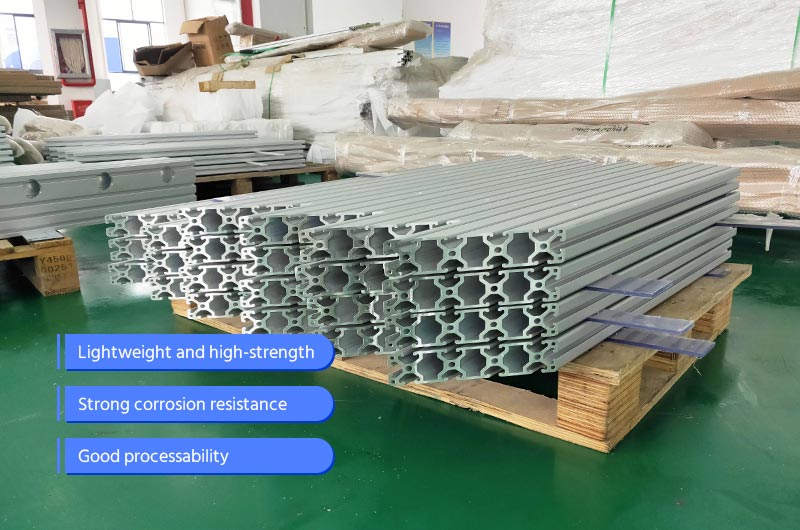

Chalco's 6063 Aluminum Flat Bar is a premier extrusion grade alloy. With roughly half the strength of 6061, it excels in extrudability, offering a superior surface finish and outstanding anodizing results. Its excellent corrosion resistance makes it ideal for architectural, decorative, and electrical applications.

Click below to view detailed specifications and properties of 6063 Aluminum Flat Bar ↓

Chalco maintains a substantial in-stock inventory of 6063 flat bar for immediate availability and fast delivery. Our ASTM B221 compliant products are ready to meet your project's demands promptly.

[Click to download 6063 aluminum flat bar stock.pdf]

Hot selling size table of 6063 T52 aluminum flat bar

| Details | Weight (lbs/ft) |

| 1/16" x 1" 6063 T52 Aluminum Flat Bar - Extrusion | 0.073 |

| 1/8" x 1/2" 6063 T52 Aluminum Flat Bar - Extrusion | 0.073 |

| 1/8" x 1" 6063 T52 Aluminum Flat Bar - Extrusion | 0.146 |

| 1/8" x 2" 6063 T52 Aluminum Flat Bar - Extrusion | 0.292 |

| 1/8" x 4" 6063 T52 Aluminum Flat Bar - Extrusion | 0.583 |

| 3/16" x 1" 6063 T52 Aluminum Flat Bar - Extrusion | 0.219 |

| 3/16" x 2" 6063 T52 Aluminum Flat Bar - Extrusion | 0.437 |

| 1/4" x 1" 6063 T52 Aluminum Flat Bar - Extrusion | 0.292 |

| 1/4" x 3" 6063 T52 Aluminum Flat Bar - Extrusion | 0.875 |

| 1/4" x 6" 6063 T52 Aluminum Flat Bar - Extrusion | 1.749 |

| 3/8" x 1" 6063 T52 Aluminum Flat Bar - Extrusion | 0.437 |

| 3/8" x 2" 6063 T52 Aluminum Flat Bar - Extrusion | 0.875 |

| 1/2" x 1" 6063 T52 Aluminum Flat Bar - Extrusion | 0.583 |

| 1/2" x 2" 6063 T52 Aluminum Flat Bar - Extrusion | 1.166 |

Chalco 6063 aluminum flat bar specifications

| Name | 6063 aluminum flat bar |

| Temper | T5,T52 |

| Equivalent name | A96063,3.32206,AlMgSi0.5,EN AW 6063,AA6063 |

| 6061 aluminum flat bar thickness | 0.2"-7.8"(5-200mm) |

| 6061 aluminum flat bar width | 0.32"-9.8"(8-250mm) |

| 6061 aluminum flat bar length | Max 6m, Fix & Cut Length or Customized |

| Surface treatment | Tin plating, anodizing, click to view detailed surface treatment |

