Winding wire is a key conductor used in coils for motors, transformers, relays, inductors, and new energy systems. Made from copper or aluminum and coated with insulating materials like enamel, paper, or glass fiber, it ensures stable electrical and mechanical performance.

As a core material in energy conversion, its quality directly affects system efficiency, heat management, and durability. Chalco, leveraging its aluminum expertise, offers a full range of copper, aluminum, enameled, and high-temperature winding wires—serving everything from microelectronics to heavy-duty industrial systems.

Winding wire conductor material:

Winding wire insulation material:

Industry solutions:

Chalco winding wire product specifications and introduction

Winding round wire diameter range: 7-36 GUAGE (0.2mm-15.0mm)

Winding flat wire size range: the widest flat wire can reach 3.5mm

Chalco enameled winding wire coating thickness grades: Grade 1 / Grade 2 / Grade 3 (thin to thick), suitable for different slot filling ratios

Cable reel: PT25, PT30, PT35, PT60, PT90, PT200, PT270 wooden reels, each with a maximum load of 150kg. Conical reels or other reels are available, and the models can be customized according to customer requirements.

Chalco winding wire industry standards and testing basis

- IEC 60317 / IEC 60264 – International Electrotechnical Commission standards for magnet wire and winding conductors

- GB/T 7672, GB/T 7095, GB/T 11022 – Chinese National Standards

- Customer-specified standards – Benchmarking solutions can be provided according to special certification systems such as UL, VDE, JIS, etc.

High purity EC grade wire rod delivering high-performance winding conductors

At Chalco, the foundation of superior winding wire lies in the quality of our conductor rods. We leverage advanced continuous casting and rolling technologies combined with precision drawing and annealing processes to achieve full vertical integration—from metal melting and casting to rod production and wire drawing. This comprehensive manufacturing capability ensures that our rods exhibit excellent purity, uniform grain structure, and outstanding mechanical properties.

Copper conductors for winding applications

Chalco's copper conductors offer exceptional electrical performance, making them the preferred choice for demanding winding applications such as motors and transformers. With a conductivity of up to 99.9%, they provide excellent current-carrying capacity and thermal stability under high-speed and high-temperature working conditions.

We supply high-purity bare copper wire and enameled copper conductor wire in multiple sizes, backed by precision drawing and annealing processes to ensure consistent performance and excellent processability.

Instant QuoteAvailable in loose coils, small spools, or large reels for automated coil winding processes.

Structure type: Round and flat copper conductors; customizable SWG/AWG diameters supported

Insulation options: PEW, EIW, AIW; double-layer insulation or bare copper conductors as required

Typical applications: Motor coils, transformer windings, precision electromagnetic systems

Copper-clad aluminum conductors for lightweight solutions

Chalco's copper-clad aluminum (CCA) conductors combine the conductivity of copper with the lightweight and cost advantages of aluminum. Using advanced metallurgical bonding techniques, our CCA wires feature excellent copper layer uniformity, strong bonding, and stable performance for electrical winding applications.

We offer round or flat CCA conductors with customizable copper cladding ratios (typically 10%, 15%, or 20%), as well as optional insulation coatings to support automated manufacturing needs.

Instant QuoteIdeal for volume production of cost-sensitive or weight-constrained electromagnetic components.

Structure type: Round or flat CCA conductors; standard and customized copper ratios available

Insulation options: PEW, EIW, and other high-temperature enamels; also available as bare CCA wire

Typical applications: Fan motors, home appliance transformers, speaker coils

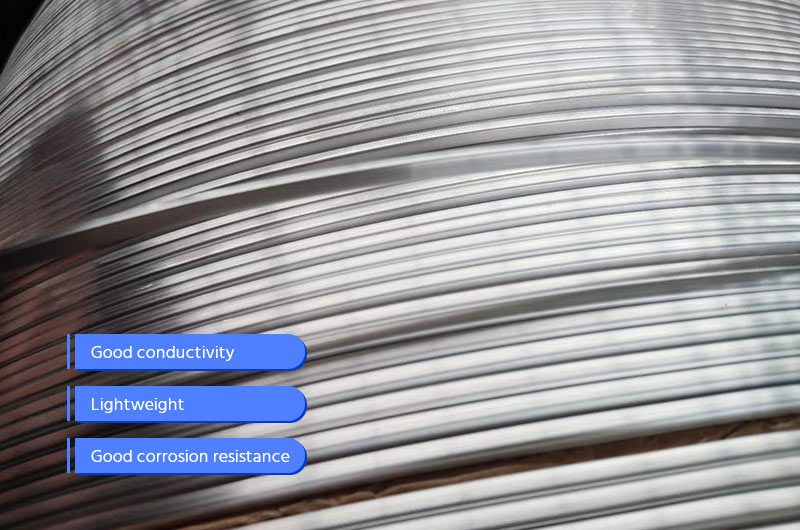

Aluminum conductors for electrical winding

Chalco supplies high-quality aluminum conductors made from alloy grades such as 1350, 1370, and 6101, offering a reliable alternative to copper for electrical winding applications. Our aluminum conductors are produced through continuous casting, rolling, and fine drawing processes, ensuring uniform structure and excellent electrical properties.

Both bare aluminum wire and insulated aluminum conductor options are available to meet various customer needs in terms of structure, size, and processing method.

Instant QuoteReel sizes from 1kg to 200kg are supported for automated coil winding lines.

Structure type: Round or flat aluminum conductors; support for standard 30–36 SWG or custom sizes

Insulation options: PEW, EIW, or composite enamel; also available as bare aluminum wire

Typical applications: Fans, distribution transformers, submersible motors

If you're unsure whether copper, aluminum, or copper-clad aluminum is the best fit for your winding application, our technical team is here to help. Whether you require detailed specifications, performance comparisons, or customized conductor solutions, feel free to contact us for expert advice and tailored recommendations.

Insulation types and structures for Chalco winding wires

Chalco offers a wide range of insulation systems for winding conductors, designed to meet the complex performance demands of modern electromagnetic equipment. From high-speed motors to high-voltage transformers and harsh environments such as submersible or high-temperature systems, our insulation structures ensure thermal stability, dielectric strength, and process compatibility.

We provide various insulation materials and coating structures—including enamel types (PEW, EIW, AIW, PI), paper wrapping, glass fiber wrapping, and multi-layer composite insulation—to support automated production and long-term system reliability. Customized insulation thickness, thermal grade, and slot-fill performance are available to match specific design requirements.

Enameled winding wire——insulated and suitable for automatic winding

Enameled wire is the most widely used type of winding wire. The surface of the conductor is covered with one or more layers of uniform insulating paint film, and can be directly used for winding coils without additional treatment. Chalco provides enameled wires with various conductor materials (copper/aluminum) and different heat resistance grades and structures, suitable for various electromagnetic devices such as motors, transformers, inductors, relays, etc.

Instant QuoteThe product is compatible with automated winding equipment and can be delivered in small spools or high- precision layer-wound large rolls.

Structure type: round wire/flat wire, supports Grade 1/2/3 paint thickness, wire diameter covers the full range of AWG/SWG

Insulation treatment: Supports various paint film types such as PEW, EIW, AIW, PI, etc., with thermal ratings ranging from 130°C to 220°C

Typical Applications: enameled copper wire for motor coil, transformer winding, inductor & choke coil

Paper covered winding wire — ideal for high voltage oil-immersed systems

Paper-covered winding wire is a traditional insulated wire structure used in medium and high voltage transformers and reactors. It usually uses copper or aluminum conductors and is covered with one or more layers of high-strength electrical paper or crepe paper. It has excellent impregnation performance and dielectric strength. This product is widely used in key parts such as the main winding of oil-immersed transformers, inter-turn insulation of reactors, and tap switching.

Instant QuoteChalco can provide a variety of paper types, layers and coating forms according to the winding structure and oil-paper system requirements to meet IEC or GB standard requirements.

Structure type: Bare copper/aluminum conductor covered with electrical paper, crepe paper, composite paper, optional single/double/multi-layer structure

Supporting insulation system: suitable for oil-immersed insulation, gas insulation, electrical impregnation system

Typical applications: paper insulated winding wire for oil-immersed transformers, reactor winding conductor

Glass fiber covered winding wire — high temperature resistance, high strength

Glass fiber covered wire is made of high-temperature glass fiber coated on the surface of copper or aluminum conductor and cured by resin. It has excellent heat resistance, mechanical protection ability and surface protection performance. It is widely used in dry-type transformers, reactors, electric furnaces and large motors and other occasions with extremely high requirements on temperature and mechanical stress.

Instant QuoteChalco can provide single or multi-layer glass fiber braided structure to meet various insulation requirements of IEC and GB standards.

Structure type: bare copper/aluminum conductor + single/double layer glass fiber braid + thermosetting resin treatment

Heat resistance: insulation level can reach 200~220℃, short-term temperature resistance> 260℃

Typical applications: fiberglass insulated winding wire for dry-type transformers, electric furnaces, high-temp reactors

Litz Wire — Optimized Conductors for High-Frequency Applications

Litz wire consists of multiple thin enameled strands individually insulated and precisely twisted or braided to reduce the skin effect and proximity effect in high-frequency AC currents. This structure significantly lowers AC resistance and improves energy efficiency in electromagnetic systems operating at tens or hundreds of kilohertz.

Chalco supplies customized litz wire constructions to meet the requirements of high-frequency transformers, resonant circuits, wireless charging systems, and induction heating equipment. Strand counts, wire gauge, twist pitch, insulation type, and outer bundling can all be tailored to specific system performance targets.

Instant QuoteAvailable specifications:

- Strand type: Enameled copper, copper-clad aluminum

- Strand diameter: Typically 0.04–0.2 mm per wire, customized upon request

- Bundle type: Twisted, braided, or concentric structures

- Outer insulation: Silk, nylon, polyester yarn, or heat-shrink tubing

Typical applications: High-frequency transformers, induction heating, EV charging coils, medical and radio-frequency devices

Specialty winding wire——high frequency, high voltage, miniaturized electromagnetic system

In addition to conventional structures, Chalco also provides a series of functional winding wires for special application scenarios, suitable for high-tech barrier equipment such as high-frequency transformers, micro coils, industrial power modules and new energy electric drives. This type of wire has structural advantages such as multi-layer insulation, high flexibility, high-frequency loss control, and self-adhesion properties, and is widely used in occasions with extremely high requirements for electrical performance and size integration.

Main types:

- Triple insulated wire: Three layers of insulation structure with different dielectrics, replacing traditional isolation windings, can realize small volume high voltage isolation system

- Self-bonding wire: The surface has hot-melt or electric self-adhesive properties, which simplifies the coil structure and improves the winding stability

- Highly flexible/radiation-resistant wire: suitable for special scenarios in medical equipment, rail transportation, and aerospace

Chalco offers a comprehensive range of winding wire solutions—from basic copper and aluminum conductors to advanced insulated wires like litz wire, triple-insulated wire, and specialty formats. Whether you need technical guidance, product customization, or a quick quotation, our team is ready to assist you with expert support and responsive service.

Instant QuoteChalco winding wire product technical parameters

The winding wire products provided by Chalco strictly follow international and industry standards, from wire diameter tolerance to insulation grade, from paint layer structure to thermal stability, to ensure that each batch of winding wire can be stably used in efficient and high reliability electromagnetic systems.

Thermal grade coverage: 130℃, 155℃, 180℃, 200℃, 220℃, customizable up to 240℃

Thermal shock test: 155℃~300℃, suitable for industrial frequent start-stop or high-power systems

Breakdown voltage: up to 7 kV, meeting the safety requirements of high-voltage electromagnetic systems

Mechanical properties reference:

- Tensile strength: 70–90 N/mm²

- Elongation: 15%–48%

- Wear resistance: >67.75 N

- Scratch resistance(Grade 1:1.95 N, Grade 2:3.15 N)

| Thermal performance and electrical parameters | |||||

| Production | 130 class polyester enameled | 155 class polyester enameled | 180 class polyester imide enameled | 200/220 class polyester imide/polyamide composited | 240 class high-temperature resistant |

| Heat resistance grade | B | F | H | C | HC |

| Thermal Shock | Lowest thermal shock temperature 155℃ | Lowest thermal shock temperature 175℃ | Lowest thermal shock temperature 200 ℃ | Lowest thermal shock temperature 220 ℃ | Lowest thermal shock temperature 300 ℃ |

| Breakdown Voltage | 4.4kv | Can reach 7kv | |||

| Insulation performance | Resistant to mechanical overload, heat, chemical, and corona, making it easy to weld and sinter | ||||

| Minimum tensile strength | 70-90 N/mm2 | ||||

| Elongations % | 15%-48% | ||||

| Resistance to abrasion | >67.75N | ||||

| Scrape resistance | 1 grade enameled wire: 1.95N 2 grade enameled wire: 3.15N | ||||

| Common transformers and corresponding winding wire heat resistance grades | |||

| Transformer type | Application | Features | Heat resistance grade |

| power transformer | Transformation and distribution of power systems | Large capacity, high voltage level, high efficiency, stable operation | Class B or F |

| Electric locomotive transformer | Traction of electric locomotives | Small size, light weight, vibration and impact resistance | Class F or H |

| Industrial transformer | Industrial production | Various varieties, diverse structures and strong adaptability | B , Class F or Class H |

| Electronic transformer | Electronic equipment | High frequency, small size, high efficiency | Class F or H |

| Large transformer | Capacity greater than 1000kVA | High power, large volume, inconvenient to transport | Class B or F |

| medium transformer | Capacity is 100~1000kVA | Moderate capacity and wide application range | Class B or F |

| small transformer | Capacity less than 100kVA | Small size, light weight and low price | Class B |

| dry type transformer | No cooling medium is used | Safety and environmental protection, good fire protection performance, low maintenance cost | Class B or F |

| Oil-immersed transformer | Use oil as cooling medium | Good heat dissipation performance, large capacity and high efficiency | Class B or F |

Chalco winding wire product application and cooperation field

Focusing on the key needs in the field of electromagnetic equipment manufacturing, Chalco provides winding wire material solutions for various equipment types such as transformers, motors, fans, submersible pumps, etc., helping customers improve electrical efficiency, structural integration and system reliability.

Transformer winding wire | Withstands voltage, heat and structural plasticity

Transformer winding wires must meet the requirements of electrical insulation strength, thermal stability and forming processability. Especially in dry, high-frequency and oil-immersed systems, it is crucial to reasonably match the wire structure.

Instant Quote- Flat copper/aluminum winding wire (for dry main winding)

- Paper wrapped winding wire (for oil immersed power transformers)

- Triple insulation structure winding wire (for isolation transformers, switching power supplies)

Motor winding wire | High-speed operation and heat resistance

As the main application field of winding wire, motors are widely distributed in industries such as industrial drives, household appliances, and automotive electric drive systems. Typical working conditions require the wire to have high conductivity, excellent mechanical strength, and compatibility of the insulation system with automatic winding equipment.

Instant Quote- Copper enameled winding wire (suitable for industrial motors, variable frequency motors)

- Aluminum winding wire (suitable for lightweight design such as air-conditioning compressors and small motors)

- Self-adhesive copper winding wire (suitable for compact, low-power motors)

Winding wire for fans and household appliances | Lightweight economy and automated processing requirements are equally important

Small motor products such as household appliances, fans, and rice cookers have multiple requirements for winding wires during mass production, including lightweight, insulation consistency, and automatic winding efficiency.

Instant Quote- Aluminum enameled winding wire (suitable for large-volume products such as fans and electric blowers)

- Copper enameled winding wire (suitable for export brand home appliances or occasions with higher durability requirements)

- Self-adhesive winding wire (improves winding density and reduces external bonding process)

Submersible pumps and high temperature coils | Insulation stability assurance in hot and humid environments

Submersible pumps, electric heating coils, reactors and other equipment are mostly used in harsh working conditions of high humidity, high heat and high electric field. The winding wire must not only carry current but also have long-term insulation resistance.

Instant Quote- Glass-fiber covered copper winding wire (for dry submersible motors and electric heating systems)

- Paper-wrapped winding wire (for oil-immersed submersible pumps, voltage regulators)

- High temperature grade enameled winding wire (AIW/PI, suitable for frequent starting or high load operation)

Production capacity and quality assurance

As a professional winding wire material manufacturer, Chalco has a complete integrated manufacturing system. From metal conductor casting, wire drawing, coating, painting, curing to high-speed winding and forming, the whole process is strictly controlled to achieve stable, efficient and traceable product output.

Complete production process control

Raw material guarantee: 9.5mm high-quality copper/aluminum metal rods are selected and processed through multiple wire drawing dies to the target wire diameter to ensure stable conductivity.

Multi-layer painting system: The mold coating machine supports the superposition of multiple layers of insulating paint film, with a thickness range of 60~450μm, which is uniform and stable.

High temperature curing process: using advanced infrared oven with precise temperature control, the paint film will not crack at up to **350℃**, ensuring the consistency of heat resistance level.

Automatic lubrication system: Patented lubricant layer improves surface smoothness and significantly reduces wear and jamming during automatic winding.

Precision winding equipment: high-speed tension-controlled winding machine, supports coil forming in the range of 5kg to 200kg, can adjust tension/speed/angle, and is suitable for various bobbin structures and assembly processes.

Multiple line type support and finished product forms

Chalco can produce winding conductors with various cross-sections according to customer drawings or process requirements, which are widely used in various electromagnetic structures:

Round winding wire: standard single-core conductor, suitable for most motors and small transformers

Square winding wire: used for equipment with high space utilization requirements and compact structure

Flat winding wire: suitable for directional winding applications such as dry-type transformers and low-inductance coils

Multi-strand composite structure (Litz stranded wire, etc.): Reduce high-frequency loss and optimize skin effect

Supports customization of spools: cylindrical, conical, horizontal and other structures are available, with a maximum load of 200kg. The packaging is moisture-proof and shock-proof, suitable for domestic and overseas transportation.

Full process testing and quality traceability

Each batch of winding wires is fully tested according to the standards before leaving the factory to ensure the consistency of the electrical performance, mechanical performance and thermal stability of the products:

- Factory inspection report:

- Raw material certification

- Paint film thickness and uniformity test

- Breakdown voltage, dielectric loss test

- Elongation, tensile strength and elasticity tests

- Solvent resistance and thermal shock resistance evaluation

The highly automated production process and strict quality control system enable Chalco winding wire to have high consistency, high durability and batch stability, helping customers improve system performance and safely implement engineering projects.

Price reference and purchasing suggestions

| Conductor material comparison | Copper vs Aluminum vs Copper Clad Aluminum | |||

| Conductor Type | Features | Unit price trend | Recommended Uses |

| Copper winding wire | Highest conductivity and good strength | ★★★★ (higher price) | High performance motors, large transformers |

| Aluminum winding wire | Lightweight and cost-effective | ★★☆ (low) | Fans, compressors, small transformers |

| Copper clad aluminum winding wire | A compromise solution that balances weight reduction and electrical conductivity | ★★☆ (medium-low) | Household appliance motors, voice coils, secondary coils |

| Conductor Type | Features | Unit price trend | Recommended Uses |

| Copper winding wire | Highest conductivity and good strength | ★★★★ (higher price) | High performance motors, large transformers |

Conductor selection recommendations:

- Strict performance requirements → Pure copper winding wire is preferred

- Weight sensitive / cost-constrained → Aluminum or CCA wire recommended

Insulation structure recommendations:

- High frequency occasions → Litz structure/ self-adhesive wire is recommended

- High temperature environment → AIW and PI winding wires are preferred

Thermal level selection:

- Industrial motor: 155℃~180℃

- Submersible pump, electric heating ring: above 200℃

- Electronic transformer: 220~240℃ grade enameled structure is optional

Want to know the most suitable wire for your equipment? Chalco technical engineers can provide you with personalized selection suggestions and sample matching solutions. Please click to contact us.

Instant QuoteAnswers to core questions about the selection and use of winding wire

How to choose copper wire and aluminum wire in winding applications?

Copper winding wire has higher conductivity and mechanical strength, and is suitable for high-performance or long-term operation equipment; aluminum wire is lighter and more cost-effective, and is suitable for light-load equipment such as fans and small motors. If you want to strike a balance between conductivity and cost, you can also choose copper-clad aluminum (CCA) winding wire as an alternative.

What thermal ratings do you offer for your enameled winding wire?

Chalco can provide enameled winding wires with 130℃, 155℃, 180℃, 200℃, 220℃ and 240℃ grades, corresponding to B, F, H, C, HC insulation grades respectively. We also support customization of different paint film structures (PEW, EIW, AIW, PI) to meet different environmental requirements.

What types of winding wire structures can you make?

We can produce round, square, flat, Litz structure, stranded and other winding wires, support copper, aluminum, copper clad aluminum conductors, as well as enameled, paper-wrapped, glass fiber-wrapped and other insulation forms, adapting to various structural requirements such as transformers, motors, induction coils, etc.

Can you provide samples or small batch customization?

Yes. We support customized proofing services for parameters such as wire diameter/structure/insulation, with flexible minimum order quantity, suitable for testing or development verification. Samples are usually delivered within 3-7 days.

Can winding wire products be accompanied by a test report?

Each batch of factory products can provide:

- Raw material chemical composition report

- Film thickness, insulation breakdown, voltage test

- Tensile strength, elongation, thermal shock and other test data

We also support third-party testing and certification cooperation.

Do you support export business? How are the packaging and shipping methods?

Support export. We can provide wooden reels (cylindrical/conical), carton/pallet packaging that meet international transportation specifications according to customer requirements, and have experienced sea and air shipping processes. Export countries include Germany, India, Vietnam, UAE, etc.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote