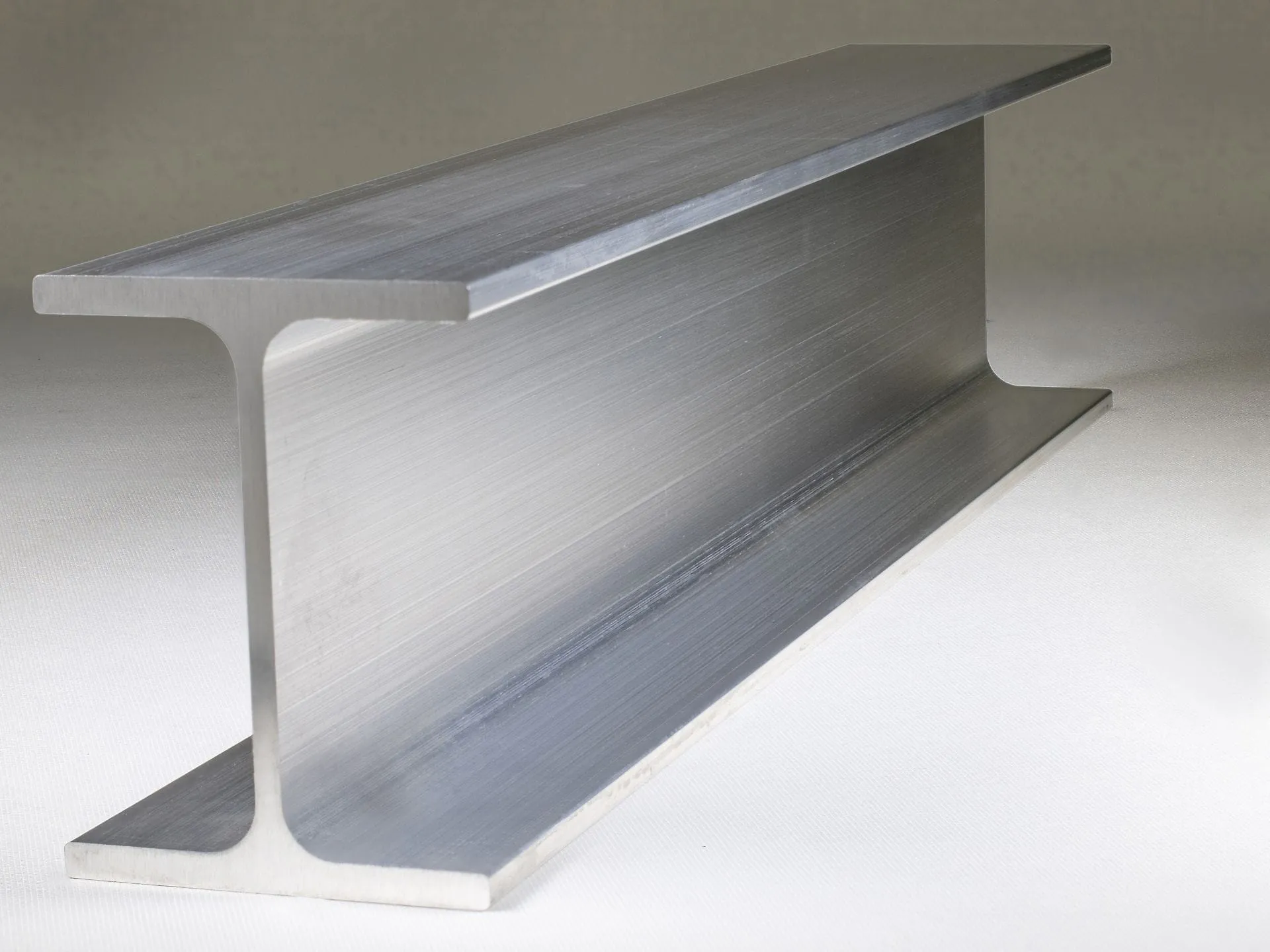

Aluminum i-beams offer a high strength-to-weight ratio, corrosion resistance, and a slim profile. Our most popular profiles are the aluminum association i-beam (parallel flanges) and the american standard aluminum i-beam (tapered flanges), both engineered to carry heavy loads with less weight.

6061 aluminum is the most commonly specified alloy for these i-beams, providing excellent weldability, easy machinability, and long-lasting durability for construction, industrial equipment, and harsh environments.

Specifications of aluminum i beams

Standards: ASTM B308, AMS-QQ-A-200/8, AMS-QQ-A-200/16, ASTM B221, EN 755, EN 573, ISO 6362

Certifications: ISO 9001, ISO 14001, RoHS, REACH, CE, AS9100

Anodized surface finish meets MIL-PRF-8625 requirements.

We provide a full factory inspection report with each shipment. This includes key metrics like tensile strength,yield strength, and chemical composition—ensuring every batch fully meets ASTM and GB standards!

Aluminum i beam products

Chalco offers a wide range of aluminum i beams, covering specifications from the Aluminum Association (AA standards)and ASTM B221.

Our aluminum i beams are lightweight, durable, and high-strength with excellent corrosion resistance—providingefficient and reliable structural solutions for construction and engineering projects.

Instant Quote-

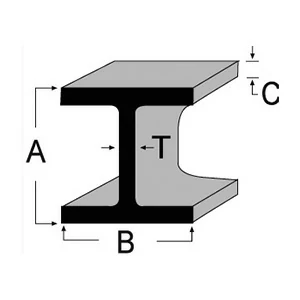

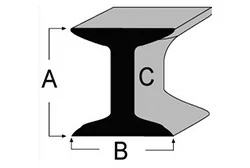

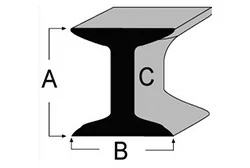

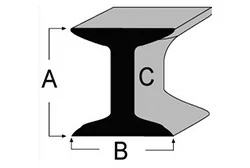

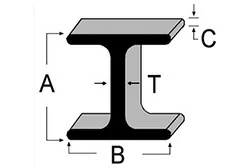

Aluminum Association

Designed with parallel flanges and consistent thickness, making it ideal for structural and industrial applications requiring uniform load distribution.

-

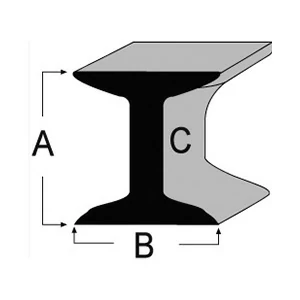

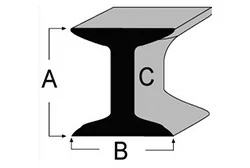

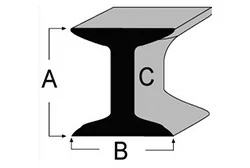

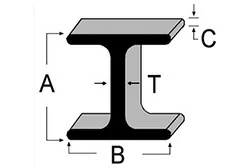

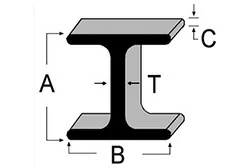

American Standard I-Beam

Features tapered flanges and rounded edges, ensuring optimized strength-to-weight ratio and improved load-bearing capacity in construction and engineering projects.

Aluminum I beam

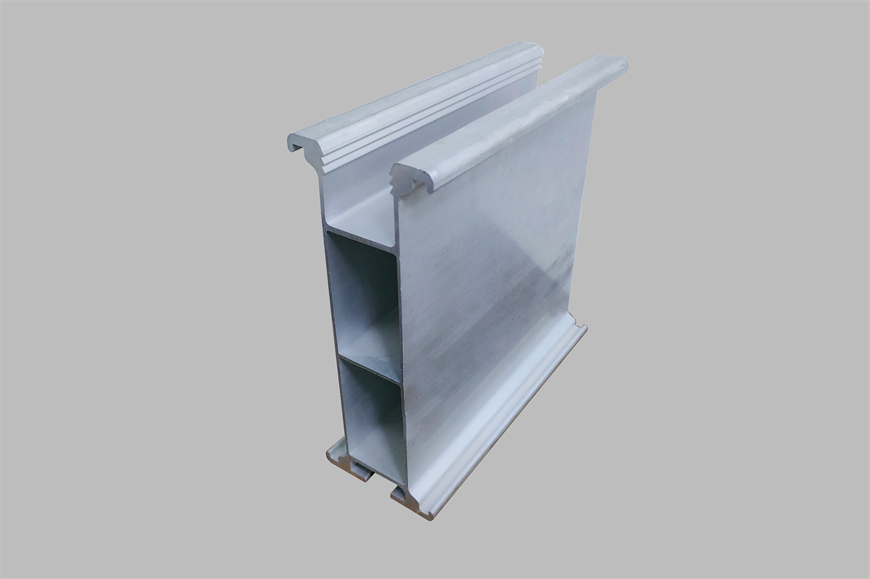

Aluminum Shoring Beams

Aluminium Posts and Beams

Aluminum Box Beam

Self Mating Aluminum Beams

Small Aluminum I Beam

Popular sizes of aluminum i beams

- Standard stock lengths available: 2 ft, 4 ft, 6 ft, 8 ft, 12 ft, 25 ft (custom cut lengths available uponrequest)

- Stock length tolerance: ± 1/16 inch

- Stock surface finish: Mill finish (anodizing, powder coating, sandblasting, and other finishes available uponrequest)

- Processing and customization: Die extrusion, precision cutting, CNC machining

- Our high-quality aluminum I beams come in various sizes and thicknesses, ensuring the right fit for yourproject.

Contact us today for available sizes and fast delivery!

Instant QuoteThe majority of our supply and sales are Aluminum Association I-Beams and American Standard I-Beams.

Use the navigation links below to view each category.

Aluminum association i-beam

Designed with parallel flanges and consistent thickness, making it ideal for structural andindustrial applications requiring uniform load distribution.

-

3" x 2.5" Aluminum Association I beamsInquire Now

3" x 2.5" Aluminum Association I beamsInquire NowSize: 3 x 2-1/2 x 0.260/0.150in -

4" x 3" Aluminum Association I beamsInquire Now

4" x 3" Aluminum Association I beamsInquire NowSize: 4 x 3 x 0.230/0.150in -

6" x 4" Aluminum Association I beamsInquire Now

6" x 4" Aluminum Association I beamsInquire NowSize: 6 x 4 x 0.290/0.190in -

8" x 5" Aluminum Association I beamsInquire Now

8" x 5" Aluminum Association I beamsInquire NowSize: 8 x 5 x 0.350/0.230in -

10" x 6" Aluminum Association I beamsInquire Now

10" x 6" Aluminum Association I beamsInquire NowSize: 10 x 6 x 0.410/0.250in -

12" x 7" Aluminum Association I beamsInquire Now

12" x 7" Aluminum Association I beamsInquire NowSize: 12 x 7 x 0.470/0.290in -

14" X 8" Aluminum Association I beamsInquire Now

14" X 8" Aluminum Association I beamsInquire Now14" X 8" X .60/.30" STRUCTURALI-BEAM X 30'

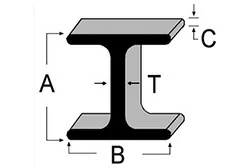

American standard i-Bbeam

Features tapered flanges and rounded edges, ensuring optimized strength-to-weight ratio and improvedload-bearing capacity in construction and engineering projects.

We maintain a large inventory, supporting bulk discounts and small order purchases.

-

3" X 2.330" X .170" X 25' 6061 T6 I-BeamInquire Now

3" X 2.330" X .170" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

3" X 2.509" X .349" X 25' 6061 T6 I-BeamInquire Now

3" X 2.509" X .349" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

4" X 2.660" X .190" X 25' 6061 T6 I-BeamInquire Now

4" X 2.660" X .190" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

4" X 2.796" X .326" X 25' 6061 T6 I-BeamInquire Now

4" X 2.796" X .326" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

5" X 3.000" X .210" X 25' 6061 T6 I-BeamInquire Now

5" X 3.000" X .210" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

6" X 3.330" X .230" AMERICAN STANDARD I-BEAM - 6061-T6 X 25'Inquire Now

6" X 3.330" X .230" AMERICAN STANDARD I-BEAM - 6061-T6 X 25'Inquire NowSurfaceFinishes: Clear anodized, satin anodized, mill finish, painted -

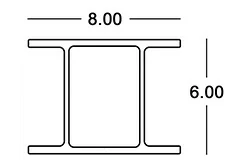

8" X 4.000" X .270" X 25' 6061 T6 I-BeamInquire Now

8" X 4.000" X .270" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

10" X 4.680" X .310" X 25' 6061 T6 I-BeamInquire Now

10" X 4.680" X .310" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted -

12" X 5.000" X .350" X 25' 6061 T6 I-BeamInquire Now

12" X 5.000" X .350" X 25' 6061 T6 I-BeamInquire NowSurface Finishes: Clearanodized, satin anodized, mill finish, painted

Boat trailer i-beams

Our marine trailer extrusions are rust-resistant products with a high strength-to-weight ratio, quick assembly time, and superior surface finishes—making them the ideal choice for your marine trailer manufacturing needs.

In addition, our marine trailer components feature a universal design compatible with most trailer systems.

Instant Quote-

4" X 3" X .285/.170" BOAT TRAILER I-BEAMInquire Now

4" X 3" X .285/.170" BOAT TRAILER I-BEAMInquire NowSize: 4 in x 3 in x.285/.170 in x 20 ft -

6" X 4" X .350/.210" BOAT TRAILER I-BEAMInquire Now

6" X 4" X .350/.210" BOAT TRAILER I-BEAMInquire NowSize: 6 in x 4 in x.350/.210 in x 28 ft -

7" X 4.5" X .380/.230" BOAT TRAILER I-BEAMInquire Now

7" X 4.5" X .380/.230" BOAT TRAILER I-BEAMInquire NowSize: 7 in x 4.5 in x.380/.230 in x 31 ft -

8" X 5" X .410/.250" BOAT TRAILER I-BEAMInquire Now

8" X 5" X .410/.250" BOAT TRAILER I-BEAMInquire NowSize: 8 in x 5 in x.410/.250 in x 45 ft -

10" X 6" X .500/.290" BOAT TRAILER I-BEAMInquire Now

10" X 6" X .500/.290" BOAT TRAILER I-BEAMInquire NowSize: 10 in x 6 in x.500/.290 in x 45 ft -

12" X 7" X .620/.310" BOAT TRAILER I-BEAMInquire Now

12" X 7" X .620/.310" BOAT TRAILER I-BEAMInquire NowSize: 12 in x 7 in x.620/.310 in x 55 ft

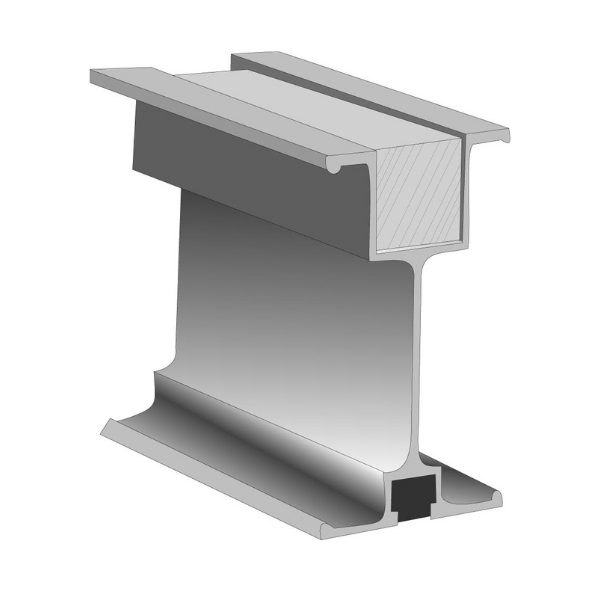

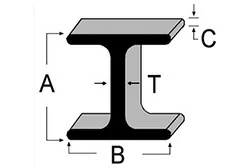

Double i-beams

Consists of two I-beams combined for increased load capacity and enhanced structural support, oftenused in heavy-duty applications.

-

6" X 8" X .190/.290" X 30' 6061 T6 M/F DOUBLE I-BEAMInquire Now

6" X 8" X .190/.290" X 30' 6061 T6 M/F DOUBLE I-BEAMInquire NowPrecisetolerances,No burrs,Excellent surface -

6" X 8" X .190/.290" X 20' 6061 T6 M/F DOUBLE I-BEAMInquire Now

6" X 8" X .190/.290" X 20' 6061 T6 M/F DOUBLE I-BEAMInquire NowPrecisetolerances,No burrs,Excellent surface

Light i-beam

A lightweight alternative to traditional I-beams, designed for applications where reduced weight andmoderate strength are required.

-

3" X 1.374" X 2.5" X .093"/.124" X 72' 6061 T6 LIGHT I-BEAMInquire Now

3" X 1.374" X 2.5" X .093"/.124" X 72' 6061 T6 LIGHT I-BEAMInquire NowPrecisetolerances,No burrs,Excellent surface -

2.5" X 3" X 9' 6061 T6 M/F LIGHT I-BEAMInquire Now

2.5" X 3" X 9' 6061 T6 M/F LIGHT I-BEAMInquire NowPrecise tolerances,Noburrs,Excellent surface -

2.5" X 3" X 12' 6061 T6 M/F LIGHT I-BEAMInquire Now

2.5" X 3" X 12' 6061 T6 M/F LIGHT I-BEAMInquire NowPrecise tolerances,Noburrs,Excellent surface -

2.5" X 3" X 28' 6061 T6 M/F LIGHT I-BEAMInquire Now

2.5" X 3" X 28' 6061 T6 M/F LIGHT I-BEAMInquire NowPrecise tolerances,Noburrs,Excellent surface -

3" X 1.374" X 2.5" X .093"/.124" X 36' 6061 T6 LIGHT AA I-BEAMInquire Now

3" X 1.374" X 2.5" X .093"/.124" X 36' 6061 T6 LIGHT AA I-BEAMInquire NowPrecise tolerances,No burrs,Excellent surface

Common alloys for aluminum i beams

-

6061 aluminum I beams

6061 aluminum I beams are heat-treatable alloys known for their excellent strength, corrosionresistance, and machinability.

-

6063 aluminum I beams

6063 aluminum I beams are recognized for their superior surface finish and excellentextrudability, making them ideal for architectural applications.

-

5083 aluminum I beams

5083 aluminum I beams offer high strength and exceptional corrosion resistance, especiallysuitable for ships and offshore structures.

-

5086 aluminum I beams

5086 aluminum I beams provide outstanding corrosion resistance and medium strength, making themwidely used in marine and shipbuilding industries.

-

5454 aluminum I beams

5454 aluminum I beams deliver better corrosion resistance and weldability than 5086, making themideal for chemical tanks and transport applications.

-

5456 aluminum I beams

5456 aluminum I beams are high-strength marine-grade alloys often used in ship structures andmilitary equipment for their durability and toughness.

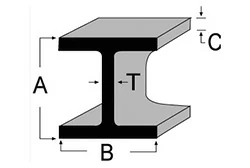

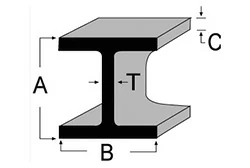

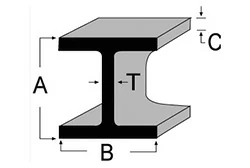

Existing die sizes (no new tooling)

Choose from our in-house metric i-beam dies to save tooling cost and lead time. If you need aluminum association i-beam or american standard aluminum i-beam sizes, see the sections above.

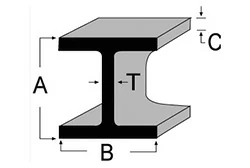

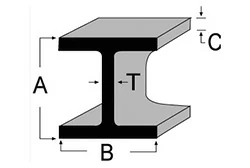

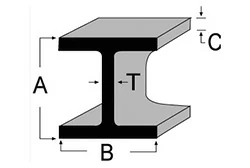

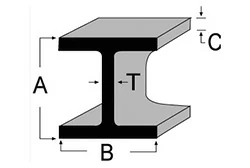

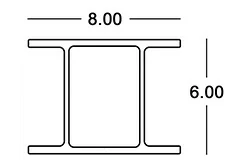

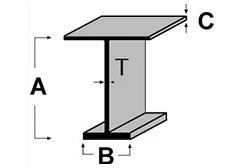

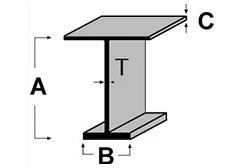

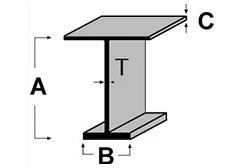

In-house i-beam dies — dimensions in mm (approx. inch) and theoretical weight.

| Model | A (mm / in) | B (mm / in) | T (mm / in) | Weight (kg/m / lb/ft) | Notes |

| E12×9.1–1.3 | 12 (0.472) | 9.1 (0.358) | 1.3 (0.051) | 0.107 (0.072) | Light section; 6063-T5 / 6061-T6 |

| E15×22.5–1.0 | 15 (0.591) | 22.5 (0.886) | 1.0 (0.039) | 0.136 (0.091) | Display/frames; 6063-T5 / 6061-T6 |

| GE-ME0014 | 15 (0.591) | 13.1 (0.516) | 1.3 (0.051) | 0.140 (0.094) | Compact; 6063-T5 / 6061-T6 |

| GE-ME0017 | 15 (0.591) | 28.9 (1.138) | 1.7 (0.067) | 0.253 (0.170) | Wider flange; 6063-T5 / 6061-T6 |

| E22×13.5–1.5 | 22 (0.866) | 13.5 (0.531) | 1.5 (0.059) | 0.221 (0.149) | Light duty; 6063-T5 / 6061-T6 |

A = depth, B = flange width, T = web thickness. Weights are theoretical. Close-to-size customization available without new tooling.

For a fast quote, include the model code, alloy (6063-T5 / 6061-T6), length (ft or m), quantity, and documents (EN 10204 3.1, anodizing, etc.).

Instant QuoteBest-selling aluminum i-beam sizes

Popular aluminum i-beam sizes — also searched as: aluminum h-beam sizes, aluminium i-beam standard sizes

| Size (imperial / metric) | Profile type | Available alloys | Also searched as | Notes |

| 1/2 in aluminum I-beam | AA / AS | 6061-T6 | — | Made-to-order |

| 2 in aluminum I-beam | AA / AS | 6061-T6, 6063-T5 | — | Light frames, displays |

| 3 in aluminum I-beam | AA / AS | 6061-T6, 6063-T5 | 3 aluminum i beam | Common replacement size |

| 4 in aluminum I-beam | AA / AS | 6061-T6, 6063-T5 | 4 aluminum i beam | Popular for light structures |

| 6 in aluminum I-beam | AA / AS | 6061-T6, 6082-T6 | 6 aluminum i beam | Doors, windows, frames |

| 8 in aluminum I-beam | AA / AS | 6061-T6, 5086 | 8 aluminum i beam | Heavier-duty spans |

| 6 × 4 in aluminum I-beam | AA / AS | 6061-T6, 6063-T5 | 6 x 4 aluminum i beam | Depth × flange width |

| 2 × 6 in aluminum beam | AA / AS | 6061-T6, 6063-T5 | 2x6 aluminum beam | Depth × flange width |

| 6 × 6 in aluminum I-beam | AA / AS | 6061-T6, 5083 | 6x6 aluminum i beam | Square profile option |

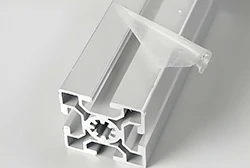

| 20 mm × 20 mm extruded beam | T-slot / small profile | 6061-T6, 6063-T5 | 2020 extruded aluminum beam | T-slot commonly requested |

| 150 mm × 50 mm aluminium beam | Metric I-beam | 6061-T6, 6063-T5 | 150 x 50 aluminium beam | Metric match-ups |

| 10 ft aluminum I-beam | Stock length | 6061-T6, 6063-T5 | 10 foot aluminum i beam | Cut-to-length from mill bars |

| 12 ft aluminum I-beam | Stock length | 6061-T6, 5086 | 12 foot aluminum i beam | Economical for short spans |

| 20 ft aluminum I-beam | Stock length | 6061-T6, 5083 | 20 aluminum i beam | Standard mill length |

| 24 ft aluminum beam | Stock length | 6061-T6, 5083 | 24 aluminum beam | Extended span, fewer joints |

Tip: Standard mill lengths are typically 20 ft and 24 ft; 10 ft / 12 ft are cut-to-length. AA = Aluminum Association, AS = American Standard.

Applications of aluminum i beams

- Building structures: Ideal for roof trusses, building frames, and load-bearing structures. High strength,lightweight, and easy to install.

- Marine and offshore: Made from marine-grade alloys like 5083, 5086, and 6061-T6. Corrosion-resistant and perfectfor boat frames, docks, and offshore platforms.

- Transportation: Used in trailers, truck frames, and railway structures. Lightweight yet strong, helping improvefuel efficiency.

- Industrial machinery: Suitable for equipment supports, production lines, scaffolding, and warehouse racks. Builtfor long-term durability.

- Solar PV mounting systems: Designed for outdoor environments. Wind-resistant, corrosion-resistant, andstructurally stable.

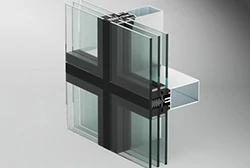

Aluminium Sections for Windows

Aluminum Shoring Beams

Aluminium Curtain Wall Section

Aluminium Partition Section

Aluminium Ladder Beam

Marine Hull

Advantages of aluminum i beams

- Lightweight and strong: Excellent load-bearing capacity, easy to transport and install.

- Corrosion-resistant: Ideal for marine, outdoor, and industrial environments.

- Easy to fabricate: Can be cut, welded, and drilled for quick and flexible installation.

- Low maintenance: Rust-resistant with a long service life—durable and cost-effective.

- Multiple sizes available: Compliant with AA/ASTM standards and fully customizable.

Contact us to get the aluminum I beams that best suit your project needs!

Instant QuoteProcessing services for aluminum I beams

We offer high-precision machining to ensure the structural integrity and performance stability of aluminum I beams,suitable for use in construction, industrial, and transportation sectors.

- Precision cutting, drilling, and tapping for accurate dimensions

- Custom cutting of lengths and angles to improve installation efficiency

- Friction stir welding (FSW) for strong and efficient aluminum beam connections

- Advanced TIG/MIG welding ensures solid and reliable joints

- Anodizing enhances corrosion resistance with various surface finish options

- Powder coating provides a more refined appearance, ideal for decorative or exposed structures

Note: Drilling into aluminum I beams may compromise their structural integrity.

Related products for aluminum i beams

At Chalco, we offer a wide range of aluminum profiles, including I beams, H beams, C beams, and more, to meet thediverse needs of our customers.

Our one-stop service ensures that you can find all the aluminum solutions you needin one place—helping you streamline your sourcing process and reduce costs.

Aluminum H Beam

Aluminum C Beam

Aluminium Box Profile

Hat Profile

Aluminium U Profile

Aluminium T Profile

Packaging and shipping of aluminum i beams

- Protected with film, reinforced wooden crates or steel frames, and strapping to prevent deformation andscratches during transit

- Optional moisture-proof film, vacuum packaging, or anti-rust coating to reduce humidity and oxidation effects

- Customized packaging solutions available: individual wrapping, bulk packing, or container loading

- In-stock items available for shipment within one week

- Global delivery by sea, air, or rail to meet regional needs

- Support for FCL (full container load), LCL (less than container load), or loose cargo shipping

- Partnered with international logistics providers to offer DDP/DDU services—making customs clearance easier forcustomers

Protective film

Kraft paper

Wooden crate

Pallet

Full container load (FCL)

Less than container load (LCL)

Frequently asked questions about aluminum i beams

Are aluminum i beams as strong as steel?

Is aluminum stronger than steel? Many grades of aluminum are considered high-strength and can even compare tocertain steel alloys.

However, when comparing samples of the strongest aluminum alloy and steel alloy of the same size, steel is typicallythe stronger material.

What are aluminum i beams used for?

Aluminum I beams are commonly used in structural applications where a high strength-to-weight ratio and corrosionresistance are essential.

Are aluminum i beams expensive?

The price of aluminum I beams depends on factors such as alloy type, size, surface treatment, and market aluminumprices.

While aluminum is generally more expensive than steel per unit, it offers significant long-term cost savings due toits lightweight nature, corrosion resistance, and low maintenance requirements.

How do I choose the right size and alloy for my project?

We offer a wide range of standard and custom sizes to meet your specific needs!

Whether you need 4-inch, 6-inch, 8-inch I beams or specially customized dimensions, we provide the perfect solution.

Our aluminum I beams are made from high-strength, corrosion-resistant alloys such as 6061-T6, 6063, 5083, and5086—ensuring long-lasting reliability and performance.