5083 aluminum round bar delivers marine-grade corrosion resistance in seawater and industrial environments while maintaining high strength and excellent weldability for dependable performance.

Non-heat-treatable and rated for continuous use up to 65 °C, this alloy is perfect for shipbuilding, transportation, and pressure-vessel applications.

Instant QuoteKey specifications for EN AW-5083 aluminum round bar

We can supply 5083 aluminum round bar in the following tempers: O, H111, H32, and F.

- ASTM B221 / B221M: Extruded bars, rods & wire of aluminum & aluminum alloys

- GB/T 3191: Cold drawn & cold rolled bars of aluminum & aluminum alloys

- ISO AlMg4.5Mn0.7 (EN 573-3): Chemical composition limits for 5083 alloy

- EN 755-2: Mechanical properties, dimensions & tolerances for aluminum extruded products

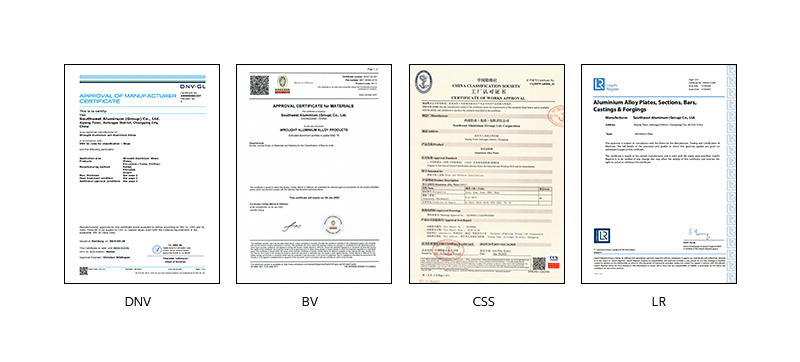

- Classification Society Approvals: ABS, DNV-GL, LR, NK for marine structures

Chalco marine-grade aluminum is certified to ABS, DNV-GL, LR and NK standards, meeting stringent requirements for light weight, high strength, corrosion resistance and weldability in marine applications.

Instant Quote

5083 aluminum round bar sizes

We have the most comprehensive inventory sizes, the fastest delivery methods, and professional logistics services.The following are our inventory sizes.

Instant QuoteMetric sizes of 5083 aluminum round bar

| Size | Diameter (in) | Diameter (mm) | Length |

| 5083 H112 Aluminum Round Bar Dia. 15 mm | 0.591" | 15 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 20 mm | 0.787" | 20 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 25 mm | 0.984" | 25 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 30 mm | 1.181" | 30 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 35 mm | 1.378" | 35 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 40 mm | 1.575" | 40 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 45 mm | 1.772" | 45 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 50 mm | 1.969" | 50 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 55 mm | 2.165" | 55 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 60 mm | 2.362" | 60 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 65 mm | 2.559" | 65 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 70 mm | 2.756" | 70 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 80 mm | 3.150" | 80 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 85 mm | 3.346" | 85 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 90 mm | 3.543" | 90 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 95 mm | 3.740" | 95 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 100 mm | 3.937" | 100 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 110 mm | 4.331" | 110 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 120 mm | 4.724" | 120 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 130 mm | 5.118" | 130 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 140 mm | 5.512" | 140 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 150 mm | 5.906" | 150 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 160 mm | 6.299" | 160 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 180 mm | 7.087" | 180 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 200 mm | 7.874" | 200 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 250 mm | 9.843" | 250 | 3000 mm (cut to size) |

| 5083 H112 Aluminum Round Bar Dia. 300 mm | 11.811" | 300 | 3000 mm (cut to size) |

Imperial sizes of 5083 aluminum round bar

| Size (in.) | Weight (lbs./ft.) | Standard Length (ft.) |

| 3/16" | .032 | 12'–20' (cut to length by request) |

| 1/4" | .058 | 12'–20' (cut to length by request) |

| 5/16" | .090 | 12'–20' (cut to length by request) |

| 3/8" | .130 | 12'–20' (cut to length by request) |

| 1/2" | .231 | 12'–20' (cut to length by request) |

| 5/8" | .361 | 12'–20' (cut to length by request) |

| 3/4" | .520 | 12'–20' (cut to length by request) |

| 7/8" | .707 | 12'–20' (cut to length by request) |

| 1" | .924 | 12'–20' (cut to length by request) |

| 1-1/8" | 1.169 | 12'–20' (cut to length by request) |

| 1-1/4" | 1.443 | 12'–20' (cut to length by request) |

| 1-3/8" | 1.746 | 12'–20' (cut to length by request) |

| 1-1/2" | 2.078 | 12'–20' (cut to length by request) |

| 1-5/8" | 2.439 | 12'–20' (cut to length by request) |

| 1-3/4" | 2.829 | 12'–20' (cut to length by request) |

| 1-7/8" | 3.247 | 12'–20' (cut to length by request) |

| 2" | 3.695 | 12'–20' (cut to length by request) |

| 2-1/4" | 4.676 | 12'–20' (cut to length by request) |

| 2-1/2" | 5.773 | 12'–20' (cut to length by request) |

| 3" | 8.313 | 12' (cut to length by request) |

| 3-1/2" | 11.314 | 12' (cut to length by request) |

| 4" | 14.778 | 12' (cut to length by request) |

| 4-1/2" | 18.703 | 12' (cut to length by request) |

| 4-3/4" | 20.839 | 12' (cut to length by request) |

| 5" | 23.091 | 12' (cut to length by request) |

| 5-1/2" | 27.940 | 12' (cut to length by request) |

| 6" | 33.251 | 12' (cut to length by request) |

| 6-1/2" | 39.023 | 12' (cut to length by request) |

| 7" | 45.258 | 12' (cut to length by request) |

| 8" | 59.112 | 12' (cut to length by request) |

| 9" | 74.814 | 12' (cut to length by request) |

| 10" | 92.363 | 12' (cut to length by request) |

| 11" | 111.759 | 12' (cut to length by request) |

| 12" | 133.002 | 12' (cut to length by request) |

| 13" | 156.093 | 12' (cut to length by request) |

| 14" | 181.031 | 12' (cut to length by request) |

| 15" | 207.816 | 12' (cut to length by request) |

Can't find the size you are looking for, please contact us.

Instant QuoteChemical composition of EN AW-5083 aluminum round bar

The material’s chemical composition complies with the EN 573-3 standard.

| Silicon (Si) | ≤ 0.4% |

| Iron (Fe) | ≤ 0.4% |

| Copper (Cu) | ≤ 0.1% |

| Manganese (Mn) | 0.4 – 1.0% |

| Magnesium (Mg) | 4.0 – 4.9% |

| Chromium (Cr) | 0.05 – 0.25% |

| Zinc (Zn) | ≤ 0.25% |

| Titanium (Ti) | ≤ 0.15% |

| Other Elements (each) | ≤ 0.05% |

| Aluminum (Al) | Balance |

Physical properties of EN AW-5083

| Thermal Expansion (20–100 °C) | 24.2 × 10⁻⁶ K⁻¹ |

| Thermal Expansion (20–200 °C) | 25 × 10⁻⁶ K⁻¹ |

| Thermal Expansion (20–300 °C) | 26 × 10⁻⁶ K⁻¹ |

| Thermal Expansion (–50–20 °C) | 22.3 × 10⁻⁶ K⁻¹ |

| Density | 2.66 g/cm³ |

| Electrical Conductivity (max) | 19 m/Ω·mm² |

| Electrical Conductivity (min) | 16 m/Ω·mm² |

| Elastic Modulus | 71 GPa |

| Shear Modulus | 26.8 GPa |

| Specific Heat | 900 J/(kg·K) |

| Thermal Conductivity (max) | 140 W/m·K |

| Thermal Conductivity (min) | 110 W/m·K |

Mechanical properties of EN AW-5083

| Standard | EN 755-2:2013 |

| Alloy | EN AW-5083 |

| Temper | H112 |

| Tensile Strength (Rm) | 200 – 270 MPa |

| Yield Strength (Rp0.2) | ≥ 125 MPa |

| Elongation | ≥ 12 % |

| Brinell Hardness | 70 HB |

| Elongation A50mm | ≥ 10 % |

Click to view specific performance applications of 5083 Aluminum Round Bar.

These values are typical characteristics and may not meet your specific requirements. If you have special needs,please

Instant QuoteAluminium 5083 round bar equivalent grades

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) | UK |

| AW-AlMg4,5Mn0,7 | AG4,5MC | 3.3547 | A95083 | AlMg4,5Mn0,7 | 5083 | AlMg4,5Mn | BS 5083 |

Key features & benefits of 5083 aluminum round bar

- Excellent weldability for reliable fabrication and assembly.

- Outstanding corrosion resistance in seawater and normal atmospheric conditions.

- High strength-to-weight ratio for durable performance.

- O-temper cold-formed (soft annealed) with low internal stress.

- Maintains strong core strength even at larger diameters.

Typical applications of 5083 aluminum round bar

- Shipbuilding

- Rail vehicles

- Automotive body panels

- Dump truck bodies

- Mine skips and cages

- Pressure vessels

- Tool, mold & model making

- Machine & fixture manufacturing

- Tank & equipment fabrication

- Automotive components

Weldability & machinability

- Weldability:

- Gas welding: Fair

- Arc welding: Excellent

- Resistance welding: Excellent

- Brazing: Poor

- General weldability: Poor

- Recommended filler metals: 5183; alternatives: 5356, 5556

- Machinability:

- Cold workability: Fair

- Overall machinability: Poor

How to Calculate the Weight When Purchasing 5083 Aluminum Rods

To estimate the weight of a 5083 aluminum rod, use the formula:

Weight (kg) = π × (D² / 4) × L × ρ

- D = rod diameter (m)

- L = rod length (m)

- ρ = density of 5083 aluminum = 2,660 kg/m³

For a quick calculation, try our Aluminum Rod Weight Calculator.

Popular products related to 5083 aluminum rods

5083-aluminum-pipe

5083-aluminum-plate

5083-armored-vehicle-sheet

5083-square-bar

5083-oil-tanker-plate

5083-aluminum-tube

5083 aluminum round bar packaging

- Separate each layer of aluminum bars with pearl cotton.

- Wrap pearl cotton around the ends of each layer.

- Use waterproof kraft paper and moisture-proof film externally.

- Utilize wooden crates, slat crates, or cardboard boxes for packaging.

- Avoid impact, compression, and bending.

Feel free to leave your requirements below, and we will respond to you as quickly as possible.

Instant Quote

Frequently asked questions (FAQ)

What is a 5083 aluminum grade?

5083 aluminum alloy is a wrought aluminum–magnesium alloy containing 4.0–4.9% magnesium, known for its excellent corrosion resistance, good weldability, and high strength, making it ideal for marine and shipbuilding applications.

Is 5083 stronger than 6061?

5083-H116 has a tensile strength of approximately 317 MPa, comparable to 6061-T6 (around 310 MPa). However, 6061-T6’s yield strength (~276 MPa) exceeds that of 5083-H116 (~215 MPa). Overall, 6061 offers slightly higher strength, while 5083 excels in corrosion resistance and low-temperature toughness.

What is equivalent to 5083 aluminum?

Common equivalents for 5083 aluminum include EN AW-5083 (Europe), UNS A95083 (USA), ISO AlMg4.5Mn0.7, and JIS A5083 (Japan).

Is 5083 marine grade aluminum?

Yes, 5083-H116 is widely recognized as a marine-grade aluminum alloy due to its outstanding seawater corrosion resistance and excellent weldability, making it the preferred choice for ships, offshore platforms, and other marine structures.