If you're looking for a high-strength, easy-to-machine, and highly durable aluminum alloy, 2017 (2017A) aluminumplate is the ideal choice.

It's widely used in aerospace, machinery, and mold applications—especially for high-stress structural parts andprecision components where both performance and efficiency matter.

2017A / 2017 aluminum plate specifications

- EN 485, EN 573, ASTM B209, AMS 4120, AMS 4172, QQ-A-250/3, AIR 9051A

- EN designation: AW-2017A (Europe)

- AA designation: 2017 (USA)

We are certified to AS9100, AS9120, ISO 9001, ISO 14001, IATF 16949, NADCAP, and BSI standards.

Each batch comes with a Material Test Certificate (MTC) and quality inspection report. Third-party testing is alsoavailable to ensure full compliance and quality assurance.

2017A / 2017 aluminum plate product details

- Temper: O, T3, T351, T4, T42, T451, T4511

- Thickness: 0.4mm – 200mm (For ultra-thick plates, contact us for custom solutions)

- Width: 1500mm

- Length: 3000mm

- Surface finish: mill finish, clad aluminum

We offer aluminum plate cutting services and can process plates into smaller pieces as needed.

Single sheets are available from stock with no minimum order quantity required.

Instant Quote

2017A / 2017 aluminum plate stock size list

If you're planning a bulk purchase, feel free to browse our up-to-date stock list for available sizes.

If your required size is not listed, contact us for a custom order.We offer aluminum plate cutting services, andsingle sheets from stock are also available.

All in-stock items can be shipped within 48 hours!

EN AW 2017A aluminum plate stock size list

| Description | Standard | Thickness (mm) | Width (mm) | Length (mm) |

| EN AW 2017A-T4511 Aluminum Busbar | EN755 | 55 | 65 | 2000 |

| EN AW 2017A-T4 Aluminum Plate | EN 485 | 2 | 1335 | 2000 |

| EN AW 2017A-T4 Aluminum Plate | EN 485 | 3 | 1000 | 2000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 12 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 15 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 16 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 18 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 20 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 22 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 25 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 26 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 28 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 30 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 36 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 40 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 50 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 55 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 60 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 65 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 70 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 75 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 80 | 1500 | 3000 |

| EN AW 2017A-T451 Aluminum Plate | EN 485 | 120 | 1500 | 3000 |

AA 2017 aluminum plate stock size list

| Alloy | Standard | Thickness (mm) | Width (mm) |

| AA 2017 Aluminum Plate | ASTM B209 | 5 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 6 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 8 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 10 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 12 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 15 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 20 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 25 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 30 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 35 | 800 |

| AA 2017 Aluminum Plate | ASTM B209 | 40 | 800 |

If we don't have the size you need, please contact us for a custom order.

Instant Quote2017A / 2017 aluminum plate chemical composition

We supply both ASTM 2017 (USA) and EN 2017A (Europe) aluminum plates.

Please specify the required standard when placing your order so we can ensure accurate delivery.

| Weight% | Alloy 2017 USA | Alloy 2017A EAA |

| Al | Rem | Rem |

| Si | 0.20-0.8 | 0.20-0.8 |

| Fe | 0.7 max | 0.7 max |

| Cu | 3.5-4.5 | 3.5-4.5 |

| Mn | 0.40-1.0 | 0.40-1.0 |

| Mg | 0.40-0.8 | 0.40-1.0 |

| Cr | 0.10 max | 0.10 max |

| Zn | 0.25 max | 0.25 max |

| Ti | 0.15 max | - |

| Zr + Ti | - | 0.25 max |

| Others Each | 0.05 max | 0.05 max |

| Other Total | 0.15 max | 0.15 max |

Mechanical properties of 2017A aluminum alloy (EN 485)

| Temper | Thickness (mm) | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Bend radius | Hardness (HB) |

| O | 0.4 - 25 | Max. 255 | Max. 145 | 14 | 180° 0.5t-1.0t 90° 1.0t- 4.0t | 55 |

| T4, T451 | 0.4 – 12.5 | Min. 390 | Min. 245 | 14 | 180° 3.0t-5.0t 90° 3.0t- 8.0t | 110 |

| T4, T451 | 12.5 – 150 | Min. 350 | Min. 240 | 4-12 | - | 105-110 |

| T4, T451 | 150 - 200 | Min. 300 | Min. 200 | 2 | - | - |

| T42 | 0.4 -12.5 | Min. 390 | Min. 235 | 14 | - | 109 |

Thermal properties of 2017A / 2017 aluminum plate

| Latent Heat of Fusion | 390 J/g |

| Melting Completion (Liquidus) | 650 °C |

| Maximum Temperature: Mechanical | 220 °C |

| Melting Onset (Solidus) | 510 °C |

| Specific Heat Capacity | 880 J/kg-K |

| Thermal Conductivity | 150 W/m-K |

| Thermal Expansion | 23 µm/m-K |

Corrosion resistance of 2017A / 2017 aluminum plate

2017 aluminum alloy has relatively poor corrosion resistance due to its high copper (Cu) content, making itsusceptible to galvanic and stress corrosion.

- Alclad layer: A thin layer of pure aluminum is applied to the surface of 2017 alloy to shield it from corrosiveenvironments.

- Protective coating: Anti-corrosion coatings (e.g., paint or spray) are applied to isolate the alloy fromenvironmental exposure.

- Alloy combination: Combined use with corrosion-resistant alloys such as manganese or silicon-rich alloys.

- Avoid contact with dissimilar metals: Prevents galvanic corrosion by insulating 2017 aluminum from directcontact with other metals using pads or coatings.

Advantages of 2017A / 2017 aluminum plate

- High strength: Performs even better than 7075 aluminum at elevated temperatures (>125°C) and rivals certainsteels, making it ideal for high-stress structural parts.

- Excellent fatigue resistance: Perfect for dynamic structures in aerospace, machinery, and automotiveapplications that endure repeated loads over time.

- Great machinability: Easy to cut, drill, turn, and form while maintaining mechanical stability after processing.

- Lightweight: With a density of about 2.79 g/cm³, it delivers high strength with reduced weight—perfect forlightweight structural designs.

- Improved corrosion resistance: Though not as naturally corrosion-resistant as 5xxx or 6xxx series, itsdurability can be greatly enhanced through anodizing and coatings, meeting the demands of most environments.

Applications of 2017A / 2017 aluminum plate

If you require certifications, aerospace standards, or company-specific compliance for 2017 aluminum plates, pleasecontact us for more details.

We offer tailored documentation and support to meet your project requirements.

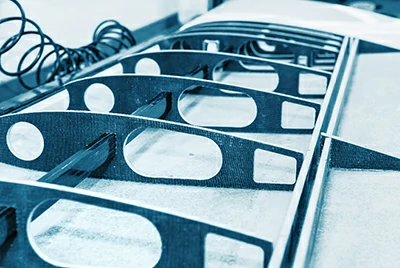

Instant QuoteAerospace

Fuselage frames, wing spars, landing gear components

Aircraft skins, ailerons, rudders, and other control surfaces

Engine accessories, door frames, structural connectors

Military equipment

In applications where fatigue resistance, high strength, and reliability are critical, 2017A is widelyused in small UAV structures and vehicle-mounted platform components.

Sports and outdoor gear

High-strength trekking and hiking poles, including shafts and joints

Bicycle frame joints, pedal axles, and fork structures

Ski equipment parts such as mounting brackets and binding housings

Transportation

Automotive suspension systems, structural wheel hubs, truck components

Railcar structures and urban transit equipment supports

Vibration-resistant parts and highway/railway transition joints

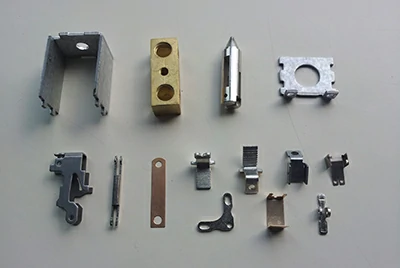

Machinery and manufacturing

High-strength parts like precision molds, guide rails, pulleys, and bearing housings

Machine frames, fixtures, and industrial connection systems

Automation equipment frames, gauges, and instrumentation parts

Consumer and light industrial components

Crochet hooks, knitting needles, metal hangers, and small pulleys

Household structural accessories and hardware supports

Metal frames and tool parts

Processing and heat treatment recommendations for 2017A / 2017 aluminum plate

We offer one-stop processing services to deliver finished products that meet your performance and applicationneeds—including cutting, heat treatment, and grinding of bars, plates, and sheets.

Formability

O temper (annealed): Best formability; ideal for applications requiring high ductility.

T4 temper: Good formability with moderate strength; suitable for light to medium stamping or drawing operations.

Machinability

T4 temper: Excellent machinability; the most recommended state for machining.

O temper: Lower machinability; not ideal for mechanical processing.

Use oil-based lubricants for better surface finish and extended tool life during machining.

Weldability

Not recommended for standard welding methods, as it can significantly reduce corrosion resistance.

If welding is required, resistance welding is preferred and must be carefully controlled.

Not suitable for TIG/MIG welding unless special pre-treatment and filler materials are used.

Solution heat treatment

Heat at 940°F (approx. 500°C) for 3–4 hours, followed by water quenching.

Natural aging at room temperature is required to achieve T4 temper.

O temper annealing

Anneal at 775°F (approx. 415°C) for 3 hours, then cool at 50°F (10°C) per hour down to 500°F (260°C), followed byair cooling.

Cold working performance

T4 temper is best suited for cold working such as bending, forming, or stamping.

Compatible with standard forming processes and adaptable to various tooling setups.

Related products of 2017A / 2017 aluminum plate

We offer a wide range of high-quality, high-precision aluminum products for industrial equipment, automotive,marine, construction, and more.

Available forms include sheets, plates, wire, tubes, rods, and bars.

For a complete list of 2017A / 2017 aluminum stock, please contact us.

Instant Quote

2017 Aluminum Bar

2017 Aluminum Sheet

2017 Wire / Rod

2017 Aluminum Forgings

2017 Aluminum Extrusion

2017 Aluminum Tube

Aluminium 2017 Sheet & Plates Equivalent Grades

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4MgSi | AU4G | 3.1325 | A92017 | AlCu4SiMg | 2017 | AlCuMg1 |

Why choose Chalco as your 2017 aluminum plate supplier?

- High-quality raw materials: We use high-purity aluminum ingots to ensure superior strength and durability of our2017 aluminum plates.

- Advanced manufacturing: Equipped with state-of-the-art facilities and strict quality control systems, meetinginternational standards such as ASTM, EN, and AMS.

- Customizable options: Thickness, dimensions, temper, surface treatment, and packaging can all be tailored toyour needs.

- Competitive pricing: We offer cost-effective pricing with bulk purchase discounts available.

- Fast delivery: With ample stock, standard orders ship within 7–15 days, and urgent requests can be expedited.

- Global service experience: Trusted by customers in 30+ countries, with a responsive and knowledgeable supportteam.

- Complete certification: Material certificates, third-party inspection reports, ROHS, and REACH documents areavailable.

- Free samples: Free samples are offered to help you evaluate product quality and performance.

- Flexible payment terms: We support multiple international payment methods, including T/T and L/C, to ensuresecure transactions.

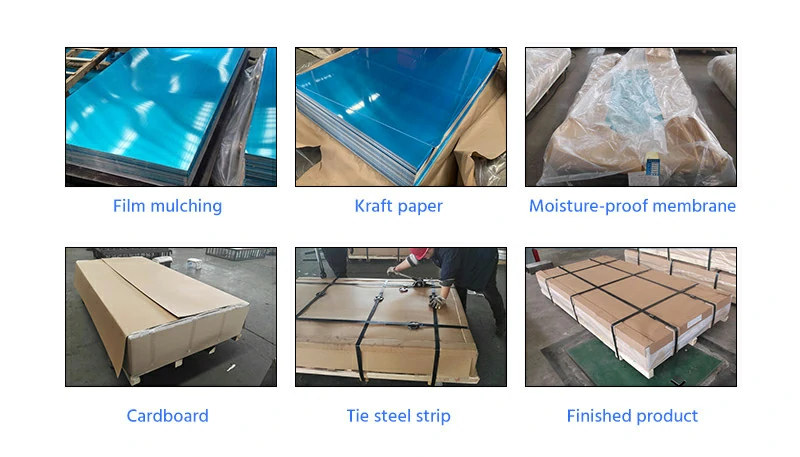

Packaging and shipping of 2017 aluminum plate

- Export-standard packaging: Packed with fumigation-free wooden pallets and waterproof plastic film—strong,durable, and suitable for sea freight.

- Individual protection: Each piece is wrapped with transparent film or tissue paper to prevent scratches andcontamination.

- Outer packaging: Each bundle is wrapped with PE film or kraft paper to protect against moisture and impact, andto maximize space efficiency.

- Custom packaging options: Protective films or outer wraps with your logo are available at a reasonable cost toenhance your brand image.

- Global logistics support: We can work with your designated freight forwarder or arrange international shippingvia express or sea freight.

- Flexible sourcing: In case of stock shortages, we leverage our global supply network to fulfill your order asquickly as possible.

- Full process transparency: From production to delivery, we keep you informed with real-time updates at everystage.

- Efficient container loading: Our experienced team optimizes loading plans to help reduce your shipping costs.

2017 aluminum plate – frequently asked questions

What is the price of 2017 aluminum plate per kg?

The price varies depending on quantity, thickness, and temper (T4, T3, etc.) For exact pricing, contact us with yourspecifications.

What’s the difference between 2017 and 2024 aluminum plate?

Both are high-strength 2xxx series alloys, but 2024 offers slightly higher strength and better fatigue resistance,while 2017 provides better machinability and is easier to process in T4 condition.

2017 vs 2014 aluminum – how do they compare?

2014 has higher strength and better toughness, especially for aerospace applications, while 2017 is more suitablefor machined components and applications requiring good cutting performance.

How does 2017 compare with 7075 aluminum?

7075 is much stronger and used in highly stressed structural parts (e.g., aircraft wings), but 2017 is moreaffordable, easier to machine, and sufficient for medium-strength applications.

How does 2017 differ from 6061 aluminum?

6061 is a Mg-Si alloy with better corrosion resistance and weldability, but its strength is lower than 2017, making2017 more suitable for mechanical components requiring greater load-bearing capacity.

How to Choose the Right Aluminum Plate?

When choosing between 2017, 2024, 7075, or 6061, consider your priorities—7075 offers the highest strength, 2017excels in machinability and cost-performance, while 6061 provides the best corrosion resistance and weldability forgeneral applications.

Still not sure which alloy suits your application? Contact us — our technical team will help you select the optimalsolution for your project.

Instant QuoteHow to buy 2017 aluminum plate from Chalco

If you're looking for high-quality 2017 aluminum plate, Chalco is your trusted supplier. We offer custom solutions,bulk order support, and on-time delivery to meet your business needs.

Ordering steps:

- Share your specifications with our sales team.

- Receive a custom quote based on your requirements.

- Confirm your order and delivery schedule.

- Receive your high-quality 2017 aluminum plate at your location.