Flanged shafts, crankshafts and forged stepped shafts are widely used across multiple industries, including aerospace, automotive, energy, marine and defense, and so on. Other forged shaft shapes available include main shafts, round bars and hubs.

Chalco supplies forged shafts for aerospace, automotive, energy, marine and industrial applications. With a full range of alloys, rapid delivery and compliance with global standards, we help customers reduce lead times and secure reliable shaft solutions.

Forged shafts are engineered for exceptional strength, fatigue resistance, and long service life.

Our open-die forging process delivers superior grain structure and mechanical performance, while also enabling cost and material savings.

We provide aluminum forged shafts in common medium-to-large dimensions (up to 800 mm diameter and 6 m length), while much larger steel shafts (up to 84 in diameter, 39 ft length, and 77,000 lbs weight) can be supplied through custom production — please contact us for exact specifications.

- Production stages: rough forged, semi-machined, or fully finished shafts

- Materials: aluminum as primary supply; steel & alloy steels available on request

- Processes: open-die forging, step-shaft forging, precision machining

- Value-added services: CNC turning, boring, drilling, custom heat treatment

- Compliance with major international standards (ASTM, AMS, AISI, SAE) and OEM specifications (GE, Boeing, etc.)

- Aerospace, defense and military applications

- Automotive, motorsport, rail and heavy machinery

- Marine, shipbuilding & offshore equipment

- General industrial equipment and OEM solutions

- Oil & gas, petrochemical equipment

- Power generation and water treatment systems

- Free samples · 5% bulk discount · 24-hour quote response

Aluminum Forged Shafts

Chalco focuses on lightweight forged shafts with high strength-to-weight ratio and natural corrosion resistance. These products are widely applied in aerospace sub-shafts, motorsport drive shafts, UAV motor shafts, and lightweight machinery. Common aluminum alloys include:

- 6061 aluminum forging

- 6082 aluminum forging

- 7075 aluminum forging

- 2219 aluminum forging

- 2618 aluminum forging

- 7050 aluminum forging

-

Flanged Forged Shaft

Use cases: aerospace, marine, lightweight machinery

Features: one-piece flange, high joint integrity

Materials: 7075-T73, 7050-T7451, 6061-T6

QA: dimensional control, UT

-

Stepped Forged Shaft

Use cases: aviation hydraulics, compressors

Features: multi-diameter, bearing / seal seats

Materials: 6061-T6, 2024-T6, 7075-T73

QA: keyway / spline machining

-

Hollow Forged Shaft

Use cases: UAV drive shafts, lightweight motors

Features: weight reduction, hollow / deep-hole design

Materials: 6082-T6, 7050-T7451, 6061-T6

QA: UT on thin/thick sections

-

Lightweight Rotor Shaft

Use cases: UAV, drones, small electric motors

Features: lightweight, balanced, high RPM capable

Materials: 7075-T6, 2618-T6

QA: balancing, UT

-

Eccentric Forged Shaft

Use cases: automotive engines, lightweight machinery

Features: offset axis, lightweight variant

Materials: 6061-T6, 7075-T6

QA: concentricity control

-

Custom Lightweight Shaft

Use cases: UAV drive shafts, racing cars, lightweight machinery

Features: customized ends, holes, keyways, or special geometries

Materials: 6061-T6, 7075-T6, 2024-T6

QA: dimensional inspection, UT, fatigue testing

Other Forged Shafts

These heavy-duty shafts are typically forged in alloy steel, stainless steel or other special alloys. Material selection depends on application requirements — please contact our engineering team to discuss the best option for your project.

-

Main Forged Shaft

Use cases: turbines, compressors, large motors

Features: high load capacity, long service life

Materials: alloy steel / stainless steel (on request)

-

Mandrel Forged Shaft

Use cases: rolling mills, petrochemical equipment

Features: core shaft, withstands heavy torque

Materials: alloy steel (on request)

-

Gear Blank Forged Shaft

Use cases: gear trains, heavy transmissions

Features: integrated gear sections

Materials: alloy steel, stainless steel (on request)

-

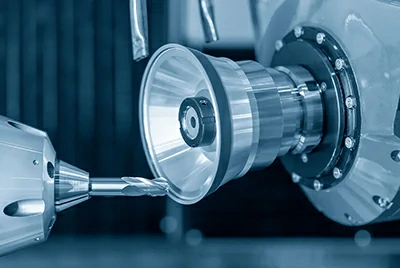

Spindle Forged Shaft

Use cases: machine tools, drilling rigs

Features: high precision, wear resistance

Materials: tool steel / alloy steel (on request)

-

Large Rotor Forged Shaft

Use cases: power plants, wind turbines

Features: large-diameter, high fatigue resistance

Materials: alloy steel (on request)

-

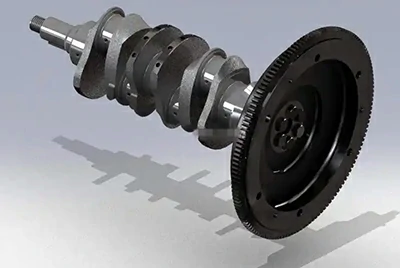

Forged Crankshaft

Use cases: automotive, marine engines, diesel compressors

Features: multi-journal, controlled grain flow

Materials: alloy steel / ductile iron

Why Choose Chalco – Forged Shaft Expertise & Manufacturing Capabilities

Chalco specializes in lightweight aluminum forged shafts with excellent strength-to-weight ratio, corrosion resistance, and precision CNC finishing. We provide end-to-end blank-to-finish supply with full traceability and compliance to international aerospace and industrial standards, making us a trusted forged shaft partner for critical applications.

- Material expertise: 2xxx / 6xxx / 7xxx aluminum alloys (main), with alloy steel & stainless options on request

- Forging capacity: open-die and die forging; stepped / hollow integrated; max weight ≤ 80,000 kg

- Heat treatment: T6 / T73 / T7451; quench & temper (Q&T); solution + aging

- Machining: CNC turning, deep-hole drilling, keyways, spline / gear cutting, balancing

- Tolerances: finish to ±0.05 mm; run-out & concentricity control

- Quality assurance: 100% Ultrasonic Testing (UT), hardness & mechanical tests, dimensional checks, CMM on request

- Compliance: ASTM / AMS / DIN / GB / ASME standards; SGS / TÜV / BV certifications

- Max size: OD up to 800 mm (aluminum); larger sizes available for steel shafts

- Delivery: on-time shipments; expedited prototypes & pilot runs; global sea/air freight

- Documentation: mill certs, heat-treat records, UT reports, CoC; full traceability

- Speed: 24-hour quotation response; fast engineering review of drawings

Chalco Forged Shaft Application Areas

Aluminum forged shafts play a key role in industries that demand lightweight, corrosion resistance and high strength-to-weight ratio. Steel and stainless-steel shafts are also available for heavy-duty projects where maximum load capacity is required.

Aerospace · Lightweight & High Reliability

Aluminum forged shafts play a vital role in aerospace, offering high strength-to-weight ratio, fatigue resistance, and stability under extreme conditions. Typical uses include flight-control linkages, hydraulic pump drives, and UAV motor shafts.

Contact us now

| Application | Supporting Products | Alloys | Features |

| Flight-control linkage | Hollow shaft | 7075-T73 | Lightweight, high fatigue resistance |

| Hydraulic pump drive | Stepped shaft | 2024-T6 | Stable under vibration |

Related: precision rings · structural blocks · stepped bars.

Automotive · Precision & Durability

Forged aluminum shafts reduce vehicle weight while maintaining high torque capacity. They are widely used in motorsport drive shafts, EV powertrain components, and steering systems.

Contact us now

| Application | Supporting Products | Alloys | Features |

| Motorsport drive shaft | Crankshaft | 6082-T6 | High torque, reduced weight |

| EV powertrain | Transmission shaft | 6061-T6 | Corrosion resistance, machinability |

Related: blocks · thick forged plates · bars · tubes.

Defense · Strength & Reliability

Defense applications demand forged shafts with extreme durability and reliability. Typical applications include naval propulsion, missile launch systems, and armored vehicle drivetrains.

Contact us now

| Application | Supporting Products | Alloys | Features |

| Naval propulsion | Main shaft | 7075-T651 | High strength, seawater resistance |

| Armored drivetrain | Stepped shaft | 2219-T6 | Excellent toughness |

Related: precision hollow shafts · thick forged plates · blocks · high-integrity rings.

Rail & Marine · Heavy-Duty Performance

In rail and marine industries, forged aluminum shafts are used in large-scale propulsion and heavy-duty machinery, balancing corrosion resistance with structural reliability.

Contact us now

| Application | Supporting Products | Alloys | Features |

| Ship propeller shaft | Main shaft | 5083-O | Corrosion resistance, weldability |

| Rail traction system | Stepped shaft | 6061-T651 | High load capacity |

Related: long hollow shafts · bearing rings · precision blocks · corrosion-resistant plates.

Energy & Heavy Industry · High Load & Durability

Energy and heavy industries require shafts capable of withstanding extreme loads and long service life. Forged aluminum shafts are applied in turbines, power generation, and industrial presses.

Contact us now

| Application | Supporting Products | Alloys | Features |

| Gas turbine | Crankshaft | 2618-T6 | High temperature resistance |

| Industrial press | Stepped shaft | 7050-T7451 | Excellent load bearing |

Knowledge Center & FAQs About Purchasing Forged Shafts

What Is the Forging Process for Aluminum Shafts?

Aluminum forged shafts are produced by free or die forging, refining the grain flow and improving density, fatigue life, and load-bearing performance—far superior to shafts machined only from rolled bars.

- Forming: free forging / die forging (solid, hollow, stepped, flanged)

- Heat treatment: T6 / T651 / T73 / T7451, solution + aging, annealing

- Machining: CNC turning, deep-hole drilling, spline/gear cutting, balancing

- NDT & testing: Ultrasonic Testing (UT), mechanical, hardness, dimensional checks

- Documentation: mill certs, UT reports, CoC, full traceability

This process ensures stable properties and reliability for aerospace, automotive, energy and heavy equipment projects.

How Do Forged Shafts Compare with Machined Shafts?

Forged shafts deliver superior grain flow, higher density, and greater fatigue strength—ideal for high-speed and heavy-duty parts. Machined shafts from rolled bars are more suitable for medium or non-critical applications.

Can You Manufacture Custom Shaft Designs?

Yes—we produce stepped, hollow, flanged, eccentric and rotor shafts directly from customer drawings, with material and heat-treatment recommendations to meet performance targets.

Which Aluminum Alloys Are Commonly Used?

Typical alloys include 2024, 6061, 6082, 7075, and 7050. Heat treatment options cover T6 / T651 / T73 / T7451 depending on strength, fatigue, and corrosion requirements.

Do You Provide Testing and Certification?

Yes—we provide UT, mechanical, hardness, and dimensional testing with full reports. Third-party certifications (SGS, TÜV, BV) are available, and deliveries comply with AMS / ASTM / GB / DIN / ASME.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote