Copper-to-copper brazing is widely used in HVAC refrigeration systems, electrical connections, home appliances, and copper piping assemblies. For copper-to-copper joints, phosphorus copper (BCuP) alloys are the standard brazing materials, offering reliable wetting, strong joints, and good thermal and electrical conductivity.

Chalco supplies copper-to-copper brazing rods based on phos-copper (BCuP) alloys, with selected grades containing silver to improve toughness and corrosion resistance. These products are designed to balance joint performance, process stability, and cost efficiency across different application requirements.

- Simple process: Most BCuP alloys are self-fluxing on copper, eliminating the need for additional flux and improving brazing efficiency.

- Stable joint performance: Brazed joints offer good pressure resistance, sealing performance, and maintain copper's electrical and thermal conductivity.

- Flexible alloy options: From silver-free grades for cost-sensitive projects to silver-bearing alloys for higher performance requirements.

With a complete BCuP alloy series, Chalco enables flexible selection between cost and performance to match specific copper-to-copper brazing applications.

Chalco Copper-to-Copper Brazing Rod Product Series (BCuP Alloys)

Chalco offers a complete range of copper-to-copper brazing rods based on phos-copper (BCuP) alloys, covering silver-free grades for cost-sensitive applications and silver-bearing grades for higher joint strength and durability. Different BCuP alloy series are designed to match the performance, process, and service requirements of HVAC refrigeration, electrical connections, appliance piping, and industrial copper systems.

BCuP-2 – Phos-Copper Brazing Alloy (Silver-Free)

-

Contains phosphorus and is silver-free, providing self-fluxing behavior on copper and requiring no additional flux for copper-to-copper brazing.

Offers the lowest material cost with good fluidity, making it suitable for large-volume, standard copper brazing applications. Not suitable for use on steel or nickel alloys, as phosphorus may cause joint embrittlement.

Typical applications: HVAC refrigeration copper tubing, heat exchangers, and household appliance copper piping.

Technical Specifications:

| Alloy grade (AWS) | ISO | Ingredients (wt%) | Melting point range (°C) | Recommended brazing temperature (°C) |

| BCuP-2 | CuP 181 | Cu + 6.8–7.2% P | 710–793 | 740–790 |

BCuP-3 / BCuP-6 – Phos-Copper-Silver Brazing Alloys (Low Silver)

-

Containing approximately 2–5% silver added to the phosphorus copper base, these alloys provide improved fluidity compared to silver-free BCuP grades.

The addition of silver improves joint toughness and corrosion resistance, enhancing overall brazed joint reliability. Suitable for applications involving low to moderate vibration or where certain fatigue resistance is required.

Typical applications: appliance piping, copper valves, and copper assemblies operating under low to moderate vibration conditions.

Technical Specifications:

| Alloy grade (AWS) | ISO | Ingredients (wt%) | Melting point range (°C) | Recommended brazing temperature (°C) |

| BCuP-3 | CuP 281 | Cu + 5.8–6.2% P + 4.8–5.2% Ag | 645–815 | 680–740 |

| BCuP-6 | CuP 280 | Cu + 7% P + 2% Ag | 643–788 | 670–720 |

BCuP-4 – Phos-Copper-Silver Brazing Alloy (Medium Silver)

-

Containing approximately 6% silver in a phosphorus copper base, this alloy provides improved wettability and produces denser, more reliable brazed joints.

Compared with low-silver BCuP grades, BCuP-4 offers enhanced joint durability and service reliability.

It represents a balanced solution between cost and performance, making it a versatile option for general-purpose copper-to-copper brazing applications.

Typical applications: refrigeration equipment, electrical contacts, and copper piping systems for potable water.

Technical Specifications:

| Alloy grade (AWS) | ISO | Ingredients (wt%) | Melting point range (°C) | Recommended brazing temperature (°C) |

| BCuP-4 | CuP 283 | Cu + 7% P + 6% Ag | 643–724 | 680–720 |

BCuP-5 – Phos-Copper-Silver Brazing Alloy (High Silver)

-

Containing approximately 5% phosphorus and up to 15% silver, this alloy provides excellent wettability and joint integrity for demanding copper-to-copper brazing applications.

Brazed joints exhibit high toughness and fatigue resistance, making BCuP-5 suitable for applications subjected to strong vibration, mechanical stress, and pressure.

Although material cost is relatively high, BCuP-5 is commonly selected for critical components where joint reliability and service performance are priorities.

Typical applications: motor coils, aerospace electrical systems, and copper-to-copper connections operating under strong vibration and high-pressure conditions.

Technical Specifications:

| Alloy grade (AWS) | ISO | Ingredients (wt%) | Melting point range (°C) | Recommended brazing temperature (°C) |

| BCuP-5 | CuP 284 | Cu + 5% P + 15% Ag | 645–800 | 670–720 |

Chalco's copper-to-copper brazing electrode series, ranging from the economical BCuP-2 to the high-performance BCuP-5, covers all major applications including HVAC, home appliances, electrical systems, and industrial systems. In addition to these alloys, Chalco also provides a wide range of other brazing rods and brazing consumables to support different welding processes, which you can explore in the product list below.

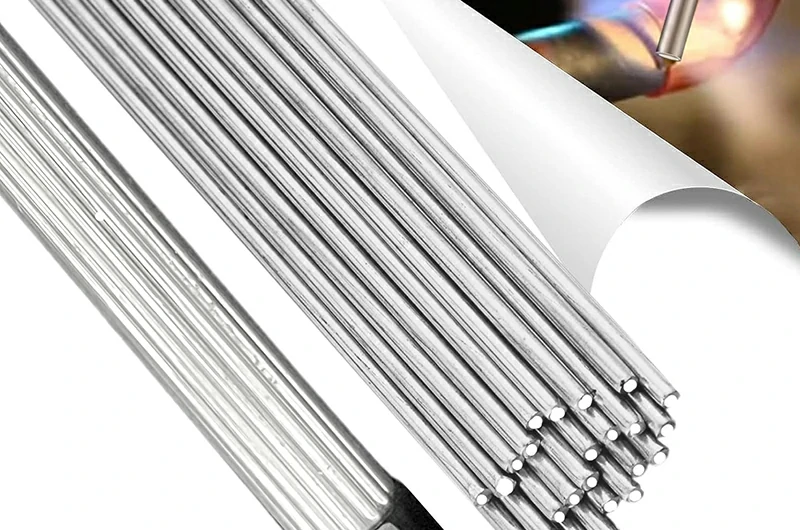

Aluminum Brazing Rod

Flux-core Aluminum Brazing Rod

Aluminum Stick Welding Rod

Silver Brazing Solder Rod

Copper Brazing Rod

Brazing Ring Preforms

Copper-to-Copper Brazing Rod Applications and Alloy Selection

Chalco copper-to-copper brazing rods are widely used in HVAC refrigeration, electrical power systems, and drinking water and gas piping. By selecting appropriate BCuP alloy grades, from economical silver-free to high-performance silver-bearing types, an effective balance between cost, joint reliability, and service performance can be achieved.

HVAC & Refrigeration Systems

Copper-to-copper brazing rods are extensively used for joining copper tubes in air conditioners, condensers, evaporators, and heat exchangers. These applications require brazed joints with high airtightness and pressure resistance to ensure long-term, stable system operation.

Recommended alloys:

BCuP-2 → Economical silver-free option suitable for large-volume, standard copper tube connections.

BCuP-3 → Low-silver alloy offering improved joint durability and corrosion resistance for higher-reliability refrigeration systems.

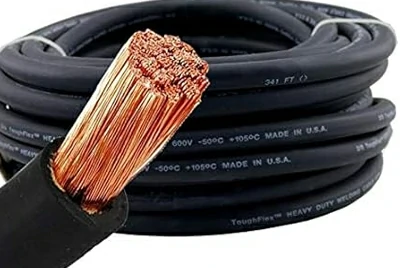

Electrical and Power Systems

High conductivity and contact reliability are critical in copper busbars, electrical contacts, coil terminals, and other current-carrying joints. Copper-to-copper brazing rods help maintain low electrical resistance and stable conductivity over long service periods.

Recommended alloys:

BCuP-4 → Medium-silver alloy providing dense, reliable brazed joints for electrical contacts and busbar connections.

BCuP-5 → High-silver alloy with excellent fatigue resistance, suitable for demanding applications such as motors and aerospace electrical systems.

Piping and Gas Distribution

Drinking water, gas, and industrial piping systems require safe, sealed, and corrosion-resistant joints. Copper-to-copper brazing rods offer reliable leak resistance and long-term joint stability in these applications.

Recommended alloys:

BCuP-3 → Balanced-performance option suitable for general piping installations and residential systems.

BCuP-4 → Medium-silver alloy producing denser brazed joints for high-standard drinking water and gas pipeline systems.

From standard copper piping in refrigeration systems to high-reliability electrical connections and sealed joints for drinking water and gas pipelines, Chalco provides a complete range of copper-to-copper brazing rod solutions. Alloy selection support, technical guidance, and sample availability are available upon request.

Process Guidelines and Operating Recommendations for Copper-to-Copper Brazing Rods

Although copper-to-copper brazing is relatively straightforward, achieving consistent, high-quality brazed joints still requires proper process control and operating practices. The following guidelines summarize key considerations for using phos-copper (BCuP) brazing rods.

Heating Method

- Flame brazing: Use a neutral or slightly reducing flame to heat the copper components evenly until the brazing filler metal becomes bright and flows smoothly into the joint.

- Induction brazing: A typical heating rate of approximately 20–40 ℃/s is recommended, with a short holding time of 2–3 seconds after filler metal penetration to avoid overheating.

- Furnace brazing: Maintain uniform heating within the recommended temperature range, suitable for batch production of copper tube and copper component assemblies.

Brazing Gap

- A recommended joint clearance of 0.03–0.08 mm ensures sufficient capillary action for proper filler metal flow.

- Excessive joint gaps may reduce joint strength, while insufficient clearance can hinder wetting and filler metal penetration.

Surface Preparation

- Remove oil, grease, and oxide films before brazing to ensure clean copper surfaces.

- Mechanical polishing or appropriate chemical cleaning methods can be used to improve wettability and joint consistency.

Heating and Cooling

- During heating, avoid applying the heat source directly to the brazing rod; the base copper material should be heated first to promote proper capillary flow.

- After brazing, natural cooling is recommended. Rapid or forced cooling should be avoided to reduce the risk of joint cracking or residual stress.

Common Defects and Solutions

| Defect Type | Possible Causes | Recommended Solutions |

| Pores | Surface contamination or excessively rapid heating | Improve surface cleaning and control the heating rate |

| Incomplete penetration | Insufficient heating or excessive joint clearance | Adjust heating method and optimize joint gap |

| Embrittlement | Use on steel or nickel-based materials (phosphorus embrittlement) | Restrict use to copper-to-copper or compatible copper alloy applications |

| Overheating | Excessive temperature or concentrated heat input | Ensure even heating and avoid prolonged exposure to high temperatures |

FAQ – Copper to Copper Brazing Rod Selection and Purchasing

Q1: Is flux always unnecessary for copper-to-copper brazing?

Most phosphorus copper alloys (such as BCuP-2 through BCuP-5) exhibit self-fluxing behavior when used for copper-to-copper brazing, eliminating the need for additional flux in most applications. However, when brazing copper alloys or components with heavy surface oxidation, the use of flux is recommended to improve wetting and joint consistency.

Q2: How should I choose between silver-free and silver-bearing brazing rods?

- Silver-free grades (e.g., BCuP-2): Lower material cost, suitable for large-volume brazing of standard copper piping.

- Silver-bearing grades (e.g., BCuP-3 / BCuP-4 / BCuP-5 / BCuP-6): Improved joint toughness, corrosion resistance, and fatigue performance, recommended for vibration, thermal cycling, or higher-reliability applications.

Q3: Can copper-to-copper brazing rods be used for copper-to-brass or copper-to-steel joints?

Not recommended. Phosphorus-containing brazing alloys can cause embrittlement when used on iron- or nickel-based materials. For copper-to-brass, copper-to-steel, or copper-to-aluminum joints, appropriate alternative brazing alloys should be selected based on material compatibility.

Q4: How does copper-to-copper brazing compare with other brazing methods?

- Compared with copper-to-aluminum brazing: Copper-to-copper brazing offers a simpler process, stronger self-fluxing behavior, and lower overall process cost.

- Compared with silver brazing (BAG series): Phos-copper brazing rods are well suited for mass copper pipe assembly, while silver brazing alloys are typically selected for dissimilar metals and critical structural components.

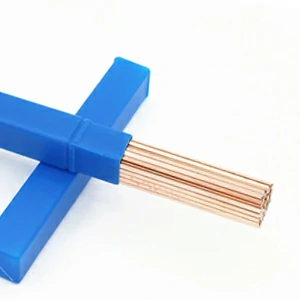

Chalco Copper to Copper Brazing Rod Supply and Specifications

Chalco provides a complete range of copper-to-copper brazing rods based on BCuP alloy systems, supporting diverse operating conditions and project requirements.

Applicable standards: Manufactured in accordance with international standards such as AWS A5.8 and ISO 3677, with full material certification available.

Available sizes: Diameter range from 1.5 mm to 6.0 mm; custom dimensions available upon request.

Supply forms: Straight rods, coiled rods, cored types, and coated types.

Packaging: Small packages, coils, cartons, or export-grade wooden crates to ensure safe transportation.

Delivery and service: Common specifications are available from stock. Fast delivery, sample support, and OEM customization services are supported.

Looking for a reliable copper-to-copper brazing rod supplier?

With a complete BCuP alloy series ranging from silver-free to high-silver grades, Chalco supports efficient and reliable copper-to-copper brazing for HVAC, electrical, and industrial piping applications.

Contact us for technical selection support, quotations, or sample requests.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote