Need a stronger, more reliable solution for your industrial framework?

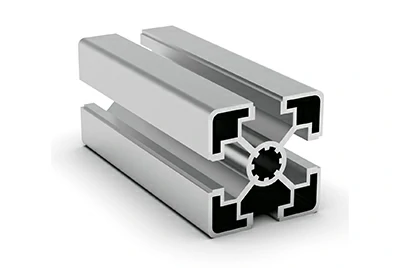

Our 15 Series Aluminum Extrusions deliver heavy-duty strength, full modular compatibility, and professionalfinish—engineered to support your toughest applications with ease.

15 series aluminum extrusion specifications

Standards: GB/T 5237, GB/T 6892, EN 755, EN 573, EN 12020-2, ASTM B210/B221M

Certifications: RoHS, REACH, ISO 9001, SGS/BV inspection

15 series aluminum extrusion product overview

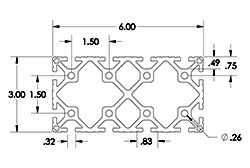

- Dimensions: 1.5" x 1.5", 1.5" x 3.0", 1.5" x 4.5", 3" x 3", 3" x 6", .75" x 1.5", .75" x 3"

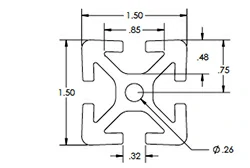

- T-slot: 0.32"

- Alloy: 6105-T5, 6063-T6, 6061

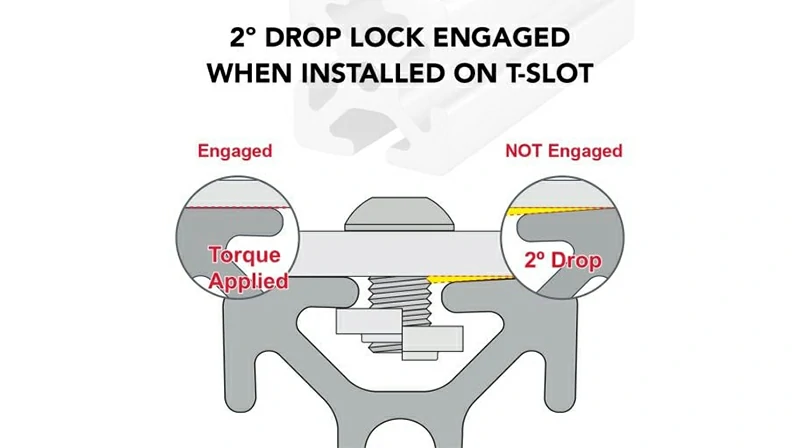

- Drop lock: 2°

- Finish: Anodized

- Color: Clear, black, silver, yellow

- Length: 1500mm – 6000mm or custom length

- Parco cut tolerance: ±0.015 in

- Available with pre-drilled holes and threaded ends

We know compatibility matters. That's why we ensure all our aluminum extrusions and hardware are fully compatiblewith other major suppliers.

Instant Quote

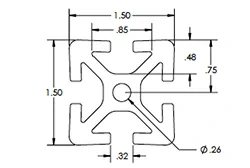

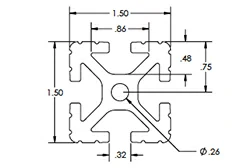

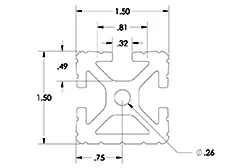

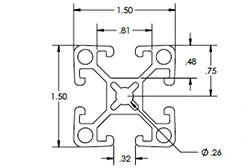

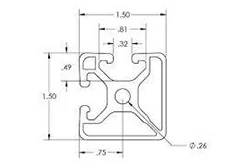

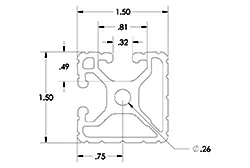

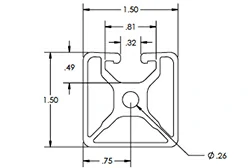

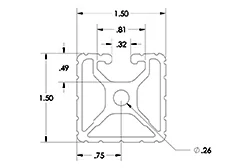

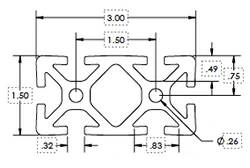

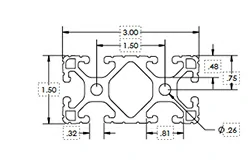

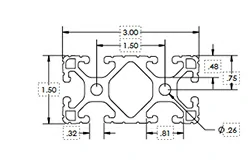

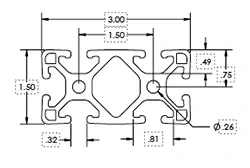

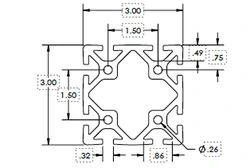

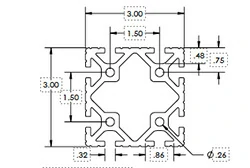

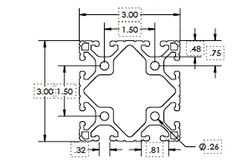

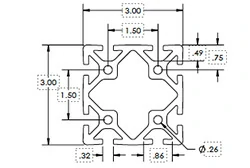

15 series aluminum extrusion dimensions

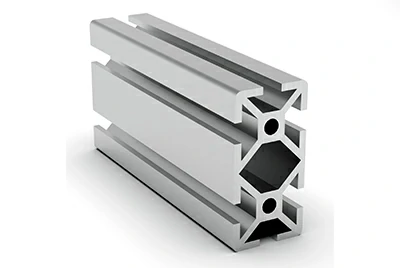

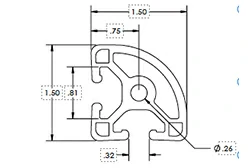

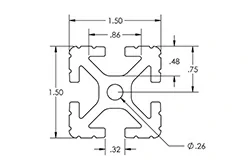

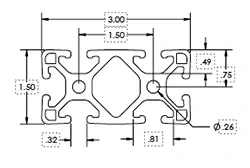

1.5" x 1.5" T-Slot Aluminum Extrusion

1.5" x 1.5" .32" Aluminum Extrusion

Black 1.5" x 1.5" .32" Aluminum Extrusion

1.5" x 1.5" Grooved .32" Aluminum Extrusion

Black 1.5" x 1.5"Light .32" Aluminum Extrusion

Yellow 1.5" x 1.5"Light .32" Aluminum Extrusion

1.5" x 1.5" .32" Aluminum Extrusion

1.5x1.5 Grooved 0.32" Aluminum Extrusion

1.5" x 1.5" VeryLight .32" Aluminum Extrusion

1.5" x 1.5" .32" Aluminum Extrusion

1.5x1.5 Lite Grooved 0.32" Aluminum Extrusion

1.5" x 1.5" .32" Aluminum Extrusion

1.5x1.5 Lite Grooved Black 0.32" Aluminum Extrusion

1.5" x 1.5" Quarter Round .32" Aluminum Extrusion

1.5x1.5 Lite Grooved 45 Degree 0.32" Aluminum Extrusion

1.5x1.5 Grooved Yellow 0.32" Aluminum Extrusion

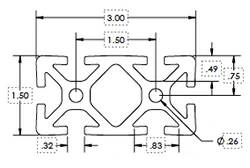

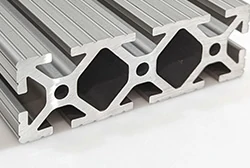

1.5" x 3.0" T-Slot Aluminum Extrusion

1.5" x 3" .32" Aluminum Extrusion

Black 1.5" x 3" .32" Aluminum Extrusion

1.5" x 3" Grooved .32" Aluminum Extrusion

Black 1.5" x 3"Light Grooved .32" Aluminum Extrusion

1.5" x 3"Light .32" Aluminum Extrusion

Black 1.5" x 3"Light .32" Aluminum Extrusion

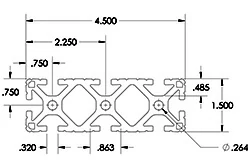

1.5" x 4.5" T-Slot Aluminum Extrusion

1.5" x 4.5" Grooved .32" Aluminum Extrusion

1.5 x 1.5 Lite Grooved Black 0.32" Aluminum Extrusion

1.5" x 4.5" .32" Aluminum Extrusion

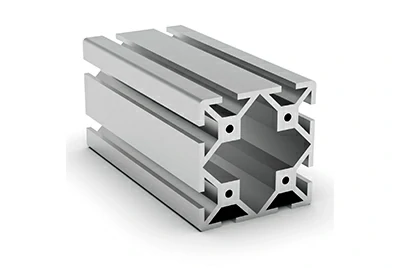

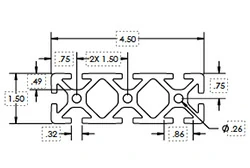

3" x 3" T-Slot Aluminum Extrusion

3" x 3" .32" Aluminum Extrusion

3" x 3" Grooved .32" Aluminum Extrusion

Black 3" x 3"Light Grooved .32" Aluminum Extrusion

Black 3" x 3" Black Anodize

Other size profiles

3" x 6" T-Slot Aluminum Extrusion

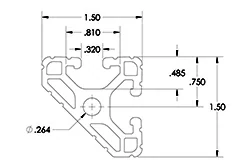

.75" x 1.5" T-Slot Aluminum Extrusion

.75" x 3" T-Slot Aluminum Extrusion

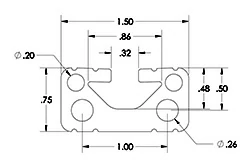

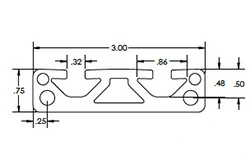

Aluminum extrusion accessories

As a full-service manufacturer, we can supply raw materials (parts and extrusions) as-is, as pre-machined kits readyfor assembly, or as fully assembled units according to your specifications.

Instant Quote

6-hole connector plate

6-hole slotted angle bracket

8-hole internal corner gusset

3-hole connector strip

Square triangle bracket

T-slot nut

T-slot swivel caster (100mm)

T-slot floor mounting base plate (3 inch)

Gray T-slot cover

As a full-service manufacturer, we can supply raw materials (parts and extrusions) in the following ways:

- Unmachined

- As kits, machined and prepared for assembly according to your specifications

- Or fully assembled by our team

Performance of 15 series aluminum extrusion

| Drop Lock | 2° |

| Moment of Inertia - IX | 0.2542"⁴ |

| Moment of Inertia - IY | 0.2542"⁴ |

| Surface Area | 1.152 Sq. In. |

| Yield Strength | 25,000 psi |

| Modulus of Elasticity | 10,000,000 Lbs. / Sq. In. |

| Weight lbs | 0.1123 per inch |

| Weight | 0.112300 |

Advantages of 15 series aluminum extrusion

Stronger and more robust

With a 1.5-inch profile size, 15 series offers higher load-bearing capacity—ideal for heavy-duty frames andindustrial automation systems.

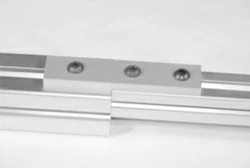

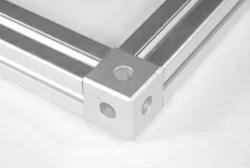

Larger T-slots for more secure connections

Supports bigger fasteners and accessories, providing improved rigidity and structural stability.

Versatile and widely compatible

Fully compatible with most 15 series connectors, joining plates, brackets, and panel mounts in both imperial andmetric systems.

Modular and easy to assemble

No welding needed—parts can be cut, joined, and adjusted on-site with basic tools, saving time and labor.

Ideal for large-scale structures

Perfect for workstations, machine frames, safety enclosures, and custom automation setups requiring both strengthand precision.

Durable surface finish

Typically anodized for corrosion resistance and a clean, professional look—suitable for industrial and commercialuse.

Applications of 15 series aluminum extrusion

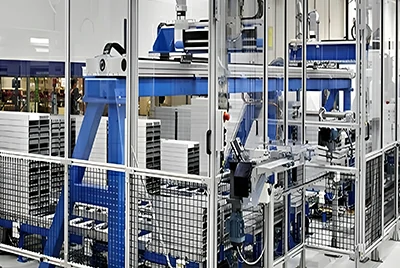

We provide product solutions for a wide range of applications in the medical, automotive, and manufacturingindustries—solutions that enhance productivity, optimize workflow, and ensure the safety of your valuable employees.

Our design team can assist you during the conceptual stage of your project and will provide quotations and CADdrawings for your review.

Instant QuoteHeavy-duty machine frames

Ideal for building strong, stable frames for industrial equipment and automation systems.

Contact us now

Workstations and assembly lines

Commonly used in manufacturing environments for adjustable workbenches and production setups.

Contact us nowLarge enclosures and safety guards

Provides structural support for protective enclosures around machines and robotic cells.

Contact us now

Conveyor systems

Used to build support frames and guide rails for heavy or long conveyor lines.

Contact us nowCustom industrial structures

Perfect for constructing modular structures like carts, racks, test rigs, and gantry systems.

Contact us now

Panel mounting and integration

Wide slots make it easy to install panels, doors, or wiring for control systems and cabinets.

Contact us nowSurface treatment of 15 series aluminum extrusion

Anodizing

Parts are machined, vibratory polished, and/or sanded as needed before entering the anodizing process.

Each step includes a visual inspection to ensure high quality and consistent surface finish.

You're not limited to natural or clear anodizing—we offer a full range of custom anodized colors to match yourspecific application needs.

Special coating services

Painting and powder coating are excellent alternatives to anodizing.

Chalco's special coating services allow you to integrate a variety of surface finishes into your project. Sincedifferent designs require different functions, we offer a full range of options to meet your needs:

- Powder coating

- Paint coating

- Sandblasting

- Chromate treatment

- Anodizing

- Oxidation

- Electroplating

- Galvanizing

Notes

In addition to anodized profiles, we also provide anodized connector strips, corner gussets, brackets, plates, andT-slot nuts.

Please note that if machining or cutting is required, some areas of the anodized profile may be exposed.

We're happy to assist you with any projects involving black anodized T-slot extrusions. If you can’t find whatyou’re looking for, feel free to contact us directly.

Instant QuoteCustom machining for 15 series aluminum extrusion

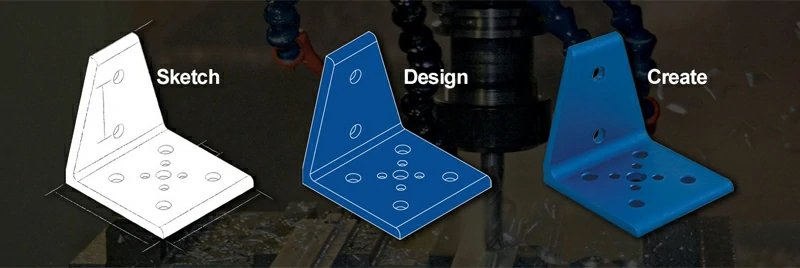

We offer a one-stop solution for your entire T-slot system—including custom parts, fittings, and accessories.

With over 200 stocked structural profiles, we can quickly manufacture your custom brackets or components.

No need to coordinate with multiple vendors—our advanced equipment handles both single parts and large productionruns efficiently.

Concept

Design

Complete

All hot selling products and sizes of Chalco T-slot

This is our hot-selling stock product, you can contact us for customization

10 Series Aluminum Extrusion

15 Series Aluminum Extrusion

45 Series Aluminum Extrusion

2020 2040 Aluminum Extrusion

3030 3060 Aluminum Extrusion

4040 4080 Aluminum Extrusion

Chalco service advantages

Compatibility and versatility

One of the key benefits of choosing Chalco T-slot aluminum profiles is their full compatibility with both imperialand metric systems from leading manufacturers.

Experienced team

Our deep industry knowledge ensures you get more than just products—you receive tailored solutions designedspecifically for your application needs.

Personalized attention

What sets Chalco apart is our commitment to one-on-one support throughout your entire project.

This level of service is especially valuable for complex or custom builds that require more than off-the-shelfcomponents.

Competitive pricing

Chalco offers highly competitive pricing, making us an ideal choice for customers looking to maximize value withoutcompromising on quality.

Professional and experienced team

Accuracy up to 0.005 inches

Quality guaranteed

Packaging, shipping, and trade support

Packaging

Each profile is wrapped with a protective film to prevent scratches, then packed with kraft paper or EPE foam.

Wooden crates or cartons can be added as needed. Custom logo packaging and accessory sorting are available.

Shipping options

We support ocean freight (FCL/LCL), air freight, and international express (such as DHL and FedEx).

Trade terms include FOB, CIF, DDU, and DDP to meet your logistics needs with fast dispatch.

Payment methods

We accept T/T (wire transfer), L/C (letter of credit), PayPal, and other flexible payment options.

What's the difference between 10 series and 15 series?

10 series extrusions are based on 1/2-inch and 1-inch dimensions.

The centerline is 1/2 inch from the edge, and the center-to-center spacing is 1 inch.

15 series extrusions are based on 3/4-inch and 1.5-inch dimensions.

The centerline is 3/4 inch from the edge, with a center-to-center spacing of 1.5 inches.