristics and typical application requirements.

- Extruded aluminum tube: produced using dedicated aluminum tube extrusion lines, enabling consistent wall thickness control, stable roundness, and repeatable tube geometry across batches.

- Drawn aluminum tube: extruded tubes can be further cold drawn to achieve tighter dimensional tolerance and improved surface finish, supporting applications with higher dimensional accuracy requirements.

- Heat treatment capability: tempers such as T5 and T6 are applied under controlled conditions after extrusion or drawing to ensure stable and repeatable mechanical performance for tubing supply.

By combining extrusion, optional drawing, and controlled heat treatment, Chalco supports project-based supply of 6060 aluminum tube with consistent quality, dimensional reliability, and stable delivery.

Specifications of Chalco 6060 Aluminum Tube

The following specifications are provided to support material selection and supply reference for 6060 aluminum tube. For project-specific load requirements or application conditions, Chalco can assist in confirming suitable tube forms and supply options based on your drawings or specifications.

| Temper | T4, T5, T6, T64, T66, H112 | |||

| Metric round tube dimensions | Large diameter thick-wall aluminum tube | Diameter Φ200–1000 mm | Wall thickness 20–100 mm | |

| Extruded round tube | Diameter Φ6–500 mm | Wall thickness 0.5–50 mm | ||

| Seamless round tube | Diameter Φ90–300 mm | Wall thickness 5–20 mm | ||

| Cold drawn round tube | Diameter Φ1–20 mm | Wall thickness 0.1–0.5 mm | ||

| Metric square tube dimensions | For commonly supplied sizes, please refer to the detailed 6060 aluminum tube size reference table below. Other dimensions can be customized based on project requirements. [View 6060 Aluminum Tube Size Table] | |||

| Metric rectangular tube dimensions | For commonly supplied sizes, please refer to the detailed 6060 aluminum tube size reference table below. Other dimensions can be customized based on project requirements. [View 6060 Aluminum Tube Size Table] | |||

| Surface treatment | Chemical treatment | Anodizing, electrophoretic coating, fluorocarbon coating, powder coating, wood grain transfer printing, etc. | ||

| Mechanical processing | Cutting, drawing, polishing, sandblasting, embossing, and other tube-related processing. | |||

| Production standards for 6060 aluminum tube | ||||||

| EN 573-3 / EN 755-1,2,8 | DIN EN 573-3 | ASTM B221 | AS 2848.1 / AS-NZS series | ISO 209 | JIS H4000 / H4040 | GB/T 3190 / GB/T 3880.2 |

Chemical composition of Chalco 6060 aluminum tube

The following chemical composition and mechanical properties are provided as general reference for EN AW-6060 aluminum tube. Actual values may vary depending on temper, tube dimensions, and production conditions.

| Element | Composition % |

| Al | 97.9-99.3 |

| Mg | 0.35-0.6 |

| Si | 0.3-0.6 |

| Fe | 0.1-0.3 |

| Zn | 0-0.15 |

| Mn | 0 -0.1 |

| Ti | 0-0.1 |

| Cu | 0-0.1 |

| Cr | 0-0.050 |

| Residuals | 0-0.15 |

Mechanical properties of Chalco 6060 aluminum tube pipe

| Temper | T4 | T5 | T6 | T64 | T66 | H112 |

| Elongation at Break | 16% | 9.0% | 11% | 13% | 9.1% | - |

| Fatigue Strength (MPa) | 37 | 56 | 70 | 61 | 67 | - |

| Shear Strength (MPa) | 86 | 93 | 130 | 120 | 130 | - |

| Tensile Strength: Ultimate (MPa) | 140 | 160 | 220 | 200 | 220 | 215 |

| Tensile Strength: Yield (MPa) | 71 | 110 | 170 | 140 | 170 | 160 |

Mechanical properties are influenced by tube size, extrusion parameters, and heat treatment conditions. Final material selection should be confirmed based on application requirements and fabrication processes.

Selection Guide for 6060 Aluminum Tube

The selection of 6060 aluminum tube is typically based on tube structure, manufacturing method, and dimensional requirements. Instead of focusing on theoretical load calculations, most projects select tube types according to fabrication needs, appearance requirements, and cost efficiency.

1. Seamless Tube vs. Structural Tube

Seamless aluminum tube features a uniform structure without welded seams, providing consistent wall thickness and stable dimensional accuracy. It is commonly selected for applications where precision, surface quality, and reliability during fabrication are important.

Structural aluminum tube refers to tubes used in framed or supported assemblies. This type of tube is widely chosen for architectural and industrial structures due to its cost efficiency and ease of fabrication rather than extreme mechanical performance.

2. Extruded Tube vs. Drawn Tube

Extruded aluminum tube is suitable for most general applications, offering flexible size availability, stable geometry, and good surface quality. It is commonly used for architectural systems, equipment frames, and general fabrication projects.

Drawn aluminum tube is produced by further processing extruded tubes through cold drawing. This option is typically selected when tighter dimensional tolerance, improved roundness, or smoother surface finish is required.

3. Thin Wall Tube vs. Thick Wall Tube

Thin wall aluminum tube is lightweight and material-efficient, making it suitable for applications where weight reduction, appearance, and ease of handling are priorities.

Thick wall aluminum tube offers increased rigidity and machining allowance, and is commonly selected for components that require further processing or enhanced structural stability within supported systems.

Final tube selection is usually confirmed based on drawing requirements, surface finish expectations, and fabrication processes. Chalco supports project-based selection by matching tube type, temper, and dimensions to specific application needs.

Applications of 6060 Aluminum Tube

6060 aluminum tube is widely applied in projects where dimensional consistency, surface quality, and fabrication efficiency are more critical than extreme mechanical loading. Its excellent extrusion performance and clean appearance make it a preferred choice for architectural, industrial, and decorative tube applications.

- Architectural and building systems: curtain wall components, railing systems, sunshade structures, and decorative tube assemblies requiring uniform appearance and corrosion resistance.

- Lightweight structural frames: frames, brackets, and supported assemblies used in equipment enclosures, display systems, and modular structures.

- Industrial equipment and housings: machine covers, protective enclosures, and auxiliary structures where clean geometry and ease of fabrication are required.

- Decorative and anodized tube components: anodized aluminum tube products used in interior design, furniture structures, and visual-oriented applications.

- Custom project-based applications: aluminum tube components supplied according to drawings for specialized assemblies and system integration projects.

Application suitability is typically determined by tube size, temper, surface treatment, and fabrication requirements. Chalco supports project-based aluminum tube supply by assisting with material confirmation and dimensional coordination.

Why Choose Chalco for 6060 Aluminum Tube Supply

As a material-focused manufacturer and supplier, Chalco provides 6060 aluminum tube with an emphasis on production stability, dimensional consistency, and project-oriented coordination. Instead of supplying isolated tube products, our focus is on supporting practical fabrication and assembly requirements across different application scenarios.

- Dedicated aluminum tube manufacturing capability: extrusion-based production lines optimized for aluminum tubing, ensuring consistent geometry and repeatable quality.

- Project-oriented supply support: tube dimensions, tempers, and processing options can be coordinated according to drawings and application requirements.

- Stable quality and batch consistency: controlled extrusion, drawing, and heat treatment processes help maintain uniform performance across deliveries.

- International standard compliance: support for EN AW-6060 and other common international standards for aluminum tube supply.

- Export experience and delivery coordination: familiarity with international packaging, logistics, and documentation requirements for global projects.

By combining manufacturing capability with application-focused coordination, Chalco supports reliable supply of 6060 aluminum tube for architectural, industrial, and project-based applications.

Size Reference Table of Chalco 6060 Aluminum Tube

Below are typical sizes of Chalco 6060 aluminum tubes commonly supplied for projects, with standard lengths ranging from 1 to 6 meters. Other lengths and dimensions can be customized based on specific requirements.

| Chalco 6060 metric round tube pipe | ||

| Outer diameter | Wall thickness | Length |

| 6 | 0.5 | 1000-6000 |

| 8 | 1 | 1000-6000 |

| 10 | 1 | 1000-6000 |

| 12 | 1 | 1000-6000 |

| 15 | 1 | 1000-6000 |

| 20 | 1 | 1000-6000 |

| 25 | 1.5 | 1000-6000 |

| 30 | 2 | 1000-6000 |

| 35 | 2 | 1000-6000 |

| 40 | 2 | 1000-6000 |

| 45 | 2.5 | 1000-6000 |

| 50 | 2.5 | 1000-6000 |

| 55 | 3 | 1000-6000 |

| 60 | 3 | 1000-6000 |

| 65 | 3 | 1000-6000 |

| 70 | 3 | 1000-6000 |

| 80 | 2 | 1000-6000 |

| 120 | 5 | 1000-6000 |

| 140 | 5 | 1000-6000 |

| Chalco 6060 metric rectangular tube pipe | ||

| Height | 20, 25, 30, 34, 35, 40, 45, 50, 60, 70, 80, 100, 120, 140, 150, etc. | |

| Width | 10, 15, 18, 20, 25, 30, 34, 40, 50, 60, 80, 100, etc. | |

| Thickness | 1.5, 2, 2.5, 3, 4, 5, etc. | |

| Length | 3000, 6000, etc. | |

| Width, depth, or flatness tolerance | Size | Tolerance |

| ≤10mm | ±.30mm | |

| > 10 mm-25 mm | ±.40mm | |

| > 25 mm-50 mm | ±.60mm | |

| > 50 mm-100 mm | ±.90mm | |

| > 100mm-150mm | ±1.1mm | |

| Chalco 6060 metric square tube pipe | ||

| Available size | 25x25x2 mm | 40x40x3 mm |

| 25x25x3 mm | 45x45x2 mm | |

| 25x25x2.5 mm | 45x45x2.5 mm | |

| 30x30x3 mm | 50x50x2 mm | |

| 35x35x2 mm | 50x50x2.5 mm | |

| 35x35x3 mm | 50x50x3 mm | |

| 40x40x2 mm | 60x60x2 mm | |

| 40x40x2.5 mm | 60x60x3 mm | |

| Width, depth, or flatness tolerance | Size | Tolerance (≤100mm) |

| ≤10mm | ±.25mm | |

| > 10 mm-25 mm | ±.30mm | |

| > 25 mm- 50 mm | ±.50mm | |

| > 50 mm-100 mm | ±.70mm | |

FAQs About 6060 Aluminum Tube

Is 6060 aluminum tube extruded or forged?

6060 aluminum tube is produced by extrusion rather than forging. Extrusion provides better dimensional consistency and efficiency for long hollow tube products.

What tempers are available for 6060 aluminum tube?

Common tempers include T5 and T6. Other tempers can be confirmed based on tube size and application requirements.

Can custom tube sizes be supplied?

Yes. Custom tube dimensions, lengths, and surface treatments can be supplied based on drawings or project specifications.

Is 6060 aluminum tube suitable for structural applications?

6060 aluminum tube is typically used in supported or framed structures. Final suitability should be confirmed based on application design and fabrication requirements.

Which standards does 6060 aluminum tube comply with?

6060 aluminum tube is commonly supplied according to EN AW-6060 and related international standards.

Project Inquiry for 6060 Aluminum Tube

If you are sourcing 6060 aluminum tube for architectural, industrial, or project-based applications, please contact Chalco with your drawing or specification requirements. Our team will assist with material confirmation, dimensional coordination, and quotation support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote