Chalco's precision ground aluminum rods feature a diameter tolerance of less than -0.02mm, straightness below 0.2mm/m, and true roundness of 0.005mm. The material exhibits excellent consistency, and the double-ended chamfering ensures smooth machining without material jamming. These rods are particularly suitable for applications with strict tolerance and diameter size requirements, especially in the utilization of Swiss-type CNC machines with spindle speeds exceeding 8000.

Chalco hot sale precision ground aluminum rod

2011 precision ground aluminum rod bar

2011 Precision Ground Aluminum Rod Bar

Temper: T3

Diameter: φ4-40mm

Length: 2m, 2.5m, 3m

Contact us now

Standard

EN 573, DIN EN 754-3, BS EN 755, ASTM B211, ASTM B221, QQ-A-225/3

Surface and Tolerances of 2011 precision ground aluminum rod bar

| Diameter tolerance | Straightness | True roundness | Surface roughness |

| -0.02mm | 0.2mm/m | 0.005mm | <Ra0.3 |

Features of 2011 precision ground aluminum rod

EN AW-2011 Polished Aluminum Bar is known for its lightweight, high strength, and easy machinability. Compared to pure aluminum, its alloy characteristics make this aluminum rod stronger, more durable, and with superior mechanical properties. Its exceptional free-cutting ability allows for smooth surfaces and precise tolerances.

Applications of 2011 precision ground aluminum rod Bar

The outstanding machining capabilities of 2011-T3 Precision Ground Aluminum Rod make it suitable for precision mechanical components, small gears, screw machine parts, and more. Its excellent strength and durability make it widely used in aerospace, automotive, and mechanical processing industries.

2017 precision ground aluminum rod bar

2017 Precision Ground Aluminum Rod Bar

Temper: T4, T451, T6

Diameter: φ4-40mm

Length: 2m, 2.5m, 3m

Contact us now

Standard

EN 573 , DIN EN 754-3 , BS EN 755 , ASTM B211 , ASTM B221 , QQ-A-225/5

Surface and Tolerances of 6061 precision ground aluminum rod bar

| Diameter tolerance | Straightness | True roundness | Surface roughness |

| -0.02mm | 0.2mm/m | 0.005mm | <Ra0.3 |

Features of 2017 precision ground aluminum rod bar

2017 centerless ground bar is characterized by outstanding cutting performance, high strength, and excellent fatigue strength, with superior machinability. Its strength even surpasses that of 7075 alloy at temperatures exceeding 125°C, displaying good heat resistance. The alloy exhibits good formability in the annealed, solution heat-treated, and new quenched states, with significant strengthening effects through heat treatment, demanding strict process control.

Applications of 2017 precision ground aluminum rod bar

2017-T4 Precision Ground Aluminum Rod is the preferred choice for Swiss screw machining, CNC machining, and automatic screw machining, thanks to its exceptional cutting performance and high strength. Suitable for heavy-duty structures, it offers high strength, good fatigue strength, and outstanding machinability. Particularly, 2017 T451 T6 aluminum rods find extensive use in high-strength structures in aerospace, mechanical manufacturing, military equipment, rivets, and other applications.

2024 precision ground aluminum rod bar

2024 precision ground aluminum rod bar

Temper: T351, T3511, T4

Diameter: φ4-40mm

Length: 2m, 2.5m, 3m

Contact us now

Standard

EN 573, DIN EN 754-3, BS EN 755, ASTM B211, ASTM B221, QQ-A-225/6

Surface and Tolerances of 2024 precision ground aluminum rod bar

| Diameter tolerance | Straightness | True roundness | Surface roughness |

| -0.02mm | 0.2mm/m | 0.005mm | <Ra0.3 |

Features of 2024 precision ground aluminum rod bar

The EN AW 2024 Precision ground aluminum rod is commonly used in the aerospace industry. It features high copper content, lightweight, high strength, excellent strength-to-weight ratio, and outstanding fatigue resistance.

Applications of 2024 precision ground aluminum rod bar

The AL2024 Precision ground aluminum rod finds widespread applications in the aerospace industry, including aircraft components, airplane propellers, aircraft rivets, hydraulic valve bodies, gears and shafts, bolts, couplings, clock parts, fuse components, and more. Due to its high strength and excellent resistance to stress corrosion cracking, it is particularly suitable for components subjected to tension, such as wing and fuselage structures, meeting the stringent requirements of the aerospace industry for material performance.

6061 precision ground aluminum rod bar

6061 precision ground aluminum rod bar

Temper: T6, T651, T6511

Diameter: φ4-40mm

Length: 2m, 2.5m, 3m

Contact us now

Standard

EN 573, DIN EN 754-3, BS EN 755, ASTM B211, ASTM B221, QQ-A-225/8

Surface and Tolerances of 6061 precision ground aluminum rod bar

| Diameter tolerance | Straightness | True roundness | Surface roughness |

| -0.02mm | 0.2mm/m | 0.005mm | <Ra0.3 |

Features of 6061 precision ground aluminum rod bar

6061 aluminum, containing magnesium and silicon, is a widely used heat-treatable aluminum alloy. It possesses excellent mechanical properties and corrosion resistance, making it easy to cold work. It is highly suitable for forming and welding, while retaining the superior qualities of aluminum.

Applications of 6061 precision ground aluminum rod bar

6061 polished ground aluminum rod has a wide range of applications, including yacht components, bicycle parts, chemical instrument appearance parts, medical stethoscope appearance parts, surgical knife racks, and screw machine parts. Its versatility and adaptability make it a reliable and cost-effective choice in various industries, such as industrial machinery, construction, aerospace, and automotive.

6262 Precision Ground Aluminum Rod Bar

6262 Precision Ground Aluminum Rod

Temper: T4, T6

Diameter: φ4-40mm

Length: 2m, 2.5m, 3m

Contact us now

Standard

EN 573, DIN EN 754-3, BS EN 755, ASTM B211, ASTM B221, QQ-A-225/10

Surface and Tolerances of 6061 precision ground aluminum rod bar

| Diameter tolerance | Straightness | True roundness | Surface roughness |

| -0.02mm | 0.2mm/m | 0.005mm | <Ra0.3 |

Features of 6262 precision ground aluminum rod bar

6262 polished ground aluminum rod is a medium-strength aluminum alloy with good formability, weldability, and machinability. The alloy contains elements such as copper, lead, silicon, magnesium, and bismuth. The addition of lead and bismuth enhances its excellent processing performance, making it a heat-treatable and corrosion-resistant aluminum alloy.

Applications of 6262 precision ground aluminum rod bar

6262 aluminum rod is widely used in various fields such as screw machine products, camera components, nuts, couplings, and marine accessories. It is an ideal choice for easily machinable alloys, especially in applications where improved machining quality is required.

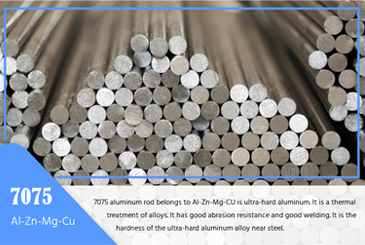

7075 Precision Ground Aluminum Rod Bar

7075 Precision Ground Aluminum Rod

Temper: T6, T651, T6511

Diameter: φ4-40mm

Length: 2m, 2.5m, 3m

Contact us now

Standard

EN 573, DIN EN 754-3, BS EN 755, ASTM B211, ASTM B221, QQ-A-225/9

Surface and Tolerances of 7075 precision ground aluminum rod bar

| Diameter tolerance | Straightness | True roundness | Surface roughness |

| -0.02mm | 0.2mm/m | 0.005mm | <Ra0.3 |

Features of 7075 precision ground aluminum rod bar

7075 precision ground aluminum rod is a high-strength-to-weight ratio aluminum rod. Due to its high copper content, it is prone to corrosion, but it strikes a balance in producing robust and fully functional aluminum alloys. While lacking the same corrosion resistance or weldability as some other alloys, its strength, stress resistance, and strain capability make it an ideal choice for aircraft applications.

Applications of 7075 precision ground aluminum rod bar

AA7075 precision ground aluminum rod is widely used in high-precision aircraft components, bicycle parts, tent stake exterior components, climbing safety hook exterior components, and other high-strength applications. Its lightweight characteristics and high strength-to-weight ratio make it widely applicable in aerospace, construction, automotive, and other fields, especially suitable for manufacturing robust yet lightweight exterior components for bicycles, aircraft, cars, etc.

Chalco precision ground aluminum rod dimensional tolerance chart

Precision ground aluminum rod imperial size tolerance chart

| Product | OD(in) | OD (Fractional) | Tolerance(in) | Standard |

| Precision Ground Aluminum Rod Bar | 0.125 | 1/8" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.1875 | 3/16" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.25 | 1/4" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.3125 | 5/16" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.375 | 3/8" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.5 | 1/2" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.625 | 5/8" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.75 | 3/4" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 0.875 | 7/8" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 1 | 1" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 1.25 | 1-1/4" | -0.0008 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 1.5 | 1-1/2" | -0.0008 | EN 754, ASTM B211 |

Precision ground aluminum rod metric size tolerance chart

| Product | OD (Metric) | Tolerance(mm) | Standard |

| Precision Ground Aluminum Rod Bar | 4MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 5MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 6MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 8MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 10MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 12MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 15MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 20MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 25MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 30MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 40MM | -0.02 | EN 754, ASTM B211 |

| Precision Ground Aluminum Rod Bar | 40MM | -0.02 | EN 754, ASTM B211 |

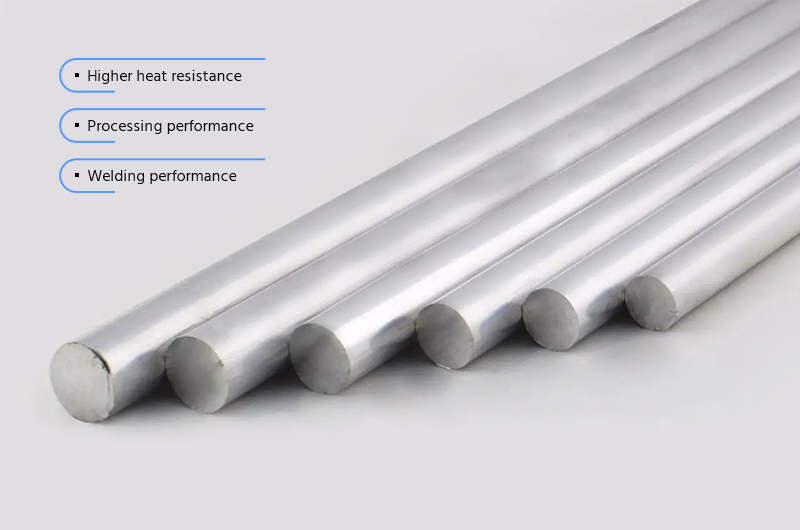

Advantages of precision ground aluminum rod bar

- Small diameter tolerance, good straightness, high material consistency, excellent true roundness, stable production, and convenient for subsequent processing.

- Superior straightness supports high-speed spindles above 8000, effectively improving production efficiency, reducing equipment damage, and extending equipment life.

- Chamfering at both ends of the material for easy automatic feeding, no material jamming, improving operational efficiency, and maintaining high-quality finished products.

- Manufactured with high-quality alloy for outstanding machining performance.

- Cost-effective in terms of material and labor, reduces waste and rework, and increases material yield.

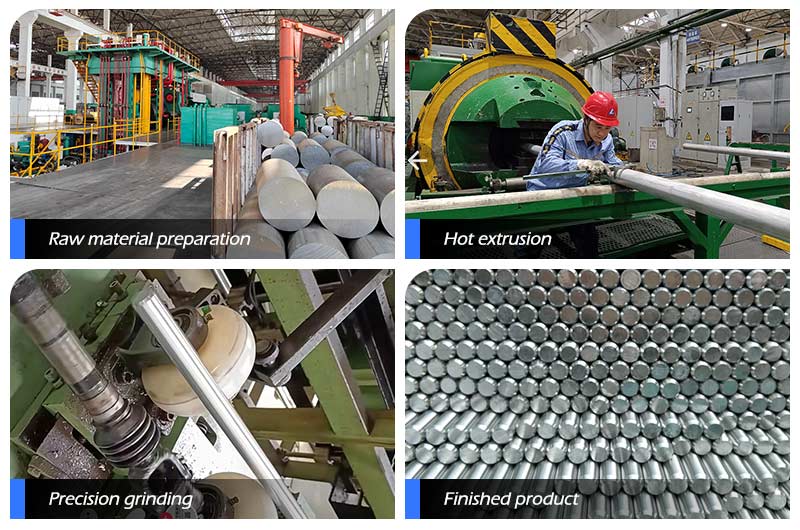

Production process of precision ground aluminum rod

- Raw Material Preparation: Select high-quality aluminum rod blanks to ensure they meet specific production requirements and standards.

- Extrusion: The aluminum rod blanks undergo hot extrusion to form preliminary aluminum round rods. Hot extrusion helps improve grain structure and enhance mechanical properties.

- Straightening: Through stretching and straightening processes, ensure that the aluminum rods achieve the specified straightness and accuracy.

- Chamfering: Chamfer the aluminum rods for easy automatic feeding during machining, preventing material jamming.

- Grinding: The preliminary formed aluminum rods go through a grinding process using abrasives or grinding wheels to remove surface irregularities and improve surface smoothness. This step helps ensure the final product's accurate diameter and smooth surface.

- Fine Polishing: Perform fine polishing on the ground aluminum rods to reduce roughness and further enhance surface smoothness, meeting customer final requirements.

- Heat Treatment: Subject the aluminum alloy to heat treatment, including heating and cooling processes, to adjust the alloy's crystal structure, improving strength and hardness.

- Inspection and Quality Control: Conduct strict measurements of tolerances, true roundness, and straightness on the ground aluminum rods to ensure compliance with standards and customer requirements.

- Packaging and Delivery: Properly package the qualified ground aluminum rods for final delivery to customers, ensuring product integrity during transportation.

Precision ground aluminum rod vs. Precision drawing(CF)aluminum bar

Difference in Accuracy

- Precision Ground Aluminum Rod: Utilizes grinding processes, Accuracy can achieve outer diameter tolerance of -0.02, true roundness <0.005mm, straightness <0.2mm/m.

- Precision drawing(CF)aluminum bar: Utilizes drawing processes, Accuracy can achieve outer diameter tolerance of -0.03, true roundness <0.01mm, straightness <0.3mm/m.

Difference in Production Process

- Precision Ground Aluminum Rod: Grinding process using grinding wheels or grinding machines to achieve specified diameter, tolerance, and surface smoothness.

- Precision drawing(CF)aluminum bar: Drawing process involves stretching aluminum rod blanks multiple times, gradually reducing the cross-sectional area to form the desired diameter.

Difference in Surface Treatment

- Precision Ground Aluminum Rod: Further improves surface smoothness through grinding processes.Minimum roughness after fine polishing can reach Ra0.1, suitable for direct use in appearance parts.

- Precision drawing(CF) aluminum bar: Higher surface smoothness due to the characteristics of the drawing process, often eliminating the need for additional grinding steps.

Difference in Production Speed and Cost

- Precision Ground Aluminum Rod: Slower production speed due to additional grinding steps, resulting in relatively higher costs.

- Precision drawing (CF) aluminum bar: Typically faster production speed, allowing for efficient mass production at lower costs.

Difference in Applications and Characteristics

- Precision Ground Aluminum Rod: Suitable for applications with high demands on diameter tolerance, straightness, and surface smoothness.Applications include precision instrument manufacturing, coreless machines, medical stethoscopes, surgical clamp, climbing safety buckles, etc.

- Precision drawing (CF) aluminum bar: Used in applications with high surface smoothness requirements but relatively lower demands on diameter accuracy.Applications include some mechanical components, automotive engine parts, tent pegs, aircraft rivets, etc.

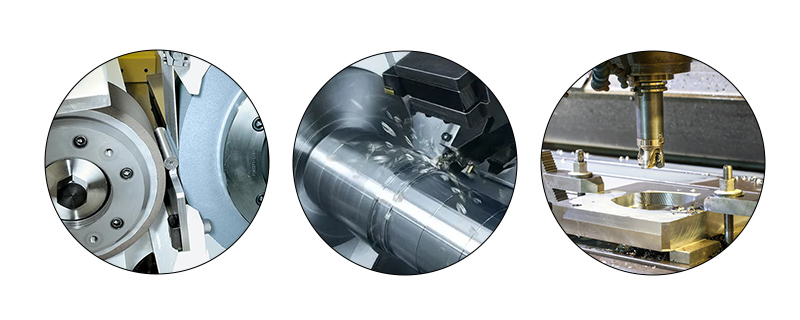

Chalco's Grinding Services as an Aluminum Supplier

Chalco focuses on providing precision centerless grinding services, utilizing grinding wheels to remove surface material from aluminum round bars. This process achieves a flawless, uniform, and polished surface on the aluminum rods. This critical manufacturing step ensures the highest quality and precision of the aluminum round bars, featuring excellent straightness and roundness, minimizing vibrations during high-speed rotations. Key highlights of Chalco's grinding services include:

- Centerless Grinding Services: Producing precise roundness and polished surfaces on high-quality materials.

- Chamfering: Creating enclosed chamfered ends for materials tailored to specific purposes.

- Custom Machining: Expert operations to meet stringent customer requirements.

- Metal Turning Services: Enhancing physical surface textures through turning operations.

- Milling: Employing progressive metal removal processes for rough-cut milling and precision finishing.

Product list of precision ground aluminum rod

| l Precision ground aluminum rod bar | l Finish Fine Polished Aluminum Rod |

| l Aluminum Precision Ground Rod Bar | l Polished Finish Aluminum Rod Bar |

| l precision ground aluminum round bar | l 4-40mm Small Solid Aluminium Rods |

| l Precision Aluminum Rods bar | l Brushed Aluminum Rod |

| l Solid Aluminium Alloy Rod | l Metric Aluminum Threaded Rod |

| l Aluminum Round Termination Bar | l Precision Ground Slot Aluminum Bar |

| l Cold Polished Finished Aluminium Bar | l Aluminum Round Solid Rod |

| l Precision Ground Solid Aluminium Round Bar | l Solid Aluminum Alloy Round Bars |

| l Fine Polished 4mm Aluminium Rod Bar | l 4-40mm Aluminum Metal Bar |

| l Precision ground aluminum rod bar | l Finish Fine Polished Aluminum Rod |