The 7075 aluminum alloy wire, containing 1% to 8% zinc, along with magnesium, copper, and chromium, is prized for its high corrosion resistance, making it a popular choice in aviation and marine. Its superior quality makes it ideal for aircraft fuselage structures and critical components.

Chalco can produce 7075 AMS 4122 7075-T6 Cold finished aluminum wire, AMS 4124 7075-T7351 Cold finished aluminum wire, AMS 4186 7075-TFCold finished aluminum wire, AMS 4187 7075-0 Cold finished aluminum wire, customizable in size and quality, serving top aviation manufacturers like Collins Aerospace, Boeing, and Airbus.

7075 aluminum alloy wire specifications for aviation

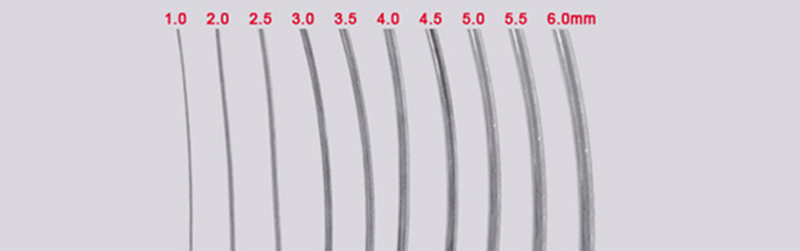

Diameter: 0.2mm-12mm

Length: can be coiled or fixed length.

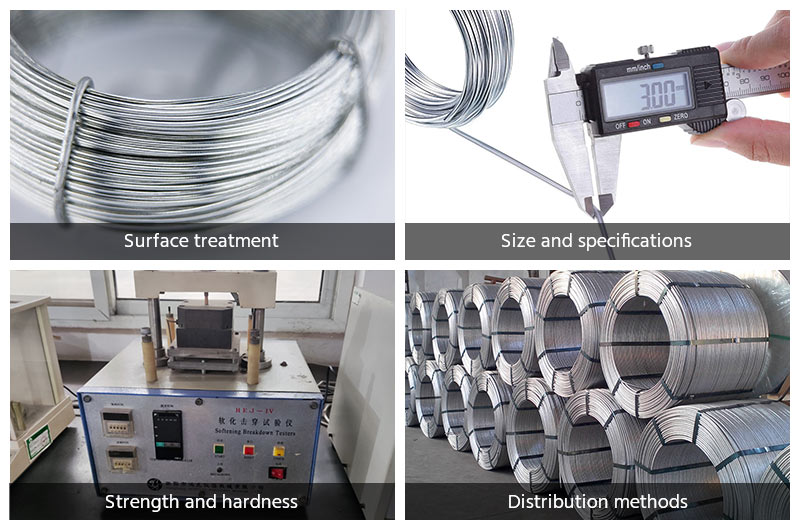

Surface treatment: anodizing, sandblasting or coating

The specific specifications can be determined according to customer requirements and specific requirements.

Contact us now

Chalco 7075 aerospace aluminum wire hot selling products

- 7075 T6 aluminum wire

- 7075 T7351 aluminum wire

- 7075 T652 aluminum wire

- 7075 H12/H14 aluminum wire

- ASTM B221 Aluminium 7075 Cold Rolled Wires

- 7075 aluminum wire in cold heading applications

In addition to the popular 7075 aluminum wire mentioned above, we also supply other hot-selling 7075 aluminum wire products:

- ASTM B211 Aluminum 7075 Wires,

- Aluminium Alloy 7075 Soft Wires,

- Aluminium Alloy 7075 Hard Wires,

- Aluminium 7075 Plated Wires,

- Aluminium 7075 Galvanised Wires,

- Aluminium 7075 Coil Wire/Continuous Coil Wire,

- Aluminium 7075 Wire Bobbin,

- Aluminium Alloy 7075 Industrial WiresAluminium

Equivalent name of 7075 aluminum wire

| STANDARD | UNS | EN | DIN | ISO | WNR |

| 7075 | A97075 | ENAW-AlZn5.5MgCu EN AW-7075 | AlZnMgCu1.5 | AlZn6MgCu | 3.4365 |

Chemical composition of 7075 aluminum alloy wire for aviation

| Chemical composition limits | |||||||||||

| Weight% | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other each | Others total |

| Alloy 7075 min | Rem | - | - | 1.2 | - | 2.1 | 0.18 | 5.1 | - | - | - |

| Alloy 7075 max | Rem | 0.4 | 0.5 | 2 | 0.3 | 2.9 | 0.28 | 6.1 | 0.2 | 0.05 | 0.15 |

Physical and Mechanical properties of 7075 aluminum alloy wire

| Physical properties | value |

| Density | 2.81 g/cm3 |

| Melting point | 477-635°C |

| Mechanical behavior | AMS 4122 7075-T6 cold-draw aluminum wire | AMS 4124 7075-T7351 cold-draw aluminum wire | AMS 4186 7075-TF cold-draw aluminum wire | AMS 4187 7075-0 cold-draw aluminum wire |

| Tensile strength | 524MPa | 572MPa | 572MPa | 331MPa |

| Yield strength | 455MPa | 503MPa | 503MPa | 228MPa |

| Elongation | 11% | 11% | 11% | 15% |

| hardness | 150HB | 150HB | 150HB | 87HB |

Standard Tolerances of 7075 aluminum wire

0.0625" - 0.144" dia +0.001"/- 0.0005" ( 1.6mm - 3.7mm dia + 0.025mm/-0.013mm)

0.145" - 0.167" dia +/- 0.001" (3.7mm - 4.2mm dia +/- 0.025mm)

0.168" - 0.500" dia + 0.002"/- 0.001 (4.3mm - 12.7mm dia + 0.5mm/ -0.025)

0.501" - 0.6875" dia + 0.003"/-0.01" (12.7mm-17.5mm dia + 0.076/ 0.025mm)

Tighter than standard tolerances are also available.

Typical finishes of aluminium cold heading wire

Anodizing Finish: An oxide-free surface suited for color anodizing or bright dipping, enhancing the part's luster and corrosion resistance.

Bright Finish: Resembling stainless or chrome, it enhances the cosmetic appeal of aluminum wire.

DNR Finish: Tailored for minimizing surface imperfections, effectively detecting and removing defects up to 1% of the finished diameter.

DOX Finish: A satin white finish perfect for heat-treated cold heading wire and rod, enhancing metal flow uniformity during heading.

MICRO Finish: A bright, lustrous finish for heat-treated wire, ideal for applications requiring close diameter tolerances and improved corrosion resistance.

Instant QuoteApplication of 7075 aluminum alloy wire for aviation

7075 aluminum wire is a very important material in the aviation industry. Its high strength, excellent rigidity and corrosion resistance make it widely used in aircraft manufacturing, Aircraft structure, Engine components, Spacecraft structure.

Instant Quote

Other hot selling aerospace aluminum wire products in Chalco

1100 aerospace aluminum wire

1050 aerospace aluminum wire

2014 aerospace aluminum wire

2024 aerospace aluminum wire

6061 aerospace aluminum wire

4047 aerospace aluminum wire

FAQ for purchasing 7075 aviation aluminum wire

Q1: How is the price of 7075 aviation aluminum alloy wire determined?

A: The price of 7075 aviation aluminum alloy wire is calculated based on factors including the LME ingot price, processing fees, weight, packaging costs, and transportation expenses. It can be influenced by market supply and demand, raw material prices, processing costs, specifications, and sizes. Different manufacturers and suppliers may have varying pricing strategies. Currency exchange rates and international economic conditions can also impact prices. For the best quotation and service, please contact Chalco aluminum.

Q2: How do I choose the right specifications and sizes for 7075 aluminum wire?

A: The selection of specifications and sizes for 7075 aluminum wire depends on your specific usage scenario and requirements, including wire diameter, length, straightness, and more.

Q3: What material certification should I look for when buying 7075 aluminum wire for aerospace applications?

A: Suppliers should provide material certification to ensure that the 7075 aluminum wire meets the relevant aerospace industry standards and requirements, such as AMS specifications.

Q4: How important is surface treatment for 7075 aluminum alloy, and how can I confirm if the supplier complies with standards?

A: Surface treatment is crucial for improving corrosion resistance and mechanical properties. When purchasing, confirm whether the supplier has performed the necessary surface treatment and complies with the relevant standards and requirements.

Q5: What quality assurance measures should suppliers provide for 7075 aluminum wire?

A: Suppliers should offer rigorous quality assurance measures, including test reports and quality control plans, to ensure that the quality and performance of the 7075 aluminum wire meet industry requirements.

Q6: How should I consider lead time, price, and the reputation of the supplier when buying 7075 aluminum wire?

A: When purchasing, evaluate the supplier's lead time and pricing, and compare these with other suppliers to ensure you receive the right price and delivery schedule. Additionally, confirm the reputation and qualifications of the supplier to guarantee the quality and reliability of the purchased 7075 aluminum wire and minimize potential risks.

Instant Quote

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote