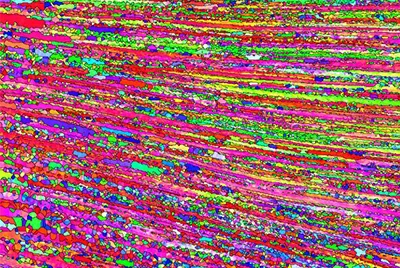

The new aluminum armor plate belongs to the Al-Mg-Mn (5xxx) alloy system, optimized with trace additions of Sc/Zr elements. This advanced design maintains the corrosion resistance and weldability of the 5xxx series while significantly enhancing ballistic and blast performance.Under high-velocity impact, strain-rate sensitivity and shear-band refinement during penetration or blast dynamically enhance strength.

- Equivalent ballistic protection to 7039 armor, reliably resisting penetration.

- Blast resistance superior to 5059 armor, delivering stable performance under explosive shock.

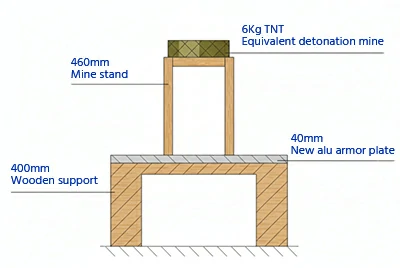

- 40 mm plate withstands 6 kg TNT, ~170 mm backface, Level 2.

- Excellent weldability (≥0.8), MIG/TIG/FSW compatible, high joint strength.

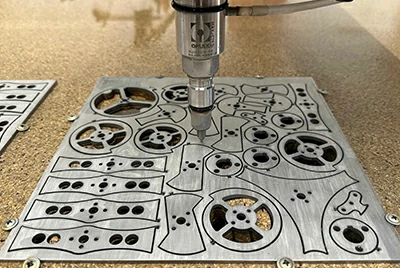

Chalco offers more than high-performance plates – we can deliver ready-to-assemble armor components based on customer drawings. With laser cutting, waterjet cutting, and CNC machining, we supply finished parts such as hull panels, side skirts, turrets, and hatches, reducing project lead times and overall cost.

Why Choose the New Aluminum Armor Plate?

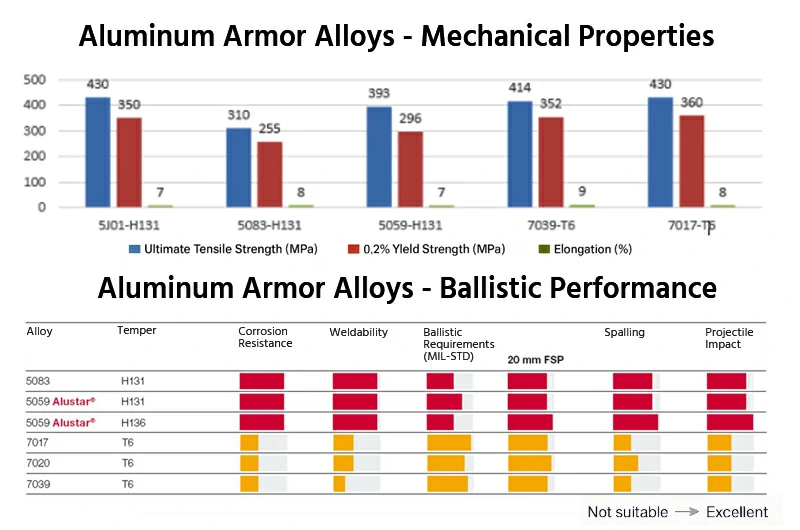

The new alloy surpasses all commonly used aluminum armor grades while retaining the manufacturability and durability of 5xxx alloys.

Strength and ballistic comparison — new plate vs 5083 / 5059 / 7039

Compared with 5083 armor plate: the representative state strength is significantly improved (Rm≈410–430 MPa, Rp0.2≈305–335 MPa), and it has higher penetration and detonation resistance at the same thickness, which can achieve "stronger with the same thickness/thinner with the same strength".

Compared with 7039 armor plate:This alloy provides similar ballistic protection but offers easier machining and welding, better corrosion resistance, and eliminates common service issues found in 7xxx series alloys.

Compared with 5059 armor plate:It shows higher stability under blast loading; a 40 mm plate can resist 6 kg TNT with about 170 mm backface deformation, meeting Protection Level 2 performance.

Welding and corrosion performance

Welding efficiency ≥0.8 (MIG / TIG / FSW compatible); SCC rated "excellent"; exfoliation corrosion PB/PC; no intergranular corrosion – ensuring long-term reliability in service.

This means customers can achieve near-7xxx ballistic performance while maintaining 5xxx-level weldability and corrosion resistance, gaining higher dynamic protection margins without changing existing manufacturing processes.

Specifications of New Aluminum Armor Plate

Specification Parameters

| Item | Specification |

| Product Name | 5xxx New Aluminum Armor Plate |

| Temper | H131 / H136 |

| Thickness | 5 – 40 mm |

| Width | ≤1500 mm |

| Length | ≤10000 mm |

| Density | 2.645 g/cm³ |

| UT (Ultrasonic Test) | ASTM B209 / EN 485, Level B |

| Flatness Tolerance | ≤2 mm/m (customizable) |

| MOQ | From 1 ton, small trial orders supported |

| Lead Time | Standard 25–30 days; urgent 10–15 days |

| Mill Certificate | EN 10204 3.1 / 3.2 |

Quality & Standards Assurance

- All plates undergo UT ultrasonic inspection Level B, following ASTM B209 / EN 485.

- Mechanical and ballistic performance exceed comparable military alloys (5083-H131, 7039-T64).

- Ballistic testing conducted under NATO STANAG 4569, third-party witnessed reports available (SGS / National Laboratory).

- Supplied with EN 10204 3.1 / 3.2 certificates, with full batch traceability.

Send us your drawings, and the Chalco team will provide a custom quotation and delivery schedule within 24 hours.

New Aluminum Armor Plate Technical Parameter

Alloy Composition

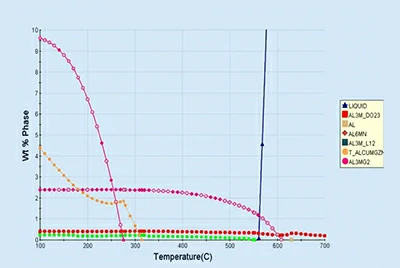

The new aluminum armor plate is based on the Al-Mg-Mn (5xxx system), with trace Sc additions and optimized Sc-Zr ratios to form a fine Al₃(ScZr) dispersion phase. This significantly enhances strength and stability, while eliminating coarse AlMnCr / Al₇Cr phases, ensuring excellent weldability and corrosion resistance.

Contact us now

Mechanical Properties

| Parameter | 5xxx-H131 | 5xxx-H136 |

| Tensile Strength (Rm) | ≥410 MPa | ≥395 MPa |

| Yield Strength (Rp0.2) | ≥335 MPa | ≥305 MPa |

| Elongation (A) | ≥7% | ≥8% |

Mechanical tests show that both strength and elongation surpass conventional 5xxx alloys, significantly improving ballistic protection while maintaining toughness.

Service Reliability

| Indicator | 5xxx-H131 | 5xxx-H136 |

| Impact Energy (KU₂) | ≥15 J | ≥15 J |

| Welding Efficiency | ≥0.8 | ≥0.8 |

| Stress Corrosion Cracking | Excellent | Excellent |

| Exfoliation Corrosion | PC grade | PB grade |

| Intergranular Corrosion | None | None |

The plate offers outstanding weldability and corrosion resistance, ensuring long-term reliability under harsh service conditions without compromising protective performance.

Ballistic Performance of New Aluminum Armor Plate

Ballistic performance is the core indicator of armor quality. Chalco new 5xxx aluminum armor plate has demonstrated in actual tests: overall ballistic protection comparable to 7039, with blast resistance superior to 5059, while retaining the weldability and corrosion resistance of the 5xxx series. The following results are based on real test data.

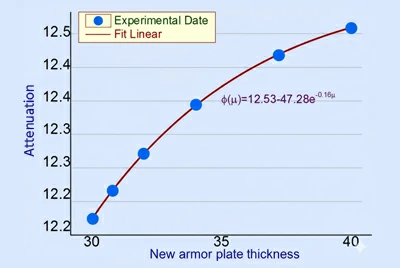

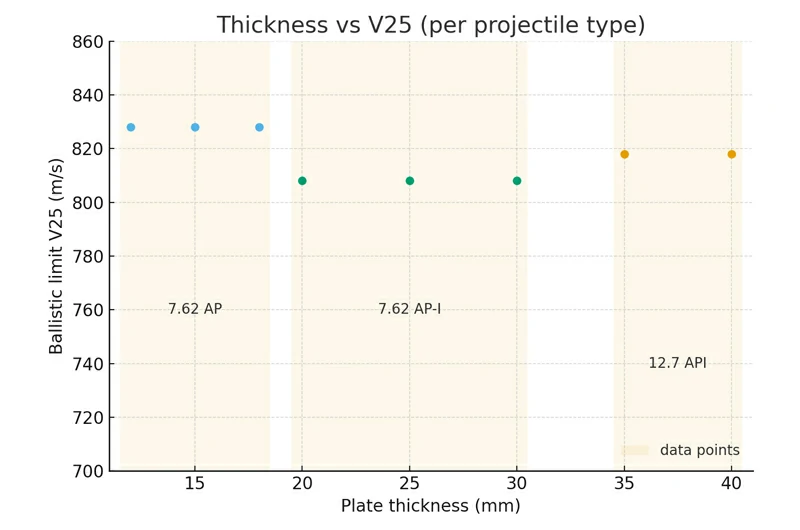

Thickness–V25 Curve (By Ammunition Type)

The chart demonstrates the V25 ballistic limit at different thicknesses. Values are only comparable within the same ammunition type.

Ballistic Performance Data

| Thickness (mm) | Ammunition Type | V25 (m/s) | Range (m) | Normal Angle (°) | Valid Shots |

| 12 | Type 53 7.62 mm steel-core bullet | 828 (+7/−8) | 100 | ≤58 | 5 |

| 15 | Type 53 7.62 mm steel-core bullet | 828 (+7/−8) | 100 | ≤47 | 5 |

| 18 | Type 53 7.62 mm steel-core bullet | 828 (+7/−8) | 100 | ≤39 | 5 |

| 20 | Type 53 7.62 mm WO-109C AP-I | 808 (+7/−8) | 100 | ≤45 | 5 |

| 25 | Type 53 7.62 mm WO-109C AP-I | 808 (+7/−8) | 100 | ≤40 | 5 |

| 30 | Type 53 7.62 mm WO-109C AP-I | 808 (+7/−8) | 100 | ≤33 | 5 |

| 35 | Type 54 12.7 mm AP-I | 818 (+7/−8) | 100 | ≤44 | 5 |

| 40 | Type 54 12.7 mm AP-I | 818 (+7/−8) | 100 | ≤43 | 5 |

*Note: V₂₅ is the velocity corresponding to a 25% probability of complete penetration. Data based on 100 m range, upper limit incidence angle, n=5 valid shots per group.

Blast Resistance of New Aluminum Armor Plate

In addition to excellent ballistic resistance, the Chalco new aluminum armor plate also delivers outstanding blast protection. Test results show:

- 40 mm plate successfully resisted 6 kg TNT equivalent, with backface deformation ~170 mm, achieving Protection Level 2.

- Superior to traditional 5059 aluminum armor in shock absorption and structural integrity.

- Provides reliable all-round protection for armored vehicles and special equipment against IEDs and explosive blasts.

This means the plate offers comprehensive protection, performing equally well under sustained small-arms fire and explosive shock waves.

Applications & Delivery

- Lightweight Protection (12–20 mm, 7.62 AP): Hull panels, external structures.

- Core Protection (25–30 mm, 7.62 AP-I): Side skirts, turret sections.

- Heavy Protection (35–40 mm, 12.7 API): Bottom plates, glacis armor.

Chalco can deliver ready-to-assemble armor components directly from customer drawings, using laser cutting, waterjet cutting, and CNC machining. This reduces lead time, lowers processing risk, and ensures reliable assembly.

Core Advantages of New Aluminum Armor Plate

- Ballistic ≈ 7039: Overall ballistic level comparable to 7039 armor plate, effective against 7.62 AP / 7.62 AP-I / 12.7 API threats.

- Blast > 5059: 40 mm plate resisted 6 kg TNT, backface deformation ≈170 mm, reaching Protection Level 2.

- 5xxx-Class Manufacturability: Welding efficiency ≥0.8 (MIG/TIG/FSW), corrosion resistance consistent with the 5xxx system.

- Ready-to-Assemble: Integrated laser cutting / waterjet cutting / 5-axis CNC machining / welding, enabling direct installation to reduce lead time and cost.

- Replacement for Traditional Alloys: Upgrade solution for 5083 / 5059 / 7039 / 2139 / 7085, balancing strength, blast resistance, and weldability.

| Item | New 5xxx Aluminum Armor Plate | 5083 Armor Plate | 5059 Armor Plate | 7039 Armor Plate |

| Ballistic Protection | ★★★★★ | ★★★☆☆ | ★★★☆☆ | ★★★★★ |

| Blast Resistance | ★★★★★ | ★★★☆☆ | ★★★★☆ | ★★★☆☆ |

| Weldability & Corrosion Resistance | ★★★★★ | ★★★★☆ | ★★★★☆ | ★☆☆☆☆ |

The Chalco new aluminum armor plate has comprehensively surpassed traditional alloys in strength, protection, and manufacturability. Contact us to get a customized solution and fast delivery quotation, making your next-generation armor project lighter, stronger, and more reliable.

Application Fields of New Aluminum Armor Plate

The Chalco new 5xxx aluminum armor plate outperforms 5083 in strength, matches or exceeds 5059/7039/2139 in ballistic and blast resistance, and can be widely applied in various military protection systems.

Armored Vehicles

Hull Plates: Traditionally produced with 5083 (e.g., M113) or 7039 (e.g., Bradley). The new 5xxx plate can directly replace them, offering higher strength with the same corrosion resistance.

Turret & Glacis Plates: Traditionally using 7039/2139. The new alloy provides equal or superior penetration resistance while maintaining weldability and toughness.

Side & Rear Armor: Conventional use of 5083/5059. The new plate delivers the same compatibility with enhanced blast resistance.

Mine-Resistant & IED-Protected Vehicles

Belly & Side Modules: Traditionally using 5059 and 2139 for blast and toughness. The new 5xxx plate demonstrated superior anti-blast performance to 5059, suitable for MRAP vehicles and modular belly armor.

Naval & Coastal Defense

Naval Armor & Decks: 5083/5059 are widely used in naval defense. The new 5xxx armor plate offers excellent corrosion resistance and weldability, making it ideal for fast patrol boats and coastal vessels.

Whether for light armored vehicles using 5083, medium platforms with 7039/2139, or naval and MRAP systems with 5059, customers can confidently select the Chalco new 5xxx aluminum armor plate as a direct upgrade, gaining higher protection, better toughness, and superior weldability.

From Ingot to Vehicle Components: Chalco's One-Stop Armor Delivery Capability

For armored vehicle manufacturers, selecting the right armor plate is only the first step. What truly impacts project timelines and costs is whether the material can be rapidly transformed into ready-to-assemble components.

Chalco provides a complete process from ingot → plate → precision machining → finished components, ensuring not only material stability but also a fully integrated ready-to-assemble armor solution. This one-stop service helps customers minimize outsourcing, shorten lead times, and guarantee every armor part meets strict protection standards.

Armor Plate Production

- Ingot Casting & Inspection: Strict composition control ensures uniform and stable microstructure.

- Hot & Cold Rolling: Guarantees consistent thickness and mechanical properties in large-format plates.

- Heat Treatment & Straightening: Proven H131/H136 processes, delivering required ballistic and blast resistance.

- Final Inspection & Packing: 100% UT ultrasonic testing, EN 10204 certification, and export-standard packing.

Precision Processing Capabilities

- Laser Cutting: Ideal for large-size and complex-profile components.

- Waterjet Cutting: Cold cutting that preserves the mechanical integrity of armor plates.

- CNC Machining: 5-axis processing with tolerance control ≤0.2 mm.

- Welding Services: Welding efficiency ≥0.8, supporting modular armor assembly.

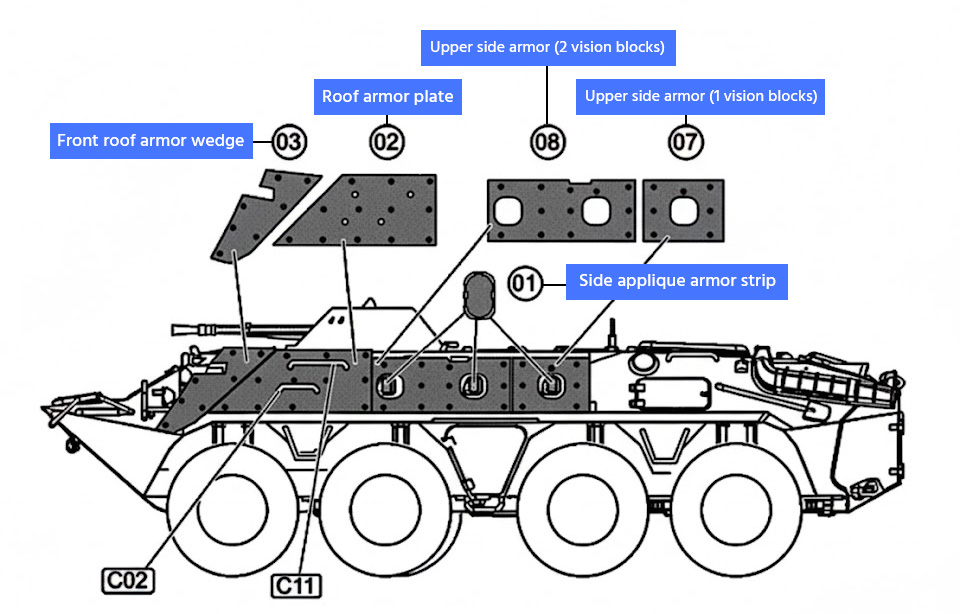

Build-to-Drawing Armor Components

Based on customer vehicle layout and BOM, Chalco supplies key armor parts that are cut, formed, and precisely machined, ensuring both assembly efficiency and protection performance.

- Hull Structures: Roof, belly plate, glacis (upper/lower), side panels, rear plates.

- Turret & Upper Parts: Turret shells and roof, hatches, cupolas, engine covers, access panels, roof assemblies.

- Internal Functional Parts: Bulkheads, protective liners, equipment mounting panels, cable/pipe shields.

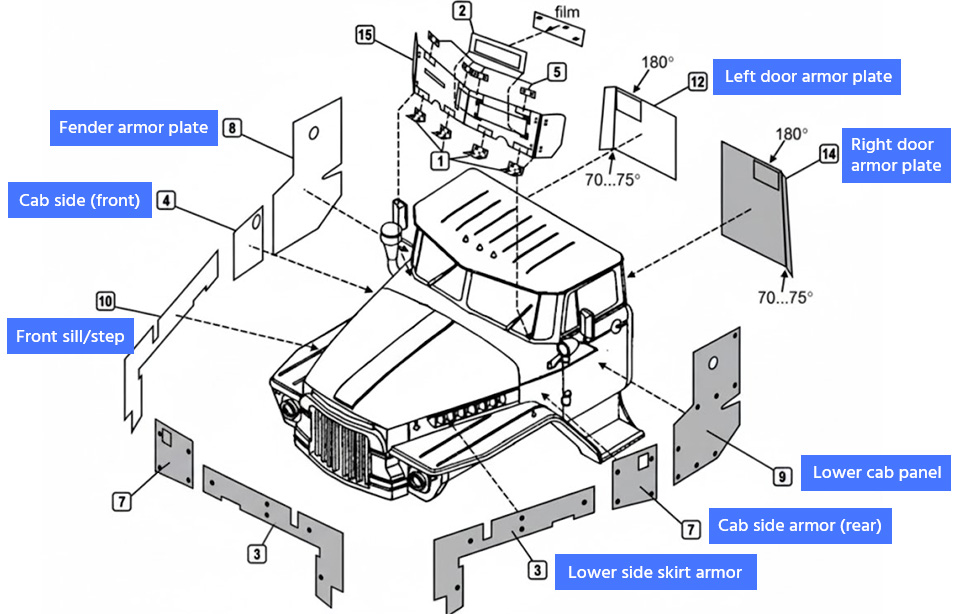

BTR-70 Add-on Armor Layout (Right-side View)

Ural-375D / Ural-4320 Local Add-on Armor Layout (Cab Section View)

All components are manufactured through laser/waterjet cutting, 5-axis CNC machining, and high-efficiency welding, ensuring accuracy and protection integrity. This integrated chain avoids tolerance mismatches and performance losses caused by outsourcing. Customers receive ready-to-assemble parts, fully matched to vehicle design, reducing rework risks while significantly shortening delivery cycles and overall manufacturing costs.

The new 5xxx aluminum armor plate delivers strength and protection superior to 5083/5059, while retaining the weldability and corrosion resistance of the 5xxx series. Proven platforms such as the M113 (5083 aluminum hull) and Bradley (5083/7039 hybrid armor) can adopt the new alloy as a direct replacement—achieving higher ballistic resistance and blast protection without adding weight.

Other Aluminum Armor Plate Options

While the new 5xxx aluminum armor plate is the optimal solution, Chalco also offers a complete portfolio of aluminum armor materials to meet the diverse needs of different platforms and defense projects:

Chalco offers a full range of aluminum armor plates, including traditional and advanced alloys such as 5083, 5059, 7039, 7085, 7A52, 7B52, and 2139, as well as five-layer aluminum composite armor plates. Whether for light armored vehicles or high-protection platforms, we provide the right lightweight protection solution to meet your needs.

FAQ

What is the difference between the new 5xxx aluminum armor plate and 5083, 5059, or 7039?

The Chalco new aluminum armor plate reaches the ballistic performance of 7039 armor plate, surpasses 5059 aluminum armor plate in blast resistance, and retains the excellent weldability and corrosion resistance of 5083 armor plate. It eliminates the trade-off between strength and manufacturability, making it the superior upgrade choice for next-generation platforms.

How does the 40 mm plate perform in blast tests?

Tests confirmed that a 40 mm new aluminum armor plate successfully resisted a 6 kg TNT equivalent explosion, with ~170 mm backface deformation, achieving Protection Level 2. Compared with 5059 armor, it shows higher energy absorption and structural integrity, ideal for IED protection and blast environments.

Can it directly replace 5083 or 7039 in existing armored vehicles?

Yes. Platforms such as the M113 (5083 aluminum armor hull) and the Bradley IFV (5083/7039 hybrid armor) can be upgraded with the new 5xxx aluminum armor plate. Customers benefit from stronger protection at the same weight, along with easier welding and machining during manufacturing.

Do you supply only plates, or also finished armor components?

Chalco provides ready-to-assemble solutions. Using laser cutting, waterjet cutting, 5-axis CNC machining, and welding, we can deliver turret shells, glacis armor, side panels, and belly plates directly from customer drawings or BOMs. This reduces assembly lead time and outsourcing risks.

What are the maximum supply dimensions and quality certifications?

The new aluminum armor plate is available in 5–40 mm thickness, widths up to 1500 mm, and lengths up to 10000 mm, in H131 / H136 tempers. All plates undergo 100% ultrasonic testing and come with EN 10204 3.1/3.2 certificates. Although not a MIL-listed alloy, its verified ballistic and blast performance meets or exceeds equivalent military standards.

Is it suitable for marine or high-humidity environments?

Yes. As a 5xxx-series aluminum alloy, it offers natural corrosion resistance. Optimized composition further improves stress corrosion cracking resistance and exfoliation corrosion performance, making it highly reliable for naval armor, coastal defense, and humid combat zones over long service life.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote