Chalco supplies forged aluminum bars designed for aerospace, defense, tooling and high-performance industrial systems. Compared with rolled or cast bars, forged bars deliver denser grain flow, higher fatigue strength, and improved dimensional stability — ideal for structural components requiring extreme strength, precision and durability.

Our capabilities cover forged round bar, square bar and rectangular bar stock, supplied in standard sizes or custom large diameters with tight tolerances. Main alloys include 7075, 6061, 7050, 2024, 2219, and 4032, available in T6, T651 and other heat-treated tempers with full aerospace certifications.

- Product Types – Round, Square, Rectangular & Custom Profiles

- Main Alloys – 7075 / 6061 / 7050 / 2024 / 2219 / 4032

- Applications – Aerospace, Military, Rail, Medical, Energy

- Production Capability & Quality Certifications

- Selection Guide & Related Forged Products

- FAQs – Specs, Stock vs Custom, Certification, Delivery

Chalco Forged Aluminum Bar Types – Round, Square, Rectangular & Custom

Chalco supplies forged aluminum bars for aerospace, defense, tooling and energy systems. Shapes include round, square, rectangular, hexagonal and custom shapes, offered as forged bar stock or made-to-drawing with tight tolerances and certifications. Main aluminum options cover 7075, 6061, 7050, 2024, 2219, 4032, 2618, etc.; selected steel grades are available on request.

-

Large-Diameter Forged Bars – For Structural Loads

Diameters up to 800 mm for shafts, landing gear and heavy-duty machine components. Dense grain flow and uniform properties support extreme load and fatigue requirements.

-

Custom-Profile Forged Bars – Shape-to-Drawing Solutions

Grooved, asymmetric or near-net cross-sections for connecting arms, brackets and structural parts. Optimized for machining adaptability and dimensional repeatability.

-

Forged Round Bars – Most Common Form

For shafts, rods and rotating components. Available as forged bar stock or custom lengths; high fatigue resistance for aerospace and precision tooling applications.

-

Forged Square Bars – For Milling & Machining Bases

Ideal for mold plates, tooling bases and structural blocks. Sharp edge accuracy supports precision milling, drilling and slotting.

-

Forged Rectangular Bars – Precision Width-to-Thickness Control

Recommended for extrusion base plates, rail components and machine tool frames. Tight dimensional control and uniform mechanical properties along length.

-

Forged Hexagonal Bars – For Fasteners & Transmission Parts

For high-strength nuts, bolts and threaded parts. Enhanced thread integrity, low material loss and stable, repeatable machining performance.

Aluminum Forged Bar Grades – 6061 / 7075 / 7050 / 2024 / 4032 & More

Chalco specializes in high-performance aluminum forged bars with reliable stock and custom supply. Core grades include 7075, 6061, 7050, 2024, 4032 and 5083, with extended support for 2618, 2219, 6082 and 7475. Certified for aerospace and precision machining, optimized for fatigue strength and thermal stability.

Bars are available in T6, T651, O, H116 and other tempers, with cut-to-length service, documentation and global delivery. For multi-material forging solutions (e.g., titanium or stainless/steel grades), please contact us for details.

Instant Quote-

6061 Aluminum Forged Bar

Versatile and easy to machine for structural frames, jigs and general CNC parts. Available as bar stock or cut-to-length with certification.

-

7075 Aluminum Forged Bar

Ultra-high strength for aerospace joints, weapon mounts and high-load components. Supplied in T6/T651 with tight-tolerance forging and test reports.

-

7050 Aluminum Forged Bar

Excellent stress-corrosion resistance and toughness for landing gear and structural ribs. Stock and custom sizes available with aerospace documentation.

-

2024 Aluminum Forged Bar

High fatigue strength and good machinability for load-bearing fuselage and gear parts. Delivered as bar stock or precision-cut lengths.

-

4032 Aluminum Forged Bar

High-silicon, wear-resistant and thermally stable for engine pistons and moving parts. Custom diameters and heat-treat options on request.

-

5083 Aluminum Forged Bar

Marine-grade corrosion resistance for offshore structures, pressure vessels and mold blocks. Certification-ready supply with cut-to-length service.

7075 aluminum forged bar

7050 aluminum forged bar

4032 aluminum forged bar

Need another grade? In addition to the alloys above, Chalco supports 2618, 2219, 6082 and 7475 aluminum forged bars, supplied with full documentation and tailored processing options. Selected steel grades are also available on request.

Not sure which alloy fits your project? Get quick recommendations, alloy selection guidance and fast quotes from Chalco experts.

Instant QuoteChalco Forged Aluminum Bar Applications in Key Industries

High-strength, fatigue-resistant forged aluminum bars for weight-critical structures across aerospace, automotive, defense, rail/industrial and energy sectors.

Aerospace Applications

Typical Uses: landing gear, wing spars, fuselage frames, engine mounts

Recommended Alloys: 7075 / 7050 / 6061 / 2024 / 2219 / 2618 / 4032

Features: lightweight, fatigue-resistant, AMS/ASTM compliant

Automotive & Powertrain

Typical Uses: suspension arms, knuckles, crash members, battery rails

Recommended Alloys: 6082 / 6061 / 7075 / 4032

Features: high strength-to-weight ratio, excellent machinability

Defense & Military

Typical Uses: UAV frames, armored connectors, missile rails, actuators

Recommended Alloys: 7050 / 2024 / 6061 / 7075

Features: impact-resistant, corrosion-resistant, long service life

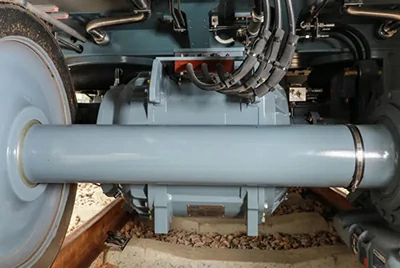

Rail Transit & Industrial Equipment

Typical Uses: subframes, linear rails, mold bases, machine frames

Recommended Alloys: 5083 / 7075 / 6061 / 2024

Features: stable under thermal cycles, supplied in T6 / T651

Energy, Oil & Gas

Typical Uses: wind hubs, offshore platforms, power casings, utility hardware

Recommended Alloys: 5083 / 6061 / 7075

Features: marine-grade corrosion resistance, lightweight, semi-finished supply

Need industry-specific guidance on alloys, sizes and tolerances? Email us for quick recommendations, selection support and delivery plans tailored to your application.

Contact ChalcoChalco Forged Aluminum Bar Production Capacity and Quality Control

Chalco specializes in the manufacturing of aluminum forged bars with advanced forging and heat treatment capabilities. We support both standard and custom aluminum forging requirements across aerospace, military, industrial, and precision machining sectors.

Our forged bar production covers a wide range of materials, including high-strength 7075/7050, corrosion-resistant 5083, and high-performance 6061/2024 aluminum alloys. We offer comprehensive services from forging and rough machining to precision sizing and surface treatment.

Aluminum Forging Capabilities

- Forging methods: free forging, closed die forging, and shaped forging for aerospace and defense applications

-

Forging equipment:

- 8000-ton hydraulic press – ideal for large-diameter aluminum bar production

- 4000-ton hydraulic hammer – suitable for aerospace-grade forged bars

- Auxiliary lines include automated manipulators, high-temperature furnaces, and precision sawing systems

-

Forged aluminum bar dimensions:

- Diameter: Ø50mm to Ø1000mm

- Length: 300mm to 5000mm

Heat Treatment and Processing Services

- Advanced quenching and aging lines with temperature control accuracy of ±2℃

- Heat treatment states supported: T6, T651, O, H116, and solution/aging treatments for aerospace and defense bars

-

Processing services:

- Rough turning, cut-to-length sawing, center drilling, precision chamfering, custom stamping

- Surface roughness controllable to Ra ≤ 1.6μm (depending on process)

Testing and Certification

- Ultrasonic testing (UT) to ASTM A388 / GB/T 6402 standards

- Metallographic analysis: grain size, inclusion content, and fiber flow control

- Mechanical properties test: tensile, yield, elongation, and hardness (HB/HV)

- Dimension and flatness inspection, surface defect detection

- Traceable documentation: material COA, heat treatment logs, third-party test reports (SGS/BV/TÜV)

Standards and Compliance

- Aerospace: AMS 4127, AMS 4124, HB/Z 140

- Military & Engineering: ASTM B247, ASME SB-247, GB/T 3190, ISO 683, EN 754-5

- All aluminum forged bars meet export-grade specifications with optional EN/AMS/ISO certification

Chalco is committed to delivering high-performance aluminum forged bars through precise process control, full traceability, and flexible production. to request technical support or a quote today.

Instant QuoteForged Aluminum Bar Selection Guide & Related Solutions

Forged aluminum bars represent the high-performance category within Chalco's aluminum bar products. Engineered for critical structural components, they offer superior strength, fatigue resistance, and dimensional stability — making them the ideal choice for aerospace structures, defense parts, precision molds, and heavy-duty industrial assemblies.

To help you select the most suitable alloy for your application, Chalco offers a comprehensive range of forged aluminum grades:

- 7075 forged aluminum bar – Ultra-high strength, widely used in aerospace, military, and performance-critical structures.

- 7050 forged aluminum bar – Excellent stress corrosion resistance and toughness, ideal for thick-section aerospace components.

- 6061 forged aluminum bar – Balanced strength, corrosion resistance, and good machinability; suitable for structural frames, brackets, and general-purpose CNC parts.

- 2024 forged aluminum bar – High fatigue strength and good machinability, preferred in aviation joints and transportation systems.

- 4032 forged aluminum bar – Excellent wear resistance and dimensional stability, used in high-temperature or motion-heavy parts such as automotive engine components.

In addition to forged bar stock, Chalco also supplies a full range of aluminum forged components, including forged discs, forged rings, forged blocks, forged shafts, and forged fittings, tailored for structural and high-load applications. Explore our full range of precision-forged aluminum parts to match your machining or assembly requirements.

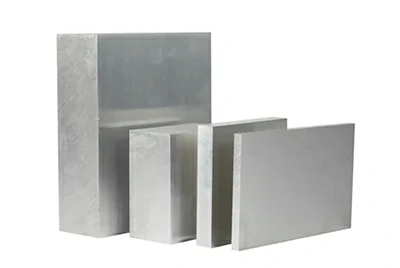

Aluminum forged plate

Aluminum forged block

Aluminum forged disc

Aluminum forged shaft

Aluminum forged tube and fittings

Aluminum forged & rolled ring

Need help choosing the right forged aluminum bar or shape for your project? Contact Chalco now for expert recommendations and a fast quote.

Instant QuoteFrequently Asked Questions (FAQ) About Forged Aluminum Bar Products

What is the size range available for forged aluminum bars?

Chalco supplies forged aluminum bars with diameters from Ø50mm to Ø1000mm and lengths from 300mm to 5000mm. We also support custom sizes based on your engineering drawings or performance requirements.

Do you support custom forged bar shapes and pre-machining?

Yes. We offer custom forging bar services for non-standard shapes, grooved or slotted profiles, and stepped geometries. Machining services such as rough turning, chamfering, center drilling, and part marking are also available.

What heat treatment conditions are available?

Our aluminum forged bars are available in T6, T651, O, H112, and other states depending on the alloy and application. We can recommend suitable heat treatment solutions for strength, corrosion resistance, or machinability needs.

Can you provide complete material certification and testing reports?

Absolutely. All forged bar shipments include a Certificate of Analysis (COA), heat treatment records, and are eligible for third-party inspections (SGS, BV, TÜV) as well as ultrasonic or other non-destructive testing upon request.

What is your minimum order quantity (MOQ)? Do you support small orders?

Our MOQ for standard-size forged aluminum bars is just 1 piece. We welcome sample orders for testing or trial runs. For custom alloys or special-shaped bars, the MOQ may vary—please send us your drawing or specifications for confirmation.

What is your typical lead time for forged bar orders?

We maintain stock for popular forged aluminum alloys such as 6061, 7075, and 2024. Standard items can ship within 7–10 days, while custom or heat-treated products typically require 2–4 weeks. Rush orders are available on request.

Do you offer international shipping and export-grade packaging?

Yes. Chalco supports global export of all forged bar products. Items are packaged in seaworthy wooden crates or pallets, with rust-proof wrapping, part labeling, and secure bracing to ensure safe air or ocean freight delivery.

How can I start a custom forged aluminum bar order with Chalco?

Simply contact our technical team with your alloy, dimension, and application requirements. We offer engineering consultation, fast sampling, and full production support to help you streamline your supply chain. Click 'Get a Quote' to get started.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote