Thanks to a tensile strength of ≈ 310 MPa in T6, low density and weld-friendly chemistry, 6061 aluminum forgings are widely adopted for aerospace, automotive, marine and energy equipment that demand both strength and weight savings.

Compared with cast or extruded parts, forged 6061 offers a pore-free, continuous grain flow and up to 20 % longer fatigue life. Versus other forged alloys:

- High Strength-to-Weight – Matches many structural steels while cutting mass by ≈ 30 %.

- Superior Corrosion Resistance – Better than 2xxx series and on par with 5xxx grades in marine environments.

- Easy Machining & Welding – Machines cleaner than 7xxx and welds readily, unlike 2xxx.

- Heat-Treat Flexibility – T6/T651 for peak strength, T4 for post-forming, T62 for balanced ductility.

Backed by AS9100-certified presses, ring-rollers and precision dies, Chalco delivers standard plates & blocks, large structural rings & shafts, high-pressure flanges and tight-tolerance aerospace parts — all quoted within 24 hours.

Instant QuoteChalco Standard 6061 Aluminum Forgings – Plates, Blocks & Tubes

Used across machinery, aerospace, rail and marine sectors, our 6061-T6/T651 standard forgings deliver high strength, fatigue resistance and CNC-friendly machinability.

- Plates / Blocks – up to 2 000 × 4 000 mm • Thickness 30–400 mm

- Tubes / Pipes – OD 30–800 mm • Wall 4–60 mm

- MOQ – 1 pc prototype • 3 t for batch orders

Forging routes include open-die, rotary-forging, die-forging and ring-rolling. Main product lines:

6061 Aluminum Forged Plate

Open-die forged • Thickness ≤ 400 mm • High impact & fatigue resistance for aerospace skins, ship panels and heavy tooling bases.

6061 Aluminum Forged Block

Free-forged to size • Uniform grain flow • Ideal for precision CNC molds, press tooling and high-tolerance machine beds.

6061 Aluminum Forged Tube & Fitting

Seamless rotary-forged • OD ≤ 800 mm • Rated to 35 MPa for aerospace hydraulics, gas cylinders and military launch tubes.

6061 Aluminum Forged Bar / Rod

Free-forged & rolled • Ø ≤ 500 mm • Superior fatigue life for drive shafts, landing-gear beams and high-load pins.

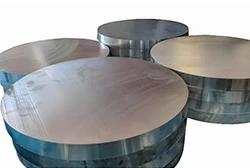

6061 Aluminum Forged Disc

Rotary-forged, grain-aligned • Ø ≤ 1 500 mm • Excellent balance & wear resistance for flywheels, pressure-vessel end-caps and turbine plates.

Looking for other shapes or alloys? Explore our full range of Forged Bars, Forged Plates, Forged Blocks, Forged Discs and Forged Tubes & Fittings, or click to contact our aluminum forging experts.

Instant QuoteChalco 6061 Aluminum Structural Forgings – Forged Rings, Shafts & Gears

Engineered for high-load aerospace, wind-power and shipbuilding structures, our 6061-T6/T651 structural forgings combine excellent fatigue resistance with tight dimensional control.

- Large Rings – Ø up to 10 m • Wall 60–350 mm

- Shafts – Length up to 8 m • Ø ≤ 800 mm

- Gears & Discs – Ø ≤ 1 500 mm • Module up to 20 mm

Processes include free forging, ring-rolling, rotary-swaging and closed-die forging. Key products:

6061 Aluminum Large Diameter Forged Ring

Ring-rolled & heat-treated • Ø ≤ 10 m • Ideal for wind-turbine yaw bearings, ship propeller flanges and rocket casings.

6061 Aluminum Forged Ring

Rolled & rotary-forged • Grain flow circumferential • Zero welds for superior fatigue life in structural couplings.

6061 Aluminum Forged Disc

Free-forged & die-forged • Ø ≤ 1 500 mm • Used in aircraft wheels, clutch plates and high-speed rotating hubs.

6061 Aluminum Forged Shaft

Free-forged & rotary-swaged • Length ≤ 8 m • High torque capacity for marine prop-shafts, motor spindles and aerospace actuators.

6061 Aluminum Forged Gear

Closed-die forged • High hardness & wear resistance • Widely used in EV gearboxes, construction-equipment drives and industrial reducers.

Need additional sizes or alloys? View our full catalog of Forged Rings, Forged Discs, Forged Shaft, or request a custom quote.

Instant QuoteChalco 6061-T6 Flanges & Connection Forgings

For high-pressure fluid systems in aerospace, shipbuilding and chemical plants, connection parts must combine leak-free sealing with corrosion resistance. Forged in 6061-T6/T651 and finished to ASME/ISO tolerances, Chalco flanges and pipe fittings deliver dependable strength at a fraction of steel weight.

- Pressure rating ≤ 35 MPa • Size ½ – 24 in

- Surface options: rough-turned, CNC-finished, anodized

- NDT per ASTM E1444 / ISO 9712 • 100 % traceability

6061 Aluminum Forged Flange

Closed-die forged • High pressure & corrosion resistance for aerospace hydraulics, petro-chem pipework and offshore platforms.

6061 Aluminum High-Pressure Flange

Designed for nuclear, chemical and cryogenic service • Vacuum-tight machining and 100 % PMI test.

6061 Aluminum Forged Joint

Closed-die forged • High strength & fatigue life for marine risers, oil-line connectors and structural couplings.

6061 Aluminum Forged Elbow

Seamless-forged 45° / 90° • Pressure-tight for subsea umbilicals, hydraulic manifolds and LNG piping.

6061 Aluminum Forged Tee

Closed-die forged • Uniform microstructure • Ideal for oil, gas and industrial pipeline branch connections.

6061 Aluminum Forged Cross

Closed-die forged • High rigidity for compact manifolds in aerospace, chemical and power-plant equipment.

Need seamless connections to match? Explore our Aluminum flange, Forged Tubes & Fittings, Aluminum Elbow, or request a tailored quotation.

Instant QuoteCustom 6061 & 7075 High-Precision Forgings – Aerospace, Defense & Racing

When extreme environments demand lightweight strength, ±0.02 mm tolerances and flawless fatigue life, 6061-T6/T651 precision forgings are the material of record. Using rotary, closed-die and near-net free forging, Chalco supplies mission-critical parts for aircraft structures, armor systems and motorsport suspension.

- Dimensional tolerance ≤ ±0.02 mm • Surface roughness ≤ Ra 1.6 µm

- Ultrasonic 100 % C-scan • NADCAP NDT & Heat Treat

- Batch traceability to AMS / ASTM / ISO standards

Weight-optimised ribs, frames & brackets • Rotary-forged and 5-axis pre-machined for quick assembly.

Rotary & free-forged armor panels, vehicle swing arms and turret rings • Impact- and corrosion-resistant.

Racing Suspension & Brake Forgings

Near-net arms, hubs & calipers — heat-treated grain flow for ultra-strong, podium-level reliability.

Require even tighter tolerances or special alloys? Email Chalco for a bespoke engineering solution within 24 hours.

Instant Quote6061 Aluminum Forging Capabilities – Open-Die, Closed-Die, Precision & Ring Rolling

From 5-ton open-die blocks to 10 m ring-rolled yaw bearings, Chalco's AS9100 shop delivers pore-free 6061-T6/T651 forgings with NADCAP heat treatment and full NDT.

- Max weight 5 t • Max ring Ø 10 m • Tolerance ±0.02 mm

- 5-100 MN hydraulic presses • CNC ring-rollers • Robotic handling

- Certs: AS9100D | ISO 9001 | NADCAP NDT & Heat Treat

Open-Die Forging

5 t blocks, bars & tubes with continuous grain flow; water-quench + CNC pre-machining cut lead-time 30 %.

Closed-Die Forging

1 000–4 000 t presses form net-shape flanges & gears; isothermal dies deliver fine, equiaxed microstructure.

Precision Forging

±0.02 mm near-net parts for aerospace & racing; 5-axis flash removal + CMM 100 % dimensional report.

Ring Rolling & Radial Forging

Seamless rings Ø ≤ 10 m, wall ≤ 350 mm; CNC load control boosts grain uniformity 25 %.

Request a process audit or sample coupon—email Chalco for a 24 h response.

Instant Quote

6061 Aluminum Forging Processing – Heat Treat, CNC & Finishing

From furnace to final surface, Chalco handles every 6061 forging step in-house—ensuring strength, accuracy and corrosion protection in a single supply chain.

- Heat Treatment T6/T651 (UTS ≈ 310 MPa) | T4 (best ductility) | T42 | T62 – all run in NADCAP furnaces with water-quench & ageing control.

- CNC Machining 5-axis ±0.02 mm on complex aerostructures; turning, milling, drilling & tapping keep shafts, flanges and plates assembly-ready.

- Surface Finishing Hard-anodizing for marine & aerospace, powder coat / e-coat for transport parts, plus polishing or grinding for decorative faces.

- Assembly & Welding TIG/MIG high-strength joints, riveting and sub-assembly modules—ship ready-to-install 6061 flanges, tubes and frames.

Need a custom spec? Email Chalco for a 24 h process proposal.

Instant Quote

6061 Aluminum Forging – Key Application Areas

Aerospace 6061 Forged Components

Lightweight, fatigue-resistant 6061 forgings boost airframe efficiency and safety. Click to explore more aerospace forging products.

Fuselage frames & stiffeners – weight ↓15 % vs steel, same load rating.

Satellite brackets – survive −180 °C ↔ +150 °C thermal cycling.

Landing-gear lugs – fatigue life ↑20 % after T6/T651.

Contact us now

Automotive & Rail — 6061 Forgings for Lightweight Chassis

High-strength 6061 forgings cut mass and extend range for EVs and trains. Click to find more auto forging products.

EV chassis beams – rigidity ↑25 %, mass ↓30 %.

Crash-box bumpers – absorb 32 kJ in NCAP tests.

Battery brackets – spark-free, corrosion-proof housings.

Contact us now

Marine-Grade 6061 Forgings for Hulls & Platforms

Seawater-resistant 6061 forgings deliver lighter, longer-lasting vessels.

Hull frames – pitting rate <0.1 mm/yr in ASTM G44.

Ring-rolled platform supports – Ø ≤ 10 m, weld-free.

Gangway brackets – weight cut 35 % vs cast steel.

Contact us now

New-Energy Systems — 6061 Forged Hubs & Battery Housings

6061 forgings strengthen wind, solar and battery systems for long-term reliability.

Wind-turbine hubs – seamless rings Ø ≤ 10 m.

PV tracker brackets – anodized 25 µm for 25-year life.

Battery housings – conductivity 167 W/m·K for rapid cooling.

Contact us now

Architectural 6061 Forged Frames & Bridge Gussets

Durable, aesthetic 6061 forgings lighten and future-proof buildings and bridges.

Curtain-wall frames – fire rating A2, anodized finish.

Bridge gussets – weight ↓40 %, corrosion life 50 yrs.

Decorative profiles – scratch-resistant, easy CNC.

Contact us now

Aluminum Forging Alloy Comparison – 6061 vs 7075 vs 6082 vs 7050

Not sure which alloy fits your project? The table below highlights the key differences in strength, density and weldability.

| Property | 6061-T6 | 7075-T6 | 6082-T6 | 7050-T7451 |

| Ultimate Tensile Strength (MPa) | ≈ 310 | ≈ 560 | ≈ 340 | ≈ 510 |

| Yield Strength (MPa) | ≈ 275 | ≈ 500 | ≈ 310 | ≈ 455 |

| Density (g/cm³) | 2.70 | 2.81 | 2.71 | 2.83 |

| Weldability | Excellent | Poor | Good | Fair |

| Corrosion Resistance | Good | Fair | Good | Fair |

| Typical Applications | General structures, flanges | High-strength aircraft parts | Bridges, cranes | Wing skins, bulkheads |

How to choose? If ultra-high strength outweighs weldability, consider 7075 forged parts or 7050 forgings. For balanced strength, corrosion resistance and easy welding, 6061 remains the most versatile choice. Still unsure? Email us for a tailored alloy recommendation in 24 hours.

Instant QuoteFAQ — 6061 Aluminum Forgings

Q1. What is your typical lead time for 6061 forgings?

Prototype orders ship in 7 – 10 days. Production batches leave in 3 – 4 weeks once your PO and drawings are approved.

Q2. What is the minimum order quantity (MOQ)?

One piece for prototypes; 3 t for regular production runs.

Q3. Which heat-treat tempers can you supply?

T4, T42, T6, T651 and T62. All cycles are run in NADCAP-approved furnaces with water quench and controlled ageing.

Q4. Which certificates can you provide?

AS9100D, ISO 9001, EN 10204-3.1, full chemical & mechanical test reports and ultrasonic inspection to ASTM B594.

Q5. What payment terms do you accept?

T/T, irrevocable L/C and PayPal for sample or small orders.

Q6. What should I look for when choosing a 6061 forging supplier?

- Full-process capability — die, open-die and ring-rolling under one roof.

- Press fleet 5 – 100 MN — blocks ≤ 5 t, rings ≤ Ø 10 m, ±0.02 mm precision.

- Aerospace-grade quality — AS9100D, NADCAP NDT & Heat Treat, ASTM/AMS compliance.

- Proven industry record — long-term supply to aviation, rail, new-energy and defense OEMs.

- Global logistics — 24 h quote, 3 – 4 week lead time, door-to-door delivery worldwide.

Chalco meets all of these criteria, making us a reliable partner for high-performance 6061 forgings.

Q7. Is 6061 aluminum forged or cast?

6061 can be supplied in cast, extruded or forged form. Forged 6061-T6 delivers ~20 % higher fatigue life and a pore-free grain flow compared with castings or extrusions.

Need a fast quote?

Send part shape, dimensions, quantity and (if available) a PDF/DWG drawing to us and receive pricing in 24 hours.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote