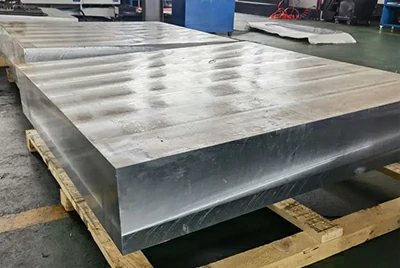

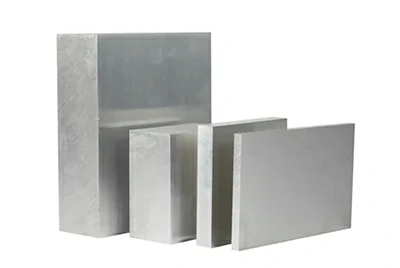

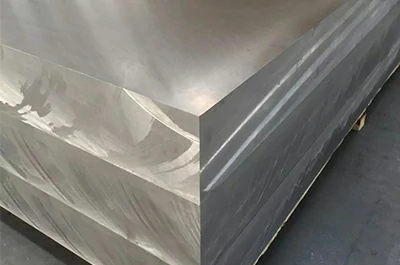

Aluminum forged plate — also known as high-strength near-net plate or 7075/6061 forged blank — is formed by high-temperature, high-pressure forging, giving it a denser grain structure than rolled plate. The result: superior fatigue life and impact resistance for aerospace, energy, heavy machinery, mold, defense and shipbuilding components.

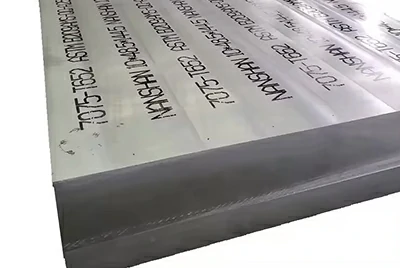

Chalco stocks 7075-T651, 6061-T6/T651, 7050-T7451 aluminum forged plates — plus steel & titanium options — up to 3000 × 1500 mm. Need custom thickness, 100% UT, or pre-machined near-net blanks?

Instant QuoteWhy Choose Chalco High-Strength Forged Plates (7075 / 6061 / 7050)

Chalco's aluminum forged plates (7075, 6061, 7050…) deliver higher strength and fatigue life than rolled plates, thanks to controlled grain flow and full-process QA. They are ideal for critical parts that demand high load capacity and precision machining.

- Stronger & More Reliable — Dense, uniform structure with controlled grain flow; excellent fatigue strength and impact resistance for heavy-duty applications.

- Core Grades in Stock — 7075-T651 / 7050-T7451 / 6061-T6(T651) / 5083-H112, etc., covering both high-strength and corrosion-resistant needs.

- Near-Net Machining — Pre-cut and pre-machined blanks reduce removal volume and cycle time; flatness and parallelism controlled for precision setups.

- Quality Assurance — 100% UT (ASTM B594 class A on request), MTC, mechanical tests, and heat-treatment traceability; typical lead time for stock blanks: 7 days.

Need 7075/6061/7050 forged plate with custom thickness or near-net blank? Get a 12-hour quote

Instant Quote

Aluminum Forged Plate Grades & Standards in Stock

Chalco focuses on aluminum forged plates for high-strength and precision-machining applications. Core grades include 7075-T651, 7050-T7451, 6061-T6/T651 and 5083-H112. Stock blanks up to 3000 × 1500 mm are available, with custom thickness and 100% UT on request. Request a fast quote

Instant Quote| Alloy / Temper | Typical Standards | Typical Max Blank | Use Case Highlights |

|---|---|---|---|

| 7075-T651 | AMS 4045, ASTM B209 | 3000 × 1500 × 150 mm | Ultra-high strength; fatigue-critical structures & tooling plates |

| 7050-T7451 | AMS 4050, ASTM B209 | 1600 × 800 × 100 mm | Excellent SCC resistance; high-load connectors & frames |

| 6061-T6 / T651 | ASTM B209 | 3000 × 1500 × 200 mm | Mold bases, fixtures, general structures; good machinability |

| 5083-H112 | EN 485, ASTM B209 | 2000 × 1000 × 80 mm | Marine & cryogenic; outstanding corrosion resistance |

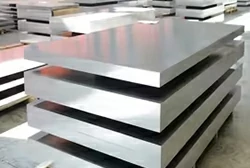

Compared with rolled plate, aluminum forged plates offer denser, more uniform grain flow for superior fatigue resistance and dimensional stability — ideal for weight-saving structures and precision machining. Typical finishing: sawn, face-milled; optional anodizing/painting.

- 7075-T651 forged plate

Ultra-high strength & fatigue performance; preferred for high-load structures and tooling plates.

AMS 4045, ASTM B209

- 7050-T7451 forged plate

Superior stress-corrosion resistance; reliable for critical connectors and ribs.

AMS 4050, ASTM B209

- 6061-T6 / T651 forged plate

Balanced strength & machinability; weldable and corrosion-resistant for molds/fixtures.

ASTM B209

- 2024-T351 forged plate

High fatigue strength and stiffness; suitable for frames and connectors.

AMS 4037, ASTM B209

- 5083-H112 forged plate

Excellent corrosion resistance & weldability for marine and cryogenic service.

EN 485, ASTM B209

- 6082-T6 forged plate

Higher strength within 6xxx; good weldability for transport & lifting equipment.

EN 573-3, ASTM B209

Need other metals? Titanium (e.g., Grade 5/23/2) and steel (e.g., 15-5PH, F6NM, A182-F22) forged plates are also available on request — contact us for specifications and lead time.

Instant QuoteNeed the same properties in other shapes? We also supply aluminum forged blocks, bars, tooling plates and heavy sections.

Near-net blocks for heavy machining. Up to 3000×1500×200 mm; 100% UT; T6/T651/T7451.

Aluminum Forged Bar (Round/Square)

Round/square bars. Sawn or pre-machined to length. Alloys: 7075 / 7050 / 6061.

6061-T651 Tooling/Mold Plate (Flatness-Controlled)

Stress-relieved, flatness-controlled; ideal for mold bases, jigs & fixtures.

High-Strength Mold Plate (7075-T651 / 7050-T7451)

Ultra-high strength for inserts & structural plates. UT/MTC on request.

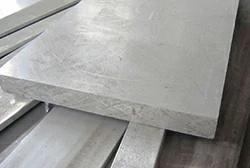

Aluminum Thick Plate (>150 mm Heavy Section)

Uniform through-thickness properties; stepped near-net plates available.

For flanges & bearings; OD up to Ø1200 mm. With machining allowance.

Industries & Use Cases of Aluminum Forged Plates

Chalco's aluminum forged plates (7075 / 7050 / 6061 / 5083…) combine high strength, fatigue resistance and stable machinability for critical parts. From aerospace and mold making to heavy/precision machinery, energy equipment, automotive, defense and marine, we deliver near-net blanks and pre-machined stock to shorten your CNC cycle and reduce waste.

Aluminum Forged Plates for Aerospace

High strength-to-weight and dimensional stability for frames, pylons, connectors and tooling plates. Popular choices include 7075-T651, 7050-T7451, 7475, 2024-T351 and 6061-T6/T651.

Instant Quote- 7075 T651 al forged plate

- 7050 T7451 al forged plate

- 7475 aluminum forged plate

- 2024 T351 al forged plate

- 6061 T6/T651 al forged plate

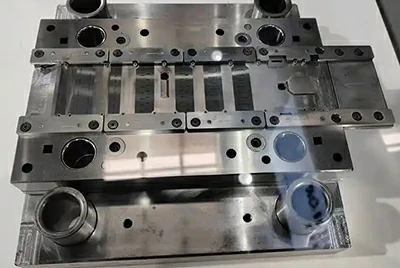

Aluminum Forged Plates for Mold & Die Making

Dense, uniform grain structure supports precise machining and long service life of mold bases, inserts and fixtures. Recommended grades: 6061-T6/T651, 7075-T651, 6082-T6, 2024-T351, 5083-H112.

Instant Quote- 6061 T6/T651 al forged plate

- 7075 T651 al forged plate

- 6082 T6 al forged plate

- 2024 T351 al forged plate

- 5083 H112 al forged plate

Aluminum Forged Plates for Heavy/Precision Machinery & CNC

High toughness and dimensional stability for gears, frames, carriers and support plates under complex loads. Go-to alloys: 7075, 6061, 2024, 5083.

Instant Quote- 7075 aluminum forged plate

- 6061 aluminum forged plate

- 2024 aluminum forged plate

- 5083 aluminum forged plate

Aluminum Forged Plates for Energy Equipment

Corrosion-resistant, stable performance for shells, heat-exchanger plates, supports and structural flanges in power and petrochemical service. Focus grades: 5083-H112, 5086, 6061-T6.

Instant Quote- 5083 H112 al forged plate

- 5086 aluminum forged plate

- 6061 T6 al forged plate

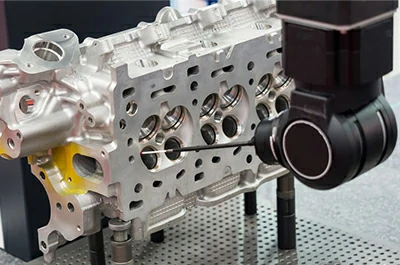

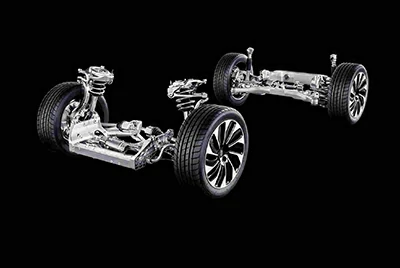

Aluminum Forged Plates for Automotive Manufacturing

Lightweight strength for EV structures, chassis and suspension carriers with good machinability and weldability. Frequently requested: 6061, 6082, 6016, 6009, 6111.

Instant Quote- 6061 aluminum forged plate

- 6082 aluminum forged plate

- 6016 aluminum forged plate

- 6009 aluminum forged plate

- 6111 aluminum forged plate

Aluminum Forged Plates for Defense & Protection

High toughness and corrosion resistance for protective structures, mounts and support components. Typical aluminum options include 7039, 5083-H131, 6061-T6 and 5086.

Instant Quote- 7039 aluminum forged plate

- 5083 H131 al forged plate

- 6061 T6 al forged plate

- 5086 aluminum forged plate

Aluminum Forged Plates for Shipbuilding & Marine

Excellent seawater corrosion resistance and weldability for hull structures, bulkheads, shafts and marine fittings. Preferred grades: 5083, 5086, 6061.

Instant Quote- 5083 aluminum forged plate

- 5086 aluminum forged plate

- 6061 aluminum forged plate

Besides aluminum, titanium (e.g., Grade 5/23/2) and steel (e.g., 15-5PH, F6NM, A182-F22) forged plates are also available on request—contact us for specifications and lead time.

Forging, CNC Machining & Quality Assurance

Core Forging & Forming Capability

- Blank size: up to 3000 × 1500 mm; typical thickness 20–200 mm (custom up to 400 mm for selected alloys).

- Plate types: standard rectangular, thick plates >150 mm, extra-wide, stepped/special-shaped near-net plates.

- Processes: open-die forging with controlled grain flow; heat treatment per T6/T651/T7451/H112 as required.

- Alloys focus: aluminum 7075 / 7050 / 6061 / 5083; other metals on request.

- Ultrasonic test (UT): 100% scan available (ASTM B594 class A on request); mechanical tests with MTC traceability.

Precision CNC & Surface Finishing

- Machining: 3/4/5-axis CNC; face-milling, drilling, tapping, slotting, chamfering; ±0.01 mm tolerance possible on request.

- Flatness/parallelism: controlled for quick fixturing; near-net blanks to reduce stock removal & cycle time.

- Surface options: sawn, face-milled; anodizing/painting available.

- Delivery: stock blanks typically ship in 7 days; custom near-net plates in 10–25 working days depending on complexity.

Project Support & Documentation

- Made-to-print: sizes per drawing with reserved allowances or finished parts delivery.

- Certificates: MTC, chemical analysis, mechanical properties, UT report, hardness; third-party tests & COC on request.

- Standards: ASTM/AMS/EN compliance for aluminum forged plates.

Send your drawing—get a 12-hour quote →

Instant QuoteForged Plate Selection—Quick Technical Guide

Use the following comparisons and selection table to decide when to choose aluminum forged plates (7075 / 7050 / 6061 / 5083) and how to specify near-net blanks for faster CNC.

Forged Plate vs Rolled Plate

| Aspect | Forged Plate | Rolled Plate |

| Internal structure | Dense, controlled grain flow; fewer laminations | Layered structure; higher delamination risk in thick sections |

| Mechanical properties | Higher strength & fatigue life, better impact tolerance | Balanced properties for general use |

| Thickness range | Available in heavy sections (>150 mm typical) | Practical limits in very thick gauges |

| Best use | High-load, fatigue-critical, precision-machined parts | General structures, covers, base plates |

Open-Die vs Closed-Die (for plates & near-net blanks)

| Aspect | Open-Die Forging | Closed-Die Forging |

| Forming | Free forming between anvils; ideal for large plates/blocks | Shaped by die cavity; closer to net shape |

| Tooling cost | Low; good for small batches/large parts | High; economical for mass production |

| Dimensional accuracy | Medium; finish-machining needed | High; near-net shape |

| Typical use | Plates, blocks, stepped near-net blanks | Complex brackets, gears, rods |

Aluminum Grade Quick Selection (Forged Plates)

| Alloy | Strength & Fatigue | Corrosion/Weld | Machinability | Typical Uses |

|---|---|---|---|---|

| 7075-T651 | ★★★★★ (ultra-high) | ★★★☆☆ | ★★★★☆ | High-load structures, tooling plates |

| 7050-T7451 | ★★★★★ | ★★★★☆ (SCC-resistant) | ★★★☆☆ | Connectors, frames, ribs |

| 6061-T6/T651 | ★★★☆☆ | ★★★★☆ (good weldability) | ★★★★★ | Mold bases, fixtures, general structures |

| 5083-H112 | ★★★☆☆ | ★★★★★ (marine/cryo) | ★★★☆☆ | Marine, cryogenic plates, tanks |

Need other metals? Titanium and steel forged plates can be supplied on request—tell us the spec, standard and size, we'll advise quickly.

Share your alloy/size—get a fast quote →

Instant QuoteBuying FAQ for Aluminum Forged Plates

What's the maximum size you can supply?

Up to 3000 × 1500 mm blank size for selected alloys; typical thickness 20–200 mm (custom up to 400 mm on request).

Do you provide 100% ultrasonic test?

Yes. 100% UT is available; ASTM B594 class A can be provided on request together with MTC and mechanical tests.

Can you deliver near-net blanks to cut my CNC time?

Yes. We pre-cut and face-mill to near-net shapes, controlling flatness/parallelism for quick set-up and smaller removal volume.

How long is the lead time?

Stock blanks typically ship in 7 days; custom near-net plates in 10–25 working days depending on complexity and quantity.

What certificates and standards are supported?

MTC, chemistry, mechanical test, UT report, hardness; compliance with ASTM/AMS/EN for aluminum forged plates.

Which aluminum alloys are most popular?

7075-T651, 7050-T7451, 6061-T6/T651, 5083-H112—chosen based on strength, corrosion resistance and machinability needs.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote