Chalco conductive aluminum tubular bus pipe conforms to ASTM B241, ASTM B 317M-07, GB/27676-2011, GB/T 33228-2016, IS:5082, IS:2673 etc. standards. Hot selling alloy products include 1350, 1060, 1070, 3003, 3A21, 6061, 6063, 6101 and some others.

1060 1070 alloy has good conductivity, low temperature rise, and low loss. Its tubular conductive product is a new type of conductor that replaces traditional rectangular, groove and strip busbar, and is one of the key equipment in transmission and transformation systems.

Instant QuoteWhy choose Chalco 1060 1070 EC aluminum busbar

- Chalco aluminum conductive bus pipes are produced by using the technology of casting hollow core billet + three roll rolling + cold stretching. The products have uniform and stable mechanical and electrical properties in both length and cross-sectional directions;

- Chalco conductive aluminum tube products use independently developed rare earth and heat-resistant aluminum alloy materials, which have excellent processing, welding, conductivity, and heat resistance properties;

- To meet diverse application needs, Chalco offers custom fabrication services such as bending, welding, cutting, and hole-drilling, along with advanced surface treatments like tin plating, copper cladding, and nickel plating to enhance conductivity and corrosion resistance.

- Chalco conductive aluminum tubes are widely used in power engineering such as transmission and transformation stations, as well as in power equipment such as transformers, and have established cooperation with many well-known enterprises.

Specification of Chalco 1060 1070 EC aluminum tubular busbar

| Temper | H18 O |

| Outer diameter | Φ60mm-Φ450mm |

| Wall thickness | 3mm-15mm |

| Length | The length of a single bus pipe can reach 15 meters; deviation:+15~+25mm |

| Curvature | m/L<2.0mm |

| Size and Deviation | Click to view the [Size and Deviation Table] |

| Surface requirement | The surface is smooth and flat, without cracks, wrinkles, inclusions, deformation, or distortion. |

| Product requirement | The finished pipeline is completely straight; High dimensional accuracy and high tensile strength; Not prone to discharge and corona. |

| Profiles can be provided | Certificate of origin; Invoice and PL certified by Chamber of Commerce; Test certificate according to EN 10204 3.1; Other test reports that may be requested by the customer. |

Mechanical and electrical properties of Chalco 1060 1070 aluminum EC tubular bus bar

| Alloy | 1060 | 1070 |

| Temper | H18 | O |

| Tensile Strength MPa | ≥150 | ≤95 |

| Yield strength MPa | - | - |

| Elongation % | ≥8 | ≤30 |

| Thermal conductivity, (KrC xcm xs) | 0.5 | |

| Electrical Conductivity, IACS% | 60 | 61 |

| Temperature coefficient of electrical resistance, I/℃ | 0.0042 | |

| Electrical Resistivity ρ, Ω·mm2/m | 0.029 | 0.028264 |

| Poisson's Coefficient μ | 0.31 | |

Product detail of Chalco 1060 & 1070 Aluminum Conductive Bus Pipe

- 1060 Aluminum Bus Pipe

Known for its high aluminum purity (≥99.6%), 1060 aluminum offers excellent conductivity and corrosion resistance. It is widely used in electrical applications requiring good electrical performance with moderate mechanical strength.

- 1070 Aluminum Bus Pipe

With an even higher purity (≥99.7%), 1070 aluminum provides slightly better conductivity than 1060 and is ideal for environments demanding maximum electrical efficiency, such as substations and high-current equipment.

| Specification | 1060 Aluminum Bus Pipe | 1070 Aluminum Bus Pipe |

| Aluminum Purity | ≥ 99.6% | ≥ 99.7% |

| Conductivity (IACS) | ~60% | ~61% |

| Corrosion Resistance | Excellent | Excellent |

| Weldability | Good | Good |

| Mechanical Strength | Moderate | Slightly lower than 1060 |

| Application Suitability | Standard power transmission | High-efficiency power systems |

Purchase guide for 1060 & 1070 conductive aluminum bus pipes

Choosing the right conductive aluminum bus pipe depends on multiple factors such as conductivity requirements, installation environment, mechanical strength, and processing needs. This guide will help you compare 1060 and 1070 alloys and determine the most suitable option for your specific application.

Instant Quote- Choose 1060 when you need a cost-effective solution with reliable conductivity for general electrical systems or busbar frames.

- Choose 1070 when high conductivity is critical, such as for substations, jumpers, or large-scale grid connections.

- Consider additional factors such as required bending, surface treatment (e.g., tin plating), and corrosion environment when selecting the right alloy.

- For enhanced performance and durability, inquire about Chalco's custom fabrication and plating options.

Production and Processing Capability of Chalco 1060 & 1070 aluminum bus pipes

Chalco offers advanced production and precision processing capabilities to ensure high-quality, reliable 1060 & 1070 aluminum bus pipes for a wide range of electrical applications.

Instant QuoteHigh-Purity Alloy Casting: Chalco uses high-purity 1060 and 1070 aluminum alloy billets, cast using advanced degassing and filtration systems to ensure superior conductivity and material stability.

Seamless Extrusion & Cold Drawing: Our seamless extrusion and multi-pass cold drawing techniques deliver excellent dimensional accuracy, smooth surfaces, and consistent mechanical and electrical properties across the full length of the pipe.

Custom Machining & Fabrication: Chalco offers flexible processing options, including precision cutting, bending, punching, welding, and hole-drilling to match specific electrical layouts and project needs.

Surface Treatment Options: To enhance performance in harsh or corrosive environments, we provide tin plating, nickel plating, and copper cladding to improve conductivity and resistance.

Long-Length Production: Single pipe lengths up to 15 meters are available, reducing the number of connections and improving efficiency in high-voltage transmission systems.

Advantage of Chalco 1060 1070 aluminum conductive bus pipe

Chalco 1060 & 1070 aluminum conductive bus pipes offer exceptional electrical conductivity, reliability, and versatility, making them ideal for a variety of power transmission and equipment applications.

Instant QuoteAdvantages of tubular busbar

- The tubular conductor has a larger cross-sectional area, reduces the influence of Skin effect and resistance loss, and improves the transmission efficiency;

- Reduce Corona Inception Voltage;

- Can be customized and assembled through various methods such as connection, bending, welding, etc., to adapt to different circuit layouts and topological structures.

Advantage of 1060 1070 aluminum tubular busbar

- The internal grain structure is dense, with strong corrosion resistance;

- Not easy to freeze, strong disaster resistance, and long service life;

- Good convective heat dissipation conditions, strong conductivity, high load-bearing capacity;

- Low power loss, equivalent to 40% of rectangular busbars and cables;

- Excellent mechanical processing, welding, and heat resistance performance;

- The installation area is small, and the combined busbar is 1/3 of the installation area of soft conductors.

Chalco other aluminum tubular buspipe products

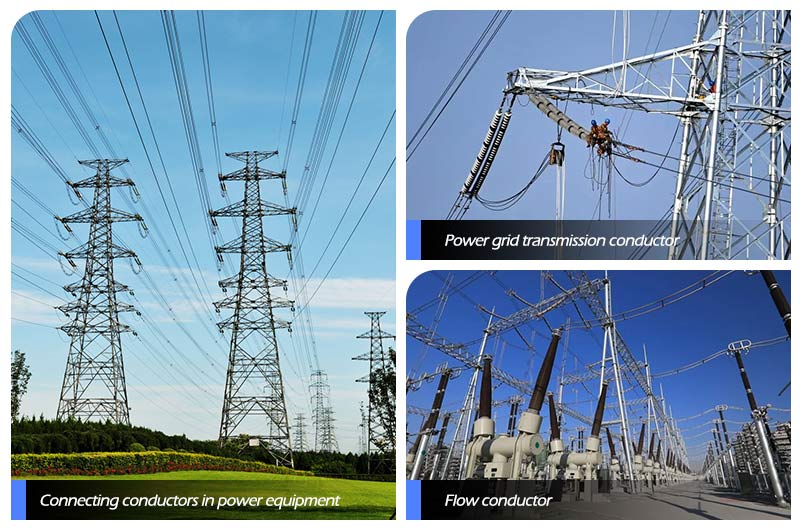

Cooperative field of Chalco 1060 1070 aluminum conductive tubular busbar

Tubular conductors are a new type of conductor that replaces traditional transmission conductors such as rectangular, slot shaped, strip busbar, and flexible conductors.

Used for 400KV, 220KV, 132 KV, and 33 KV switchyards, as well as for connecting large pivot twist substations such as 220KV, 500KV, 750KV, and 1000KV with multi circuit power grid lines and main transformers.

Instant QuoteChalco 1060 1070 conductive aluminum tubes are mainly used in the power industry in the following areas:

- Current conductors in power construction projects;

- The conductor connection between the power grid transmission conductor and the substation;

- Jumpers in transmission lines;

- Connecting conductors in power equipment

- High current DC ice melting device, etc.

More electrical aluminum products in Chalco

- EC Grade aluminum wire rod

- Conductive aluminum busbar

- Electrical aluminum tubular bus pipe

- Aluminum plate strip foil for capacitor

- Aluminum wire for electrical application

Size and deviation table of Chalco 1060 1070 aluminum tubular busbar

| Size table reference table | ||||

| SCH 40 Nominal size (in.) | Outside diameter of tube (in.) | Wall Thickness (in.) | Area (sq. in.) | Weight (lb/ft) |

| 1 | 1.315 | 0.133 | 0.4939 | 0.581 |

| 1.25 | 1.66 | 0.14 | 0.6685 | 0.786 |

| 1.5 | 1.9 | 0.145 | 0.7995 | 0.94 |

| 2 | 2.375 | 0.154 | 1.075 | 1.264 |

| 2.5 | 2.875 | 0.203 | 1.704 | 2.004 |

| 3 | 3.5 | 0.216 | 2.228 | 2.621 |

| 3.5 | 4 | 0.226 | 2.68 | 3.151 |

| 4 | 4.5 | 0.237 | 3.174 | 3.733 |

| 5 | 5.563 | 0.258 | 4.3 | 5.057 |

| 6 | 6.625 | 0.28 | 5.581 | 6.564 |

| 8 | 8.625 | 0.322 | 8.399 | 9.879 |

| SCH 80 Nominal size (in.) | Outside diameter of tube (in.) | Wall Thickness (in.) | Area (sq. in.) | Weight (lb/ft) |

| 1 | 1.315 | 0.179 | 0.6388 | 0.751 |

| 1.25 | 1.66 | 0.191 | 0.8815 | 1.037 |

| 1.5 | 1.9 | 0.2 | 1.068 | 1.256 |

| 2 | 2.375 | 0.218 | 1.477 | 1.737 |

| 2.5 | 2.875 | 0.276 | 2.254 | 2.65 |

| 3 | 3.5 | 0.3 | 3.016 | 3.547 |

| 3.5 | 4 | 0.318 | 3.678 | 4.326 |

| 4 | 4.5 | 0.337 | 4.407 | 5.183 |

| 5 | 5.563 | 0.375 | 6.112 | 7.188 |

| 6 | 6.625 | 0.432 | 8.405 | 9.884 |

| 8 | 8.625 | 0.5 | 12.763 | 15.009 |

| Wall thickness deviation | ||||||||

| Nominal wall thickness | 3-5 | >5 -8 | >8-10 | >10-12 | >12-15 | >15 -20 | ||

| Ordinary level | Average & nominal wall thickness | ±0.30 | ±0.50 | ±0.70 | ±0.9 | ±1.10 | ±1.3 | |

| Any & nominal wall thickness | H14 | ±0.40 | ±0.60 | ±0.90 | ±1.10 | ±1.3 | ±1.6 | |

| T5A, T6, T10 | ±12% of the specified wall thickness, maximum value is 1.90 | |||||||

| High precision level | Average & nominal wall thickness | ±0.15 | ±0.20 | ±0.38 | ±0.50 | ±0.70 | ±1.00 | |

| Any & nominal wall thickness | H14 | ±0.2 | ±0.3 | ±0.5 | ±0.76 | ±1.00 | ±1.4 | |

| T5A, T6, T10 | ±10% of the specified wall thickness, maximum value is 1.70 | |||||||

| Outer diameter deviation | |||

| Nominal OD | Ordinary level | ||

| Average & Nominal outer diameter | Any & Nominal outer diameter | ||

| H14 | T5A, T6, T10 | ||

| 50.00-80.00 | ±0.24 | ±0.30 | ±0.45 |

| > 80.00-120.00 | ±0.35 | ±0.40 | ±0.62 |

| >120.00-150.00 | ±0.45 | ±0.50 | ±0.75 |

| >150.00-200.00 | ±0.65 | ±0.7 | ±1.00 |

| >200.00-250.00 | ±0.77 | ± | ±1.2 |

| >250.00-300.00 | ±0.96 | ±1 | ±1.5 |

| >300.00-350.00 | ±1.3 | ±1.4 | ±1.8 |

| High precision level | |||

| Nominal OD | Average & Nominal outer diameter | Any & Nominal outer diameter | |

| H14 | T5A, T6, T10 | ||

| 50.00-80.00 | ±0.15 | ±0.15 | ±0.3 |

| > 80.00-120.00 | ±0.20 | ±0.20 | ±0.41 |

| >120.00-150.00 | ±0.25 | ±0.25 | ±0.5 |

| >150.00-200.00 | ±0.38 | ±0.38 | ±0.76 |

| >200.00-250.00 | ±0.50 | ±0.5 | ±1.00 |

| >250.00-300.00 | ±0.64 | ±0.64 | ±1.25 |

| >300.00-350.00 | ±0.9 | ±0.9 | ±1.6 |