Why is 6063 aluminum extrusion so popular?

In the fields of architectural decoration, rail transportation, electronic equipment housing and general industrial manufacturing, the material's machinability, surface treatment performance and corrosion resistance are crucial. 6063 aluminum extrusions have become one of the preferred materials in mid-to-high-end structural and decorative applications due to their excellent extrudability, good anodizing effect and balanced strength-to-weight ratio.

6063 aluminum alloy is a medium-strength grade among extrudable aluminum alloys, especially in the 6063-T5 and 6063-T6 states, with a tensile strength of about 205–245MPa. Although it is not as good as 6061 aluminum extrusion, its excellent surface treatment performance and corrosion resistance make it an ideal material for building door and window profiles, curtain walls, LED lamp housings, electric vehicle battery housings, etc. Its high cross-sectional accuracy makes it suitable for manufacturing special-shaped materials with complex cross-sections, combining beauty and practicality.

More importantly, 6063 aluminum alloy has low extrusion difficulty and good processing performance. It is easier to shape and more efficient during the extrusion process, and the subsequent surface treatment processes such as anodizing and electrophoretic coating are mature and stable, which greatly improves the appearance and durability of the product. This also makes 6063 aluminum extrusion more cost-effective in standardized production and mass customization, becoming the preferred choice of many suppliers and end customers.

Why Choose Chalco as your 6063 aluminum extrusion supplier?

As a world-leading aluminum profile manufacturer, Chalco is committed to providing customers with 6063 aluminum alloy extrusion products with stable performance and mature technology, widely serving mid-to-high-end application fields such as building structures, industrial profiles, electronic radiators, rail transportation, etc.

Strong production line support: The company has 98 production lines covering large-scale extrusion equipment from 5MN to 125MN, meeting the multi-specification customized production needs from ultra-thin-wall small profiles to complex hollow structural parts.

Mature process guarantee: Adopting optimized high-precision molds and stable temperature-controlled heat treatment technology to improve the surface quality, corrosion resistance and mechanical consistency of 6063 aluminum profiles.

Perfect quality inspection system: Each batch of products undergoes strict metallographic analysis, dimensional measurement, and mechanical property testing to ensure that the finished products meet the standards for architectural aluminum profiles (GB/T 5237), industrial materials (ASTM B221), etc.

Complete international qualifications: The products comply with QQ-A-200/9, AMS 4156, ASTM B210, ASTM B221, ASTM B241, ASTM B345, ASTM B429, ASTM B483, ASTM B491, EN 755-9 and other international standards, and can be widely used in doors, windows, curtain walls, radiators, high-speed rail carriages, marine structures, power systems and other industries.

If you are looking for 6063 aluminum extrusion profiles with mature technology, stable performance and support for customization, welcome to choose Chalco. We will provide you with professional advice, engineering support and efficient delivery.

Instant QuoteChalco 6063 aluminum extrusion product parameters

Temper: T4, T5, T6, T52

Extrusion tonnage: 600T-12500T extruder

Mould development: Support OEM and ODM services, and design exclusive moulds according to customer drawings or requirements

Deep processing capabilities: CNC processing/cutting/punching/inspection/tapping/drilling/milling, etc.

Surface treatment: polishing, anodizing, electrophoresis, powder coating, wood grain transfer, brushing, sandblasting, etc.

Optional colors: silver, champagne, bronze, gold, black, gray, coffee, sand, etc. Customized colors or acid-base anodized surfaces are also available

Product Types of 6063 Aluminum Extrusion

6063 standard solid extrusion profile

6063 standard solid extruded profiles have excellent extrudability and surface treatment properties and are widely used in architectural decoration, rail transportation and general industrial structures. With high cross-sectional precision and strong corrosion resistance, it is a medium-strength aluminum alloy solution that combines beauty and practicality. The following are common types:

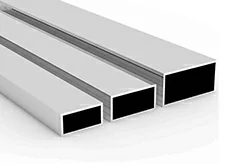

6063 hollow extrusion profile

6063 hollow extruded profiles have good forming properties and corrosion resistance, and are often used in applications with light structures but moderate strength requirements, such as doors and windows, curtain walls, and radiators. Its surface is easy to anodize, which can achieve a variety of decorative effects and protective functions.

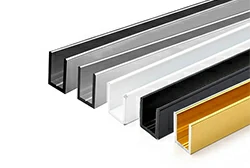

6063 standard extrusion parts

6063 standard extrusions such as Aluminum Angle, Aluminum T Bar and Aluminum U Channel are mainly used in basic structural applications such as support, frame structure and connection components. They have good strength and corrosion resistance and are suitable for building assembly, rack construction and light structural systems.

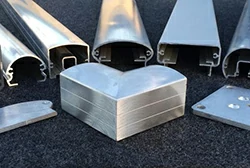

6063 Custom Extrusions

6063 custom extrusions refer to non-standard profiles made of 6063 aluminum alloy through special extrusion molds according to drawings or specific application requirements provided by customers. Compared with standard profiles, custom extrusions can achieve complex cross-sectional design, higher dimensional accuracy and functional integration. They are widely used in building curtain walls, rail transit, electrical housings, solar energy frames and other fields, combining decorative and structural performance.

Specifications: AMS 4156, ASTM B221, EN 755 / EN 12020, JIS H4100, ISO 6361

Common types

6063 aluminum extrusions for doors and windows

6063 Radiator

6063 Aluminum Guardrail

Still looking for suitable aluminum profiles? Chalco provides professional 6063 aluminum alloy custom extrusion services, supports OEM drawing development, and accurately meets your structural and performance requirements.

Instant Quote6063 t5 aluminum extrusion

6063-T5 aluminum extrusion profiles are artificially aged directly after extrusion molding. They have medium strength and good dimensional stability, and are suitable for construction, decoration and general structural applications. They have excellent surface quality and are very suitable for surface treatment processes such as anodizing and electrophoresis. They are widely used in scenes such as doors and windows, curtain walls, furniture and heat dissipation structures.

6063 t6 aluminum extrusion

6063-T6 aluminum extrusion profiles are first subjected to solution heat treatment after extrusion, and then artificial aging to obtain higher mechanical strength. Compared with T5 state, T6 has higher strength and stronger rigidity, and is suitable for industrial structural parts, electrical housings, mechanical frames and other fields with higher load-bearing capacity requirements.

6063 aluminum extrusion

6063 aluminum extrusion profiles for construction

6063 aluminum is widely used in modern building doors and windows, curtain wall systems and structural decorative components due to its good extrudability, excellent anodizing performance and medium strength. It has a delicate appearance and is easy to color, making it particularly suitable for facade decoration and functional structural parts.

Contact us now

Specification: ASTM B221, AMS 4156

Application:

- Building door and window frames

- Curtain wall system vertical frame beam

- Balcony guardrail

- Blinds & Shading Systems

- Stair handrail

- Decorative edging & exterior wall moldings

Case display:

Furniture and interior decoration

6063 aluminum profiles are smooth and beautiful, with strong corrosion resistance. They are very suitable for high-end furniture structures, office partitions, and mobile slides in smart home systems, and are lightweight, durable, and beautiful.

Contact us now

Specification: EN 755, ASTM B221

Application:

- High-end furniture frame

- Wardrobe Slides & Sliding Door Tracks

- Office partition profiles

- Smart curtain track

- Lamp cooling bracket

- Display racks & window frames

Case display:

Device Framework

6063-T5/T6 aluminum profiles are widely used in industrial frames, equipment brackets, assembly line structures and transmission systems due to their good strength-to-weight ratio and excellent machinability. They are particularly suitable for industrial occasions with high requirements on appearance and precision.

Contact us now

Application:

- Industrial aluminum profile frame system (aluminum alloy tooling)

- Automated conveyor line structure

- Hood support

- Electrical control cabinet bracket

- Equipment Support Base & Slide Rail System

Case display:

Transportation

6063 aluminum is often used in interior and exterior decoration and electrical installation parts of buses and subway cars due to its light weight and good formability. It takes into account both weight control and aesthetics, and is an ideal material for lightweight interior solutions.

Contact us now

Application:

- Interior trim border

- Ceiling profiles & light strip rails

- Door trim & window trim

- Subway seat frame

- Cable support system

Case display:

Lamp heat dissipation

The excellent heat dissipation capacity and beautiful surface treatment performance of 6063-T5 aluminum alloy make it one of the indispensable materials for LED lamp heat sinks and new energy photovoltaic support systems.

Contact us now

Application:

- LED lamp housing and cooling fins

- Photovoltaic solar support system

- Lighting structure frame

- Battery box bracket and frame

Case display:

Chalco's 6063 Aluminum Extrusion Customization Capabilities

As a leading supplier of 6063 aluminum extrusion profiles, Chalco not only provides high-quality aluminum alloy profiles that meet international standards, but also has advanced precision machining and surface treatment capabilities. We give full play to the excellent extrudability, good surface treatment performance and moderate strength advantages of 6063 aluminum alloy to provide one-stop solutions for industries such as building decoration, transportation, and electronics and electrical.

Strong 6063 aluminum profile production capacity

Chalco has multiple aluminum profile extrusion production lines ranging from 600T to 8800T, which can meet the diversified production needs from ultra-thin wall precision profiles to large-section structural profiles. They are widely used in architectural decoration, transportation, electronic equipment, furniture manufacturing and other industries.

- Extrudable wall thickness range: 0.5mm ~ 20mm

- Maximum length: up to 30 meters, support customized length

- Available alloy states: O, T4, T5, T6 and other standard heat treatment states

600T ~ 1600T extrusion line

Specially designed for the production of small-section, high-precision 6063 aluminum profiles:

- Application areas: LED lamp housings, electronic product frames, radiator profiles, furniture frames, small decorative profiles, etc.

- Features: high dimensional accuracy, precise wall thickness control, suitable for complex section design

1800T ~ 2800T extrusion line

For the manufacture of medium-section 6063 profiles:

- Application areas: Door, window and curtain wall systems, building guardrails, advertising frames, rail transit interior decoration parts, etc.

- Features: High molding efficiency, capable of processing multi-cavity and special-shaped structures

3000T ~ 8800T large extrusion line

Production of large-section, high-strength 6063 aluminum structural profiles:

- Application areas: large-scale sunshade systems, solar brackets, industrial aluminum frames, transportation infrastructure profiles, etc.

- Features: Supports the extrusion of thick-walled and long-size products, meeting the one-piece molding requirements of engineering structural parts

Precision machining capabilities

6063 aluminum alloy is widely used in a variety of industrial structures due to its excellent machinability and dimensional stability. Compared with high-strength aluminum alloys, 6063 is more suitable for high-efficiency, low-loss batch deep processing. Chalco has mature CNC machining technology, which can achieve high-efficiency and high-precision structural parts processing:

- CNC machining center: used for precision cutting of complex cross-section components and special-shaped parts, with an accuracy of up to ±0.0 1 mm

- Automatic cutting & punching system: suitable for rapid processing of batch industrial profiles and building components

- Tapping and milling linkage system: improve assembly accuracy and installation efficiency between components

- High-speed sawing equipment: the cutting surface is neat and tidy, meeting the aesthetic requirements of architectural decoration

Chalco's deep processing team can carry out customized production according to customer drawing requirements, including processing of special-shaped aluminum components, electrical housing structure design, assembly guides and profile connectors, etc.

Bending and forming capabilities

6063 aluminum alloy has good ductility and medium strength, and is particularly suitable for various forms of bending and forming processes. Chalco is equipped with a full-process aluminum profile bending system that can complete the flexible forming of components of multiple specifications.

- Cold bending: suitable for small or medium cross-section structural parts, such as window frame tracks, light box frames, furniture components, etc., with a small bending radius and consistent cross-section.

- Roll Forming: Suitable for large-span components such as curtain wall keels, sunshade systems, etc., with smooth curves and high forming accuracy

- Stretch Forming: used for components with high precision requirements such as bridge railings and traffic sign brackets to keep the surface free of creases

- Local hot bending: suitable for thick-walled profiles to ensure that the material does not crack at large bending angles

For components with complex structures or requiring a large radius of curvature, Chalco can perform pre-annealing or customize bending molds according to customer needs to ensure the final size and structural stability.

6063 aluminum extrusion profile excellent surface treatment

High surface finish, suitable for a variety of fine processing

6063 aluminum alloy has good fluidity and extrudability, and it is easier to form a profile section with clear edges and corners, uniform texture, and smooth surface during the extrusion process. This natural "good foundation" allows any subsequent surface treatment (anodizing, spraying, electrophoresis, etc.) to achieve better texture and visual effects.

Excellent anodizing performance, uniform color and strong weather resistance

6063 aluminum is one of the most suitable grades for anodizing among all aluminum alloys. Its metallographic structure and impurity content are well controlled, and it is not easy to produce black spots, color difference or peeling problems. The thickness of the anodic film is easy to control, with strong adhesion and high corrosion resistance.

The following are the anodized products that Chalco can provide:

Strong adaptability to electrophoretic coating and spraying, rich colors and good adhesion

In scenarios where high decorativeness or customized colors are required, 6063 aluminum profiles can be easily electrophoretically coated with clear coating or fluorocarbon/powder spraying. Due to its smooth metal surface and uniform structure, the coating is not easy to peel or fall off, showing:

- High adhesion

- UV aging resistance

- Strong resistance to salt spray corrosion

- Long service life of 15–25 years (suitable for outdoor use)

Surface processes such as wire drawing, polishing, wood grain transfer, etc.

6063 aluminum has good ductility and is suitable for complex decorative processes such as wire drawing, mirror polishing, wood grain transfer, ceramic spraying, etc. It is widely used in:

- High-end doors, windows and guardrails

- Furniture decorative borders

- Electrical appliances, lamps, heat dissipation housings

FAQ

What are the factors that affect the price of 6063 aluminum extrusions?

The price of 6063 aluminum extrusion profiles is affected by the following key factors:

- Fluctuations in raw material prices: The international market conditions of aluminum ingots (such as LME aluminum prices) directly affect the cost of finished products.

- Extrusion die costs: Customized cross-sections require mold making, which will incur mold making fees. The larger the order volume, the more the cost can be spread out. Some suppliers support annual purchase volume refunds.

- Extrusion difficulty and wall thickness: Complex cross-sections or ultra-thin walls have high requirements for extrusion equipment, increased process losses, and corresponding price increases.

- Surface treatment process: The cost of anodizing, electrophoresis, spraying and other treatment processes varies greatly. The cost of anodizing is low, while the cost of spraying and electrophoresis is slightly higher.

- Processing and deep processing requirements: such as drilling, tapping, slot milling, CNC processing, etc., processing fees will be calculated separately according to the complexity of the drawings.

- Purchase quantity: The larger the batch, the lower the unit price. There may be a minimum order quantity surcharge for small batches or proofs.

- Delivery time requirements: Expedited orders may involve insertion fees or overtime charges.

What is the minimum order quantity (MOQ) for 6063 aluminum extrusion?

The MOQ requirements for different types of products are as follows:

- Standard stock profiles (tubes, square tubes, angle aluminum, etc.): small batch purchases can be supported and shipped within 7 days at the earliest

- Standard mold products: MOQ is 500~1000kg, matching according to existing molds to save mold costs

- Customized profiles (moulding required): MOQ is 1 - 3 tons, customers with large quantities can enjoy a mould fee refund policy

What is the lead time for 6063 aluminum extrusion?

Delivery time varies depending on the order content:

- In stock products: Customs clearance and shipment within 7 working days

- Standard mold matching products: delivery within 15~20 days after mold confirmation

- Customized mold material: mold development + extrusion production takes about 25~30 days

Chalco has a complete international logistics system that supports multiple modes of transportation, including sea, air and land, and can flexibly respond to the needs of global customers.

What is the Difference Between 6063 and 6061 Aluminum Extrusion?

6063 has lower strength but excellent surface treatment performance, suitable for decorative profiles and door and window frames; 6061 has higher strength and is suitable for structural parts and industrial use. 6063 is easier to extrude into complex cross-sections, while 6061 focuses more on mechanical properties and comprehensive processing. For more information, please see 6061 vs 6063 Aluminum Extrusion.

Is 6063 aluminum extrusion suitable for welding?

6063 aluminum alloy has good welding performance and is suitable for conventional aluminum welding processes such as TIG welding and MIG welding. The weld strength after welding is relatively high and is suitable for use in building structures, door and window frames, assembly components and other fields.

Recommended welding method:

- TIG welding, MIG welding: suitable for standard thickness 6063 aluminum extrusions

- Screw connection and riveting: simple connection methods when the weld consistency is not required

- Laser welding and friction welding: used for industrial applications that require higher strength and aesthetics