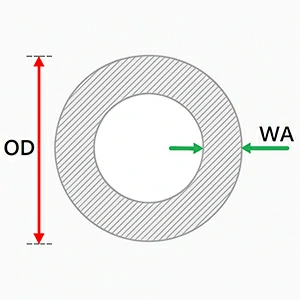

Chalco maintains 1,000+ existing aluminum round tube dies, covering mainstream sizes from OD 6–760 mm and wall thickness 0.8–50 mm.

Most dies can be set up on press immediately, so common sizes run with no / reduced die cost, samples can be ready in 3–5 days, and production in 7–14 days.

For non-standard dimensions, we can open a new die quickly and provide a clear plan for die life, achievable tolerances, and approval.

- Faster Lead Time: existing dies are prioritized on the press to shorten project launch time.

- Lower Upfront Cost: common sizes run with no / reduced die charge.

- Stable Quality: straightness ≤0.2 mm/m, roundness / concentricity kept stable, consistent anodizing appearance.

Aluminum Round Tube Mold List (PDF)

Aluminum Round Tube Die Size List — No / Reduced Die Cost, Instant Match

-

General Die Library (≤ Ø285 mm)

Wide alloy compatibility — most common alloys run on the same aluminum round tube dies

Multiple wall options per OD — weight / cost flexibility

Small OD can be drawn to size — one-stop high-precision tube

-

Large-OD Exclusive (6061 / 6063 / 6082)

Custom-tolerance dies for 6061 / 6063 / 6082

Press capacity up to 22,500T | Max OD ≤ Ø760 mm

In-stock tooling for large OD & thick wall:faster, more stable production

Quick Jump to Large-OD Die Library (6061 / 6063 / 6082)

General Alloy Aluminum Round Tube Die Table

-

The table below lists common aluminum round tube dies and sizes that can go straight to press. Some sizes run with no / reduced die cost.

If you do not see an exact match, you can request a quote. An engineer will respond within 2 hours with the closest feasible option and lead time.

- Alloy Coverage: 3003 / 5083 / 5754 / 6061 / 6063 / 6082 / 7005 / 7075 / 2024

- Multiple Wall Thickness for the Same OD: common ODs are available in several wall options.

- Small OD Can Be Drawn to Size: one-stop supply for high-precision aluminum round tube.

| Size | OD(mm) | WA (mm) | Linear Weight (kg/m) |

| Ø 6X1 | 6 | 1 | 0.042 |

| Ø 8x1 | 8 | 1 | 0.06 |

| Ø 8X1.2 | 8 | 1.2 | 0.07 |

| Ø 8X1.5 | 8 | 1.5 | 0.084 |

| Ø 8.5X1.75 | 8.5 | 1.75 | 0.101 |

| Ø 9X1 | 9 | 1 | 0.069 |

| Ø 9.5X1.75 | 9.5 | 1.75 | 0.116 |

| Ø 9.53X1 | 9.53 | 1 | 0.075 |

| Ø 10X1 | 10 | 1 | 0.077 |

| Ø 10X1.2 | 10 | 1.2 | 0.09 |

| Ø 10X1.5 | 10 | 1.5 | 0.109 |

| Ø 10X2.0 | 10 | 2 | 0.137 |

| Ø 10X2.5 | 10 | 2.5 | 0.16 |

| Ø 11.5X0.9 | 11.5 | 0.9 | 0.081 |

| Ø 12.5X1.0 | 12.5 | 1 | 0.098 |

| Ø 12.7x1.59 | 12.7 | 1.59 | 0.15 |

| Ø 12X1 | 12 | 1 | 0.094 |

| AT2309 | 12 | 1 | 0.094 |

| Ø 12x1.5 | 12 | 1.5 | 0.134 |

| Ø 12x2 | 12 | 2 | 0.171 |

| Ø 12.7x1 | 12.7 | 1 | 0.099 |

| Ø 12.7X1.1 | 12.7 | 1.1 | 0.109 |

| Ø 12.7x1.27 | 12.7 | 1.27 | 0.124 |

| Ø 13X1.5 | 13 | 1.5 | 0.147 |

| Ø 15X1 | 15 | 1 | 0.119 |

| Ø 15X2.0 | 15 | 2 | 0.222 |

| Ø 15x3.0 | 15 | 3 | 0.307 |

| Ø 15.5x0.8 | 15.5 | 0.8 | 0.1 |

| Ø 15.5X1.75 | 15.5 | 1.75 | 0.205 |

| Ø 15.9X1.0 | 15.9 | 1 | 0.127 |

| Ø 16X1.0 | 16 | 1 | 0.128 |

| Ø 16x1.25 | 16 | 1.25 | 0.157 |

| Ø 16x1.5 | 16 | 1.5 | 0.185 |

| Ø 16x2 | 16 | 2 | 0.239 |

| Ø 18X1.0 | 18 | 1 | 0.145 |

| Ø 18x1.5 | 18 | 1.5 | 0.211 |

| Ø 18x2 | 18 | 2 | 0.273 |

| Ø 19.1x2.14 | 19.1 | 2.14 | 0.333 |

| Ø 19.05x0.8 | 19.05 | 0.8 | 0.125 |

| Ø 19.05X1.0 | 19.05 | 1 | 0.154 |

| Ø 19.05X1.2 | 19.05 | 1.2 | 0.182 |

| Ø 19.05X1.27 | 19.05 | 1.27 | 0.194 |

| Ø 20x1 | 20 | 1 | 0.161 |

| Ø 20X1.2 | 20 | 1.2 | 0.192 |

| Ø 20X2 | 20 | 2 | 0.305 |

| Ø 20x3.0 | 20 | 3 | 0.434 |

| Ø 20X5 | 20 | 5 | 0.638 |

| Ø 21.34x2.77 | 21.34 | 2.77 | 0.438 |

| Ø 21.5x1.4 | 21.5 | 1.4 | 0.24 |

| Ø 22X1 | 22 | 1 | 0.179 |

| Ø 22X1.1 | 22 | 1.1 | 0.196 |

| Ø 22X2 | 22 | 2 | 0.341 |

| Ø 22X6.0 | 22 | 6 | 0.817 |

| Ø 22.6x1.3 | 22.6 | 1.3 | 0.235 |

| Ø 23.6x2.3 | 23.6 | 2.3 | 0.447 |

| Ø 23.8x0.9 | 23.8 | 0.9 | 0.175 |

| Ø 24x3.25 | 24 | 3.25 | 0.574 |

| Ø 25X1.2 | 25 | 1.2 | 0.243 |

| Ø 25X2.0 | 25 | 2 | 0.392 |

| Ø 25X2.5 | 25 | 2.5 | 0.479 |

| Ø 25X3 | 25 | 3 | 0.562 |

| Ø 25X8.38 | 25 | 8.38 | 1.185 |

| Ø 25.3X0.9 | 25.3 | 0.9 | 0.187 |

| Ø 25.4X1 | 25.4 | 1 | 0.209 |

| Ø 25.4X1.0 | 25.4 | 1 | 0.208 |

| Ø 25.4x1.27 | 25.4 | 1.27 | 0.26 |

| Ø 25.4X3.0 | 25.4 | 3 | 0.572 |

| Ø 26x6.5 | 26 | 6.5 | 1.079 |

| Ø 27.5x3 | 27.5 | 3 | 0.626 |

| Ø 28X2.0 | 28 | 2 | 0.443 |

| Ø 29X3.3 | 29 | 3.3 | 0.722 |

| Ø 30x1.0 | 30 | 1 | 0.247 |

| Ø 30x1.5 | 30 | 1.5 | 0.364 |

| Ø 30x2 | 30 | 2 | 0.475 |

| Ø 30X3.0 | 30 | 3 | 0.69 |

| Ø 30X4.0 | 30 | 4 | 0.937 |

| Ø 30X11 | 30 | 11 | 1.779 |

| Ø 31.75X1 | 31.75 | 1 | 0.261 |

| Ø 32X1.2 | 32 | 1.2 | 0.315 |

| Ø 32X2.0 | 32 | 2 | 0.511 |

| Ø 32x3 | 32 | 3 | 0.741 |

| Ø 33.4x3.38 | 33.4 | 3.38 | 0.863 |

| Ø 34X4.0 | 34 | 4 | 1.022 |

| Ø 35x1 | 35 | 1 | 0.289 |

| Ø 35x1.5 | 35 | 1.5 | 0.428 |

| Ø 35x2 | 35 | 2 | 0.56 |

| Ø 35x3.0A | 35 | 3 | 0.817 |

| Ø 35X5 | 35 | 5 | 1.277 |

| Ø 35X11 | 35 | 11 | 2.248 |

| Ø 37X2.0 | 37 | 2 | 0.596 |

| Ø 38X1.2 | 38 | 1.2 | 0.375 |

| Ø 38X1.5 | 38 | 1.5 | 0.467 |

| Ø 38X2.8 | 38 | 2.8 | 0.839 |

| Ø 38X4.0 | 38 | 4 | 1.158 |

| Ø 38X5.0 | 38 | 5 | 1.405 |

| Ø 38.1x1.0 | 38.1 | 1 | 0.315 |

| Ø 38.1x1.2 | 38.1 | 1.2 | 0.375 |

| Ø 38.5X5.1 | 38.5 | 5.1 | 1.45 |

| Ø 39X4 | 39 | 4 | 1.192 |

| Ø 40X1.0 | 40 | 1 | 0.332 |

| Ø 40x2 | 40 | 2 | 0.645 |

| Ø 40x2.5 | 40 | 2.5 | 0.799 |

| Ø 40X2.8 | 40 | 2.8 | 0.887 |

| Ø 40X3 | 40 | 3 | 0.945 |

| Ø 40X4.0 | 40 | 4 | 1.226 |

| Ø 40X5 | 40 | 5 | 1.49 |

| Ø 40X10 | 40 | 10 | 2.554 |

| Ø 42.7X1.2 | 42.7 | 1.2 | 0.424 |

| Ø 42.16x3.56 | 42.16 | 3.56 | 1.169 |

| Ø 44X1.52 | 44 | 1.52 | 0.55 |

| Ø 45x2.0 | 45 | 2 | 0.732 |

| Ø 45X2.5 | 45 | 2.5 | 0.905 |

| Ø 45X5.0 | 45 | 5 | 1.703 |

| Ø 47X1.2 | 47 | 1.2 | 0.468 |

| Ø 48x1.2 | 48 | 1.2 | 0.488 |

| Ø 48X2.8 | 48 | 2.8 | 1.074 |

| Ø 48X3 | 48 | 3 | 1.149 |

| Ø 48.3X4.05 | 48.3 | 4.05 | 1.526 |

| Ø 48.3X4.2 | 48.3 | 4.2 | 1.577 |

| Ø 48.3X4.47 | 48.3 | 4.47 | 1.668 |

| Ø 48.3x9.9 | 48.3 | 9.9 | 3.225 |

| Ø 48.6X3 | 48.6 | 3 | 1.16 |

| Ø 48.26x3.68 | 48.26 | 3.68 | 1.398 |

| Ø 48X1 | 48 | 1 | 0.4 |

| Ø 48X1.3 | 48 | 1.3 | 0.517 |

| Ø 49x11.5 | 49 | 11.5 | 3.672 |

| Ø 50X2 | 50 | 2 | 0.818 |

| Ø 50x2.5 | 50 | 2.5 | 1.012 |

| Ø 50X3.0 | 50 | 3 | 1.2 |

| Ø 50X4.8 | 50 | 4.8 | 1.847 |

| Ø 50x5 | 50 | 5 | 1.916 |

| Ø 50x7.5 | 50 | 7.5 | 2.714 |

| Ø 50X10 | 50 | 10 | 3.405 |

| Ø 50X12.5 | 50 | 12.5 | 3.991 |

| Ø 50.1X10.15 | 50.1 | 10.15 | 3.452 |

| Ø 50.2x8.6 | 50.2 | 8.6 | 3.117 |

| Ø 50.8X1.27 | 50.8 | 1.27 | 0.535 |

| Ø 50.8X1.52 | 50.8 | 1.52 | 0.638 |

| Ø 50.8X1.6 | 50.8 | 1.6 | 0.67 |

| Ø 50.8X2.54 | 50.8 | 2.54 | 1.044 |

| Ø 50.8X3.18 | 50.8 | 3.18 | 1.289 |

| Ø 50.8X4.5 | 50.8 | 4.5 | 1.774 |

| Ø 51X1.9 | 51 | 1.9 | 0.795 |

| Ø 51x12.5 | 51 | 12.5 | 4.097 |

| Ø 52.5X1 | 52.5 | 1 | 0.439 |

| Ø 53.4X0.85 | 53.4 | 0.85 | 0.38 |

| Ø 55X7.5 | 55 | 7.5 | 3.033 |

| Ø 55X12.5 | 55 | 12.5 | 4.523 |

| Ø 56-5.5 | 56 | 5.5 | 2.795 |

| Ø 57.1X2.75 | 57.1 | 2.75 | 1.272 |

| Ø 59X1.5 | 59 | 1.5 | 0.735 |

| Ø 60X1.5 | 60 | 1.5 | 0.747 |

| Ø 60X2.0 | 60 | 2 | 0.988 |

| Ø 60x2.5 | 60 | 2.5 | 1.312 |

| Ø 60X3.0 | 60 | 3 | 1.456 |

| Ø 60x5 | 60 | 5 | 2.342 |

| Ø 60X12.5 | 60 | 12.5 | 5.056 |

| Ø 60X15 | 60 | 15 | 5.747 |

| Ø 60X17.5 | 60 | 17.5 | 6.333 |

| Ø 60.1X10.15 | 60.1 | 10.15 | 4.316 |

| Ø 60.32x3.91 | 60.32 | 3.91 | 1.879 |

| Ø 60.5x5.0 | 60.5 | 5 | 2.379 |

| Ø 61X2.0 | 61 | 2 | 1.001 |

| Ø 62X9.5 | 62 | 9.5 | 4.404 |

| Ø 63-7.0 | 63 | 7 | 3.337 |

| Ø 65.2X12.7 | 65.2 | 12.7 | 5.677 |

| Ø 65X7.5 | 65 | 7.5 | 3.672 |

| Ø 66.5x2.5 | 66.5 | 2.5 | 1.47 |

| Ø 66x9.5A | 66 | 9.5 | 4.667 |

| Ø 70X2 | 70 | 2 | 1.158 |

| Ø 70X2.5 | 70 | 2.5 | 1.437 |

| Ø 70x3.94 | 70 | 3.94 | 2.228 |

| Ø 70X5 | 70 | 5 | 2.767 |

| Ø 70X7.5 | 70 | 7.5 | 3.992 |

| Ø 70X10 | 70 | 10 | 5.108 |

| Ø 70X15 | 70 | 15 | 7.024 |

| Ø 70X20 | 70 | 20 | 8.514 |

| Ø 71.94x5.19 | 71.94 | 5.19 | 2.949 |

| Ø 73.02X5.16 | 73.02 | 5.16 | 2.979 |

| Ø 75x5 | 75 | 5 | 2.98 |

| Ø 76.2X3.18 | 76.2 | 3.18 | 1.977 |

| Ø 76.96X3.56 | 76.96 | 3.56 | 2.222 |

| Ø 76.96X5.14 | 76.96 | 5.14 | 3.143 |

| Ø 79.38x3.42 | 79.38 | 3.42 | 2.212 |

| Ø 80X2 | 80 | 2 | 1.329 |

| Ø 80X2.5 | 80 | 2.5 | 1.65 |

| Ø 80X3 | 80 | 3 | 1.967 |

| Ø 80X4 | 80 | 4 | 2.588 |

| Ø 80x5 | 80 | 5 | 3.193 |

| Ø 80X8 | 80 | 8 | 4.904 |

| Ø 80X10 | 80 | 10 | 5.959 |

| Ø 80X15 | 80 | 15 | 8.3 |

| Ø 80X20 | 80 | 20 | 10.216 |

| Ø 80x25 | 80 | 25 | 11.706 |

| Ø 80.2X20.2 | 80.2 | 20.2 | 10.319 |

| Ø 80.2X25.2 | 80.2 | 25.2 | 11.8 |

| Ø 85X1.3 | 85 | 1.3 | 0.923 |

| Ø 86.6X1.9 | 86.6 | 1.9 | 1.37 |

| Ø 87.3X2 | 87.3 | 2 | 1.453 |

