What is aluminum coil?

Aluminum coil refers to a rolled aluminum product formed by continuous rolling of aluminum sheet or strip and then wound into a coil shape using a rewinding machine. It can be made from pure aluminum or aluminum alloys, and is valued for its lightweight, excellent ductility, corrosion resistance, and thermal/electrical conductivity.

Instant QuoteAluminum coils are typically produced in two main forms: hot-rolled coils, which are suitable for deep drawing and thermal forming, and cold-rolled coils, which offer higher dimensional precision and a smoother surface finish, ideal for surface treatments like painting or anodizing.

Chalco can supply aluminum coils in a wide range of sizes, including standard widths such as 1000mm, 1220mm, 1520mm, and Ultra-wide Aluminum Sheet Coil up to 2650mm max. With our advanced production technology, including a 4+1 continuous rolling mill for rough and finish rolling, as well as innovative cross-rolling technology, we are able to meet diverse thickness and dimensional requirements.

Instant QuoteAluminum coil product introduction

Thickness range: thin aluminum coil (0.2–1.0mm), medium-thick aluminum coil (1.0–3.0mm), thick aluminum coil (3.0–6.0mm), extra-thick coil available upon request

Width range: narrow aluminum coil (20–600mm), regular aluminum coil (600–1600mm), extra-wide aluminum coil (1600–2650mm)

Alloy series: 1050 | 1060 | 1100 | 2024 | 3003 | 3105 | 5005 | 5052 | 5754 | 5083 | 6061 | 6063 | 8011

Types: embossed aluminum coil, color-coated aluminum coil, mirror aluminum coil, film-coated aluminum coil, anodized aluminum coil, stucco embossed coil

Applications: aluminum coil for building curtain walls, roofing systems, aluminum composite panels, cladding, automotive heat shields, insulation panels, ducting, packaging, and HVAC systems

Surface treatment: mill finish, anodized, color coating (PVDF, PE), mirror finish, embossed, film-coated, anti-fingerprint coating

Temper: O,H111 H12, H14, H16, H18, H24, H32

Specifications: ASTM B209, ASTM B928, EN 485, EN 573, EN 13523, GB/T 3880, GB/T 3198, JIS H4000, ISO 6361, ISO 7599

Certifications: ISO 9001:2015, ISO 14001, RoHS, REACH, DNV, SGS, BV, ABS, CCS

Chalco aluminum coil stock

- All stock items are available for retail; once the order is confirmed, customs clearance and shipping take about one week.

- As the original manufacturer with large-scale one-stop production, the quality of aluminum coil matches market standards and costs 10% less.

- A trusted brand that undergoes rigorous quality checks, ensuring no concerns about product quality.

| Product | Thickness | Width x Length |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 14" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 14" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 14" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 14" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 14" x 50' |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 16" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 16" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 16" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 16" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 16" x 50' |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 18" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 18" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 18" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 18" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 18" x 50' |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 20" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 20" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 20" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 20" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 20" x 50' |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 24" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 24" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 24" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 24" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 24" x 50' |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 36" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 36" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 36" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 36" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 36" x 50' |

| 0.19" (t) aluminum coil/trim coil | 0.19" | 48" x 50' |

| 0.24" (t) aluminum coil/trim coil | 0.24" | 48" x 50' |

| 0.27" (t) aluminum coil/trim coil | 0.27" | 48" x 50' |

| 0.32" (t) aluminum coil/trim coil | 0.32" | 48" x 50' |

| 0.4" (t) aluminum coil/trim coil | 0.4" | 48" x 50' |

What alloy series of aluminum coil can Chalco offer?

1000 Series

Alloy: 1050 1060 1070 1100

Size: Thickness 0.2–6.0mm, width ≤ 2650mm, tolerance up to ±0.02mm

Temper: O, H12, H14, H16, H18

Contact us now

1000 series aluminum coil refers to aluminum products with a purity of 99.0% or higher, typically including alloys like 1050, 1060, 1070, 1100. These are known as commercial pure aluminum coils and are widely used due to their excellent corrosion resistance, high electrical and thermal conductivity, and good workability.

- 1050 aluminum coil

Purity: ≥99.5%

Common Temper:O, H14, H24

Typical Use: Lighting, conductors, chemical equipment

- 1060 aluminum coil

Purity: ≥99.6%

Common Temper:O, H18, H24

Typical Use: Bus bars, transformer windings, signboards

- 1070 aluminum coil

Purity: ≥99.7%

Common Temper:O, H14

Typical Use: Cable sheathing, radiator fins, food packaging

- 1100 aluminum coil

Purity: ≥99.0%

Common Temper:O, H12, H14

Typical Use:Roofing, curtain walls, cookware, nameplates

2000 series aluminum coil

Alloy: 2024 2014 2011 2017 2219 2618

Size: Thickness 0.2–6.0mm, width ≤ 2650mm, tolerance up to ±0.02mm

Temper: T3,T4,T6,T651

Contact us now

2000 series aluminum coil is an aluminum-copper alloy series, typically containing 2% to 6% copper, with excellent strength, hardness, and machinability. Common grades include 2024, 2A12, 2011, 2014, and 2017. These coils are primarily used in aerospace, automotive, military, and machinery manufacturing where high structural performance is required.

- 2024 aluminum coil

Features:High strength, fatigue resistant

Typical Use: Aircraft skins, structural panels, truck chassis

- 2014 aluminum coil

Features:Strong, wear resistant

Typical Use: Aerospace frames, heavy-duty auto parts

- 2011 aluminum coil

Features: Excellent machinability

Typical Use:Precision parts, connectors, electronics

- 2017 aluminum coil

Features: Tough, good formability

Typical Use: Rivets, fittings, industrial fasteners

- 2219 aluminum coil

Features:High-temp strength, weldable

Typical Use: Rocket tanks, engine cladding, aerospace coil

- 2618 aluminum coil

Features:Thermal stability, fatigue resistant

Typical Use: Engine parts, turbo heat shields, aerospace plates

3000 series aluminum coil

Alloy: 3003 3004 3005 3105 2A21

Temper: O, H14, H16, H24, H26, H32

Features: good corrosion resistance and excellent formability

Contact us now

3000 series aluminum coil is an aluminum-manganese alloy series, primarily including 3003, 3004, 3105, and 3A21. It offers excellent corrosion resistance, good formability, and moderate strength, making it ideal for applications where both durability and workability are important.Its strength is higher than that of the 1000 series, making it commonly used in areas such as architectural decoration, roofing materials, exterior wall panels, shutters, kitchenware, and insulation covering materials. It is suitable for applications that require certain strength along with good processability.

- 3003 aluminum coil

Features: Good corrosion resistance, easy to form

Typical Use: Roofing coil, curtain wall panels, insulation cladding, kitchen equipment

- 3004 aluminum coil

Features: Higher strength than 3003

Typical Use: Beverage can bodies, roofing sheets, siding

- 3005 aluminum coil

Features:Better corrosion resistance, moderate strength

Typical Use:Building exterior panels, rainwater systems, appliance casings

- 3105 aluminum coil

Features: Good corrosion resistance, paintable

Typical Use: Color-coated aluminum coil for gutters, downspouts, signboards

- 3A21 aluminum coil

Features: Excellent anti-rust, high plasticity

Typical Use: Ship paneling, vehicle body, storage tanks

4000 series aluminum coil

Alloy: 4032 4045 4343 4047

Temper: O, H14, H24, T6,

Features: Good machinability,Excellent thermal conductivity

Contact us now

4000 series aluminum coil is mainly an aluminum-silicon (Al-Si) alloy, with silicon content typically ranging from 4.5% to 13%. Common grades include 4032, 4045, and 4343. This series offers excellent wear resistance, high heat resistance, and good thermal conductivity, making it ideal for automotive engine parts, heat exchangers, and brazing applications.

- 4032 aluminum coil

Features: High strength, heat resistant, wear resistant

Typical Use: Engine components, pistons, high-performance automotive parts

- 4045 aluminum coil

Features: Brazing-grade aluminum, good formability

Typical Use: Cladding layer for heat exchanger coils, radiator fins

- 4343 aluminum coil

Features:Excellent brazability, oxidation resistance

Typical Use: Automotive condenser coils, evaporators, air conditioning systems

5000 series aluminum coil

Alloy: 5005 5052 5056 5083 5086 5182 5454 5656 5754

Size: Thickness 0.2–6.0mm, width ≤ 2650mm, tolerance up to ±0.02mm

Temper: O, H14, H24, H32, H34, H38

Contact us now

5000 series aluminum coil is an aluminum-magnesium (Al-Mg) alloy, known for its excellent corrosion resistance, medium to high strength, and good weldability. Typical alloys include 5052, 5005, 5754, 5083, and 5182. It is widely used in marine environments, automotive parts, building materials, and pressure vessels.

- 5005 aluminum coil

Features: Moderate strength, good anodizing quality

Typical Use: Interior/exterior decoration, signage, curtain wall panels

- 5052 aluminum coil

Features:High strength, excellent corrosion resistance

Typical Use: Marine parts, automotive panels, fuel tanks, truck bodies

- 5056 aluminum coil

Features: High tensile strength, good corrosion resistance

Typical Use: marine hardware, fishing boats

- 5083 aluminum coil

Features: Superior corrosion resistance, especially in seawater

Typical Use: Shipbuilding, LNG tankers, offshore structures

- 5086 aluminum coil

Features: High corrosion resistance, weldable, marine grade

Typical Use: marine gradeBoat hulls, coastal structures, vehicle armor panels

- 5182 aluminum coil

Features: Good formability and strength

Typical Use: Beverage can ends, car doors, structural parts

- 5454 aluminum coil

Features: Good corrosion resistance, suitable for elevated temperature

Typical Use: Tankers, chemical storage tanks, pressure vessels

- 5656 aluminum coil

Features: High strength and toughness, corrosion resistant

Typical Use: Structural welding parts, ship decks, aerospace auxiliary parts

- 5754 aluminum coil

Features: High corrosion resistance, excellent paint adhesion

Typical Use:Car body panels, tankers, trailers, architectural cladding

6000 series aluminum coil

Alloy: 6005 6061 6063 6082 6101 6110 6060 6182 6951

Size: Thickness 0.2–6.0mm, width ≤ 2650mm, tolerance up to ±0.02mm

Temper: O, T4, T5, T6, T651

Contact us now

6000 series aluminum coil is an aluminum-magnesium-silicon (Al-Mg-Si) alloy system that combines moderate to high strength, excellent corrosion resistance, and good weldability. It is widely used in structural applications, automotive manufacturing, electrical busbars, and building decoration.

- 6061 aluminum coil

Features: Moderate strength, good formability

Typical Use: Railway profiles, bridges, ladders, lighting supports

- 6062 aluminum coil

Features:Moderate strength, good corrosion resistance

Typical Use: Structural parts, automotive frames, trailers, marine panels

- 6063 aluminum coil

Features: Good extrusion and surface quality

Typical Use: Window frames, curtain walls, tubing, decorative panels

- 6082 aluminum coil

Features: High strength, weldable, corrosion resistant

Typical Use: Truck bodies, trusses, marine structures, rail vehicles

- 6101 aluminum coil

Features: Excellent electrical conductivity

Typical Use: Electrical busbars, power distribution systems

- 6110 aluminum coil

Features: Improved machinability and strength

Typical Use: Precision machined parts, welded profiles

- 6060 aluminum coil

Features: Good corrosion resistance, smooth surface

Typical Use: Architectural trim, furniture profiles, light-duty structures

- 6182 aluminum coil

Features: High crash resistance, automotive grade

Typical Use: Vehicle impact components, bumpers, body structures

- 6951 aluminum coil

Features: High strength, brazing performance

Typical Use:Heat exchangers, condenser fins, automotive HVAC coils

8000 series aluminum coil

Alloy: 8011 8021 8079

Temper: O, H14, H18, H22, H24

Features: good formability, high barrier properties

Contact us now

8000 series aluminum coil is primarily designed for packaging, household foil, and electrical applications. It features good formability, high barrier properties, and excellent corrosion resistance.

- 8011 aluminum coil

Features: Moderate strength, formability, barrier performance

Typical Use: Household foil, food packaging, heat-seal lids, bottle caps

- 8021 aluminum coil

Features: High elongation, deep drawing performance

Typical Use: Pharmaceutical blister foil, cold-formed foil, battery soft pack

- 8079 aluminum coil

Features:Excellent softness, good processing performance,

Typical Use: Flexible packaging foil, lamination base foil, cosmetic pouches

Chalco's popular aluminum coil Types

Aluminum trim coil

Aluminum:3105, 3003, 5052

Width:12", 14", 24", 36", custom available

Thickness:12", 14", 24", 36"

Contact us nowAluminum trim coil is a pre-finished, roll-formed aluminum product used for wrapping exterior architectural elements, such as window and door frames, fascia boards, soffits, and roof edges. It is widely used in construction and remodeling due to its durability, weather resistance, and easy workability.

Popular color

white aluminum trim coil

black aluminum trim coil

wood grain aluminum trim coil

sandstone aluminum trim coil

green aluminum trim coil

gray aluminum trim coil

Popular Coating

pvc aluminum trim coil

poly aluminum trim coil

vinyl aluminum trim coil

Color coated aluminum coil

Color coated aluminum coil refers to an aluminum coil that has been coated with one or more layers of organic paint (such as PE, PVDF, or FEVE) through a roll coating process and then cured to form a decorative colored surface. It features an attractive appearance, excellent weather resistance, and strong corrosion resistance, making it widely used in construction, decoration, home appliances, and transportation industries.

Instant QuoteThe following are common coatings

pe coated aluminum coil

pvdf coated aluminum coil

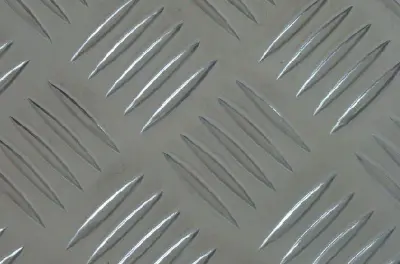

Embossed aluminum coil

Embossed aluminum coil refers to an aluminum coil that has been processed with a textured or patterned surface using an embossing roller. Common patterns include orange peel, diamond, stucco, hammer, and leaf. This textured surface not only enhances the decorative effect but also improves anti-slip performance, durability, and surface rigidity.

Embossed aluminum coils usually have the following embossing types:

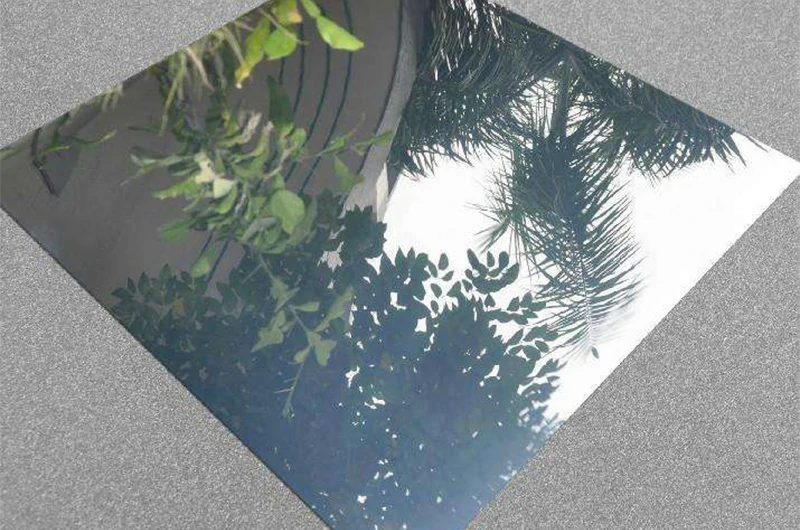

Mirror Finish Aluminum Coil

Aluminum:1050, 1060, 1070, 1100, 3003,5052,5005

Reflectivity:85%,90%,95%

Surface type:Normal mirror, high gloss mirror, colored mirror

Contact us nowMirror aluminum sheet coil refers to aluminum products with high reflectivity and mirror-like finish formed on the surface of aluminum coil through mechanical polishing, rolling polishing or chemical polishing. It has a flat surface, high brightness and strong texture, and is widely used in decoration, lamps, electronic housings, solar reflectors and other fields.

Chalco can provide you with the following mirror aluminum products:

Anodized aluminum coil

Anodized aluminum coil is produced by applying an electrochemical anodizing process to the aluminum surface, creating a dense, uniform, and firmly bonded oxide layer. This layer enhances corrosion resistance, surface hardness, and decorative appeal. It can be left in its natural silver color or dyed into various shades, making it ideal for applications in architecture, electronics, appliances, signage, and interior decoration.

Application: it is suitable for metal aluminum ceiling, curtain wall aluminum plate, aluminum plastic panel, fireproof board, honeycomb aluminum coil, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc.

To better understand how anodizing works and what makes it so effective for aluminum surface treatment, learn more about anodizing aluminum here.

Aluminum insulation coil

Aluminum insulation coil is also called pipe cladding aluminum coil, which is usually used to protect pipes and equipment from damage.

Common aluminum insulation coil alloy: 1060, 1100, 1200, 3003, 3004, 3105, 5052, 8011.

Common types of aluminum insulation coils coils:

Polysurlyn moisture retarder aluminum coil jacketing in Chalco Aluminum has three films: 1 mil high-density polyethylene, 1 mil surlyn and 1 mil low-density polyethylene. It has the advantages of low cost, effective protection of pipeline corrosion, etc. Suitable for pipeline applications exposed to water for a long time.

Color coated aluminum insulation coil is in accordance with ASTM B209 and ASTM C-1729 specifications. Colors can be provided as required.

Embossed aluminum insulation coil, generally, it is the classic orange peel embossed aluminum insulation coil. It can also be customized according to customer needs.

In addition to the above products, Chalco Aluminum also provides kraft paper coated aluminum coil jacketing, corrugated aluminum coil jacketing, and mill finish aluminum coil. All the products conform to the ASTM B209 and ASTM C-1729 standard.

Common specifications:

| Alloy | 1100,1050,1060,3003,3105,5005,5052 |

| Temper | H14 H16 H24 H26 |

| Thickness | 0.40mm-1.5mm |

| Standard width | 914mm 1000mm 1200mm 1219mm |

| Inner diameter | 305mm 405mm 505mm with or without paper core |

| Outer diameter | according to the coil weight and surface treatment, the most common coil length is 125m 150m 250m 300m 500m 1000m 2540m. |

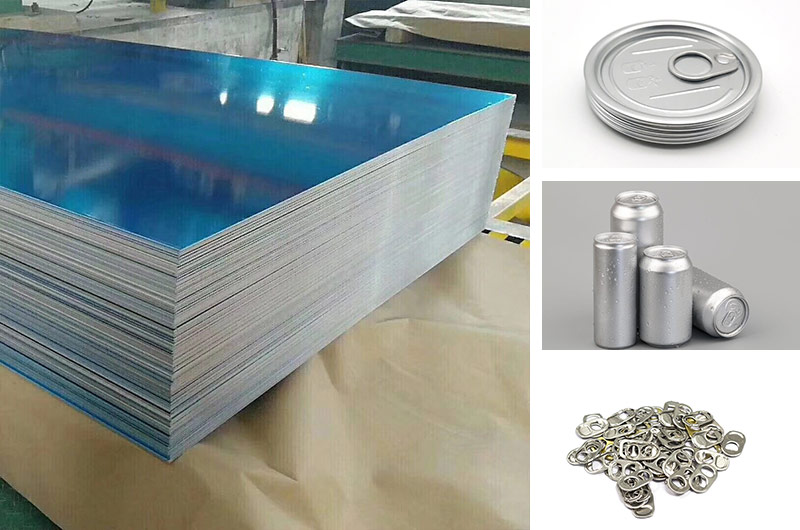

Aluminum coil for cans

Aluminum:3004, 3104, 5052, 5182, and 8011

Width: 800mm – 1600mm, custom available

Thickness:0.20mm – 0.40mm (body), 0.25mm – 0.45mm (end)

Contact us nowAluminum coil for cans refers to specially processed aluminum coils used in the manufacture of beverage cans, food cans, cosmetic containers, and industrial aerosol cans. These materials are engineered to meet strict requirements for formability, surface quality, corrosion resistance, and mechanical strength.

Aluminum gutter coil

Aluminum alloy gutters and aluminum alloy downspouts use the 3105 and 3025 aluminum alloy coil and strip. Both sides are roller coated with polyester (PET) paint. The thickness of front facial film 25-28 um, and the thickness of back facial film is 15-18 um. The color is durable.

Alloy: 3105, 3025

Temper: H24, H44

Surface treatment: PET coating, PE coating, PVDF coating.

Typical thickness: 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, etc.

Typical width: 266mm, 285mm, 300mm, 405mm, 448mm, etc. It can be sliced according to customer requirements.

Color: the common color is white. There are nearly 1000 colors available for customers to choose.

Aluminum roofing coil

Aluminum roofing coil has many advantages, such as durable, corrosion resistance, light weight, high strength, good plasticity, easy installation, etc. It is widely used in the field of civil construction field, such as the roofs of aircraft terminals, railway stations, exhibition halls, and it is also been used more and more in ordinary families.

Instant Quote

Common aluminum alloy for Aluminum roofing coil

| Alloy | Temper | Specifications | coating | Surface treatment | |

| Thickness | Width | ||||

| 3003 | h24 | 0.5mm/ 0.8mm/ 1.0mm | 1000mm/ 600mm/ 575mm | PVDF FEVE PE | Grey/Silver Grey/Flash Silver; The back coating is generally white |

| 3004 | h24, h26 | ||||

| 3105 | H44 | ||||

| The product can be coated on both sides | |||||

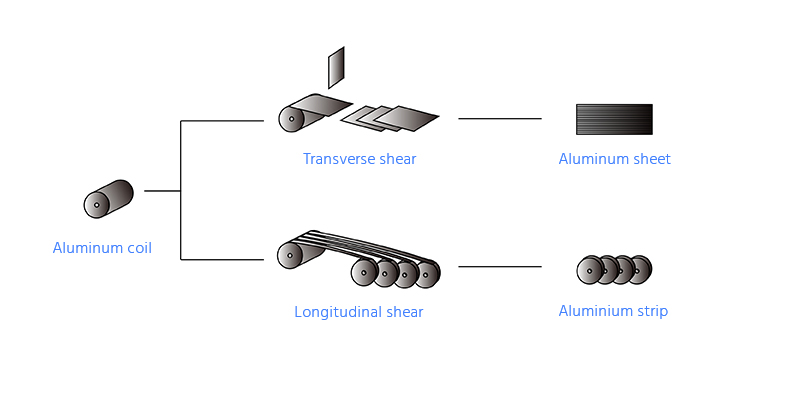

what is aluminum strip?

Aluminum strip is a narrow, flat-rolled aluminum product that is slit from aluminum coil. It typically features precise width tolerances, consistent thickness, and good surface finish, and is used in a wide range of industrial, electrical, and architectural applications.

common types of aluminum strip

Brazing aluminum strip

Fins for heat exchangers are mostly made of aluminum or copper strips. Compared with copper strip, aluminum strip is more and more used in heat exchanger fins because of its cost advantages. Heat exchanger fins are mostly made of 4-series alloy aluminum strips. In addition, multi-layer composite brazing coils are also often used to make fins.

Common aluminum strips for radiator fins

4004 aluminum alloy: 4004 brazing material contains magnesium, which is suitable for vacuum brazing. It has the characteristics of small density, low coefficient of thermal expansion, good volume stability, low melting point, good wear resistance and high temperature performance.

Common brazing aluminum coils and strip

4004/4104 aluminum coil and strip: it is a necessary raw material often used in the production of aluminum heat exchanger with vacuum brazing process.

4043 aluminum strip: 4043 aluminum strip has the advantage of low melting point, good fluidity and corrosion resistance. It is very beneficial to avoid welding cracks. The silicon content of 4343 aluminum alloy is higher than that of 4043 aluminum alloy. 4343 aluminum alloy has the characteristics of low melting point, narrow solidification range and good fluidity.

4047 aluminum strip: 4047 is an Al Mg Si alloy with high plasticity. It has the advantages of superior processing performance, excellent weldability, extrudability and electroplating, good corrosion resistance, toughness, easy polishing and other advantages. 4047 aluminum is a unique alloy, which can be used as cladding alloy or filler material in aerospace and automotive applications.

Cladding brazing coil and strip

There are two types of cladding layer:

Common brazing layer material: Al Si (4000)

Common sacrificial anode materials (anticorrosive coating): AL Zn Cr (7072), etc.

Common core materials: Al-Mn(3000),Al-Si-Mg(6000)

According to customer requirements, the cladding layer of composite brazing coil and strip can be multi-layer. Chalco can make up to 7 layers of composite brazing aluminum coil and strip.

Common composite brazing coil and strip

| Alloy | Thickness(mm) | Tolerance(mm) | Clad Ratio(%) | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) Min | Application |

| 4343/3003 | 1.2~3.0 | ±0.03 | 5~10 | 100~150 | ≥45 | 25 | Engine radiator |

| 4343/3003/7072 | 1.2~3.0 | ±0.03 | 5~10 | 100~150 | ≥45 | 25 | |

| 4343/3003/4343 | 0.1~0.12 | ±0.005 | 8~12 | 150~120 | ≥120 | 1 | Air conditioner condenser, intercooler |

| 4045/3003/4045 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | intercooler |

| 4104/3003/4104 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | Battery cooler |

| 4104/6063/4104 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 |

Aluminum strip for transformer

The transformer aluminum strip adopts the production process of casting and rolling, cold rolling, shearing and annealing. Compared with ordinary aluminum strip, its production feature is high precision. For example, it has high requirements on the surface quality, burr curling, conductivity and other technical indicators of aluminum strip.

Instant Quote

Common transformer aluminum strip alloy:

| Alloy | Temper | Transformer strip specification (mm) | ||||

| Thickness (mm) | Width (mm) | Aluminum content (%) | Conductivity (%) | characteristic | ||

| 1050 | O | 0.2--3.0 | 20-1650 | 99.5 | 60 | Dry type transformer, large transformer, solar energy, power industry, etc.No burr at the edge |

| 1060 | O | 2.0~8 | 99.6 | 61 | ||

| 1070 | O | 2.2~8 | 99.7 | 62.5 | ||

| 1350 | O | 2.5~8 | 99.35 | 60 | ||

characteristic:

- High conductivity

- The edges are smooth without burrs

- High aluminum purity

- Good surface processing, uniform texture, clean without defects

- It has high tensile strength and elongation.

- It is light and cheap compared with copper strip.

Professional suppliers and manufacturers of aluminum coils

Chalco Aluminum is a large-scale modern aluminum processing enterprise integrating scientific research, processing and manufacturing. The company can produce 1-8 series aluminum coil and strip products with complete specifications, huge capacity and good prices which can meet all your personalized processing requirements.

The product passed CE ISO9001 certification. It can be customized according to customer needs and meet the requirements of different standards, such as Japanese standards, European standards, American standards, etc.