Ground busbar is a key protective conductor used in grounding and equipotential bonding systems to centrally connect grounding conductors and provide a stable path for fault and leakage currents, ensuring the safety of personnel and equipment.

Chalco offers copper and aluminum grounding busbars with customizable dimensions and hole layouts, and optional surface treatments such as bare copper or tin plating. These products are widely applied in distribution and control cabinets, communication rooms, and various engineering grounding systems, supporting both project-based and bulk supply requirements.

Chalco Ground Busbar Application Scenarios

Communication system and data center grounding

For centralized grounding in communication rooms and data centers, supporting TMGB/TGB systems.

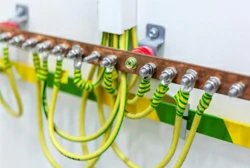

Grounding of distribution and control cabinets

For grounding and protective connections inside distribution and control cabinets.

Equipment and building equipotential grounding

For protective grounding and equipotential bonding of equipment and metal structures.

Ground Busbar Materials & Typical Configurations

Chalco Ground Busbars are made of copper or aluminum and are designed for power grounding and equipotential bonding applications. They are suitable for power distribution systems, communication systems, and project-based grounding installations, providing reliable grounding conductor solutions for various scenarios.

Chalco Ground Busbars support commonly used widths and thicknesses for engineering applications. Lengths can be customized to meet installation requirements, and hole positions and spacing can be machined according to grounding conductor or terminal connection needs. Surface treatments such as bare copper or tin plating are available to suit different environments.

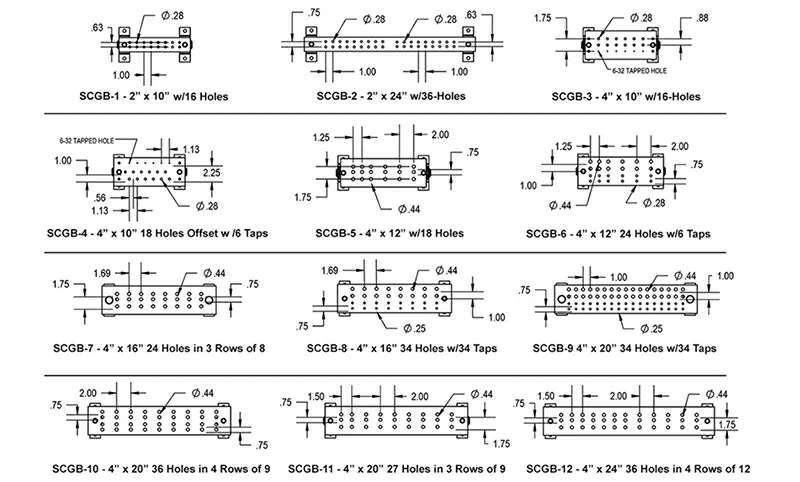

The examples below show typical size ranges and structural configurations of grounding busbars used in power and communication engineering. These parameters are for reference only and can be customized based on project requirements.

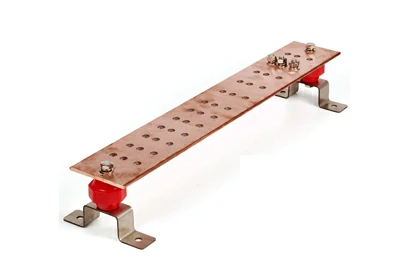

Wide grounding busbar - multi-hole high-density connection

Width:≈ 100mm Length: 600–800mm

Hole positions: Approximately 30–36 holes.

Suitable for communication rooms, data centers, and multi-circuit grounding systems, enabling centralized connection of grounding conductors.

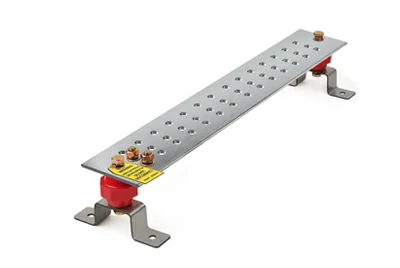

Medium-sized grounding busbar - universally applicable inside cabinets

Width:≈ 50–75mm Length: 400–600mm

Hole positions: Approximately 20–30 holes.

Suitable for grounding connections in medium-sized distribution and control cabinets, with a versatile design for various power distribution circuits.

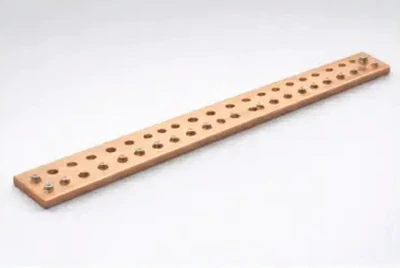

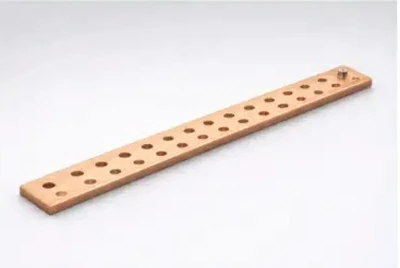

Narrow grounding busbar - for space-constrained installations

Width:≈ 25–40mm Length: 300–500mm

Hole positions: Approximately 12–24 holes.

Suitable for cabinet interiors or bracket structures with limited space. The single-row hole design is simple and practical.

Short grounding busbar assembly — rapid project integration

Width:≈ 50mm Length: 200–300mm

Hole positions: Approximately 8–16 holes

Suitable for short-distance grounding between equipment and cabinets, serving as grounding branches or connection points.

In addition to standard configurations, Chalco can also provide customized grounding busbars according to the project's grounding scheme, supporting non-standard designs in terms of size, length and hole arrangement, suitable for industrial and building equipotential grounding systems.

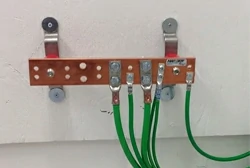

Ground Bus Bar Kit and Accessories for Electrical Grounding Systems

In power and communication engineering, Ground Bus Bars typically require supporting components for installation and connection. Depending on the project structure and installation environment, common accessories used with grounding busbars include:

-

Insulating supports/insulating pads

Used to isolate the grounding busbar from the cabinet or structural components to meet electrical insulation and fixing requirements.

-

Mounting brackets/fixed brackets

Used for fixing grounding busbars inside cabinets, on walls, or on structural components, and are suitable for different installation spaces.

-

Fasteners

Including bolts, nuts, washers, etc., are used for reliable connection of grounding wires or braided strips to busbars.

-

Grounding wires or braided strips

Used for equipotential bonding between equipment, cabinets and grounding busbars.

The specific selection and combination of supporting products need to be confirmed based on the actual grounding scheme, installation conditions, and project requirements. For information on grounding busbar matching solutions suitable for your project, please contact Chalco sales personnel.

Manufacturing & Customization Capabilities

Chalco offers customization capabilities, from busbar fabrication to project-specific configurations, to address common ground busbar configuration requirements in engineering projects. It supports the production of grounding busbars of different sizes, hole positions, and installation methods to meet the practical application needs of power and communication grounding systems.

Grounding busbar processing capability

- Supports fixed-length cutting and length customization of grounding busbars

- Drilling can be performed according to the requirements of the grounding wire or terminal.

- The aperture, spacing, and arrangement of holes can be configured according to project requirements.

Terminal & Connection-Oriented Ground Busbars Configuration

- Supports the fabrication and configuration of terminal-type grounding busbars.

- Suitable for grounding busbar applications in distribution cabinets, control cabinets, and equipment.

- The hole layout can be adjusted according to the number of wires and the installation space.

Installation-Oriented Ground Busbar Configuration Support

- Supports the fabrication and structural adaptation of grounding busbars in project-based kit configurations.

- The busbar hole positions and dimensions can be customized according to the cabinet or installation method.

- To meet the overall installation requirements of the project's grounding system.

Surface treatment and structural support

- Common surface treatments such as bare copper or tin plating.

- Adaptable to different environmental conditions and long-term operation requirements.

- The structural form and installation method can be adjusted according to project requirements.

Chalco — Electrical Power System Support

Chalco provides power conductor support capabilities for power and communications projects, covering power distribution, connection, and grounding. To meet the overall structural, installation, and application requirements of different power systems, Chalco can collaboratively configure various conductor products to address specific project application needs.

In power projects, various conductor products are typically used in combination depending on the system architecture. Chalco can provide and support the overall configuration of busbars, grounding conductors, and wires to help customers build more complete and better-matched power system solutions.

Electrical Conductor Portfolio Overview

In power system applications, Chalco supports project-based configurations of the following conductor product portfolios:

Busbar / Phase busbar System

Used for the transmission and distribution of electrical energy, as the main current-carrying conductor in the power system, it is widely used in power distribution systems and inside power equipment.

Neutral Busbar Systems

It is used to form a stable working circuit, and works in coordination with the phase busbar to ensure the normal operation of the power system and load balance.

Ground Busbar Systems

Used for grounding and equipotential bonding in power systems to improve equipment and personnel safety.

Terminal Busbar

Used for centralized wiring and management of multi-circuit conductors, suitable for cabinet and equipment grounding applications.

Electrical Conductor / Wire

Used for connection and communication between devices, adaptable to control, grounding and auxiliary connection scenarios.

Electrical Cables

Used for power transmission and wiring connections between busbar systems and terminal equipment.

FAQ – Ground Busbar Frequently Asked Questions

Q1: What is the difference between Ground Busbar and Phase Busbar/Neutral Busbar?

Ground busbars are primarily used for grounding and equipotential bonding in power systems, ensuring safe conduction of fault currents and leakage currents; phase busbars are used for power transmission and distribution, and are the main current-carrying conductors; neutral busbars form the working circuit and operate in conjunction with the phase busbars. These three types have clear differences in their functional positioning and system roles.

Q2: Should the grounding busbar be made of copper or aluminum?

Copper grounding busbars have excellent conductivity and long-term stability, and are commonly used in communication equipment rooms, data centers, and indoor grounding systems. Aluminum grounding busbars have advantages in weight and cost control, and are suitable for some industrial projects or large-scale grounding systems. The specific selection usually needs to be confirmed in combination with the project environment and grounding scheme.

Q3: Can the size and hole positions of the grounding busbar be customized?

Yes.

In addition to the standard engineering reference configuration, the length, width, thickness, number of holes, hole spacing, and arrangement of the grounding busbar can all be customized according to the project's grounding scheme to adapt to different cabinet structures and installation requirements.

Q4: Is Ground Busbar provided as a kit?

In engineering applications, "Ground Bus Bar Kit" is typically used to describe the overall concept of grounding busbars and their installation configuration. The specific kit required for a particular project needs to be confirmed in conjunction with the grounding scheme and site conditions. It is recommended to coordinate with the business personnel during the project communication phase.

Engineering Collaboration & Technical Support

In practical power and communication projects, the selection and configuration of ground busbars typically need to be confirmed in conjunction with the overall grounding scheme. Based on project requirements, Chalco can provide technical support regarding grounding busbar size selection, hole layout, and installation methods, assisting project personnel in more efficiently confirming the solution.

For different system structures and installation environments, Chalco can work with project teams to discuss the configuration of grounding busbars to adapt to the actual needs of power distribution systems, communication systems, and project-based grounding applications.

If you are currently working on a power or communications project, please feel free to contact the Chalco team to discuss Ground Busbar application solutions, technical details, and project collaboration.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote