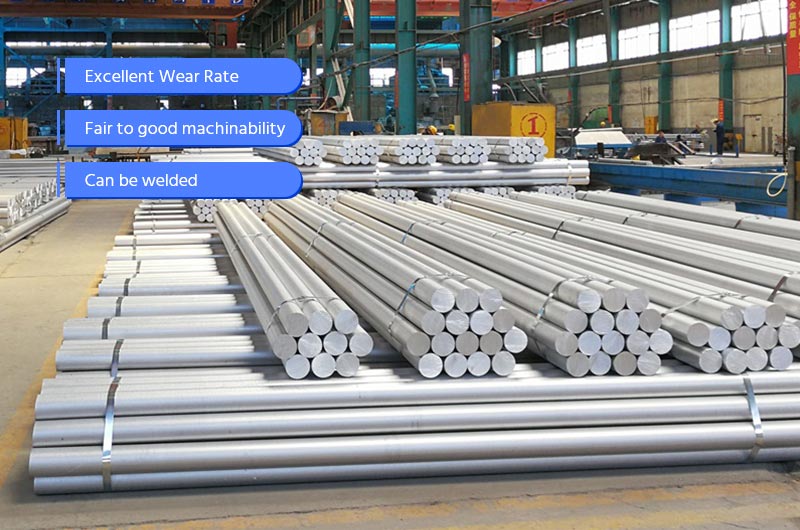

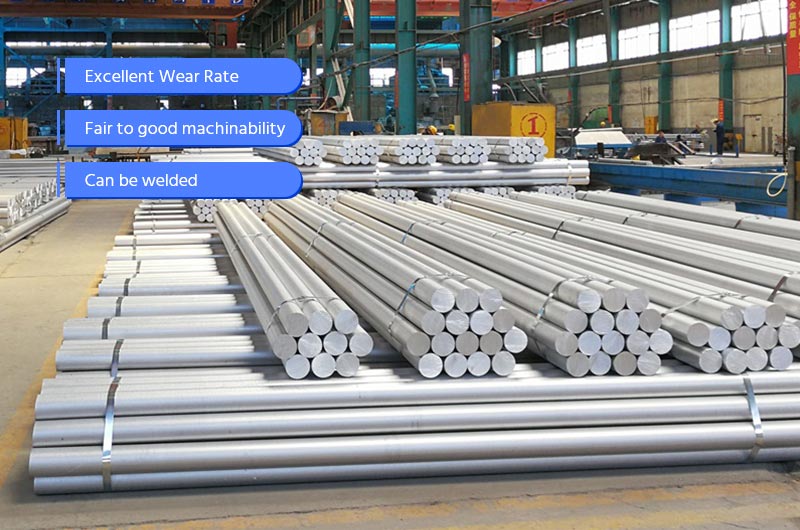

4032 aluminum round bar for racing engine parts, pistons, chassis components, and other high-temperature applications. It maintains mechanical strength up to 200 °C and remains usable to ~300 °C, with excellent wear resistance.

Diameters 0.500–23.000 in, lengths up to 12 ft. Supplied in F / H112 / T6 / T651 tempers, meeting the chemical requirements of AMS 4319.

Instant Quote4032 aluminum round bar specifications

- ASTM / AMS (USA): ASTM B211/B211M (rolled/cold-finished bar, rod, wire); ASTM B221/B221M (extruded bar/rod/shapes); AMS 4319 (4032 bar, common T6/T651).

- EN (EU): EN 573-3 (chemical composition); EN 755-2 (mechanical properties for extruded bars); EN 755-3 (round-bar dimensions/tolerances); for cold-drawn bars use EN 754-2.

- GB/T (China): GB/T 3191-2019 (extruded bars/rods); GB/T 3190-2020 (chemical composition for wrought alloys).

- Certificates / systems: EN 10204 3.1 mill test certificate; IATF 16949 supply (quality system, not a product standard); PMI/UT reports on request.

4032 aluminum round bar — stock sizes

Standard lengths: 6 ft & 12 ft (cut-to-size available). Metric is nominal; inch shown for reference.

Download or print our stock list for ready-to-ship sizes. If the size you need isn't listed, contact our sales team — we add new sizes regularly and can supply custom cuts.

Delivery tempers: T1 in stock; T6/T651 available on request.

Instant quote| Specification | Diameter (in) | Diameter (mm, nominal) |

| 4032 aluminum round bar 0.787 in dia | 0.787 | 20 |

| 4032 aluminum round bar 1.181 in dia | 1.181 | 30 |

| 4032 aluminum round bar 1.575 in dia | 1.575 | 40 |

| 4032 aluminum round bar 1.969 in dia | 1.969 | 50 |

| 4032 aluminum round bar 3.150 in dia | 3.150 | 80 |

| 4032 aluminum round bar 3.543 in dia | 3.543 | 90 |

| 4032 aluminum round bar 3.937 in dia | 3.937 | 100 |

| 4032 aluminum round bar 4.331 in dia | 4.331 | 110 |

| 4032 aluminum round bar 4.724 in dia | 4.724 | 120 |

| 4032 aluminum round bar 5.118 in dia | 5.118 | 130 |

We stock 4032 aluminum round bar in T1 so it machines/forges quickly and can be heat treated on demand to T6/T651, giving you certified properties with short lead times.

Popular sizes of 4032 aluminum round bar

Chalco is a professional 4032 aluminum bar supplier, offering customization for various sizes with short lead times.Feel free to click and inquire.

Instant Quote| Specifications | Diameter (in) | Length (ft) |

| 4032 T6 Aluminum Round Bar 0.500" Dia x 12' Lg | 1/2" | 12' |

| 4032 T6 Aluminum Round Bar 0.625" Dia x 12' Lg | 5/8" | 12' |

| 4032 T6 Aluminum Round Bar 0.688" Dia x 12' Lg | 0.688" | 12' |

| 4032 T6 Aluminum Round Bar 0.750" Dia x 12' Lg | 3/4" | 12' |

| 4032 T6 Aluminum Round Bar 0.875" Dia x 12' Lg | 7/8" | 12' |

| 4032 T6 Aluminum Round Bar 1" Dia x 12' Lg | 1" | 12' |

| 4032 T6 Aluminum Round Bar 1.125" Dia x 12' Lg | 1 1/8" | 12' |

| 4032 T6 Aluminum Round Bar 1.250" Dia x 12' Lg | 1 1/4" | 12' |

| 4032 T6 Aluminum Round Bar 2" Dia x 12' Lg | 2" | 12' |

| 4032 T6 Aluminum Round Bar 4.500" Dia x 12' Lg | 4 1/2" | 12' |

| 4032 T6 Aluminum Round Bar 3.375" Dia x 40" Lg | 3 3/8" | 3.333' |

| 4032 T6 Aluminum Round Bar 6" Dia x 24" Lg | 6" | 2' |

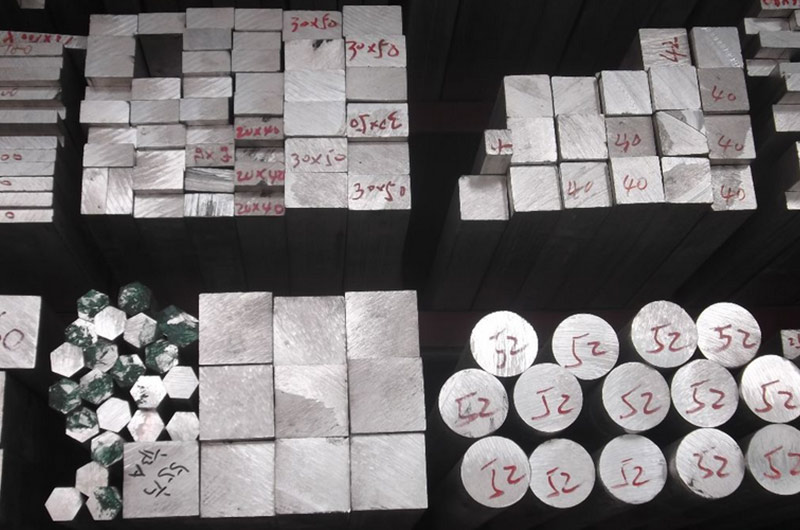

We produce 4032 Aluminum Bars in various shapes, including square, rectangular, and hexagonal.

4032 aluminum round bar chemical composition

AA/EN 4032 is a high-silicon, nickel-bearing wrought alloy designed for wear resistance and thermal stability.

| Element | Range (%) | Notes (application-focused) |

| Si | 11.0–13.5 | Raises wear resistance; stabilizes clearances at heat. |

| Mg | 0.8–1.3 | Enables heat treatment to high strength. |

| Cu | 0.5–1.3 | Strength contribution; machinability. |

| Ni | 0.5–1.3 | Lowers thermal expansion; boosts high-temp strength. |

| Fe | ≤ 1.0 | Impurity limit. |

| Mn | ≤ 0.40 | Impurity limit. |

| Cr | ≤ 0.10 | Impurity limit. |

| Zn | ≤ 0.25 | Impurity limit. |

| Ti | ≤ 0.15 | Grain refinement (typical limit). |

| Others, each / total | ≤ 0.05 / ≤ 0.15 | Residual limits. |

| Al | Balance | — |

Reference: EN 573-3/AA limits; typical AMS 4319 nominal for 4032-T651 is ~12.2 Si – 1.0 Mg – 0.90 Cu – 0.90 Ni.

Use notes: High Si + Ni give scuff resistance and thermal stability; many hot-forging uses do not require hard-coat anodizing. For laser-welded housings and piston components, 4032 offers strength comparable to 6061-T6 with better wear at temperature.

Instant quotePerformance of 4032 aluminum round bar

Among 4xxx alloys, 4032 offers the highest strength with good machinability and wear resistance. Suitable for MIG/TIG welding (use 4047 or 4043 filler), and its properties remain stable at elevated temperatures (~200 °C typical service).

| Typical physical properties | |

| Density | 2.69 g/cm³ (0.097 lb/in³) |

| Elastic modulus | 70–80 GPa (10.2–11.6 Msi) |

| Poisson's ratio | 0.33 |

| Thermal conductivity | 138–155 W/m·K |

| Coefficient of thermal expansion | ≈19.4 µm/m·°C (20–100 °C) |

| Electrical conductivity | ≈34 % IACS |

| Hardness (Brinell) | ~110–120 HB (T6/T651) |

| Typical mechanical properties (by temper) | |||

| Temper | Ultimate tensile strength | Yield strength (0.2% offset) | Elongation |

| 4032-T6 | ~390 MPa (56.6 ksi) | ~320 MPa (46.4 ksi) | ~6–8% |

| 4032-T651 | ~359–380 MPa (52–55 ksi) | ~317–331 MPa (46–48 ksi) | ~4–9% |

- Machining: good; use oil-based coolant for best surface finish.

- Welding: MIG/TIG with 4047/4043 filler; avoid high-Mg fillers.

- Note: values are typical; actual certification per ASTM B211/B221 or EN 755-2 will govern.

Advantages of 4032 aluminum round bar

- Highest-strength 4xxx wrought alloy

- Low thermal expansion; stable clearances at heat

- Excellent scuff/wear resistance for piston skirts

- Good machinability; fine finish with oil-based coolant

- MIG/TIG weldable (use 4047/4043 filler)

- Lighter than 2618; typically longer service life

- Per ASTM B211/B221; EN 10204 3.1 available

Applications of 4032 aluminum round bar

4032 aluminum round bar is chosen when parts must run hot, wear slowly, and hold tight clearances—especially in motorsport and performance automotive programs.

- Racing & performance engines: forged pistons for street/track builds (tighter piston-to-bore clearance, quieter cold start, longer life vs. 2618 in daily use).

- Automotive hydraulics & driveline: master brake cylinders, transmission valve bodies.

- Steering & bushings: bushings for rack-and-pinion steering systems; general wear sleeves/bearings.

- Electronics & instruments: sound-recording devices and copier components; laser-welded aluminum housings in hermetic packages.

- Industrial hydraulics: precision manifolds and wear-resistant components where low expansion and stable machining are required.

Customer cases: the examples below show how engineers apply 4032 to boost durability and maintain tight tolerances.

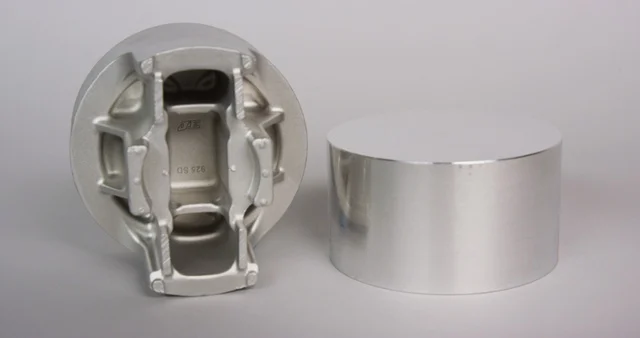

Forged piston programs: 4032-T6/T651 selected for reduced thermal growth and ring-groove stability in endurance and street-performance engines.

Valve-body blocks: bar stock rough-/finish-machined to tight flatness and bore tolerances for consistent shift control.

Rack-and-pinion bushings: oil-grooved 4032 sleeves improve wear life while holding OD/ID after heat soak.

Hermetic housings: laser-welded aluminum enclosures where low distortion and machinability matter.

This video shows a finished forged piston made from 4032 aluminum round bar (T6/T651), demonstrating the tight clearances, low thermal expansion, and wear resistance required for performance and motorsport engines.

Supplier - why choose us

Looking for 4032 aluminum round bar price or in-stock 4032 aluminum round bar for sale? Chalco supplies certified, cut-to-size bars for pistons and other high-temperature wear parts.

- Real stock: 0.500-23.000 in diameters; 6 ft or 12 ft, or custom cut.

- Quality you can audit: ASTM B211/B221; EN 10204 3.1; PMI/UT on request; IATF 16949 system.

- Engineered processing: centerless grinding, rough turning, heat treatment, anodizing.

- Fast quoting: transparent price per kg by diameter, temper, and lot size.

- Export-ready packing: EPE interleave, VCI bag, waterproof kraft, ISPM-15 crate.

- Low MOQs: sample lengths for trials; quick ramp-up for production.

If you are searching for 4032 aluminum round bar near me, we provide fast global shipping and door-to-door (DDP) delivery for convenient receiving.

Instant quote — tell us temper + diameter x length + certificates, and we will confirm stock, lead time, and a competitive price.

2618a vs 4032 — which to choose

Both alloys make excellent forged pistons, but they behave differently. 4032 (high-silicon) runs quieter with tighter clearances and better scuff resistance; 2618A (low-silicon, high-toughness) tolerates extreme loads and detonation but needs larger clearances.

| Property | 4032 | 2618A |

| Silicon content | ~12% (high) | <0.3% (very low) |

| Ductility / toughness | Moderate (lower impact tolerance) | High (handles shock/detonation) |

| Thermal expansion | Low — allows tighter piston-to-bore clearance | Higher — requires larger clearance |

| Wear / scuff resistance | Excellent (piston skirt life) | Lower — often needs coatings/hard anodize |

| Cold-start noise | Quieter | More piston slap at cold start |

| Density | ~2.69 g/cm³ (lighter) | ~2.80 g/cm³ |

| Best use cases | Street/track endurance, long service life | Extreme racing, high boost/nitrous, very high loads |

- Choose 4032 when you want lower thermal expansion, quieter operation, and long-life street/track pistons.

- Choose 2618A aluminum round bar when ultimate toughness matters and you can accept larger clearances and more noise.

Processing recommendations for 4032 aluminum round bar

- Use PCD or polished carbide tools with positive rake.

- Run high rpm with light-to-moderate feed to avoid built-up edge.

- Coolant: oil-based emulsion (6–10%) or MQL; keep fluid clean.

- Workholding: soft jaws/liners and even clamping to prevent out-of-round.

- Finish target: Ra ≤ 0.8 µm on critical faces; polish skirts as needed.

- Holes/threads: cut taps with cutting oil; light chamfer and careful deburr.

- Welding: MIG/TIG with 4047 (preferred) or 4043; clean oxide and limit heat.

- From T1 to T6/T651: solution heat treat, quench, and age; leave stock for growth.

- After heat treat: verify size/straightness and do a light corrective cut if required.

Ordering, packing, and delivery

One-stop service for 4032 aluminum round bar: fast quotes, cut-to-size, certified heat treat, and global DDP shipping.

- Fast quote: send temper + dia x length + certs

- Cut-to-size: 6 ft, 12 ft, or custom

- On-demand heat treat: upgrade T1 to T6/T651 with 3.1 MTC

- Seaworthy packing: EPE + VCI + ISPM-15 crate

- Door-to-door delivery: DDP with customs handled

- Smart labeling: PO/part no./barcode for quick receiving

Tell us your size, temper, and delivery terms — we will propose the most economical packing and DDP route for your location.

Instant Quote4032 aluminum round bar related hot selling inventory

Customers who buy 4032 for forged pistons, valve bodies, bushings, and hydraulic blocks often also consider the items below. These bars offer similar use cases (high-temperature, wear-resistant, tight-tolerance machining) and are kept in stock for fast delivery.

4032 Forging

4032 Aluminum Bar

4032 Piston Rod

2024 Aluminum Bar

2014 Aluminum Bar

7075 Aluminium Rod

Need 4032 aluminum round bar price or want these related sizes for sale and near me? We ship globally with DDP options for convenient delivery.

Instant quote — tell us alloy, temper, diameter × length, and certificate needs (EN 10204 3.1/PMI/UT).

4032 aluminum round bar faqs

What is 4032 aluminum grade?

4032 is a wrought Al-Si-Cu-Mg-Ni alloy (~12% Si) engineered for low thermal expansion, wear resistance, and good machinability. It is heat treatable (T6/T651) and commonly used for forged pistons, valve bodies, and bushings per ASTM B211/B221 and AMS 4319.

What is the equivalent of aluminum 4032?

Common equivalents: AA 4032; UNS A94032; EN AW-4032 (EN 573-3 chemistry); AMS 4319 (bars). You may also see legacy naming like AlSi12CuNiMg in older specs.

What is the difference between 6061 and 4032 aluminum?

4032 has higher Si (and Ni), giving lower thermal expansion and better scuff resistance—ideal for pistons with tighter clearances. 6061 is a general-purpose Al-Mg-Si alloy with higher ductility and broader weldability but less wear resistance. For a detailed comparison, see 6061 aluminum round bar.

Can you cast 4032 aluminum?

4032 is primarily a wrought alloy for forging and machining, not a standard foundry casting grade. For cast components, alloys such as 356/357/390 are typically used. If welding 4032 parts, common fillers are 4047 or 4043.

Is 4032 aluminum weldable?

Yes—MIG/TIG welding is feasible using 4047 or 4043 filler. Expect reduced strength in the heat-affected zone unless parts are re-heat-treated; design clearances accordingly.

Is 4032 heat treatable and what strengths are typical?

Yes. Typical T6/T651 properties: UTS ~390–400 MPa, YS ~320–330 MPa, elongation ~4–8% (values vary by size and process; certify to ASTM/EN/AMS on request).

What temperatures can 4032 operate at?

Mechanical strength remains stable to ~200 °C in service, with short-term use up to ~300 °C depending on design and duty cycle.

How do I get 4032 aluminum round bar price?

Email us the temper, diameter × length, and certificate needs (EN 10204 3.1/PMI/UT). We will confirm stock, lead time, and a competitive per-kg price with DDP delivery options.

Contact us: WhatsApp +86 173 4489 4490 | Email sale@chalcoaluminum.com