Aluminum Tube Coil, also known as Coiled Aluminum Tube or Aluminum Coil Tube, is a highly efficient tubing material for transportation and heat exchange, produced by coiling extruded and cold-drawn round or oval aluminum tubes.

It offers multiple advantages such as light weight, strong thermal conductivity, good corrosion resistance, and easy bending and forming, making it widely used in various applications including air conditioning refrigeration, heating, ventilation, and air conditioning (HVAC), heat pump systems, automotive thermal management, and medical equipment fluid transfer.

As a one-stop aluminum material manufacturer, Chalco provides a complete manufacturing process from aluminum ingot casting to coiling and forming, supporting customized services for various alloys, sizes, and structures to meet diverse needs for efficient heat transfer and system integration.

Instant QuoteCore Performance Advantages of Aluminum Tube Coil

Due to its multiple performance advantages, aluminum tube coil has become an ideal alternative to copper and stainless steel tubes in heat transfer systems and fluid transportation. The following is an overview of its main advantages:

-

Lightweight & Strong

Lightweight & Strong

Aluminum has only 1/3 the density of copper and boasts excellent specific strength, making it particularly suitable for lightweight equipment and structural optimization design scenarios, such as thermal management systems for new energy vehicles.

-

Excellent Thermal Conductivity

Excellent Thermal Conductivity

Common alloys such as 1060, 3003, and 6063 have good thermal conductivity, which can significantly improve system thermal efficiency and are widely used in heat exchanger modules such as air conditioners, condensers, and evaporators.

-

Superior Corrosion Resistance

Superior Corrosion Resistance

The surface of aluminum can naturally form a dense oxide film. Combined with treatments such as anodizing, spraying, and galvanizing, it can operate for a long time in salt spray, high humidity, and light chemical environments.

-

Excellent Fabricability

Excellent Fabricability

Supports various processing methods such as cold bending, expansion, welding, cutting, and flaring, adapting to on-site assembly and automated production lines, facilitating efficient construction and system integration.

-

Structural Flexibility & Coiling Design

Structural Flexibility & Coiling Design

Compared to fixed-length straight tubes, aluminum tube coils are easier to transport and lay out, especially suitable for applications with limited space or requiring long-distance continuous laying, such as air conditioning refrigerant circuits and medical gas supply systems.

-

Sustainable & Recyclable

Sustainable & Recyclable

Want to know how Chalco aluminum tube coils can be adapted to your heat exchange system? Welcome to contact us for a one-on-one solution.

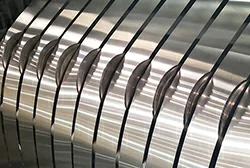

Instant QuoteSpecification Standards of Aluminum Tube Coil

| Outer diameter (O.D.) | 4.0 mm – 25.0 mm; commonly used 6.35 / 9.52 / 12.7 / 15.88 mm |

| Wall thickness (Thickness) | 0.4 mm – 2.5 mm |

| Wall thickness tolerance | ±0.05 mm |

| Ovality control (Ovality) | ≤ 0.5 mm; ensure winding and matching accuracy |

| Coil outer diameter (Coil O.D.) | 1000 – 1500 mm; can be customized according to packaging requirements |

| Coil inner diameter (Coil I.D.) | 500 – 800 mm; customized according to customer automatic winding equipment |

| Pilot hole inner diameter (Pilot Hole) | 130 – 140 mm |

| Max Coil Weight | 150 – 300 kg; can be customized |

| Packing form | Flat coil / fixed length straight tube |

| Optional status | O, H112 |

| Standard | ASTM B491 / B483 / B210 / EN 754 / EN 1396, etc. |

To obtain specific size matching advice, collaborative design solutions, or non-standard specification sample support, please feel free to contact us for Chalco's engineering customization solutions.

Instant QuoteProduct Categories of Aluminum Tube Coil

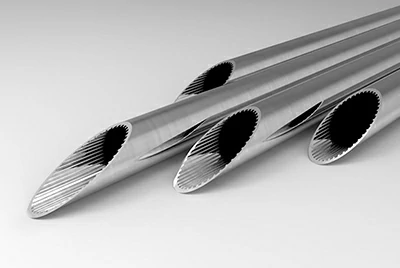

Formed by integral extrusion and then coiling, offering excellent sealing performance and pressure stability, widely used in refrigerant transportation, air conditioning systems, and other applications sensitive to weld seams. Compatible with pure aluminum and alloys such as 3003, supporting high cleanliness and custom diameter specifications.

Manufactured by the extrusion process and then coiled, suitable for cooling systems and hydraulic circuits requiring higher consistency and strength. Combines precision control and structural stability, making it a high-performance option in general industrial and HVAC piping systems. Standard: ASTM B491

Cold Drawn Aluminium Coil Tube

Enhanced dimensional accuracy and surface quality through multiple drawing processes, suitable for high-demand applications such as precision instruments, fluid control systems, and medical devices. Available in O/F temper, supplied in soft coil form.

Thin-Walled Aluminium Coil Tube

Aluminum tube coils with a wall thickness as low as 0.3mm, offering both lightweight and high flexibility advantages, widely used in medical equipment, fuel soft connections, oxygen systems, and other systems with strict bending radius and weight requirements.

O Temper Coil Tube

Made from annealed soft aluminum, possessing excellent bendability and formability, it is the most common supply state for coiled tubes. Particularly suitable for bending installation or space-constrained areas, facilitating automated cable routing or refrigerant circuit assembly.

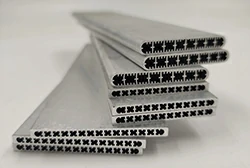

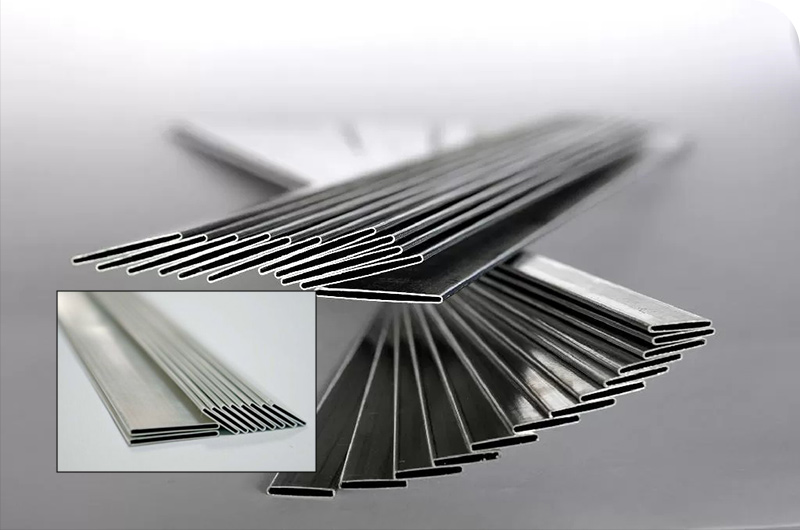

Aluminum Flat Coil Tube for Radiators

Aluminum flat tubes suitable for refrigeration systems, LED cooling modules, or heat dissipation parts of heat pumps, supplied in coil form in the annealed state. Commonly found in small cross-section oval/rectangular structures, offering good thermal conductivity and flexible arrangement capabilities.

Aluminium Copper Plating Coil Tube

Uniformly copper-plated on the surface of the aluminum base coil, combining the lightweight properties of aluminum with the thermal conductivity and weldability of copper, suitable for refrigeration units with high demands for condensation systems, electrical heat dissipation, and welded connections, making it a cost-effective alternative to copper tubes.

Pre-cut Coil Tube

Pre-cut aluminum tube coils with specifications ranging from 1 meter to 50 meters or longer are provided according to project requirements, facilitating construction deployment and on-site installation. Supports standard packaging coils, small batch sample coils, and customized cutting services.

Want to quickly find out which type is best for your application? Click the button below to let our engineers provide you with selection advice and sample solutions.

Instant QuoteAlloy Selection for Aluminum Tube Coil

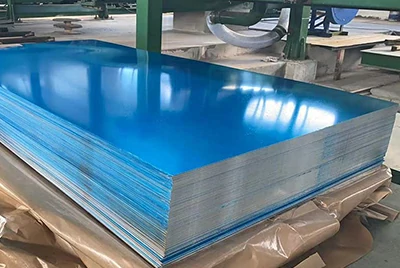

Aluminum tube coils are available in a wide range of alloys, from soft and easily formable pure aluminum to high-performance alloys with both strength and corrosion resistance, meeting diverse needs from household refrigeration to industrial heat transfer.

High purity (above 99%), possessing excellent ductility and formability; commonly used in refrigeration pipelines, water heaters, drinking water systems, condensers, and internal tubes of refrigerators in areas with high corrosion resistance requirements but low strength requirements.

Manganese is added to the 1100 base, boosting strength by about 20%, while maintaining good corrosion resistance and weldability. It's commonly used in industrial and HVAC systems, such as automotive oil cooler coils, refrigerant pipelines, heat pump circulation, and solar heat collection tubes.

Other Alloy Aluminum Tube Coils

-

1050 Aluminium Tube Coil

Possesses high thermal conductivity and excellent ductility, suitable for deep processing, commonly used in heat exchangers, air conditioning condenser coils, and liquid transfer systems.

-

1200 Aluminium Tube Coil

Combines high plasticity and oxidation resistance, commonly used in medical equipment piping, laboratory analysis systems, and electronic heat dissipation circuits.

-

1235 Aluminium Tube Coil

Soft and easy to coil, suitable for small-diameter refrigerant coils, precision refrigeration systems, and fixed-length prefabricated coils.

-

3103 Aluminium Tube Coil

Offers better structural support and forming capabilities than 3003, widely used in solar heat exchangers, HVAC systems, and light industrial installations.

-

Possesses excellent salt spray and corrosion resistance, suitable for marine air conditioning pipelines, coastal industrial installations, and chemical condensation systems.

-

Can be anodized with a high surface finish, suitable for architectural or electronic coils with high visual requirements or requiring spraying and anodizing.

Contact Chalco now to get the optimal aluminum tube coil alloy solution for your working environment, supporting customization based on drawings and bulk delivery.

Instant QuoteChalco Manufacturing Capabilities and Processing Technology for Aluminum Tube Coil

Chalco boasts an advanced integrated aluminum production system, supporting end-to-end manufacturing services for aluminum tube coils from smelting to precision processing, meeting the needs of HVAC, refrigeration, medical, automotive, and other industries:

Complete Manufacturing Process: Aluminum ingot casting → Extrusion forming → Continuous coiling and drawing → Surface treatment (anodizing/polishing/copper plating) → Precision cutting/punching;

Diversified Processing Services: Capable of complex custom processes such as bending, pre-forming, fixed-length cutting, automatic flaring, welded end caps, and welded interfaces;

Rich Surface Treatment Options:

- Anodizing: Enhances corrosion resistance and improves surface aesthetics;

- Polishing/Sandblasting: Improves surface finish and adhesion;

- Copper Plating: Used for electromagnetic/conductive requirements or specific visual effects;

- Other treatments such as degreasing, passivation, powder coating, and PVDF coating can also be customized according to project needs;

Intelligent Cleanliness Control: Equipped with a constant temperature coiling system, ultrasonic cleaning line, online eddy current flaw detection, and non-contact dimensional inspection;

Quality Assurance Testing: All aluminum coil tubes are pressure- or air-tightness-tested before delivery. High-pressure dry air or nitrogen is injected, and a pressure gauge monitors for leaks, ensuring reliable performance under high-pressure conditions.

Flexible Delivery Support: Supports bulk orders and rapid prototyping, with a minimum lead time of 5–7 days, and can provide coiling/fixed-length/ring packaging solutions according to project requirements.

For exclusive specification customization, structural optimization, or enhanced surface functionality services, please contact us for a tailored solution.

Instant Quote

Typical Application Scenarios of Aluminum Tube Coil

Due to its lightweight nature, high ductility, good thermal conductivity, and excellent corrosion resistance, aluminum tube coil plays a crucial role in various industrial systems. The following are the main application industries and typical uses:

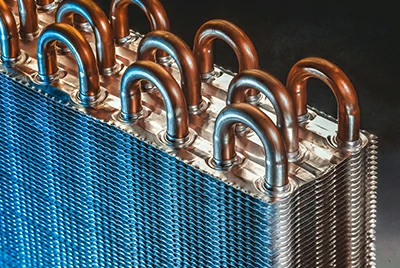

HVAC & Refrigeration

Aluminum tube coils are used in air conditioning, heat pumps, and dehumidifiers. Their lightweight and flexible design suit long-length laying and space adaptation in household and commercial refrigeration.

3003 O thin-walled aluminum tube coil

Anodized coil tube

Prefabricated refrigerant coil tube

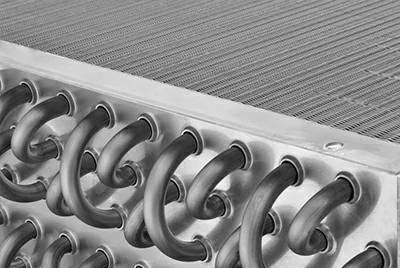

Automotive Thermal Management

Used in vehicle air conditioning, intercoolers, oil coolers, and battery cooling, aluminum tube coils balance lightweight design and structural need.

6063 pre-formed coil tube

Thin-walled aluminum tube coil for radiators

5052 copper-plated aluminum tube coil

Medical & Lab Equipment

Aluminum tube coils in oxygen concentrators, generators, and precision instruments are used for gas transport and heat exchange. Pure aluminum meets high cleanliness, corrosion resistance, and lightweight needs, replacing stainless steel capillary tubes.

1050 O seamless aluminum tube coil

Anodized capillary coil tube

Industrial Equipment & Fluid Systems

Aluminum tube coils provide stable circulation in heat exchangers, boilers, and hydraulic systems, thanks to consistent conductivity and corrosion resistance—widely used in machinery, energy, and automation.

3103 thick-walled aluminum tube coil

Cold-drawn seamless coil tube

Coated corrosion-resistant coil tube

Solar & Thermal Storage Cooling

In green energy systems like solar collectors and thermal modules, aluminum tube coils offer fast heat response, oxidation resistance, and flexible adaptation to flat plates and collector surfaces.

Anodized aluminum tube coil

Circular heat exchange coil tube

Appliances & Structural Use

Applied in refrigerator evaporators, gas ovens, heating circulation devices, decorative structural parts, etc., aluminum tube coil can be cut to fixed lengths and pre-bent according to requirements.

Colored aluminum tube coil

Decorative-grade anodized aluminum tube

Cold-bent coil tube

If you need samples of coil tubes specific to a certain industry or structural customization support, please [Click to Contact Us] to obtain technical information and quotation schemes.

Instant QuoteAluminum Solutions from Chalco for Thermal Management

Aluminum Heat Transfer Solutions

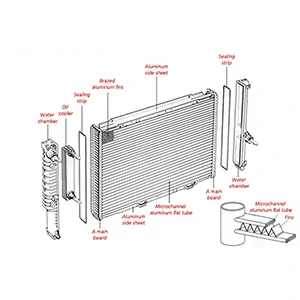

Chalco offers brazing clad materials, HFW tubes, header tubes, and stamping parts with a one-stop supply chain from casting to assembly, providing solutions in structure, cladding, and process design.

Contact us now

Micro-channel Aluminum Tubes

Aluminum Condenser Header Pipe

Inner Grooved Tube

Aluminum Capillary Tube

Aluminum Finned Tubes

Aluminum Tubes For Heat Exchangers

Aluminum Fin Stock

Aluminum Brazing Sheet

Brazing Aluminum Strip

For tailored solutions in thermal aluminum materials, contact the Chalco engineering team. We provide alloy design, structural optimization, and process integration to support your project needs.

Instant QuoteComparison Table of Aluminum vs. Copper vs. Copper-Plated Aluminum Tube Coil

| Project | Aluminum coils | Copper coils | Copper-plated aluminum coil |

| Material structure | Single-layer pure aluminum or aluminum alloy tubes | Single-layer copper | Aluminum substrate + copper coating (0.05-0.1mm) |

| Thermal conductivity | Good (about 200–235 W/m·K) | Excellent (about 390–400 W/m·K) | Close to copper, significantly better than bare aluminum |

| Weight | About 1/3 of copper | High density, heavy overall structure | Close to aluminum, taking into account both light weight and heat transfer performance |

| Material cost | Low, cost-effective | Expensive, price fluctuations | Medium, saving about 20-30% compared to copper |

| Processing performance | Strong ductility, easy to bend, roll, and expand | Moderate ductility, bending requires special equipment | Close to aluminum, the surface copper needs to pay attention to welding compatibility |

| Corrosion resistance | Need anodizing/galvanizing/coating treatment | Good corrosion resistance | Corrosion resistance under copper layer protection is better than bare aluminum |

| Appearance characteristics | Can be anodized, polished, good aesthetics | Natural luster, anti-oxidation | Combining copper appearance and aluminum light weight, suitable for high-end exposed systems |

| Application recommendation | Refrigeration transport, HVAC, solar energy, low-temperature pipelines | High-pressure condensers, HVAC systems, precision instruments | New energy thermal management, cooling system, corrosion resistance scenarios |

Considering thermal conductivity, corrosion resistance, and overall weight and cost, copper tubes are suitable for traditional systems with high demands for ultimate heat transfer and pressure resistance, while aluminum tube coils have become the mainstream choice due to their lightweight and cost advantages. Copper-plated aluminum tube coils, as a new type of composite material, combine the lightweight properties of aluminum with the heat transfer and corrosion resistance of copper, making them an ideal solution for cost-effective projects.

Whether you are pursuing ultimate performance or comprehensive cost optimization, Chalco can provide you with professionally customized aluminum tube coil solutions. Click the button below to get samples or technical drawings and communicate directly with our engineering consultants!

Instant QuoteFAQs

What customized parameters can your aluminum tube coils support?

Chalco supports comprehensive customization of aluminum tube coils, including outer diameter (Ø3.5mm–28mm), wall thickness (0.3–1.5mm), length (1–50 meters), number of turns, and coil inner diameter (coil diameter). Among these, the coil diameter can be precisely matched according to the customer's coiling equipment or automatic feeding system to ensure perfect compatibility with your process flow.

Do you provide seamless aluminum tube coils? What is the difference between seamless and welded tubes?

Yes, Chalco primarily provides seamless aluminum tube coils, integrally formed by extrusion or cold drawing processes, avoiding the risk of weld leakage and offering higher pressure resistance and service life. In comparison, welded coils, although slightly lower in cost, have insufficient stability in high-temperature, high-pressure, or corrosive environments.

Are aluminum tube coils prone to cracking during use?

All Chalco aluminum tube coils undergo multiple annealing and forming controls, possessing good bending performance and toughness, suitable for repeated winding, straightening, and flanging. Within the normal cold bending radius range, the coils will not exhibit stress cracks or fractures. For strict bending radius requirements, we can adjust the alloy temper and annealing parameters accordingly.

Can aluminum tube coils replace copper tube coils? How do they perform in actual use?

In most HVAC, heat pump systems, cold chain transportation, and general fluid transfer scenarios, aluminum tube coils are a cost-effective alternative. Although their heat transfer efficiency is slightly lower than that of copper tubes, their lightweight nature, low cost, and good corrosion resistance make them more advantageous in space optimization and large-scale piping.

However, for precision equipment requiring extremely high thermal conductivity, high pressure resistance, or long-term stability, such as large refrigeration compression systems and medical gas delivery systems, copper tubes still offer stronger adaptability.

Chalco also offers copper-plated aluminum tube coil solutions, combining the performance of both, for your evaluation and selection.

Can you provide aluminum tube coils with processing, such as punching, flaring, and cutting?

Of course. Chalco has complete secondary processing capabilities and can provide deep processing services such as cutting, punching, end capping, flaring, and bending according to drawings, and supports batch pre-assembled modular delivery, significantly reducing your process costs and production cycle.

Instant QuoteWhat are the surface treatment options for aluminum tube coils?

We can provide various surface treatments according to the application environment, including degreasing, anodizing, polishing, sandblasting, electrophoresis, PVDF coating, and surface copper plating, especially suitable for highly corrosive environments such as seaside, kitchens, and medical applications, extending the service life of the coils and enhancing their appearance.

Do you support small batch customization? What is the minimum order quantity?

Yes, we support a minimum order quantity as low as 100 meters and offer sample production services, with a lead time typically of 7–12 days. For regular specifications, we also maintain stock for rapid delivery.

Chalco is committed to providing customized, high-reliability Aluminum Tube Coil solutions for global customers, offering one-stop support from raw materials and extrusion to forming, surface treatment, and deep processing.

Welcome to click the button below to obtain technical information or a quick quotation, let us help you create lighter and more efficient heat exchange and piping systems.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote