Flux core aluminum brazing rods are low-temperature aluminum brazing consumables used for stable aluminum joining in industrial production and repair applications. Designed as aluminum brazing rods with built-in flux, they support aluminum-to-aluminum and aluminum-to-copper brazing without the need for external flux, making them suitable for controlled brazing processes in engineering environments.

Chalco offers flux core aluminum brazing rods manufactured with an aluminum alloy sheath and a controlled internal flux core. During heating, the flux activates to remove oxide films and improve wetting behavior, helping achieve clean, consistent joints while reducing the risk of base-metal overheating or distortion in batch and project-based applications.

- Built-in flux design: No external flux required, simplifying brazing operations and improving process consistency.

- Low-temperature brazing capability: Supports aluminum joining at reduced temperatures to limit thermal stress and distortion.

- Reliable joint quality: Produces clean, strong seams with smooth appearance and minimal residue.

- Production & maintenance friendly: Suitable for both industrial manufacturing and on-site repair applications.

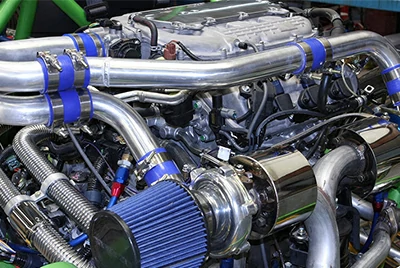

- Typical application fields: HVAC refrigeration systems, automotive radiators, aluminum tubing, and aluminum component repair.

Chalco Flux Core Aluminum Brazing Rods — Types, Forms & Selection Overview

Chalco provides a complete range of flux core aluminum brazing rods, including high-cesium, medium-cesium, low-cesium, and cesium-free variants, to match different aluminum alloys, joint conditions, and brazing processes. These aluminum brazing rods with built-in flux share a common aluminum-alloy sheath + flux core structure, eliminating the need for separate flux application in both production and maintenance environments.

Depending on the flux formulation and application requirements, Chalco flux cored aluminum rods are suitable for torch brazing, furnace brazing, and high-frequency brazing, supporting stable aluminum-to-aluminum and aluminum-to-copper joints in HVAC, refrigeration, and automotive applications.

Available specifications and supply forms:

Diameter: 1.6 mm / 2.0 mm / 2.4 mm (other sizes available on request)

Length: 330 mm / 500 mm

Packing: 5 pcs / 10 pcs small packs; 0.5 kg / 1 kg industrial packs; customized packaging supported

Form: rods / coils / wire / rings, suitable for manual and automated brazing operations

Typical flux core aluminum brazing rod types and their application-oriented characteristics are summarized below to assist material selection:

| Type | Melting Range (℃) | Brazing Temp (℃) | Flux Type | Typical Applications |

| High-Cs | 577–582 | 595–625 | Cs-AlF | Al–Al tubing, A/C heat exchangers & condensers; ideal for automated brazing |

| Medium-Cs | 570–585 | 600–630 | Cs-AlF | High-Mg aluminum tubing, refrigeration systems; enhanced corrosion resistance |

| Low-Cs | 570–585 | 595–625 | Cs-AlF | Al–Al, Al–Cu, Al–SS; HVAC and automotive parts |

| Cesium-Free | 577–595 | 600–640 | K-AlF | Eco-friendly, cost-effective for mass-produced heat exchangers and low-Mg Al alloys |

High-Cs Flux Core Aluminum Brazing Rods

The High-Cs formulation uses an Al–Si filler matrix with a high-ratio cesium-salt flux core, providing a low melting point and excellent fluidity. Upon heating, the flux rapidly removes the dense oxide film on aluminum and significantly improves wettability, allowing the molten filler to spread uniformly and fully fill the joint gap.

With its low-temperature operation, it helps avoid base-metal overheating or grain coarsening—ideal for automated mass brazing of Al–Al fittings and heat exchangers. Widely used in automotive condensers, evaporators, and HVAC systems requiring high throughput and reliability, often alongside brazing ring preforms in automated production lines.

| Item | Parameter |

| Chemical Composition | Al–Si filler (equivalent to 4047 series) |

| Flux Type | Cs-AlF |

| Melting Point (℃) | 577–582 |

| Flux Melting Point (℃) | 410–460 |

| Brazing Temperature (℃) | 595–625 |

| Flux Content (%) | 20–36 |

Medium-Cs Flux Core Aluminum Brazing Rods

The Medium-Cs variant uses an optimized mix of cesium and fluoride salts to balance lower melting with improved corrosion resistance. Compared with High-Cs, it delivers better corrosion performance—especially suitable for brazing high-Mg aluminum tubing—while helping reduce the risk of grain coarsening or corrosion issues in the heat-affected zone. It wets well and fills larger gaps reliably, offering strong process adaptability.

Commonly used in refrigeration systems, heat exchangers, and high-Mg aluminum components, it is a key choice for the HVAC industry.

| Item | Parameter |

| Chemical Composition | BAlSi (4045/4343 series) |

| Flux Type | Cs-AlF |

| Melting Point (℃) | 570–585 |

| Flux Melting Point (℃) | 420–460 |

| Brazing Temperature (℃) | 600–630 |

| Flux Content (%) | 18–30 |

Low-Cs Flux Core Aluminum Brazing Rods

The Low-Cs variant uses a lower cesium-flux ratio for cost efficiency and broad versatility. It provides good wetting and flow in most aluminum brazing tasks and supports dissimilar joints such as Al–Al and Al–Cu, with broader adaptability for mixed-metal applications.

Typical applications include HVAC systems, automotive radiators, and aluminum structural repair—balancing performance and economy.

| Item | Parameter |

| Chemical Composition | 4045 / 4047 |

| Flux Type | Cs-AlF |

| Melting Point (℃) | 570–585 |

| Flux Melting Point (℃) | 420–460 |

| Brazing Temperature (℃) | 595–625 |

| Flux Content (%) | 20–28 |

Cesium-Free Flux Core Aluminum Brazing Rods

The Cesium-Free product uses eco-friendly K-AlF composite flux with no cesium, offering low cost, environmental compatibility, and stable supply. Although wettability is slightly lower than Cs-containing formulas, it still meets most joining needs for low-Mg aluminum alloys. It is particularly suitable for mass-production of heat exchangers, reducing manufacturing cost and complying with environmental regulations.

Widely used for refrigeration equipment, low-Mg Al tubing, and general industrial Al brazing.

| Item | Parameter |

| Chemical Composition | 4045 / 4047 / 4343 |

| Flux Type | K-AlF |

| Melting Point (℃) | 577–595 |

| Flux Melting Point (℃) | 450–520 |

| Brazing Temperature (℃) | 600–640 |

| Flux Content (%) | 16–28 |

Cu–Al Flux-Cored Brazing Rods

Beyond aluminum flux-cored materials, Chalco also supplies flux-cored rods for joining copper to aluminum. These rods are engineered for Cu–Al dissimilar-metal brazing, overcoming poor wettability and unstable joints seen in traditional approaches. They are widely used in HVAC refrigeration, refrigerator tubing, and automotive A/C heat exchangers. By manufacturing process, they include:

- Seamless: Uniform flux filling and stable performance for demanding applications.

- Seamed: Simpler manufacturing and lower cost for large-scale production.

During heating, the outer copper alloy melts as the filler metal while the internal flux removes oxides and improves wetting, enabling reliable copper-to-aluminum joints.

| Item | Range |

| Chemical Composition | Zn–Al based alloys (e.g., Zn–5%Al or Zn–10%Al) |

| Melting Range (℃) | 370–420 (typically applied in non-structural joints) |

| Brazing Temperature (℃) | 450–520 |

| Flux Type | Fluoride/Chloride composite salts (KF / ZnF systems) |

| Flux Melting Point (℃) | 370–420 |

| Flux Content (%) | 10–20% |

Typical Applications of Flux Core Brazing Rods

HVAC & Refrigeration Brazing

Commonly used for brazing A/C evaporators, condensers, Cu–Al transition tubes, and fins to ensure efficient heat transfer and long-term sealing (6951 brazing core aluminum commonly used in heat exchanger assemblies).

Contact us now

Automotive & Transportation Brazing

Manufacture and repair of radiators, oil coolers, A/C lines, and truck/trailer bodies, where aluminum brazing foil and flux-cored rods are commonly used together.

Contact us nowIndustrial & Energy Equipment Welding

Al–Al and Al–Cu tube joints in large heat exchangers and energy machinery; suitable for mass production.

Contact us now

Metal Repair & Maintenance

Build-up of machinable deposits on worn or damaged parts to restore dimensions/surfaces; repair of cracked extrusions or castings.

Contact us nowMolds & Structural Components

Modification/repair of models, molds, and dies; remanufacturing of cast aluminum, sheet, and forged products.

Contact us now

Furniture & Everyday Applications

Joining and repair of aluminum furniture, door/window frames, gutters, siding, and aircraft instruments.

Contact us nowNote: Not recommended for brazing high-strength aluminum alloys such as 2011, 2014, 2017, 2024, and 7075.

How to Use & Safety Guidelines

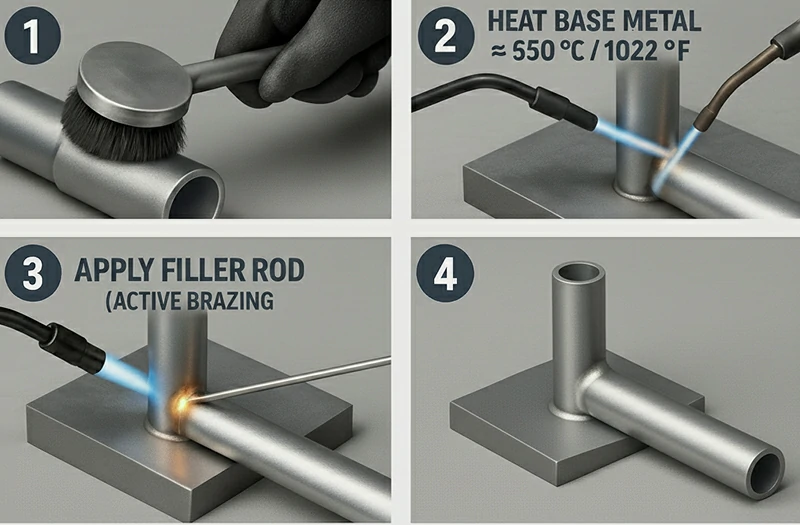

In many maintenance and field applications, flux core aluminum brazing rods are often informally referred to as aluminum welding rods. Technically, these products are designed for brazing rather than fusion welding, as the base metal is not melted during the joining process. This low-temperature brazing mechanism helps preserve base-metal properties while ensuring reliable joints. The integrated flux core replaces the need for external aluminum brazing flux, simplifying operation and reducing residue-related risks.

- Surface preparation: Thoroughly clean and polish the base metal to remove oxide, oil, and contaminants until a bright metal surface is exposed.

- Heat the base metal: Use a torch or heater to evenly heat the workpiece to about 550℃ (1022℉). Rely on base-metal heat to melt the rod—do not directly flame-melt the rod.

- Feed the rod: Once hot enough, the filler flows smoothly and capillary action fills the gap, forming a uniform seam.

- Thin aluminum repair: For thin sections, heat appropriately and gently rub the rod on the surface to melt and fill cracks.

- Cooling: Propane is fine for small parts; larger parts may require industrial gases or induction. Allow slow, natural cooling to avoid cracking.

*Always work in a well-ventilated area to avoid fume inhalation. Wear heat-resistant gloves and eye protection to prevent injury from spatter. Store rods dry to maintain flux activity. Keep the flame even to avoid localized overheating and ensure weld quality and safety.

Comparison With Other Solutions

Choosing the right consumable is critical. In terms of ease of use, weld quality, and breadth of application, flux core aluminum brazing rods outperform traditional options.

Flux Core Aluminum Brazing Rods vs. Traditional Aluminum Brazing Rods

Traditional rods require separate flux application—more steps and possible residue that affects appearance and strength. Flux-cored rods integrate flux internally and release it as they heat, simplifying operation and producing clean, dense seams—improving both efficiency and consistency.

Flux Core Aluminum Brazing Rods vs. Aluminum MIG/TIG Filler Wire

Solid wires require fusion welding at higher temperatures and shielding gas; partial melting of the base metal can cause overheating and degrade properties. Compared with aluminum welding wire, flux-cored rods join at lower temperatures with no shielding gas, protecting base-metal properties and suiting on-site repair while saving energy. This distinction explains why these brazing rods are sometimes grouped with "welding rods" in search terms, despite their different joining mechanisms.

Flux Core Aluminum Brazing Rods vs. Stick Welding Rods

Conventional stick electrodes are mainly for steel, operate at higher temperatures with larger HAZ, and are not suited to aluminum. Flux-cored brazing rods are designed for aluminum and Cu–Al dissimilar joints, operating at lower temperatures with greater flexibility and better fit for these materials.

Choose Chalco Flux Core Brazing Rods

Complete product portfolio: High-Cs, Medium-Cs, Low-Cs, and Cesium-Free aluminum flux-cored rods, plus Cu–Al flux-cored rods for HVAC, automotive, refrigeration, and repair.

Multiple supply forms: rods, coils, wire, and rings for both automated lines and manual work.

International compliance & quality assurance: Meets international standards with rigorous testing for consistent performance.

Customization & service: OEM/ODM supported; alloy, flux ratio, and packaging can be tailored; extensive global delivery experience.

No matter mass production or repair, Chalco delivers reliable brazing solutions.

FAQ

Q: Is Lucas Milhaupt 822 a specific alloy or standard?

A: Lucas Milhaupt 822 is a brand-specific commercial grade commonly used as a reference name for flux core aluminum brazing rods. It is not a standardized alloy or chemical designation. Chalco supplies flux-cored aluminum brazing rods based on material composition and application requirements rather than proprietary brand names.

Q: What's the difference between flux core aluminum brazing rods and traditional aluminum rods?

A: Flux core rods contain internal flux and require no external application, making operation easier and resulting in cleaner seams.

Q: Can they be used to join aluminum and copper?

A: Yes. Low-Cs variants can work for Al–Cu joints, and Cu–Al flux-cored rods are specifically designed for copper-to-aluminum transitions.

Q: What is the recommended working temperature?

A: Generally 550–630℃, depending on the selected type (High-Cs, Medium-Cs, Low-Cs, or Cesium-Free). Exact temperatures depend on alloy and process conditions.

Q: Is extra flux needed during use?

A: No. The flux is already integrated in the core.

Q: Are they suitable for DIY?

A: Yes. They are easy to use. Propane can handle small repairs; larger components may use industrial gases or induction heating.

Ordering & Delivery

Customization: Diameter, length, and form can be tailored to your needs.

Samples: Small-lot sample testing available for process validation.

Lead time: Standard sizes in stock; customized products scheduled quickly.

Global supply: Ocean, air, and express shipping to Europe/North America, Southeast Asia, Japan, Korea, and more.

Chalco flux core aluminum brazing rods provide reliable solutions for HVAC, automotive, refrigeration, and aluminum repair. Contact us now for specifications, quotations, and samples, and experience efficient, consistent brazing.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote