5059 Aluminum Plate is a high-magnesium marine-grade aluminum alloy that offers higher strength than 5083, with outstanding corrosion resistance and excellent weldability. It maintains high post-weld strength and performs reliably in long-term exposure to seawater and chemical environments. This alloy is widely used in ship hulls, decks, offshore platforms, armored vehicle protection, and chemical or fuel tanker trailers, making it an ideal choice for lightweight structural designs.

Chalco supplies 5059 aluminum plates in compliance with ASTM B209, ASTM B928, EN 573/EN 485, and MIL-DTL-46027 standards. Classification society 3.2 certificates (ABS, BV, LR, DNV, CCS) are available upon request. Comprehensive processing services—including cutting, welding, and surface finishing—are provided with lead times as short as two weeks.

→ View available stock and popular specifications

Product specifications and size range

| Category | Specification |

| Alloy | 5059 |

| Temper | O, H111, H116, H321, H131, H136 |

| Thickness Range | 1 – 200 mm (up to 500 mm upon request) |

| Width Range | 1000 – 2650 mm |

| Popular Dimensions | 1500 × 3000 mm, 2000 × 6000 mm, 2200 × 8000 mm (custom lengths up to 16 m) |

| Surface Finish | As-rolled, Sandblasted, Anodized, Protective Film Applied |

Chalco can customize cutting, welded assembly, and anodizing according to client drawings. Full documentation is provided, including EN 10204 3.1 Material Certificates and 3.2 Certificates from classification societies, ensuring complete batch traceability for every order.

→ Click to view technical parameters

Product Categories of 5059 Aluminum Plate

Marine-Grade 5059 Aluminum Plate

Temper:H116, H321

Thickness:3 – 50 mm

Features:Stabilized treatment ensures superior exfoliation corrosion resistance and high tensile strength, ideal for ship hulls, decks, and hatch covers operating under long-term seawater exposure.

Armor-Grade 5059 Aluminum Plate

Temper:H131, H136

Thickness:6 – 100 mm

Features:5059 - H131/H136 armor plates meet MIL-DTL-46027K and have passed ballistic V50 tests. The U.S. Army Research Laboratory (ARL-TR-4427) confirmed their superior ballistic and corrosion resistance over 5083.

Tanker-Grade 5059 Aluminum Plate

Temper:O, H111, H112

Thickness:1 – 10 mm

Features:Offers excellent formability and weldability, ideal for tanker shells and baffles. Its superior corrosion resistance and strength over 5083.

Compared with 5083, 5059 aluminum offers higher strength and more stable post-weld performance, allowing reduced plate thickness, lower weight, and increased payload capacity.

Why Choose 5059 Instead of 5083 or Steel?

5059 aluminum plate is an upgraded version of 5083, combining high strength, corrosion resistance, and superior weldability. It enables lighter structures, higher payloads, and extended service life without compromising safety.

- About 10% higher strength (depending on temper and thickness), allowing reduced plate thickness and weight

- Excellent corrosion resistance, ideal for long-term exposure to seawater and chemical environments

- High weld joint efficiency, minimizing rework and downtime

- Around 40% lighter than carbon steel, improving payload and lowering fuel consumption

- Lower lifecycle cost and higher recycling value

5059 vs 5083

| Dimension | 5059 Aluminum Plate | 5083 Aluminum Plate |

| Chemical Composition | Mg 5.0–6.0%, extremely low Cu, higher corrosion resistance | Mg 4.0–4.9%, slightly higher Cu |

| Tensile Strength (H116) | 370 – 440 MPa | 305 – 385 MPa |

| Yield Strength (H116) | ≥ 270 MPa | ≥ 215 MPa |

| Elongation | ≥ 10 % | ≥ 10 % |

| Weld Strength Retention | High — welded joints remain close to base metal strength | Moderate — slight strength loss after welding |

| Corrosion Resistance | Excellent — passed exfoliation corrosion tests; ideal for long-term seawater service | Good — suitable for general marine environment |

| Typical Applications | High-load ship hulls, armored vehicles, chemical tankers, LNG storage tanks | Conventional ship hulls, storage tanks, general structural components |

Overall performance comparison shows that 5059 aluminum plate surpasses 5083 in strength, weld integrity, and corrosion resistance—making it the ideal upgrade for lighter, stronger, and longer-lasting structures.

5059 Aluminum Plate – Technical Parameters

Chemical Composition

| Element | Content Range (wt%) |

| Silicon (Si) | ≤ 0.45 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.25 |

| Manganese (Mn) | 0.60 – 1.20 |

| Magnesium (Mg) | 5.0 – 6.0 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | 0.40 – 0.90 |

| Titanium (Ti) | ≤ 0.20 |

| Other Elements (Each) | ≤ 0.05 |

| Other Elements (Total) | ≤ 0.15 |

| Aluminum (Al) | Remainder |

Mechanical Properties

| ASTM B209 (General Engineering Tempers) | ||

| Property | O Temper | H111 Temper |

| Tensile Strength | ≥ 330 MPa (48 ksi) | ≥ 330 MPa (48 ksi) |

| Yield Strength (0.2%) | ≥ 160 MPa (23 ksi) | ≥ 160 MPa (23 ksi) |

| Elongation | 14 – 24 % (depending on thickness) | 17 – 24 % |

*ASTM B209 applies to general engineering use. O and H111 tempers provide excellent ductility, suitable for deep drawing, welded assemblies, and tank heads.

| ASTM B928 (Marine-Grade Tempers) | ||

| Property | H116 Temper | H321 Temper |

| Tensile Strength | 370 – 440 MPa (53.6 – 63.9 ksi) | 360 – 440 MPa (52.2 – 63.9 ksi) |

| Yield Strength (0.2%) | ≥ 270 MPa (39 ksi) | ≥ 260 MPa (38 ksi) |

| Elongation | ≥ 10 % | ≥ 10 % |

*ASTM B928 is specific to marine alloys. H116 and H321 tempers undergo stabilization treatment, offering excellent exfoliation corrosion resistance—ideal for hulls, decks, and pontoons operating in long-term seawater environments.

| MIL-DTL-46027 (Armor-Grade Tempers) | ||

| Property | H131 Temper | H136 Temper |

| Tensile Strength | 393 MPa (57 ksi) | 359 MPa (52 ksi) |

| Yield Strength (0.2%) | 296 MPa (43 ksi) | 290 MPa (42 ksi) |

| Elongation | 7 – 8 % | 7 – 10 % |

*H131 and H136 tempers meet MIL-DTL-46027 ballistic protection requirements and pass V50 testing, suitable for armored vehicle hulls, side walls, and blast-resistant containers, combining high protection with light weight.

5059 Aluminum Plate – Standards and Certifications

5059 aluminum plate strictly complies with international and industry standards, meeting the design and qualification requirements for marine, armor, and pressure vessel applications. Certification and documentation can be provided upon request.

Applicable Standards

- ASTM B209 – Standard specification for aluminum and aluminum-alloy sheet and plate

- ASTM B928/B928M – Specification for marine environment aluminum alloys (exfoliation corrosion resistance)

- EN 573 / EN 485 – European standards for chemical composition and mechanical properties

- ISO 12215-5 – Structural design requirements for marine hull materials

- MIL-DTL-46027 – Specification for aluminum armor plate for military vehicles

Certifications and Quality Assurance

- Classification society approvals: ABS, BV, LR, DNV, KR, NK, CCS (3.2 certificate available)

- Quality systems: ISO 9001, AS9100; EN 10204 3.1 material certificates provided

- Defense compliance: Ballistic test report (V50) and full batch traceability available

Chalco provides customized compliance solutions for project-specific standards and supports both class society verification and military inspection acceptance.

Typical Applications and Case Studies of 5059 Aluminum Plate

Marine and Offshore Engineering

5059 – H116/H321 is used for hulls, decks, hatches, and pontoons. It offers excellent exfoliation-corrosion resistance, allows reduced plate thickness, and minimizes maintenance costs.

Case Study: Royal Huisman 58 m sailing yacht "Ngoni” adopted Alustar® 5059 for high-load structural areas.

Defense and Armored Vehicles

5059 – H131/H136 meets MIL-DTL-46027, balancing ballistic protection and vehicle lightweighting. It is applied in hulls, sidewalls, and blast-resistant modules.

Case Study: The U.S. Army Research Laboratory (ARL-TR-4427) tested 5059-H131/H136 for ballistic performance, confirming superior protection over 5083 (alloy) and validating its use in lightweight armor systems.

Storage Tanks and Tanker Trailers

5059 aluminum provides higher strength and weld-joint integrity for tanker shells, heads, and baffles—achieving lightweight design and superior leakage resistance. It is used for fuel, chemical, and LNG transport tanks, often compared with 5083/5182/5454 alloys in high-performance projects.

Aerospace and Cryogenic Equipment

5059 offers excellent low-temperature toughness and stable weld performance, suitable for propellant tanks and structural test assemblies.

Case Study: NASA's Morpheus Lander project utilized welded 5059 aluminum hemispheres for its propellant tank (official NTRS documentation).

Production Capabilities & Processing Services

Chalco operates a fully integrated production line—from casting, hot rolling, cold rolling, and stretching to surface finishing—capable of supplying marine, armor, and tanker-grade wide plates and customized specifications.

- Advanced Equipment: 4500 mm SMS (Germany) hot rolling line and 2800 mm CVC cold rolling mill, both with closed-loop thickness and flatness control.

- Size Range: Width up to 2650 mm, thickness 1–250 mm; supports custom welded wide plates and extra-long sheets.

- Processing Services: One-stop laser cutting, waterjet cutting, friction stir welding, bending, sandblasting, and anodizing.

- Delivery Efficiency: Stock available for immediate order; samples within 5–7 days, bulk orders in 2–4 weeks, with expedited options available.

Chalco Advantages & Quality Assurance

Chalco provides end-to-end traceability and international certification support, ensuring your project passes audits and inspection smoothly.

- Quality Systems: Certified to ISO 9001, AS9100, and GJB 9001, covering aerospace, defense, and marine requirements.

- Comprehensive Certifications: EN 10204 3.1 MTC, ABS/BV/LR/DNV/CCS/KR/NK 3.2 certificates, and ballistic test reports available.

- Inventory & Flexibility: Extensive on-hand stock; supports small-batch trials, mixed-spec shipments, and global project supply.

- Technical Support: Welding parameter recommendations, material selection guidance, and drawing verification to reduce design and validation costs.

Procurement Guide

Pricing, MOQ & Lead Time

Pricing is quoted per sheet or kilogram, with trade terms including EXW / FOB / CIF / DDP. Submit alloy, temper, size, and quantity for a formal quotation (with validity and terms).

- Pricing Factors: Alloy/temper, dimensions/tolerances, surface finish, machining route (cutting/CNC), batch volume, and destination port.

- MOQ & Samples: Calculated by total order weight; mixed specifications supported; samples can include MTC and dimensional reports; cutting or custom sizing charged by process.

- Lead Time: Samples 5–7 days; bulk 2–4 weeks; expedited or partial delivery available upon confirmation of drawings or payment.

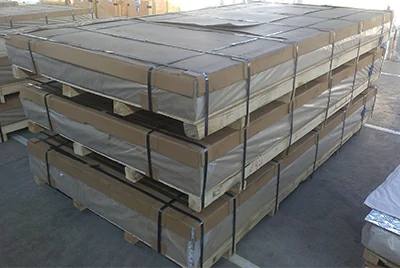

Packaging, Export & Logistics

- Packaging Structure: Inner layer with PE film or anti-rust paper + foam corner protectors; outer layer with non-fumigation pallets or plywood crates, strapped and wrapped for shipping.

- Export & Compliance: Each shipment includes MTC and inspection reports; optional COO, REACH/RoHS, and MSDS documents provided.

- Transport & Delivery: Supports sea, air, or rail; both LCL/FCL available; insurance and customs assistance offered.

- Identification & Traceability: Each package labeled with heat number, lot number, weight, and barcode; full traceability guaranteed. Claims accepted within 48 hours of receipt with evidence.

5059 Aluminum Plate – Stock List

| Alloy | Temper | Thickness | Width | Length | Weight (KG) | Piece |

| 5059 | H111 | 5.5 | 2000 | 6772 | 4340 | 22 |

| 5059 | H111 | 5.5 | 2000 | 7400 | 4305 | 20 |

| 5059 | H111 | 5.5 | 2000 | 7400 | 4315 | 20 |

| 5059 | H111 | 5.5 | 1400 | 7830 | 5245 | 33 |

| 5059 | H111 | 5.5 | 1400 | 7830 | 4450 | 28 |

| 5059 | H111 | 5.5 | 1400 | 7830 | 5085 | 32 |

| 5059 | H111 | 5.5 | 2000 | 7830 | 4295 | 19 |

| 5059 | H111 | 5.5 | 2000 | 7830 | 1355 | 6 |

| 5059 | H111 | 5.5 | 2000 | 7830 | 4320 | 19 |

| 5059 | H111 | 5.5 | 2000 | 7830 | 1360 | 6 |

| 5059 | H111 | 5.5 | 2000 | 6960 | 4420 | 22 |

| 5059 | H111 | 5.5 | 2000 | 6960 | 4045 | 20 |

FAQ (5059 Aluminum Plate)

1. What is the main difference between 5059 and 5083 aluminum plate?

5059 offers approximately 10% higher tensile and yield strength than 5083, with better weld strength retention and exfoliation corrosion resistance. It is ideal for marine hulls, armor, and tanker projects requiring higher durability, but dimensions and tolerances should always be verified against design specifications.

2. How is the weldability of 5059 aluminum plate?

5059 is well-suited for MIG/TIG welding, maintaining high post-weld strength. It is recommended to control heat input and use matching filler wires (ER5356 or ER5183). A stabilization treatment after welding ensures optimal joint performance.

3. Can 5059 aluminum be anodized or sandblasted?

Yes. The alloy produces a uniform surface finish suitable for ship decks, hatches, and decorative panels. For color-critical projects, a sample anodizing trial is recommended to confirm appearance consistency.

4. Which standards and certifications should be checked?

5059 aluminum typically meets ASTM B209, ASTM B928, and EN 573/EN 485. For armor applications, compliance with MIL-DTL-46027 is required. Marine projects must meet ABS, BV, LR, DNV, CCS, and other class society certifications. EN 10204 3.1 MTCs are available upon request.

5. How is the price calculated?

Pricing is based on per sheet or kilogram, with trade terms EXW / FOB / CIF / DDP. Final pricing depends on alloy, temper, size, tolerance, surface finish, machining (cutting/CNC machining), batch quantity, and destination port. Submit specifications for a formal quotation.

6. What are the MOQ and sample policies?

MOQ is calculated by total order quantity; mixed specifications are supported. Samples can include MTC and dimensional inspection reports. Custom cutting or sizing is charged per process, and small trial batches can be arranged to minimize production risk.

7. What are the lead time, packaging, and shipping documents?

Samples: 5–7 days | Bulk orders: 2–4 weeks, with expedited or partial shipments available.

Packaging uses anti-rust inner wrap + non-fumigation pallets, compliant with ISPM 15.

Each shipment includes MTC and dimensional reports, with optional COO, REACH/RoHS documentation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote