Anodizing forms a uniform, dense oxide layer on aluminum profiles—enhancing corrosion resistance, wear resistance, and color stability—fit for high-salt-spray and heavy-duty environments. Chalco Aluminum supplies one-stop Anodized Aluminum Extrusions (extrusion + anodizing + CNC machining); standalone anodizing jobs are not accepted.

- Standards: Executed to ISO 7599 / AAMA 611 / QUALANOD with records retained for easier acceptance.

- Parameters: AA10–AA25, Type II/III; multiple colors including black; quick matching for indoor/outdoor/coastal.

- Delivery Capability: Standard 6 m, up to 13 m; integrated Extrusion + Anodizing + CNC delivery.

Jump to what you need: Distributors | Industry Applications | T-Slot / Integrators

-

Distributors / Wholesale

Bulk replenishment of standard anodized profiles, covering Angle / Channel / Tee / U-Channel / HAT / I-Beam and other common shapes.

-

Industry Applications

For Architectural / Marine / Electronics / Industrial scenarios, we provide AA-to-environment matching guidance.

-

T-Slot / Integrators

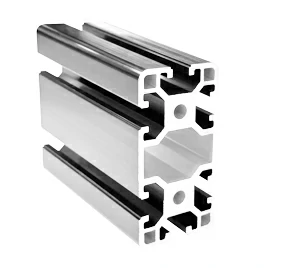

Semi-standard T-slot / V-slot system (2020 / 3030 / 4040 / 4080) with a compatible accessories ecosystem.

Chalco Anodizing Capability

Capacity Snapshot

Alloys / Tempers: 6063 / 6061 / 6082 / 6005A / 6463 | T5 / T6

Profile Families: T-slot 2020 / 3030 / 4040 / 4080; standard Angle / Channel / Tee / U / HAT / I-Beam, etc.

Length Envelope: standard 6 m, up to 13 m (long lengths mean fewer joints, steadier color match & structure).

Anodizing Type: Type II / Type III (hard anodizing)

Thickness Range: AA10–AA25 (Type II) | 25–100 μm (Type III, case-by-case)

Colors: clear / champagne / bronze / black (customizable; batch ΔE target & retain samples supported)

Sealing: hot water sealing / nickel acetate (coastal or high-pollution sites prioritize hot water)

Standards & Inspection: ISO 7599 / AAMA 611 / QUALANOD; thickness per ISO 2360 / ASTM B244; extrusion tolerances EN 755-9; EN 10204 3.1 available with shipment

Lead Time Reference: samples 1–2 weeks | mass 2–4 weeks

Note: For a bright appearance, consider 6463 + bright-dip; color will vary slightly by alloy / thickness / coloring system.

Standard Colors

Screen vs. physical may differ—request physical swatches; we can set a batch ΔE target and keep retain samples (more stable color in mass production and fewer reworks at acceptance).

Swatches: Clear / Champagne / Black / Light Bronze / Medium Bronze / Dark Bronze

Clear

Champagne

Black

Light Bronze

Medium Bronze

Dark Bronze

Anodizing Thickness & Environment

| Scenario | Recommended film thickness (AA): | Type | Sealing Recommendation | Industry Entry Point |

| Indoor dry | AA10–15 | Type II | Hot water sealing | Automotive / EV Aux Cleanroom |

| General outdoor | AA15–20 | Type II | Hot water / Nickel acetate | Architectural Renewables |

| Near sea/high salt spray | AA20–25 | Type II | Hot water sealing | Marine & Coastal |

| Heavy wear/high frequency friction | AA25–100 | Type III(hard anodizing) | Type III(hard) | Industrial Machinery |

Quick Pick: Indoor AA10–15; General Outdoor AA15–20; Coastal AA20–25 (prefer hot-water sealing); Heavy Wear 25–100 μm (Type III).

For details, see All About Anodizing.

Comparison of Anodizing Types

| Comparison Dimensions | Type II (Sulfuric Acid) | Type III (Hard) |

| Thickness Range (μm) | AA10-AA25 | AA25-AA100 |

| Appearance/Coloring | Decoratively friendly; multiple color options (including black) | Limited coloring range (primarily functional) |

| Abrasion Resistance/Hardness | Medium-grade | High (suitable for high wear/friction scenarios) |

| Typical Applications | Architectural/General Industrial Exterior Parts | Guides, jigs, sliders, tools |

| Suitable Scenarios | Indoor/General Outdoor/Offshore (matches AA grade) | Heavy wear/high load (requires evaluation in conjunction with tolerances and post-processing) |

Defects & Prevention

Color variation — Set a batch ΔE target and enforce incoming/retain-sample color matching; keep production records to ensure lot-to-lot consistency.

Streaks / burn marks — Control current density and agitation uniformity; optimize electrical contact/fixturing to stabilize film growth and avoid banding.

Pitting / spots — Strengthen pre-treatment cascade rinses and monitor water conductivity/hardness to eliminate residues that trigger pitting.

Poor sealing — Prefer hot-water sealing and verify temperature/time by sampling to secure corrosion resistance and color fastness.

See the full gallery of defects, causes, and fixes (with images): 14 Anodizing Coloring Defects

This concludes our core capability overview for anodized aluminum extrusions. If your specs are fixed (thickness / type / color / length), please submit your drawing and specification for a formal quote; if you're still evaluating by scenario, jump to: Distributors | Industry Applications | T-Slot / Integrators.

Distributors & Standard Extrusions | Ship From Existing Dies, Anodizing on Demand

For frequent small-batch replenishment, Chalco supplies mill finish standard extrusions as the baseline. Leveraging our large in-house existing-die library (most specs no die charge), production starts once the shape and dimensions are confirmed. When an appearance/corrosion upgrade is required, we add anodizing (Type II / Type III) and deliver together—backed by batch ΔE color control with retain samples, stable lead times, and export packing—so your anodized aluminum extrusions sell faster and restock with less friction.

After confirming the shape and size, submit the order with the existing die code. If the surface plan is not set, see Anodizing Thickness & Environment above. For complete frames, continue to System Assembly (T-slot); tubing specifications are available on the Anodized Aluminum Tubing page.

Industry Solutions for Anodized Aluminum Extrusions

This section turns six key end-use solutions into quick "cards," giving application notes, AA / Type / Sealing guidance, and common profiles—so you can select faster with fewer trials. Supply is based on mill finish extrusions; on request we complete anodizing + CNC on our own extrusions for one-stop delivery (no standalone anodizing jobs).

Cleanroom (Pharma / Electronics / Food Plants)

Clean zones require non-porous surfaces that are easy to clean and resistant to disinfectants. Anodized Aluminum Extrusions meet all three: stable color and corrosion resistance, withstand repeated wipe-downs without blotching, and with custom profiles and long lengths the corners/closers align smoothly with fewer joints for a visibly "clean" finish.

Recommended Anodizing Setup- Type / Thickness: Type II · AA10–15 as default; for cart aisles and frequently cleaned areas use AA15–20.

- Sealing: Prefer hot water sealing; use nickel acetate when efficiency or specific dye systems are required.

- Color: Primarily clear/silver; black for light-blocking or equipment enclosures. Batch ΔE targets and retain samples supported.

Coving / Cove Skirting : continuous wall-to-floor/wall-to-wall transitions to reduce dust traps and cleaning dead zones.

Observation Window frames / Pressure Strip: sealing, clamping and edging for doors and panel systems.

Adjustable Floor Guide / Bottom Seal: common cleanroom door components emphasizing abrasion resistance and sealing consistency.

Edge trims & connectors: U / C Channel, Angle, T-Bar, Trim / Cap / Cover for unified appearance and modular installation.

For details, see our Cleanroom Aluminum Profiles page.

Architectural Facade / Windows & Doors

Exterior-visible parts must balance weatherability and appearance consistency. Anodized Aluminum Extrusions maintain stable color and gloss under long-term UV and rain; long-length supply reduces joints, delivering a cleaner installed look.

Recommended Anodizing Setup- Type / Thickness: Type II · AA15–20 for general outdoor; AA20–25 for coastal/high-salt environments.

- Sealing: Prefer hot water sealing.

- Color: clear / champagne / bronze / black; set a batch ΔE target for color matching.

Door/window frames, curtain-wall pressure plates, muntins, sun-shade louvers: U / C Channel, T-Bar, Trim / Cap / Cover.

Stairs/railings, flashing & drip edges: Angle, Z / HAT, I-Beam (light-duty).

Mullion/transom accessories & edge finishing: Angle, U / C Channel, decorative Trim.

For more details, see our Windows & Doors aluminum page.

Marine & Coastal

Salt spray and humidity demand exceptional corrosion resistance; anodized aluminum extrusions maintain long-term appearance and structural stability in coastal environments, extending maintenance intervals.

Recommended Anodizing Setup- Type / Thickness: Type II · AA20–25; high-wear areas may evaluate Type III (25–50 μm).

- Sealing: hot water sealing preferred.

- Color: clear / bronze / black (retain color samples; multi-batch projects benefit from ΔE control).

Piers & platforms: Angle, Z / HAT, I-Beam, U / C Channel.

Handrails/rail posts, equipment brackets: Angle, U / C Channel, Trim.

For tubular handrails/guards, adopt a matched tubing solution.

Industrial Machinery / Equipment Frames

Shop-floor equipment and workstations require wear resistance and dimensional consistency; anodized aluminum extrusions unify frame appearance while reinforcing protection at wear zones.

Recommended Anodizing Setup- Type / Thickness: Frames/visible parts Type II · AA10–15; guides/sliders/jig faces Type III · 25–50 μm.

- Sealing: hot water sealing or nickel acetate (select per color/efficiency).

- Color: clear / black (black for light-blocking or marking zones).

Equipment frames & guards: I-Beam, HAT, Z, Angle, U / C Channel.

Perimeter & guidance: Rails / Tracks, functional Trim, T-Bar.

For details, see our automation frame solution page.

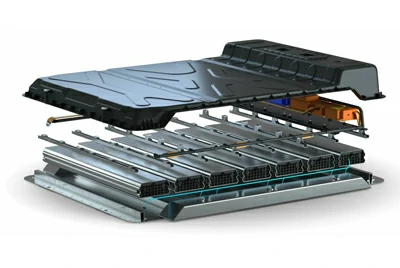

Automotive / EV Aux

Vehicle interior/exterior trims and under-hood peripherals value lightweight, appearance stability, and weatherability; anodized aluminum extrusions fit trims, rails, and functional bezels that are not primary safety structures.

Recommended Anodizing Setup- Type / Thickness: Interior/cabin Type II · AA10–15; exterior/out-of-cabin AA15–20.

- Sealing: hot water sealing; standardize the process for large volumes to control color variance.

- Color: clear / black / bronze; brand colors can be project-customized with ΔE targets.

Decorative/protective: Trim / Cap / Cover, U / C Channel, Angle.

Rails & roof-rack auxiliaries: Rails / Tracks, Z / HAT.

Battery box/enclosure frames & supports: U / C Channel, T-Bar, reinforced Trim (verify load-bearing and sealing per drawing).

For more information, see our new-energy battery application page.

Renewables / Power Electronics

Outdoor structures and power-electronics enclosures require long-term weatherability and appearance consistency; anodized aluminum extrusions withstand sand, UV, and coastal moisture, and help control batch uniformity in large projects.

Recommended Anodizing Setup- Type / Thickness: Type II · AA15–20; wind-sand/coastal AA20–25.

- Sealing: hot water sealing.

- Color: clear / black; for large lots, define ΔE and retain samples.

PV frames/rails, inverter/energy-storage enclosure profiles: U / C Channel, hat/reinforced ribs, I-Beam.

Cable trays & routing parts: U / C Channel, Angle, functional Trim.

Panel faces & edge finishing: Trim / Cap / Cover for a unified look and easier service.

See our photovoltaic aluminum section for details.

System Assembly | T-Slot Aluminum Framing

For automation equipment, frames, guarding, and workstations, Chalco offers a modular solution based on T-slot aluminum extrusions: we start from in-house standard slot profiles and add precision cutting, drilling, tapping, accessory selection, and anodizing to deliver ready-to-assemble systems.

We maintain multiple ready-to-use T-slot profiles—select directly with no new die.

T-slot T-framing system

Series Matrix (10/15/20/30/40/45) | Accessories Index | CAD/STEP & BOM. On request we add Type II anodizing (clear/black with ΔE batch control) and provide cut/drill/tap/end-cap in one run.

Contact us now

Series Selection

-

10 Series Aluminum Extrusion Light-duty|6 mm|M5

Applications: Workstation accessories / light-duty frames

Economical Compact Accessories-ready -

15 Series Aluminum Extrusion Light-to-medium|8 mm|M6

Applications: Workstations / small enclosures

General-purpose Strong Versatile -

2020 / 2040 Aluminum Extrusion Light-duty|6 mm|M5

Applications: Compact frames / small machinery bases

Compact Flexible Space-saving -

3030 / 3060 Aluminum Extrusion Medium-duty|8 mm|M6-M8

Applications: General equipment structures

Strong Stable Machine-ready -

4040 / 4080 Aluminum Extrusion Medium-to-heavy|8 mm|M8

Applications: Frames / guarding

Rigid High-load Universal -

45 Series Aluminum Extrusion Heavy-biased|10 mm|M8-M10

Applications: Large frames / conveyor uprights

High-rigidity Heavy-duty Structural

Notes: Mill finish is the default supply; anodizing (Type II) is provided only on our own extrusions and ships with the same lot. Same-series slot widths are compatible; cross-brand use requires verifying slot width and fastener spec. Orders are built to your drawings.

Related Anodized Materials | Tubing & Sheet & Wire

Beyond extruded profiles, we also supply anodized finishes for our own materials—anodized tubing, sheet, and wire—for light-duty uses such as railings/cable protection, face panels/skins, and decorative/electrical parts. Default supply is mill finish; on request we apply Type II anodizing and ship together with extrusions (ΔE batch color control and retain samples available).

Railings/handrails, cable and pneumatic/fluids outer protection; stable appearance and easy to clean.

Equipment covers, decorative skins, and signage; colors can be matched to the machine aesthetic.

Decorative wire, light-duty ties/hangers, and small electrical pieces; wear-resistant surface with good color fastness.

FAQ

When should I choose anodized extrusions instead of mill finish?

Select anodizing when you need appearance uniformity, corrosion resistance, and cleanability (e.g., architectural exterior, cleanrooms, coastal, visible equipment parts). Hidden structural pieces or one-time assemblies can start with mill finish; if later exposed to wiping, salt spray, or UV, move to anodizing and choose the AA grade by environment.

How do I choose between Type II and Type III (hard anodizing), and what about tolerances/machining?

Type II prioritizes appearance and corrosion resistance (architectural/general industrial default); Type III prioritizes wear resistance/hardness for rails, jigs, and sliding faces. The oxide layer consumes part of the tolerance and affects holes/fits—confirm the machining vs. anodizing sequence with us and submit drawings for evaluation.

How do I pick thickness and sealing—what for coastal or frequent-cleaning areas?

Indoor AA10–15, general outdoor AA15–20, coastal/high-salt AA20–25; for heavy wear consider Type III 25–50 μm. Prefer hot water sealing; choose nickel acetate when efficiency or specific dye systems are needed. For black/multi-batch projects, set a ΔE target and retain samples.

Which standards do you follow, and how do we verify compliance?

Anodizing per ISO 7599 / AAMA 611 / QUALANOD; thickness per ISO 2360 / ASTM B244; extrusion tolerances can follow EN 755-9. If a project cites particular standards/procurement clauses, please cross-check them with us before ordering.

How do you price, and what are the main cost drivers?

By meter/kilogram or per lot; drivers include alloy/temper, size/tolerance, anodizing type & AA grade, color/sealing, machining route, and batch/destination port. Send specs/drawings and we'll issue a formal quotation with terms.

What are the MOQ and sample policies? Can I mix specs?

MOQ is usually by total quantity, and mixing profiles within the same series is supported; samples can include anodized/color swatches and MTC/dimension reports. Special cutting/holes/end-capping are charged by operation after specs are confirmed.

Lead time and delivery—can you combine shipments?

Samples and mass orders are scheduled by production window; the clock starts after drawing/PO confirmation and payment. We can expedite or split/combine shipments subject to load; delivery terms include EXW/FOB/CIF/DDP.

What about packaging and shipping documents?

Inner anti-scratch/moisture protection; outer wooden cases or fumigation-free pallets with strapping; add anti-salt-spray measures for coastal/long routes. EN 10204 3.1 and color retains/inspection records are available with shipment.