Cold finished aluminum bar is a high-precision solid aluminum product manufactured through multi-pass cold drawing at room temperature. Compared with conventional extruded bars, it offers superior dimensional stability, straightness, and machining compatibility. It is widely used in aerospace, automation components, precision equipment, and other high-requirement manufacturing sectors.

- Precision Tolerances: Dimensional tolerance ±0.03 mm, roundness ≤0.01 mm — ideal for tight fits and automation.

- Excellent Straightness: ≤0.3 mm/m ensures stable machining and smooth feeding.

- Consistent Surface: Smooth, oxide-free finish supports anodizing, threading, and post-processing.

- High Machining Efficiency: Chamfered ends prevent jamming, reduce wear, and boost throughput.

Chalco offers one-stop cold finished aluminum bar solutions in alloys like 6061,6082,2011, 2024,7075, and more. Custom sizes and tempers are available for aerospace, precision machining, and high-spec production — ensuring accuracy, efficiency, and reliable delivery.

Instant QuoteChalco's hot-selling Precision Cold Drawn Aluminum Rod Bar

We stock a wide selection of cold finished aluminum bars that meet ASTM B211,AMS-QQ-A-225 standards, ready for immediate delivery. Available in multiple alloys and sizes with tight tolerances and excellent machinability for aerospace and precision manufacturing.

- 1100 Cold Finished Aluminum Bar | AMS-QQ-A-225/1

Known for its high purity, 1100 cold finished aluminum bar offers excellent formability, ductility, and corrosion resistance. It is ideal for applications requiring superior conductivity and chemical resistance, such as electronic parts, chemical containers, signage, and decorative components. As a non-heat-treatable alloy, it is best suited for cold working processes.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

- 3003 Cold Finished Aluminum Bar | AMS-QQ-A-225/2

3003 cold finished aluminum bar is a non-heat-treatable aluminum-manganese alloy featuring excellent corrosion resistance, moderate strength, and good formability. It is one of the most widely used anti-rust aluminum grades, ideal for kitchen equipment, roofing panels, decorative trims, transportation containers, and HVAC components.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

- 2011 Cold Finished Aluminum Bar | AMS-QQ-A-225/3

Known for its outstanding machinability, 2011 aluminum bar is ideal for high-speed, precision cutting under cold working conditions. It is widely used in threaded parts, miniature shafts, nozzles, connectors, and hose assemblies where tight tolerances are essential. Not recommended for welding or brazing due to its limited weldability.

Tolerance | -0.03 mm Straightnessv0.3 mm/m Roundness | 0.01 mm

- 2014 Cold Finished Aluminum Bar | AMS-QQ-A-225/4

2014 aluminum bar is a high-strength, free-machining alloy offering excellent mechanical performance and good workability, commonly used for structural load-bearing parts. Though its corrosion and fatigue resistance are moderate, it remains widely applied—especially after anodizing—in aerospace structures, fasteners, forged components, gears, and high-strength mechanical joints.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

- 2017 Cold Finished Aluminum Bar | AMS-QQ-A-225/5

Known for its excellent machinability and high strength, 2017 aluminum bar is ideal for high-speed automatic screw machining. Compared to 2014, it offers slightly lower strength but better fatigue resistance and elongation, making it suitable for load-bearing and jointing structural parts. In T451 temper, it is widely used in aerospace components, mechanical parts, hydraulic units, threaded elements, rivets, and military-grade assemblies.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

- 2024 Cold Finished Aluminum Bar | AMS-QQ-A-225/6

2024 aluminum bar is a high-strength, heat-treatable aluminum-copper alloy with excellent machinability and fatigue resistance. It is widely used in applications requiring strength and dimensional precision, such as aircraft components, truck wheels, rivets, surgical instruments, and optical devices. With good surface finish and cutting performance in cold-drawn condition, it’s ideal for precision fasteners and threaded parts.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

2024 Cold Finished Aluminum Bar in Stock

| Details | Diameter (mm) | Length (mm) | Standard |

| 2024-T4 Cold Finished Aluminum Bar | 8 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 9 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 9.252 | 3000 | QQ-A-225/6 |

| 2024-T4 Cold Finished Aluminum Bar | 9.5 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 10 | 2500 | QQ-A-225/6 |

| 2024-T4 Cold Finished Aluminum Bar | 10 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 10.5 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 11 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 11.5 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 12 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 12.5 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 13 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 14 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 15 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 16 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 17 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 18 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 19 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 20 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 21 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 22 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 23 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 24 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 25 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 26 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 27 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 28 | 2500 | QQ-A-225/6 |

| 2024-T3 Cold Finished Aluminum Bar | 29 | 2500 | QQ-A-225/6 |

- 5052 Cold Finished Aluminum Bar | AMS-QQ-A-225/7

5052 aluminum bar is a corrosion-resistant Al-Mg alloy offering excellent formability, fatigue strength, and weldability. It performs well in marine and transport applications, and is widely used for fuel tanks, liquid container rivets, ship structures, rail components, instrument housings, fasteners, furniture, and hardware parts.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

- 6061 Cold Finished Aluminum Bar | AMS-QQ-A-225/8

6061 aluminum bar is a versatile, heat-treatable alloy offering good formability, corrosion resistance, and moderate strength. In T6/T651 temper, it provides excellent structural performance and is widely used for truck parts, marine components, tooling fixtures, bicycle frames, fasteners, and general industrial applications.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

6061 Cold Finished Aluminum Bar in Stock

| Details | Diameter (mm) | Length (mm) | Standard |

| 6061-T6 Cold Finished Aluminum Bar | 4 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 6 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 6.35 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 6.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 7 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 7.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 8 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 8.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 9 | 3000 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 9.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 10 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 10.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 11 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 11.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 12 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 12.5 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 13 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 14 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 15 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 16 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 17 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 18 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 19 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 20 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 21 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 22 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 23 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 24 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 25 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 26 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 27 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 28 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 29 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 30 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 31 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 32 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 33 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 34 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 35 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 36 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 38 | 2500 | QQ-A-225/8 |

| 6061-T6 Cold Finished Aluminum Bar | 40 | 2500 | QQ-A-225/8 |

- 7075 Cold Finished Aluminum Rod | AMS-QQ-A-225/9

7075 cold finished aluminum rod is one of the strongest aluminum alloys available. It offers excellent machinability, high strength-to-weight ratio, good corrosion resistance, and refined grain structure. Widely used in aerospace, defense, and high-performance mechanical components, it is ideal for aircraft parts, automotive shafts, tent poles, and climbing safety hooks.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

7075 Cold Finished Aluminum Bar in Stock

| Details | Diameter (mm) | Length (mm) | Standard |

| 7075-T6 Cold Finished Aluminum Bar | 4.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 5.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 6.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 7.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 8.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 9.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 9.0 | 3000 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 10.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 11.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 12.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 12.0 | 3000 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 12.5 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 13.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 14.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 15.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 16.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 24.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 25.0 | 2500 | QQ-A-225/9 |

| 7075-T6 Cold Finished Aluminum Bar | 32.0 | 2500 | QQ-A-225/9 |

- 6262 Cold Finished Aluminum Bar | AMS-QQ-A-225/10

6262 aluminum bar is a lead- and bismuth-bearing free-machining alloy with excellent machinability and good corrosion resistance. Comparable in strength to 6061, it is ideal for high-speed automatic turning operations and is commonly used in threaded parts, fittings, hydraulic components, fasteners, and precision machined applications.

Tolerance | -0.03 mm Straightness | 0.3 mm/m Roundness | 0.01 mm

Looking for custom sizes or large-volume orders? Contact us for tailored solutions, fast delivery, and expert technical support.

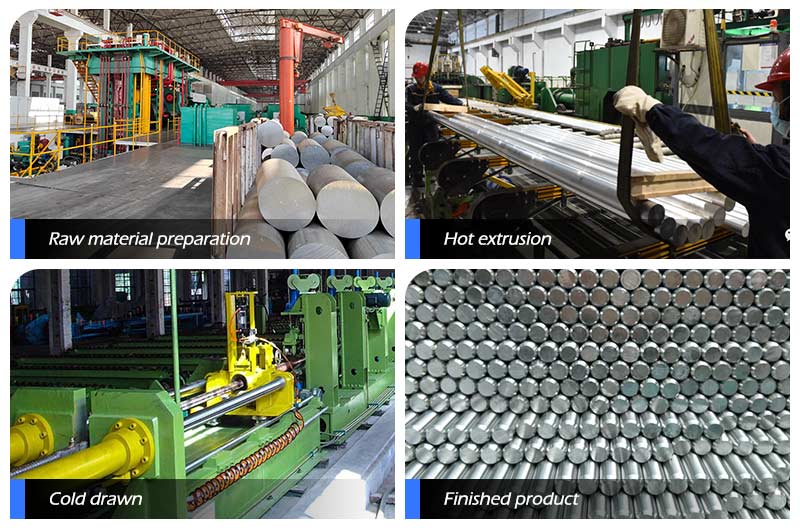

Instant QuoteProduction process of precision cold drawing aluminum rod bar

- Raw Material Preparation: Select high-purity aluminum rod blanks to ensure they meet production standards and customer requirements.

- Extrusion: Use an extrusion machine to extrude the pre-treated aluminum rod blanks into a preliminary round cross-section. Extrusion helps improve the grain structure of the blanks, enhancing mechanical performance.

- Drawing: Continue to draw the aluminum rods to further enhance strength and hardness.

- Cold Drawing: Gradually reduce the temperature and stretch the extruded aluminum round bars using a cold drawing machine to decrease the diameter.

- Multiple Drawing Passes: Subject the cold-drawn aluminum rods to multiple drawing passes to further reduce the diameter, improving product density and strength.

- Straightening: Straighten the drawn aluminum rods to ensure their straightness and length meet standard requirements.

- Chamfering: Apply chamfering treatment to the aluminum rods, making them suitable for automatic feeding during machining without material jamming.

- Heat Treatment: Subject the precision-machined aluminum rods to heat treatment, including heating and cooling processes, to adjust the alloy's crystal structure and enhance strength and hardness.

- Quality Inspection: Conduct comprehensive quality checks, including tolerance, diameter, roundness, etc., to ensure the products meet relevant standards and technical requirements.

- Packaging and Shipment: Package the qualified precision cold-drawn aluminum rods securely to prevent damage during transportation and deliver them to the customer.

Cold-Finished(CF) Aluminum Bar vs. Aluminum Extruded Bar

| Comparison Item | Cold-Finished Aluminum Bar (ASTM B211) | Extruded Aluminum Bar (ASTM B221) |

| Alloys | 6061, 7075, 2024, 2011, 5052 | 6061, 6082, 6063, 7075, 2024 |

| Tempers | T3, T4, T6, T651, H112 | F, T5, T6, T651, O |

| Diameter Range | Ø4 mm – Ø100 mm (High Precision) | Ø10 mm – Ø400 mm (Larger Range) |

| Standards | ASTM B211 / AMS-QQ-A-225 | ASTM B221 / AMS-QQ-A-200 |

| Features | Smoother finish, better straightness, higher roundness, stable dimensions | Flexible shapes, high strength, good weldability |

| Machining Efficiency | Ideal for CNC and automated feeding | Requires straightening or peeling before machining |

| Surface Quality | Bright, oxide-free, anodizing-friendly | Extrusion lines and oxide layer; rougher surface |

| Dimensional Consistency | Highly consistent across batches | More variation due to thermal expansion and extrusion process |

| Cost | Higher (multi-pass processing and tighter tolerances) | Lower (single-pass extrusion, bulk supply) |

| Typical Applications | Automation parts, aerospace fasteners, medical components, precision machined parts | Structural frames, architectural fittings, support brackets, electrical busbars |

If your project demands high dimensional precision, machining efficiency, and batch consistency—especially in aerospace, medical, or high-end CNC applications—go with Cold-Finished Aluminum Bars (ASTM B211).

If cost and structural flexibility are more important, and you are working on general engineering or architectural projects, Extruded Aluminum Bars (ASTM B221) will better suit your needs.

Click here to explore our extruded aluminum bar products

Advantages of precision cold drawing aluminum rod bar

- Superior Mechanical Performance: Manufactured with high-quality alloys, it exhibits outstanding mechanical machining capabilities, ensuring product quality.

- Relatively High Precision: Small diameter tolerances, excellent straightness, and true roundness, along with high material consistency, guarantee high-precision standards for the product.

- Improved Surface Smoothness: Enhances both quality and aesthetics while reducing the need for additional surface processing, providing customers with more attractive finished products.

- Suitable for High-Speed Spindles: Ideal for use in CNC machines with spindle speeds above 5000, supporting high-speed spindle operation to enhance production efficiency.

- Enhanced Straightness Capability: Automated bar feeding improves production efficiency, reduces manual intervention, and minimizes the possibility of human errors.

- Increased Production Efficiency: Superior straightness supports high-speed spindle operation, effectively improving production efficiency, reducing equipment damage, and extending equipment lifespan.

- Advantage in Automated Production: Chamfering at both ends facilitates automatic feeding, preventing material jamming and increasing operational efficiency, ensuring high-quality finished products.

- Cost-Effective: Saves on material and labor costs, reduces waste and rework, enhances material yield, resulting in better cost-effectiveness.

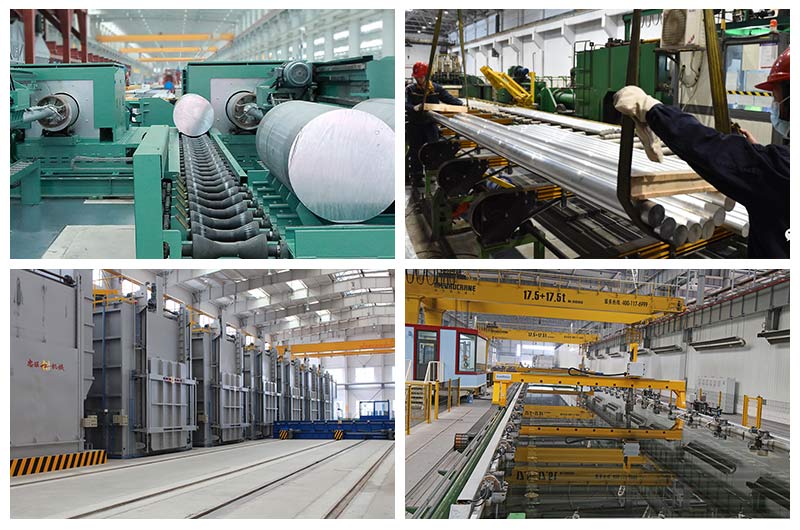

Precision Drawn Aluminum Rod Supplier - Chalco

- Comprehensive Product Range: Chalco provides a full range of aluminum products, including extruded aluminum bars and precision drawn aluminum bars, to meet diverse needs.

- Advanced Production Equipment: Equipped with advanced 12,500-ton dual-action reverse extrusion production lines, highly stable drawing production lines, a 6,000-ton stretch straightening machine, multiple imported cutting machines, fully automatic feeding saws, vertical large-scale automatic feeding machines, and other processing equipment.

- Complete Molds: Chalco possesses hundreds of molds, and most popular sizes can be directly matched, saving on customized mold costs and time, and flexibly meeting the needs of most customers.

- Precision Machining Services: Offers various precision machining services such as fixed-length cutting, precision grinding, precision turning, straightening, bending, and machining, catering to individualized requirements.

- Quality and Certifications: Chalco has obtained certifications including AS9100, OHSAS 18001, ISO 14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949, ensuring that products meet high-quality standards.

Chalco other hot selling aluminum rods

2011 aluminum bar

2017 aluminum bar

2024 aluminum bar

2618 aluminum bar

3003 aluminum bar

4032 aluminum bar

5052 aluminum bar

5083 aluminum bar

6061 aluminum bar

6063 aluminum bar

6082 aluminum bar

7075 aluminum bar

FAQs

1. What are the advantages of cold finished aluminum bars?

Cold finished bars offer tighter tolerances, better surface finish, and higher strength. Ideal for precision machining and mass production that demands consistency.

2. Are these bars suitable for welding or anodizing?

It depends on the alloy. 6061, 1100 are weldable and anodizable; 2011, 7075 are not recommended. Contact us for alloy-specific advice.

3. What tempers and alloys do you supply?

We offer cold finished bars in T3, T4, T6, T651, T8 tempers and in alloys like 2011, 2014, 2024, 2219, 3003, 5052, 6061, 6262, 7075, 1100. Custom sizes available.

4. How is dimensional tolerance controlled? Is it stable across batches?

Tolerances are held within ±0.03 mm and roundness within 0.01 mm. Stable across batches. For even tighter tolerance bars, see our Precision Ground Aluminum Bar.

5. Can you provide MTC and third-party inspection?

Yes. Every batch comes with an EN 10204 3.1 Mill Test Certificate. We also support inspection by SGS, BV or others if required.

6. What is your MOQ and lead time?

MOQ is typically 10 kg per size. In-stock items ship within 3 days. Custom orders: 2–4 weeks.

7. Do you support machining or surface finishing?

Yes. We provide CNC machining, cutting, chamfering, polishing, and anodizing to support your downstream processing.