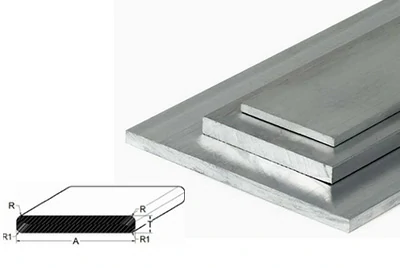

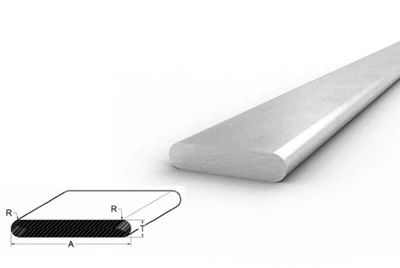

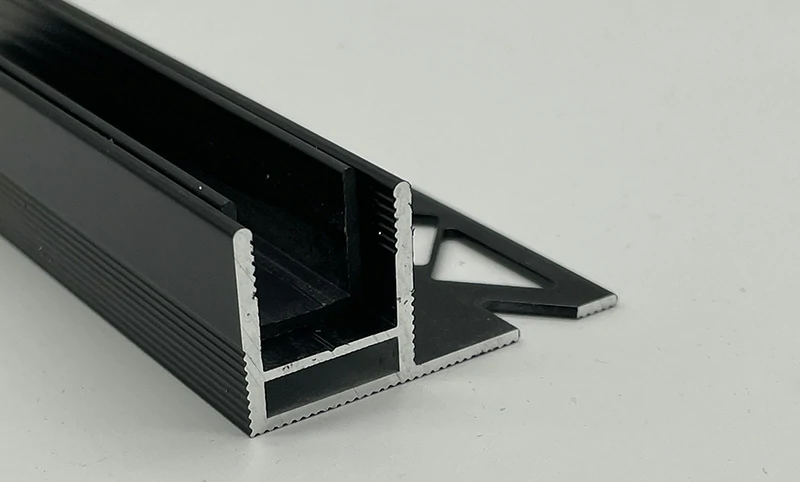

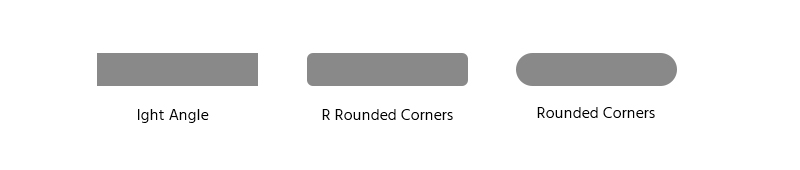

| Edge processing | Right angle, rounded corner, R rounded corner |

| Production Process | Extruded,Aluminum plate sawing |

| Package | Refer to detailed packaging requirements |

| standard | ASTM B221,AMS-QQ-A-200/8 |

Product Types of 6063 Aluminum Flat Bars

6063 Aluminum Flat Bar - Extruded

Manufactured through high-precision extrusion, this 6063 aluminum flat bar boasts excellent dimensional stability and a superior surface finish. Its exceptional formability allows for complex profiles, making it ideal for architectural and decorative applications requiring aesthetic appeal.

6063 Aluminum Flat Bar - Cold Finish

Produced using precise cold-working techniques, this 6063 flat bar features tighter dimensional tolerances and an even finer surface finish. Its enhanced machinability and bright appearance make it suitable for precision components and visible architectural elements.

6063 Aluminum Flat Bar - Flat Ends

These 6063 flat bars are either directly extruded or precision-cut, featuring sharp, square ends without a corner radius. They are ideal for applications demanding tight dimensional tolerances, such as precision assembly, structural support, and where a clean, defined edge is critical for aesthetics.

6063 Aluminum Flat Bar - Radius Ends

Featuring a rounded corner profile, this 6063 bar type effectively reduces stress concentration and enhances fatigue resistance. It is widely utilized in applications where a smoother edge is desired, or parts are subjected to cyclic loads and require improved stress distribution.

6063 Aluminum Flat Bar: Tempers and Performance Characteristics

Chalco offers various tempers for 6063 aluminum flat bars, meeting diverse requirements for strength, hardness, and formability. These tempers (such as T5, T52, T6) are achieved through specific heat treatment and cooling processes, significantly influencing the material's final mechanical properties and processing characteristics. Choosing the right temper is crucial to ensure optimal performance in specific architectural, decorative, or electrical applications.

-

6063 T5 Aluminum Flat Bar

Achieved by controlled cooling after extrusion and artificial aging, T5 temper provides 6063 aluminum flat bar with good strength and dimensional stability for general extrusion applications.

-

6063 T52 Aluminum Flat Bar

A specific variant of T52 temper results from stricter cooling rate control after extrusion. This optimizes 6063 aluminum flat bar's performance, offering a more consistent balance of strength and ductility for specific uses.

-

6063 T6 Aluminum Flat Bar

Obtained via solution heat treatment and artificial aging, T6 temper gives 6063 aluminum flat bar its highest strength. It's ideal for applications demanding maximum structural integrity while leveraging 6063's good formability.

| 6063-T5 | 6063-T52 | 6063-T6 | |

| Tensile Strength | 140-180 MPa | 140-180 MPa | 210-240 MPa |

| Shear Strength | 120 MPa | 100 MPa | 150 MPa |

| Elastic Modulus | 68 GPa | 68 GPa | 68 GPa |

| Brinell Hardness | 60 | 60 | 73 |

| Elongation at Break | 11% | 8% | 11% |

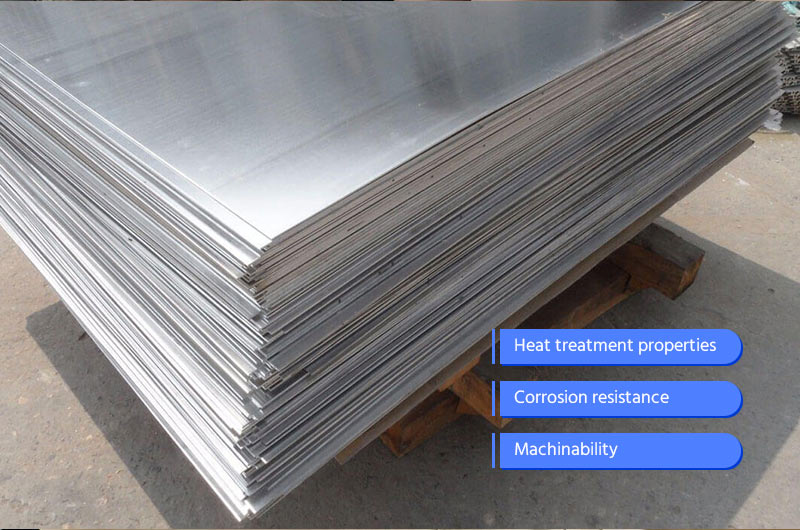

What are the characteristics of 6063 Aluminum Flat Bar?

- Good machinability

- Good formability

- Good electrical conductivity

- Excellent corrosion resistance

- Excellent surface quality

- Relatively lower strength-to-weight ratio

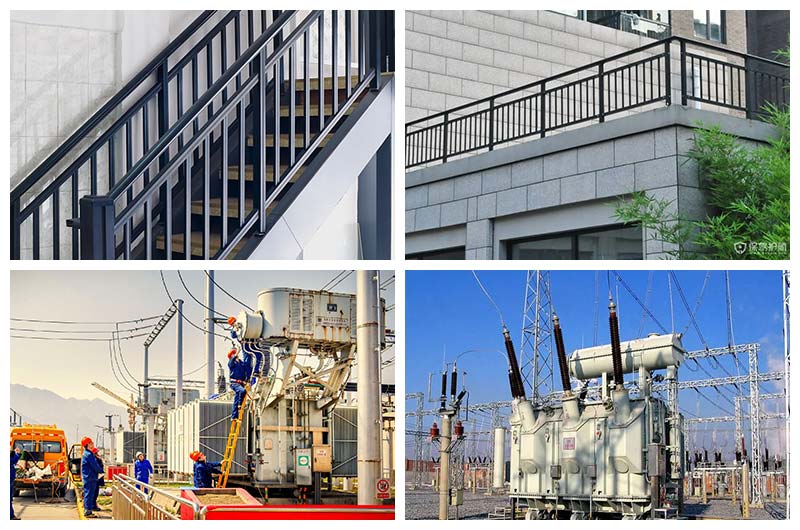

What are the best application areas for 6063 Aluminum Flat Bar?

- Construction Industry: Often used in construction and decorative applications, such as decorative work, screens, grilles, and details.

- Electrical Applications: Due to its conductivity, it can be utilized in electrical applications, such as T5, T52, and T6 electrical applications.

Other 6063 products you may be interested in

6063 aluminum plate

6063 aluminum bar

6063 aluminum tube

6063 EC aluminum busbar

6063 aluminum slug

6063 aerospace profile

6063 aluminum u channel

6063 aluminum angle

6063 aluminum t bar

Surface Treatment Options for 6063 Aluminum Flat Bars

Chalco provides various surface treatment options for 6063 aluminum flat bars, enhancing their aesthetic appeal and durability. Known for its superior response to anodizing, 6063 is ideal for achieving vibrant colors and improved corrosion resistance. We also offer polished finishes for a bright sheen and sandblasting for a uniform matte texture.

6063 Polished Aluminum Flat Bar

6063 Anodized Aluminum Flat Bar

6063 Sandblasted Aluminum Flat Bar

Chalco 6063 Aluminum Flat Bar Deep Processing Services

Beyond standard 6063 aluminum flat bars, Chalco offers comprehensive deep processing services tailored to your specific needs. With advanced equipment and professional expertise, we can transform aluminum flat bars into customized components that perfectly fit your project, helping you optimize your production process and reduce overall costs.

- Custom Length Cutting: Precise cutting to your specified length, ensuring accurate dimensions and reducing material waste.

- Edge Smoothing Treatment: Deburring and chamfering for smooth, flat edges, enhancing safety and aesthetics.

- Bending: Accurate bending and forming of aluminum flat bars according to design requirements.

- Drilling: High-precision drilling according to drawings, ensuring perfect compatibility with your components.

- Other Custom Services: We also provide various customized deep processing services like milling, welding, and surface brushing.

What Can We Offer as a Premium Supplier of 6063 Aluminum Flat Bar?

- High-Quality Products: Manufactured using high-grade aluminum ingots and advanced extrusion processes, our 6061 aluminum flat bars deliver high strength, excellent mechanical properties, and superior dimensional stability.

- Outstanding Surface Finish & Precision Control: Through high-precision extrusion, online thickness measurement, and surface treatment, we ensure a smooth, flat surface free of internal bubbles. Tolerances reach up to ±0.1mm, ideal for high-precision machining.

- Multiple Temper Options Available: We offer 6063 flat bars in a variety of tempers such as T5, T52, and T6, tailored to meet different requirements for strength, toughness, and corrosion resistance.

- Fast Delivery & Custom Services: With a large stock of standard sizes, we ensure prompt delivery. We also support custom lengths, precision cutting, pre-drilling, and anodizing upon request, helping reduce downstream processing costs.

- Competitive Pricing: Thanks to scaled production and optimized supply chains, we provide cost-effective 6061 aluminum flat bars. Whether it’s bulk purchases or small-quantity orders, we offer flexible procurement options and reasonable prices.

- Rigorous Quality Inspection: All our 6063 flat bars can be supplied with ultrasonic testing (UT), hardness testing, chemical composition analysis, and more, upon request. Products meet ASTM B221 standards and support third-party certifications.

- Professional Technical Support & Customer Service: We provide technical consultations and material selection advice to help you choose the most suitable alloy and temper. Our responsive after-sales team ensures a smooth purchasing experience.

FAQs

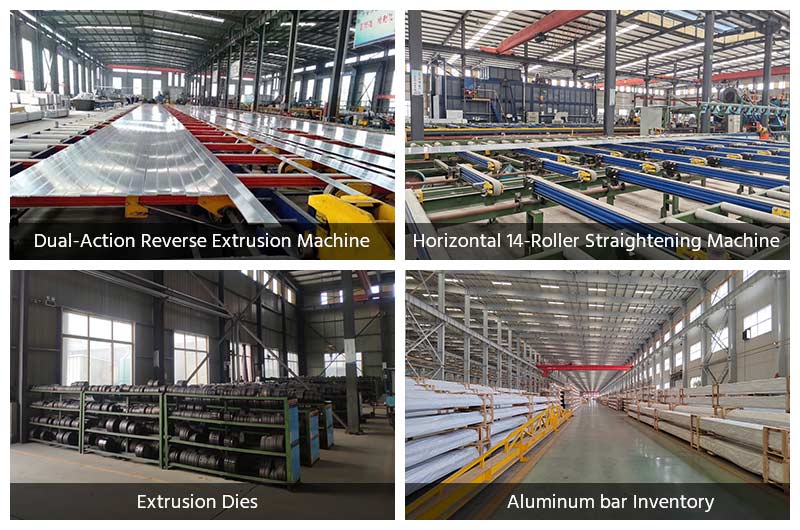

What are the processing methods for the 6063 aluminum flat bar produced by Chalco?

The manufacturing process of aluminum rows mainly includes two methods: extrusion and aluminum plate sawing.

Extrusion: This method involves feeding aluminum rods into a hot extrusion machine. By heating the rods, continuous extrusion of rectangular aluminum bars is performed. The bars are then straightened using a stretcher and cut to the required length after cooling.

Aluminum Plate Sawing: This process starts with aluminum alloy sheets. The method involves cutting, shaping adjustments, and surface treatments to create aluminum bars.

Each of these methods has its advantages, extrusion is suitable for large-scale production and complex cross-sections, while aluminum plate sawing is more suitable for small-scale production and customized dimensions.

What edge treatments can Chalco provide for 6063 aluminum Flat Bar?

Chalco can provide various edge treatments such as square edges, rounded edges, and R-rounded corners to meet the diverse requirements in different application fields.

What surface treatments can Chalco provide for 6063 aluminum Flat Bar?

Chalco can provide tin-plated aluminum bars, nickel-plated aluminum bars, and anodized aluminum bars, enhancing the electrical conductivity of the aluminum bars while significantly improving their wear resistance and corrosion resistance.

What CNC machining services can Chalco provide for 6063 aluminum Flat Bar?

Chalco can provide comprehensive secondary processing to meet your specific requirements. This includes hole punching, precision cutting, CNC milling, drilling, gradual thinning, laser cutting, laser etching, welding, machining, precision processing, heat treatment, bending, and shaping, among others.

What are the differences between 6061 aluminum flat bar vs 6063 aluminum flat bar?

- 6061 Aluminum Flat Bar possesses higher strength and is suitable for a wider range of structural applications.

- 6063 Aluminum Flat Bar features excellent corrosion resistance and a smoother surface, ideal for decorative and architectural applications.

- 6061 Aluminum Flat Bar requires solution treatment and precipitation hardening to achieve higher strength, unlike 6063 Aluminum Flat Bar.

- The strength-to-weight ratio of 6061 Aluminum Flat Bar is better, whereas the strength-to-weight ratio of 6063 Aluminum Flat Bar is relatively lower.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.