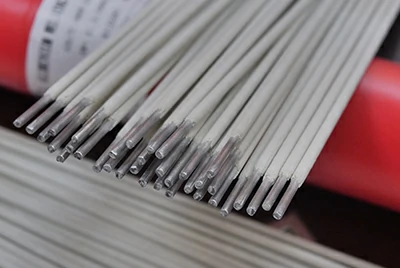

Aluminum stick welding rods are widely used in SMAW (Shielded Metal Arc Welding), a practical welding process commonly applied in structural repair, outdoor construction, and on-site maintenance. These welding rods consist of an aluminum alloy metal component combined with a flux coating. During welding, the aluminum core conducts electrical current and melts to form the weld metal, while the flux generates protective gas and slag at high temperature, creating a stable self-shielded welding environment.

Chalco supplies aluminum stick welding rods in common aluminum welding electrode alloys such as E4043 and E5356, which are widely used for aluminum joining due to their good weldability, arc stability, and corrosion resistance. These welding electrodes are available in standard diameters and lengths, with consistent alloy composition and dimensional accuracy to meet the requirements of industrial and project-based SMAW applications.

Available Specifications for Aluminum Stick Welding Rods

Rod Diameter: Standard sizes include 1/16" (1.6 mm) and 3/32" (2.4 mm); other diameters from 1.2–3.5 mm available upon request

Rod Length: Standard lengths include 300 mm, 350 mm, 400 mm, and 500 mm

Surface Condition: Drawn or bright finish, with surface treatment suitable for consistent welding performance

Dimensional Tolerance: Controlled within ±0.02 mm to ensure stable electrical performance and consistent arc behavior

Available Alloys: E4043, E5356, E5183 aluminum stick welding rod grades

Applicable Standards: AWS A5.10, ISO 18273 (Aluminum Stick Welding Electrodes)

Welding Process: SMAW (Shielded Metal Arc Welding)

Typical Applications: Structural repair, outdoor welding, on-site maintenance, and general aluminum fabrication

Common Aluminum Stick Welding Rod Alloys

Chalco supplies aluminum stick welding rods in several commonly used electrode alloy grades. These alloys are widely applied in SMAW aluminum welding due to their stable arc characteristics, good weldability, and compatibility with different aluminum base materials.

E4043 Aluminum Stick Welding Rod

Key Characteristics: Aluminum-silicon alloy with good fluidity and a relatively low melting point, helping to reduce hot cracking and improve weld bead appearance.

Typical Applications: Welding 6xxx series aluminum alloys (typically 6061 aluminum alloy welding), aluminum castings, and medium- to low-strength structural aluminum components. In some MIG and TIG applications, 4943 aluminum welding wire is also used as an alternative filler for improved strength on similar base materials. Similarly, 4643 aluminum welding wire is sometimes selected for aluminum welding applications where controlled magnesium content and post-weld performance are required.

E5356 Aluminum Stick Welding Rod

Key Characteristics: Aluminum-magnesium alloy offering higher weld strength and better corrosion resistance compared to silicon-based electrodes, with a bright and clean weld appearance.

Typical Applications: Welding 5xxx series aluminum alloys, commonly used in marine structures, vehicle repair, and applications requiring improved corrosion resistance.

E5183 Aluminum Stick Welding Rod

Key Characteristics: Higher-strength aluminum-magnesium-manganese alloy designed for demanding applications requiring strong and corrosion-resistant weld joints.

Typical Applications: Marine engineering, oil and gas equipment, aluminum pressure vessels, and heavy-duty structural repair work.

Aluminum stick welding rods are designed for SMAW applications where flux-coated electrodes provide arc stability and weld pool protection. For general information about aluminum flux materials and their role in aluminum joining processes, please refer to our aluminum brazing flux guide.

These aluminum stick welding rod grades are available in standard diameters and lengths to support different SMAW aluminum welding applications.Chalco Aluminum Stick Welding Rod Supply Capabilities

Chalco provides aluminum stick welding rods with flexible specification options to meet different project and application requirements. Standard and customized rod diameters, lengths, and alloy selections are available to support a wide range of SMAW aluminum welding scenarios.

- Multiple aluminum stick welding rod alloys available, including E4043, E5356, and E5183.

- Standard and custom diameters and lengths to match different welding practices.

- Consistent alloy composition and dimensional control for stable welding performance.

- Project-based supply support, including samples and technical documentation upon request.

Industries & Applications for Aluminum Stick Welding Rods

Aluminum stick welding rods are widely used in industries where on-site aluminum welding, repair, and maintenance are required. Due to their flexibility, portability, and suitability for outdoor and field conditions, SMAW aluminum welding rods are commonly selected for repair work, structural reinforcement, and emergency maintenance.

Power engineering & maintenance: On-site repair of aluminum components, outdoor welding, and emergency maintenance work where portable welding solutions are required.

Shipbuilding & rail transit: Structural repair, maintenance welding, and reinforcement of aluminum parts in marine and transportation equipment.

Industrial equipment & fabrication: Repair and joining of aluminum structures, frames, and fabricated components in industrial environments.

Defense & emergency systems: Field repair and rapid restoration of aluminum equipment and structural components under demanding conditions.

Project-based construction & maintenance: Aluminum welding tasks in infrastructure projects, maintenance shutdowns, and non-standard repair scenarios.

Chalco supports the supply of aluminum stick welding rods for industrial and project-based applications. Standard and customized specifications are available to match different welding requirements. For specific project needs or application details, please contact our team for support.

Complete Aluminum Welding Consumables Solution

In aluminum welding projects, selecting the right welding consumables is not only about choosing a single product, but about ensuring compatibility between welding methods, base materials, and filler metals. Chalco provides a complete aluminum welding consumables solution to support different welding processes, application environments, and project requirements.

Support for multiple aluminum welding processes: Aluminum welding projects often involve different welding methods such as SMAW, MIG, and TIG. Chalco supports aluminum stick welding, as well as gas-shielded welding processes, allowing users to select suitable consumables based on application conditions.

Clear alloy compatibility for aluminum welding: Different aluminum alloys require different filler and electrode selections. Chalco's aluminum welding consumables are designed to match common aluminum alloy systems, including 5xxx and 6xxx series aluminum, helping reduce cracking risk and ensure stable welding performance.

Project-oriented supply and specification flexibility: Aluminum welding requirements vary across repair work, outdoor welding, and industrial fabrication. Chalco supports standard and customized specifications to align with different project needs, welding positions, and site conditions.

Complete range of aluminum welding and joining consumables: In addition to aluminum stick welding rods, Chalco supplies a broad selection of aluminum welding and brazing materials to support different joining processes and application scenarios.

Knowledge Center & FAQ

What is the difference between stick welding rods, welding wire, and filler rods?

| Product Type | Flux Coated | Typical Welding Process | Conductive | Description |

| Stick Welding Rod (Electrode) | ✅ Yes | SMAW (Stick Welding) | ✅ Yes | Flux-coated electrode used for manual arc welding |

| Welding Wire | ❌ No | MIG / TIG Welding | ✅ Yes | Continuous wire supplied in coils for gas-shielded welding |

| Filler Rod | ❌ No | TIG Manual Feeding | ❌ No | Solid rod used as filler material without electrical conduction |

Aluminum stick welding rods are flux-coated electrodes designed for SMAW applications, where the coating provides arc stability and shielding during welding.

For other aluminum welding consumables, please refer to our related guides: [Aluminum Welding Wire] [Aluminum Filler Rod]

Which aluminum stick welding rod grades are commonly used?

Common aluminum stick welding rod grades include E4043, E5356, and E5183. Each alloy is selected based on base material compatibility, required weld strength, and corrosion resistance.

What welding process are aluminum stick welding rods used for?

These rods are designed for SMAW (Shielded Metal Arc Welding), which is widely used for on-site repair, outdoor welding, and maintenance work.

Are samples or technical documents available?

Technical documentation such as chemical composition references and compliance information can be provided upon request. Samples may be available for application evaluation.

How should aluminum stick welding rods be selected for a project?

Selection depends on the aluminum base material, welding position, environmental conditions, and required mechanical performance. For project-based applications, additional technical support may be helpful.

Contact Chalco for aluminum stick welding rod specifications, alloy selection guidance, or project-based SMAW welding support.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote