6101 aluminum sheet/plate is a heat-treatable aluminum alloy based on an Al–Mg–Si alloy system. In sheet and plate form, 6101 aluminum is widely selected for balancing electrical conductivity with a certain level of strength. The magnesium (Mg) and silicon (Si) ratio enables it to achieve more stable mechanical properties through heat treatment while maintaining good machinability and formability. Therefore, 6101 is commonly used in applications that require a balance of conductivity and strength, such as electrical busbars, power connectors, and conductive structural components.

Chalco can reliably supply high-quality 6101 aluminum sheet/plate in compliance with ASTM B317, EN-573, and EN-485 standards. For large projects that require extra-wide aluminum bars or large busbars, using 6101 aluminum sheet/plate can effectively avoid the width limitations of finished aluminum bars, reducing the risks of splicing and rework, and offering a more reliable and hassle-free choice. If you need customization and a quotation, please contact us promptly.

Chalco keeps 6101 aluminum sheet/plate in regular stock, covering the most commonly used specifications for projects: thickness 3-12 mm, sheet size 1250×3000 mm, with conductivity guaranteed at ≥55.

Click to view 6101 aluminum sheet/plate stock↓

Chalco 6101 Aluminum Sheet / Plate Overview

| Alloy | 6101 |

| Thickness Range | 1–250 mm (Popular: 3 / 3.5 / 4 / 5 / 6 / 8 / 10 / 12 mm) |

| Temper | H111, T6, T63, T65, T61, T64 |

| Width | 100-2600 mm (Stock) |

| Length | 3000 mm (Stock) |

| Form | Coil | Plate/Sheet |

| Electrical Conductivity | ≥55 (as required) |

| Surface & Edge | Mill finish | Protective film | Deburred / Chamfered |

| Processing Service | Cut-to-size | Slitting | Deburring | Protective packing | Marking/labeling |

| Inspection Documents | MTC | COC | Batch traceability (as required) |

6101 Aluminum Sheet / Plate in Different Tempers

Chalco can supply 6101 aluminum sheet/plate in multiple tempers to meet different customer requirements for electrical conductivity, strength, and processing performance. Whether you need high conductivity for large busbar projects or stable assembly performance for conductive structural components, we can match you with a more suitable temper and delivery solution.

-

6101 T6 aluminum sheet/plate

Electrical conductivity: ≥55.0% IACS (20°C)

In the T6 temper, while ensuring strength, it can still maintain stable electrical conductivity and is commonly used for busbars and conductive parts that require both conductivity and structural strength.

-

6101 T61 aluminum sheet/plate

Electrical conductivity: ≥57.0% IACS (20°C)

The T61 temper provides a higher minimum conductivity, making it suitable for electrical connectors and high-current conductive structures that are more sensitive to conductivity consistency.

-

6101 T63 aluminum sheet/plate

Electrical conductivity: ≥56.0% IACS (20°C)

The T63 temper offers a more balanced combination of conductivity and mechanical properties, making it suitable for busbars and conductive plates that need to balance assembly strength and conductive efficiency.

-

6101 T64 aluminum sheet/plate

Electrical conductivity: ≥59.5% IACS (20°C)

The T64 temper features more outstanding conductivity performance, making it suitable for power conductive components and extra-wide conductive plates that pursue higher conductivity while still maintaining machinability.

-

6101 T65 aluminum sheet/plate

Electrical conductivity: ≥56.5% IACS (20°C)

The T65 temper provides a stable minimum conductivity and is commonly used for project-based busbars and conductive structural components with clear acceptance requirements for both the strength window and electrical conductivity.

-

6101 H111 aluminum sheet/plate

Electrical conductivity: ≥59.0% IACS (20°C)

The H111 temper offers a relatively high minimum conductivity, making it suitable for conductive sheet applications that require high conductivity efficiency while placing more emphasis on formability and processing adaptability.

6101 Aluminum Sheet / Plate Stock Purchasing Guide

- All stock sizes support retail and small-batch purchasing, and single-sheet orders are also accepted. After the order is confirmed, we will arrange dispatch, customs clearance, and shipment as soon as possible, and the overall lead time is usually more controllable.

- As a source manufacturer with large-scale one-stop production capabilities, we produce 6101 aluminum sheet/plate steadily in accordance with common market acceptance standards. While ensuring consistent quality, we also make the overall procurement cost more competitive (with about a 10% cost advantage).

- Each batch of 6101 aluminum sheet/plate undergoes strict factory inspection and quality control to ensure smoother acceptance upon delivery and greater confidence for project use.

Chalco Best-Selling In-Stock Sizes of 6101 Aluminum Sheet / Plate

| Alloy | Temper | Thickness | Width | Length |

| 6101 | T63 | 1.5 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 3 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 3.5 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 4 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 5 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 6 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 8 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 10 mm | 1250 mm | 3000 mm |

| 6101 | T63 | 12 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 1.5 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 3 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 3.5 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 4 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 5 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 6 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 8 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 10 mm | 1250 mm | 3000 mm |

| 6101 | T65 | 12 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 1.5 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 3 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 3.5 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 4 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 5 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 6 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 8 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 10 mm | 1250 mm | 3000 mm |

| 6101 | T61 | 12 mm | 1250 mm | 3000 mm |

Can't find the right size? Please contact us promptly and tell us the size you need—Chalco will provide you with a fast and comprehensive solution.

Why Choose 6101 Aluminum Sheet / Plate Instead of Aluminum Busbar?

For busbar projects, finished aluminum busbar is certainly convenient, but once you encounter extra-wide designs, special shapes, complex holes/slots, or tight delivery schedules, 6101 aluminum sheet/plate can be a more hassle-free choice.

- 6101 aluminum sheet/plate supports laser cutting, waterjet cutting, and CNC machining, making complex busbar shapes (L, T, branches, window cutouts) easy to produce. One-piece cutting reduces joints versus spliced busbars, helping lower contact resistance, heat buildup, and long-term failure risk.

- With the right temper and proper bending process conditions, Chalco's 6101 aluminum sheet/plate can achieve 90° bending without cracking, making it suitable for conductive structural components and busbar plate applications that require bending and forming.

- Traditional aluminum busbars are limited in width and available sizes, while 6101 aluminum sheet/plate can be freely cut to width and thickness according to drawings. With a larger cross-sectional area design, it can stably carry tens of thousands of amperes, making voltage drop and current-carrying capacity more controllable.

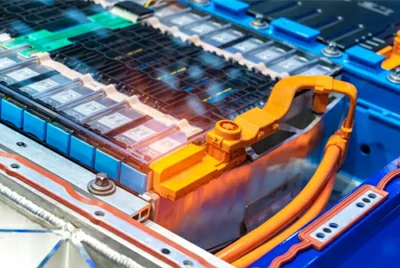

- 6101 aluminum sheet/plate combines good electrical conductivity with structural strength, allowing it to serve as both a conductor and a load-bearing component. It can be used for switchgear partitions, grounding bus plates, or new energy battery pack baseplates, reducing weight while lowering part count and simplifying assembly.

- Aluminum sheet/plate provides a larger planar contact area and can perform both electrical conduction and thermal spreading. When used as a busbar or power module baseplate, 6101 aluminum sheet/plate can significantly improve heat dissipation efficiency—something narrow strip busbars are difficult to achieve.

- Stretched 6101 aluminum sheet/plate (such as T651) has lower residual stress and better flatness. It is less prone to warping during laser cutting, automated welding, and batch assembly, helping ensure consistency and yield in automated assembly.

- For extra-wide or irregular-profile busbars, aluminum sheet/plate can be cut and processed directly to the drawing without splicing multiple busbars. This not only simplifies the structure but also avoids assembly and reliability risks caused by increased connection points.

Applications of 6101 Aluminum Sheet / Plate

Extra-wide busbars and custom conductor cutting

When standard busbar sizes limit your design, 6101 aluminum sheet/plate can be cut to drawing for the required width and shape, reducing redesign and splicing.

EV charging station parts and enclosures

For outdoor charging stations, 6101 sheet/plate offers corrosion resistance, low weight, and easy fabrication. It suits enclosure panels, support plates, and mounting backplates, with good hole-making, bending, and assembly consistency.

EV charging conductors & busbar stock

6101 sheet/plate can be cut to drawing into high-current connectors with required widths and hole patterns, reducing joints to lower poor-contact and hot-spot risks, and supporting batch delivery.

EV high-voltage conductive parts

In EV HV boxes and PDUs, connectors must carry high current in limited space. 6101 sheet/plate is used for conductive plates and tabs, balancing conductivity and assembly strength.

Energy storage PACK busbars & connections

PACK connections need current capacity, temperature control, and batch consistency. 6101 sheet/plate can be cut to drawing for busbar plates and transition tabs, supporting prototyping to mass delivery.

Switchgear & MCC connection plates

In switchgear and MCCs, 6101 sheet/plate can be made into conductive connection plates and transition bars, supporting easy hole-making, assembly, and maintenance with good batch consistency.

Other 6101 Aluminum Products You May Be Interested In

In addition to 6101 aluminum sheet/plate, Chalco also supplies various 6101-series conductive product forms to provide a one-stop 6101 solution for your project.

-

6101 aluminum busbar

6101 aluminum busbar is used for busbars and high-current conductive connections, balancing conductivity and strength. It is suitable for conductive components in switchgear, data centers, and energy storage systems.

-

6101 aluminum bus pipe

6101 bus pipe is used in busbar systems that integrate conductivity and structure, suitable for power transmission and distribution solutions requiring safer protection and cleaner routing.

-

6101 aluminum wire rod

6101 wire rod is a commonly used billet for electrical conductors. It can be used for subsequent processing such as wire drawing and stranding, meeting requirements for electrical conductivity and stable processing performance.

-

6101 precision ground aluminum rod

6101 precision ground aluminum rod offers better dimensional consistency on the surface, making it suitable for conductive or machined parts that require more stable fit-up and better surface quality.

-

6101 aluminum wire

6101 aluminum wire is used for power conductors, connection harnesses, and conductive components, emphasizing electrical conductivity and batch consistency for easier assembly and acceptance.

Chemical Composition of 6101 Aluminum Sheet / Plate

| Element | Composition(%) |

| Al | Remainder |

| Si | 0.30–0.70 |

| Fe | ≤0.50 |

| Cu | ≤0.10 |

| Mn | ≤0.03 |

| Cr | ≤0.03 |

| B | ≤0.06 |

| Mg | 0.35–0.80 |

| Zn | ≤0.10 |

| Other (Each) | ≤0.03 |

| Others (Total) | ≤0.10 |

Mechanical Properties of 6101 Aluminum Sheet / Plate

| Temper | Specified Thickness (in) | Tensile Strength (ksi, MPa) | Yield Strength (ksi, MPa) |

| T6 / T61 | 0.125–0.500 | ≥29.0 (200) | ≥25.0 (172) |

| T6 / T61 | 0.125–0.749 | ≥20.0 (138) | ≥15.0 (103) |

| T6 / T61 | 0.750–1.499 | ≥18.0 (124) | ≥11.0 (76) |

| T6 / T61 | 1.500–2.000 | ≥15.0 (103) | ≥8.0 (55) |

| T63 | 0.125–0.500 | ≥27.0 (186) | ≥22.0 (152) |

| T64 | 0.125–1.000 | ≥15.0 (103) | ≥8.0 (55) |

| T65 | 0.125–0.749 | 25.0–32.0 (172–221) | 20.0–27.0 (138–186) |

| H111 | 0.250–2.000 | ≥12.0 (83) | ≥8.0 (55) |

Production Capabilities and Processing Services

Chalco has a fully integrated production system from casting, hot rolling, cold rolling, and stretching to surface treatment. We can reliably supply high-end wide plates such as marine-grade, armor-grade, and tanker-grade materials, and support custom specifications and delivery plans based on project drawings.

Advanced equipment

Equipped with a 4500 mm SMS (Germany) hot rolling line and a 2800 mm CVC cold rolling mill, both with closed-loop thickness and flatness control to ensure stable plate shape and batch consistency.

Size range

Supports widths up to 2650 mm and thicknesses of 1–250 mm. Custom weldable wide plates and extra-long plates are available to meet large-project needs for integrated dimensions and structures.

Processing services

Provides one-stop services including laser cutting, waterjet cutting, friction stir welding, bending, sandblasting, and anodizing, supporting direct delivery of finished/semi-finished plates based on drawings.

Delivery efficiency

In-stock items can be ordered directly. Samples are typically shipped within 5–7 days. Bulk orders are generally delivered in 2–4 weeks, with expedited options available to match project schedules. View in-stock sizes.

Packaging, Export & Logistics

Chalco uses standardized export packaging to protect 6101 sheet/plate from moisture, impact, abrasion, and forklift handling, supporting smoother inspection on arrival.

- Packaging: Palletized (wood or fumigation-free), moisture-proof wrapped and strapped; corner protectors, separators, waterproofing, protective film, and interleaving paper available to reduce scratches and dents.

- Export documents & compliance: Provide standard export and inspection documents (packing list, invoice, COO, warranty/material certs, etc.), with batch marking and traceability support.

- Loading & shipment: Full-sheet or cut-to-size packing for containers, with reinforcement and anti-shift measures; sea/air/courier options available via your forwarder or our booking.

- Delivery & tracking: Provide loading photos and shipment details (container/seal/B/L), and track key logistics milestones for better schedule control.

6101 Aluminum Sheet / Plate FAQ

Bolted busbar joints—OK? How to reduce heating?

Yes. Clean contact surfaces, remove oxide/oil, ensure enough contact area, and control clamping force/anti-loosening. For high current, also check flatness and burrs to avoid hot spots.

Surface treatment—can it be done? Should conductive areas be anodized?

Yes (sandblasting, film, deburring). Conductive contact areas are usually kept as bare metal; if treatment is required, define "contact vs. non-contact" zones on the drawing.

Why is flatness important?

For large-area contact, stacked parts, or automated assembly, poor flatness can cause uneven contact and local heating.

Can you pre-machine holes/slots/countersinks?

Yes. Cut to drawing, then machine features to reduce on-site rework. Provide key tolerances and surface protection requirements.

How to balance weight, temperature rise, and strength?

Size cross-section and joint design by current/temperature rise first, then confirm thickness/contact area and reinforcement; verify fastening for load/vibration.

Quick incoming checks?

Surface dents, edge burrs, critical dimensions/hole locations vs. drawing, and batch/documents; for conductive parts, confirm contact surfaces are clean.

How to speed up sampling/trial fit?

Provide drawing/flat size, key holes, contact-surface requirements, and acceptance points (fit-up, temperature-rise test method).

What services can Chalco provide for you?

- Free samples: Samples are available for selected sizes for prototyping, trial fitting, and material verification.

- Bulk/loyal customer discounts: More competitive pricing is available for bulk purchases or long-term cooperation.

- Custom cutting support: Cut-to-length and slitting to drawing to reduce secondary processing and material waste.

- Value-added processing: Laser/waterjet cutting, bending, friction stir welding, and other processing services are available, delivering plates to drawing.

- Edge & surface finishing: Deburring, chamfering, protective film, etc., to reduce shipping scratches and assembly risks.

- Specified packaging: Pallet/crate reinforcement, moisture-proof and anti-scratch packing, with labeling and split packing options for easier storage and on-site picking.

- Shipping support: Sea/air/courier options are available, with either your nominated forwarder or our coordinated booking, customs clearance, and shipment tracking.