| Ø 87.64x3.5 | 87.64 | 3.5 | 2.507 |

| Ø 88.9X3.18 | 88.9 | 3.18 | 2.321 |

| Ø 88.9x5.49 | 88.9 | 5.49 | 3.899 |

| Ø 90X2 | 90 | 2 | 1.498 |

| Ø 90X5 | 90 | 5 | 3.618 |

| Ø 90x10 | 90 | 10 | 6.812 |

| Ø 90X12.5 | 90 | 12.5 | 8.248 |

| Ø 90X15 | 90 | 15 | 9.578 |

| Ø 90.3x15.25 | 90.3 | 15.25 | 9.744 |

| Ø 90.3X20.25 | 90.3 | 20.25 | 12.077 |

| Ø 90.3X25.25 | 90.3 | 25.25 | 13.984 |

| Ø 93X1.7 | 93 | 1.7 | 1.321 |

| Ø 100X5 | 100 | 5 | 4.044 |

| Ø 100X8.0 | 100 | 8 | 6.266 |

| Ø 100X10 | 100 | 10 | 7.662 |

| Ø 100X12 | 100 | 12 | 8.99 |

| Ø 100X15 | 100 | 15 | 10.855 |

| Ø 100x20 | 100 | 20 | 13.622 |

| Ø 100X25 | 100 | 25 | 15.963 |

| Ø 100X30 | 100 | 30 | 17.879 |

| Ø 100.2X20.2 | 100.2 | 20.2 | 13.758 |

| Ø 101.6X1.83 | 101.6 | 1.83 | 1.556 |

| Ø 101.6X3.18 | 101.6 | 3.18 | 2.664 |

| Ø 101.6X5.74 | 101.6 | 5.74 | 4.685 |

| Ø 108X1.95 | 108 | 1.95 | 1.761 |

| Ø 110X5 | 110 | 5 | 4.47 |

| Ø 110X10 | 110 | 10 | 8.515 |

| Ø 110X15 | 110 | 15 | 12.132 |

| Ø 114.3X3.05 | 114.3 | 3.05 | 2.886 |

| Ø 114.3x6.02 | 114.3 | 6.02 | 5.55 |

| Ø 114.3x8.56 | 114.3 | 8.56 | 7.707 |

| Ø 120x2.5 | 120 | 2.5 | 2.502 |

| Ø 120X5.0 | 120 | 5 | 4.9 |

| Ø 120X8 | 120 | 8 | 7.628 |

| Ø 120X10 | 120 | 10 | 9.365 |

| Ø 120X15 | 120 | 15 | 13.409 |

| Ø 120X20 | 120 | 20 | 17.027 |

| Ø 127X3.18 | 127 | 3.18 | 3.352 |

| Ø 127X3.5 | 127 | 3.5 | 3.68 |

| Ø 127X4.78 | 127 | 4.78 | 4.97 |

| Ø 130X5 | 130 | 5 | 5.3 |

| Ø 130X10 | 130 | 10 | 10.217 |

| Ø 140x5 | 140 | 5 | 5.747 |

| Ø 140X10 | 140 | 10 | 11.068 |

| Ø 140X15 | 140 | 15 | 15.962 |

| Ø 141.3x6.55 | 141.3 | 6.55 | 7.518 |

| Ø 144X4.5 | 144 | 4.5 | 5.345 |

| Ø 150X3 | 150 | 3 | 3.754 |

| Ø 150X3.18 | 150 | 3.18 | 3.975 |

| Ø 150X5.0 | 150 | 5 | 6.173 |

| Ø 150X8 | 150 | 8 | 9.671 |

| Ø 150X15 | 150 | 15 | 17.24 |

| Ø 150X20 | 150 | 20 | 22.136 |

| Ø 152.4X3.18 | 152.4 | 3.18 | 4.041 |

| Ø 156X3.0 | 156 | 3 | 3.908 |

| Ø 160X5 | 160 | 5 | 6.599 |

| Ø 160x10 | 160 | 10 | 12.771 |

| Ø 160X15 | 160 | 15 | 18.517 |

| Ø 161X8 | 161 | 8 | 10.482 |

| Ø 168.28X4.2 | 168.28 | 4.2 | 5.867 |

| Ø 170X5 | 170 | 5 | 7.024 |

| Ø 171X8.5 | 171 | 8.5 | 11.825 |

| Ø 180X5 | 180 | 5 | 7.45 |

| Ø 180x6 | 180 | 6 | 8.889 |

| Ø 180X10 | 180 | 10 | 14.473 |

| Ø 180X15 | 180 | 15 | 21.071 |

| Ø 181X8.5 | 181 | 8.5 | 12.553 |

| Ø 189X5.0 | 189 | 5 | 7.833 |

| Ø 190X5 | 190 | 5 | 7.875 |

| Ø 200X5 | 200 | 5 | 8.301 |

| Ø 200X10 | 200 | 10 | 16.176 |

| Ø 203.2X3.18 | 203.2 | 3.18 | 5.415 |

| Ø 208X4 | 208 | 4 | 6.947 |

| Ø 219.08X8.18 | 219.08 | 8.18 | 14.687 |

| Ø 221.5X10.5 | 221.5 | 10.5 | 19.311 |

| Ø 235X5.1 | 235 | 5.1 | 9.982 |

| Ø 285X6 | 285 | 6 | 14.252 |

Supported standards: EN 755 and GB 5237.1; AA / ASTM on request. Small OD can be cold drawn to final size. Final delivery is based on the approved process sheet and EN 10204 3.1 material certificate.

6061-T6 / T6511 Aluminum Round Tube Die Table

Balanced strength and machinability. Optional cold drawing can be used to improve roundness and concentricity for tighter fit.

The table below shows the dedicated 6061 aluminum round tube dies library, including in-stock tooling for large OD (up to Ø560 mm). If your required size is not listed, please send a drawing for assessment.

| OD(in) | OD(mm) | Thickness(mm) | Linear Weight (kg/m) | Extrusion Press Capacity (T) |

| 0.37" | 9.52 | 1.65 | 0.110 | 500T |

| 1/2" | 12.7 | 1.2 | 0.117 | 500T |

| 1/2" | 12.7 | 1.47 | 0.141 | 500T |

| 0.54" | 13.6 | 4.3 | 0.339 | 660T |

| 0.55" | 14 | 1.6 | 0.168 | 500T |

| 0.59" | 15 | 1 | 0.119 | 500T |

| 5/8" | 15.88 | 1.2 | 0.149 | 500T |

| 5/8" | 16 | 6 | 0.509 | 660T |

| 3/4" | 19 | 1.8 | 0.263 | 660T |

| 3/4" | 19.05 | 1.24 | 0.189 | 500T |

| 3/4" | 19.05 | 1.45 | 0.216 | 500T |

| 3/4" | 19.05 | 1.65 | 0.244 | 500T |

| 3/4" | 19.05 | 3.05 | 0.414 | 660T |

| 3/4" | 19.05 | 3.18 | 0.428 | 660T |

| 0.80" | 20.35 | 6.28 | 0.749 | 880T |

| 0.84" | 21.34 | 3.73 | 0.557 | 660T |

| 0.87" | 22 | 6 | 0.814 | 880T |

| 0.87" | 22.1 | 2 | 0.341 | 660T |

| 0.87" | 22.1 | 2.4 | 0.401 | 660T |

| 0.87" | 22.2 | 1.8 | 0.311 | 660T |

| 0.87" | 22.22 | 1-1/4" | 0.221 | 500T |

| 0.88" | 22.23 | 1.45 | 0.256 | 500T |

| 0.98" | 25 | 2.2 | 0.425 | 660T |

| 0.98" | 25 | 6.5 | 1.020 | 880T |

| 1" | 25.4 | 1.2 | 0.246 | 500T |

| 1" | 25.4 | 1.45 | 0.295 | 500T |

| 1" | 25.4 | 1.65 | 0.333 | 660T |

| 1" | 25.4 | 2.11 | 0.417 | 660T |

| 1" | 25.4 | 3.05 | 0.578 | 880T |

| 1" | 25.4 | 3.18 | 0.599 | 880T |

| 1" | 25.4 | 3.99 | 0.724 | 880T |

| 1" | 25.4 | 6.35 | 1.026 | 880T |

| 1.05" | 26.67 | 2.87 | 0.580 | 880T |

| 1.10" | 28 | 7 | 1.247 | 1250T |

| 1.13" | 28.58 | 1.45 | 0.334 | 660T |

| 1.14" | 29 | 6.75 | 1.274 | 1250T |

| 1.18" | 30 | 6.5 | 1.296 | 1250T |

| 1.18" | 30 | 10 | 1.696 | 1250T |

| 1-1/4" | 31-3/4" | 1.2 | 0.311 | 660T |

| 1-1/4" | 31-3/4" | 1.45 | 0.373 | 660T |

| 1-1/4" | 31-3/4" | 1.65 | 0.421 | 660T |

| 1-1/4" | 31-3/4" | 2.11 | 0.530 | 660T |

| 1-1/4" | 31-3/4" | 3.05 | 0.741 | 880T |

| 1-1/4" | 31-3/4" | 3.18 | 0.769 | 880T |

| 1-1/4" | 31-3/4" | 4.7625 | 1.090 | 880T |

| 1-1/4" | 31-3/4" | 6.35 | 1.368 | 1250T |

| 1.26" | 32 | 2.8 | 0.694 | 880T |

| 1.30" | 33 | 1.55 | 0.413 | 660T |

| 1.31" | 33.4 | 3.38 | 0.860 | 880T |

| 1.31" | 33.4 | 3.43 | 0.872 | 880T |

| 1.31" | 33.4 | 4.55 | 1.113 | 1250T |

| 1.33" | 33.8 | 9.95 | 2.013 | 1800T |

| 1.34" | 34 | 4 | 1.018 | 880T |

| 1.38" | 34.925 | 4.191 | 1.093 | 880T |

| 1.38" | 35 | 3.25 | 0.875 | 880T |

| 1.42" | 36 | 10 | 2.536 | 2000T |

| 1-1/2" | 38 | 1.55 | 0.479 | 660T |

| 1-1/2" | 38 | 1.9 | 0.582 | 880T |

| 1-1/2" | 38 | 3 | 0.891 | 880T |

| 1-1/2" | 38.1 | 1.45 | 0.451 | 660T |

| 1-1/2" | 38.1 | 1.65 | 0.511 | 880T |

| 1-1/2" | 38.1 | 1.8 | 0.554 | 880T |

| 1-1/2" | 38.1 | 2.11 | 0.643 | 880T |

| 1-1/2" | 38.1 | 2.18 | 0.665 | 880T |

| 1-1/2" | 38.1 | 3.05 | 0.905 | 880T |

| 1-1/2" | 38.1 | 3.18 | 0.940 | 880T |

| 1-1/2" | 38.1 | 6.35 | 1.710 | 1250T |

| 1.51" | 38.3 | 3 | 0.898 | 880T |

| 1.57" | 40 | 2.5 | 0.795 | 880T |

| 1.65" | 42 | 3.5 | 1.143 | 880T |

| 1.66" | 42.16 | 3.56 | 1.165 | 1250T |

| 1.69" | 43 | 3 | 1.018 | 880T |

| 1-3/4" | 44.45 | 1.45 | 0.529 | 660T |

| 1-3/4" | 44.45 | 3.18 | 1.111 | 1250T |

| 1-3/4" | 44.45 | 6.35 | 2.052 | 1250T |

| 1-3/4" | 44.45 | 7.62 | 2.381 | 2000T |

| 1.81" | 46 | 6 | 2.036 | 1250T |

| 1.90" | 48.26 | 3.68 | 1.392 | 1250T |

| 1.90" | 48.26 | 5.08 | 1.860 | 1250T |

| 1.91" | 48.4 | 4.47 | 1.666 | 1250T |

| 1.96" | 49.7 | 3 | 1.188 | 1250T |

| 1.97" | 50 | 1.9 | 0.775 | 880T |

| 1.97" | 50 | 2 | 0.814 | 880T |

| 1.97" | 50 | 2.7 | 1.083 | 1250T |

| 1.97" | 50 | 2.75 | 1.102 | 1250T |

| 2" | 50.8 | 1.8 | 0.748 | 880T |

| 2" | 50.8 | 3.05 | 1.235 | 880T |

| 2" | 50.8 | 3.175 | 1.283 | 880T |

| 2" | 50.8 | 3.18 | 1.281 | 1250T |

| 2" | 50.8 | 4.78 | 1.863 | 1250T |

| 2" | 50.8 | 6.35 | 2.393 | 1250T |

| 2.06" | 52.45 | 3.05 | 1.278 | 1250T |

| 2.13" | 53.98 | 7.9375 | 3.100 | 2000T |

| 2.24" | 57 | 4 | 1.798 | 1250T |

| 2.36" | 60 | 5 | 2.333 | 1800T |

| 2.38" | 60.33 | 3.91 | 1.872 | 1250T |

| 2.38" | 60.33 | 5.54 | 2.571 | 1250T |

| 2.44" | 62 | 4 | 1.968 | 1250T |

| 2-1/2" | 63.5 | 3.18 | 1.625 | 1250T |

| 2-1/2" | 63.5 | 15.875 | 6.413 | 3600T |

| 2.56" | 65 | 1.5 | 0.808 | 880T |

| 2.99" | 76 | 5 | 3.011 | 2000T |

| 3" | 76.2 | 3.18 | 1.966 | 1250T |

| 3" | 76.2 | 6.35 | 3.761 | 2000T |

| 3-1/2" | 88.9 | 7.62 | 5.254 | 2000T |

| 3-1/2" | 89 | 5 | 3.563 | 2750T |

| 3-1/2" | 89 | 6 | 4.224 | 2750T |

| 3.94" | 100 | 6 | 4.784 | 2750T |

| 4" | 101.6 | 3.18 | 2.651 | 2000T |

| 4" | 101.6 | 6.35 | 5.130 | 3150T |

| 4-1/4" | 108 | 8 | 6.786 | 3600T |

| 4.49 | 114 | 6 | 5.497 | 3150T |

| 4-1/2" | 114.3 | 5.41 | 4.996 | 2000T |

| 4-1/2" | 114.3 | 6.02 | 5.527 | 2000T |

| 4-1/2" | 114.3 | 8.56 | 7.673 | 3600T |

| 5" | 127 | 4.78 | 4.951 | 3150T |

| 5" | 127 | 6.35 | 6.496 | 3600T |

| 5" | 127 | 12.7 | 12.313 | 7500T |

| 5" | 127 | 25.4 | 21.890 | 7500T |

| 6-1/2" | 165 | 7 | 9.381 | 3600T |

| 6.62" | 168.27 | 7.11 | 9.722 | 3600T |

| 6.63" | 168.28 | 7.11 | 9.723 | 3600T |

| 6.63" | 168.3 | 10.97 | 14.641 | 3600T |

| 7" | 177.8 | 6.35 | 9.235 | 3600T |

| 7" | 177.8 | 9.53 | 13.596 | 3600T |

| 7.24" | 184 | 8 | 11.923 | 3600T |

| 8" | 203.2 | 6.35 | 10.603 | 3600T |

| 8.54" | 217 | 8 | 14.182 | 5500T |

| 8.63" | 219.1 | 8.18 | 14.631 | 3600T |

| 8.63" | 219.1 | 12.7 | 22.232 | 3600T |

| 8.66" | 220 | 16 | 27.686 | 7500T |

| 9.45" | 240 | 16 | 30.401 | 7500T |

| 10" | 254 | 15.875 | 32.065 | 7500T |

| 10.04" | 255 | 24 | 47.026 | 12500T |

| 11.10" | 282 | 6 | 14.047 | 7500T |

| 11.73" | 298 | 21.5 | 50.425 | 12500T |

| 12" | 304.8 | 6.35 | 16.075 | 7500T |

| 12.20" | 310 | 20 | 49.197 | 12500T |

| 14.57" | 370 | 8 | 24.565 | 9000T |

| 15.63" | 397 | 20.5 | 67.729 | 22500T |

| 16.18" | 411 | 30 | 96.953 | 22500T |

| 18.46" | 469 | 25.5 | 95.928 | 22500T |

| 22.05" | 560 | 25.5 | 115.612 | 12500T |

Supply Standards (Example): AA / ASTM (in production) | EN 755 (available on request) | GB 5237.1 (on request)

Note: Final delivery will follow the approved drawing / process sheet and EN 10204 3.1. For tighter tolerances, cold drawing can be evaluated.

6063-T5 / T52 Aluminum Round Tube Die Table

Fine surface finish and consistent anodizing appearance. Suitable for architectural profiles, railing systems, and display structures.

Available supply standards: EN 755, ASTM B210, ASTM B211, GB/T 14846 (high precision), GB 5237.1 (high precision).

The table below shows the dedicated 6063 aluminum round tube dies library, including in-stock tooling for large OD (up to Ø760 mm). For anodized or coated appearance parts, please note anodizing / powder coating requirements when requesting a quote.

| OD(in) | OD(mm) | Thickness(mm) | Linear Weight (kg/m) | Extrusion Press Capacity (T) |

| 1/4" | 6.35 | 1 | 0.045 | 500T |

| 5/16" | 7.95 | 1.2 | 0.069 | 500T |

| 0.35" | 9 | 1.2 | 0.079 | 500T |

| 0.39" | 10 | 1.5 | 0.108 | 500T |

| 0.39" | 10 | 2.6 | 0.163 | 500T |

| 0.39" | 10 | 3.75 | 0.199 | 500T |

| 1/2" | 12.7 | 0.9 | 0.09 | 500T |

| 1/2" | 12.7 | 1.52 | 0.144 | 500T |

| 1/2" | 12.7 | 1.63 | 0.153 | 500T |

| 0.55" | 14 | 2.925 | 0.275 | 500T |

| 0.55" | 14 | 3.75 | 0.326 | 660T |

| 5/8" | 15.875 | 1.63 | 0.197 | 500T |

| 5/8" | 15.88 | 0.9 | 0.114 | 500T |

| 5/8" | 15.88 | 1.2 | 0.149 | 500T |

| 5/8" | 15.88 | 1.42 | 0.174 | 500T |

| 5/8" | 16 | 3 | 0.331 | 660T |

| 0.67" | 17 | 1.1 | 0.148 | 500T |

| 0.71" | 18 | 1 | 0.144 | 500T |

| 0.71" | 18 | 3.25 | 0.407 | 660T |

| 3/4" | 19 | 0.8 | 0.124 | 500T |

| 3/4" | 19 | 0.9 | 0.138 | 500T |

| 3/4" | 19.05 | 0.9 | 0.139 | 500T |

| 3/4" | 19.05 | 1 | 0.153 | 500T |

| 0.79" | 20 | 1 | 0.161 | 500T |

| 0.79" | 20 | 1.5 | 0.235 | 500T |

| 0.79" | 20 | 2 | 0.305 | 660T |

| 0.83" | 21 | 1.8 | 0.293 | 500T |

| 0.84" | 21.34 | 2.77 | 0.435 | 660T |

| 0.85" | 21.7 | 2 | 0.334 | 660T |

| 0.86" | 21.8 | 1.6 | 0.274 | 500T |

| 0.87" | 22 | 1 | 0.178 | 500T |

| 0.87" | 22 | 1.6 | 0.277 | 500T |

| 0.87" | 22 | 1.6 | 0.277 | 500T |

| 0.87" | 22 | 1.7 | 0.293 | 500T |

| 0.87" | 22 | 1.8 | 0.308 | 660T |

| 0.87" | 22 | 2 | 0.339 | 660T |

| 0.87" | 22.22 | 1.65 | 0.288 | 660T |

| 0.98" | 25 | 1.15 | 0.233 | 500T |

| 0.98" | 25 | 1.2 | 0.242 | 500T |

| 0.98" | 25 | 1.8 | 0.354 | 660T |

| 0.98" | 25 | 2 | 0.39 | 660T |

| 0.98" | 25 | 2.25 | 0.434 | 660T |

| 0.98" | 25 | 4 | 0.713 | 880T |

| 1" | 25.4 | 0.9 | 0.187 | 500T |

| 1" | 25.4 | 1.22 | 0.25 | 500T |

| 1" | 25.4 | 1.57 | 0.318 | 660T |

| 1" | 25.4 | 2 | 0.397 | 660T |

| 1.02" | 26 | 1.5 | 0.312 | 660T |

| 1.02" | 26 | 2 | 0.407 | 660T |

| 1.02" | 26 | 3 | 0.585 | 660T |

| 1.05" | 26.67 | 2.87 | 0.58 | 660T |

| 1-1/16" | 27 | 1.2 | 0.263 | 500T |

| 1-1/16" | 27 | 1.4 | 0.304 | 660T |

| 1.08" | 27.5 | 2.1 | 0.452 | 660T |

| 1.09" | 27.8 | 2.1 | 0.458 | 660T |

| 1.1" | 28 | 1.3 | 0.294 | 500T |

| 1.1" | 28 | 1.5 | 0.337 | 660T |

| 1.1" | 28 | 1.5 | 0.337 | 660T |

| 1.1" | 28 | 2 | 0.441 | 660T |

| 1.1" | 28 | 2.5 | 0.541 | 660T |

| 1.1" | 28 | 3.5 | 0.727 | 880T |

| 1.11" | 28.2 | 1.8 | 0.403 | 660T |

| 1-1/8" | 28.6 | 1.4 | 0.323 | 660T |

| 1.15" | 29.1 | 1.15 | 0.273 | 500T |

| 1-3/16" | 30 | 1.5 | 0.363 | 660T |

| 1-3/16" | 30 | 1.5 | 0.363 | 660T |

| 1-3/16" | 30 | 5 | 1.06 | 1250T |

| 1-1/4" | 32 | 1 | 0.263 | 500T |

| 1-1/4" | 32 | 1.5 | 0.388 | 660T |

| 1-1/4" | 32 | 1.9 | 0.485 | 880T |

| 1.3" | 33 | 2.5 | 0.647 | 880T |

| 1.32" | 33.6 | 8.3 | 1.781 | 1250T |

| 1.33" | 33.66 | 3.11 | 0.806 | 880T |

| 1.42" | 36 | 1.3 | 0.383 | 660T |

| 1.46" | 37 | 1 | 0.305 | 660T |

| 1-1/2" | 38 | 1.7 | 0.523 | 880T |

| 1-1/2" | 38 | 2 | 0.611 | 880T |

| 1-1/2" | 38.1 | 1.2 | 0.376 | 660T |

| 1-1/2" | 38.1 | 1.57 | 0.488 | 880T |

| 1-1/2" | 38.1 | 2.64 | 0.794 | 880T |

| 1.57" | 40 | 1.3 | 0.427 | 660T |

| 1.57" | 40 | 2.75 | 0.869 | 880T |

| 1.73" | 44 | 1.3 | 0.471 | 660T |

| 1.73" | 44 | 10 | 2.884 | 2000T |

| 1-3/4" | 44.45 | 1.24 | 0.456 | 660T |

| 1.81" | 46 | 2.8 | 1.026 | 880T |

| 1.82" | 46.2 | 1.1 | 0.421 | 660T |

| 1.89" | 48 | 1.3 | 0.515 | 660T |

| 1.91" | 48.4 | 4.5 | 1.676 | 1250T |

| 1.97" | 50 | 2 | 0.814 | 880T |

| 1.99" | 50.5 | 2 | 0.823 | 880T |

| 2" | 50.8 | 2 | 0.828 | 880T |

| 2.05" | 52 | 1.3 | 0.559 | 660T |

| 2-1/8" | 53.98 | 1.54 | 0.685 | 880T |

| 2-1/8" | 54.1 | 34.7 | 0.727 | 880T |

| 2.17" | 55 | 1.5 | 0.681 | 880T |

| 2.2" | 56 | 1.3 | 0.603 | 880T |

| 2-1/4" | 57 | 3 | 1.374 | 1250T |

| 2-1/4" | 57.15 | 1.65 | 0.776 | 880T |

| 2.36" | 60 | 1.3 | 0.647 | 880T |

| 2-1/2" | 63.5 | 1.63 | 0.853 | 880T |

| 2-1/2" | 63.5 | 1.65 | 0.866 | 880T |

| 2-1/2" | 63.5 | 3.05 | 1.563 | 1250T |

| 2-1/2" | 63.5 | 3.25 | 1.661 | 1250T |

| 2-1/2" | 63.7 | 1.22 | 0.647 | 880T |

| 2.52" | 64 | 1.3 | 0.691 | 880T |

| 2.52" | 64 | 4 | 2.072 | 1800T |

| 2.68" | 68 | 1.3 | 0.736 | 880T |

| 2-3/4" | 69.85 | 1.65 | 0.955 | 880T |

| 2-3/4" | 70 | 2.5 | 1.431 | 1250T |

| 2.84" | 72.2 | 1.4 | 0.841 | 880T |

| 2.88" | 73.03 | 5.16 | 2.967 | 2000T |

| 3" | 76 | 3.5 | 2.152 | 1250T |

| 3" | 76.2 | 1.4 | 0.888 | 880T |

| 3" | 76.2 | 1.5 | 0.95 | 1250T |

| 3" | 76.2 | 1.63 | 1.031 | 1250T |

| 3.03" | 76.95 | 1.22 | 0.784 | 880T |

| 3.35" | 85 | 10 | 6.362 | 3150T |

| 3-3/8" | 85.9 | 2.675 | 1.888 | 1250T |

| 3.46" | 87.8 | 2 | 1.456 | 1250T |

| 3-1/2" | 88.9 | 1.65 | 1.222 | 1250T |

| 3-1/2" | 88.9 | 5.49 | 3.882 | 2000T |

| 3-1/2" | 89 | 4.05 | 2.918 | 1800T |

| 3.54" | 90 | 2.5 | 1.856 | 1250T |

| 3.54" | 90 | 10 | 6.786 | 3600T |

| 3.54" | 90 | 12.5 | 8.217 | 3600T |

| 3.54" | 90 | 15 | 9.543 | 3600T |

| 3.66" | 93 | 10 | 7.04 | 3600T |

| 3-3/4" | 95 | 4 | 3.088 | 2000T |

| 3.94" | 100 | 20 | 13.572 | 3600T |

| 4" | 101.6 | 1.63 | 1.379 | 1250T |

| 4" | 101.6 | 1.63 | 1.382 | 1250T |

| 4" | 101.6 | 1.65 | 1.4 | 1250T |

| 4" | 101.6 | 2.41 | 2.028 | 2000T |

| 4" | 101.6 | 3.25 | 2.712 | 3150T |

| 4" | 101.6 | 4.78 | 3.922 | 2000T |

| 4.02" | 102 | 1.6 | 1.363 | 1800T |

| 4.02" | 102 | 1.8 | 1.53 | 1250T |

| 4.13" | 105 | 22.5 | 15.745 | 7500T |

| 4.33" | 110 | 5.5 | 4.875 | 2750T |

| 4.33" | 110 | 6 | 5.293 | 3150T |

| 4.49" | 114 | 4.25 | 3.956 | 2000T |

| 4.49" | 114 | 7 | 6.353 | 3600T |

| 4.49" | 114 | 17 | 13.987 | 7500T |

| 4.53" | 115 | 10 | 8.906 | 3600T |

| 4.72" | 120 | 6 | 5.802 | 3150T |

| 4.92" | 125 | 2 | 2.087 | 2000T |

| 4.92" | 125 | 4.5 | 4.6 | 2750T |

| 5" | 127 | 3.18 | 3.335 | 2000T |

| 5-1/8" | 130 | 7 | 7.303 | 3600T |

| 5-1/8" | 130 | 25 | 22.266 | 3150T |

| 5.28" | 134 | 7 | 7.541 | 3600T |

| 5.28" | 134 | 15 | 15.141 | 7500T |

| 5.51" | 140 | 4 | 4.614 | 2750T |

| 5.51" | 140 | 6 | 6.82 | 3600T |

| 5.51" | 140 | 15 | 15.904 | 7500T |

| 5.71" | 145 | 22.5 | 23.379 | 7500T |

| 5.91" | 150 | 6 | 7.329 | 3600T |

| 5.91" | 150 | 12.5 | 14.579 | 7500T |

| 5.98" | 152 | 2.5 | 3.17 | 2750T |

| 6" | 152.4 | 2.5 | 3.179 | 2750T |

| 6.1" | 155 | 17.5 | 20.411 | 7500T |

| 6.3" | 160 | 10 | 12.723 | 5500T |

| 6.3" | 160 | 15 | 18.449 | 5500T |

| 6-1/2" | 165 | 3.5 | 4.795 | 3600T |

| 6.61" | 168 | 6.5 | 8.904 | 3600T |

| 6.61" | 168 | 6.5 | 8.904 | 3600T |

| 6.69" | 170 | 8 | 10.993 | 3600T |

| 7.09" | 180 | 15 | 20.994 | 7500T |

| 7.87" | 200 | 4 | 6.65 | 3600T |

| 8.66" | 220 | 15 | 26.083 | 5500T |

| 8.98" | 228 | 4 | 7.6 | 5500T |

| 8.98" | 228 | 10 | 18.491 | 5500T |

| 9.53" | 242 | 10 | 19.679 | 7500T |

| 10" | 254 | 7 | 14.666 | 7500T |

| 10.63" | 270 | 15 | 32.979 | 12500T |

| 11.02" | 280 | 3 | 7.049 | 7500T |

| 11.65" | 296 | 7 | 17.16 | 7500T |

| 11.81" | 300 | 5 | 12.511 | 7500T |

| 11.89" | 302 | 6 | 15.065 | 7500T |

| 11.93" | 303 | 18 | 43.514 | 12500T |

| 12.05" | 306 | 8 | 20.222 | 7500T |

| 12-3/4" | 324 | 7 | 18.822 | 12500T |

| 13.11" | 333 | 7.5 | 20.707 | 7500T |

| 13.66" | 347 | 15 | 42.242 | 9000T |

| 14.17" | 360 | 6 | 18.016 | 9000T |

| 14.45" | 367 | 32.5 | 92.213 | 22500T |

| 14.65" | 372 | 10 | 30.706 | 12500T |

| 15.45" | 392.4 | 6.2 | 20.31 | 9000T |

| 15.51" | 394 | 7 | 22.979 | 12500T |

| 15.71" | 399 | 6.5 | 21.64 | 12500T |

| 15-3/4" | 400 | 7 | 23.335 | 12500T |

| 15.83" | 402 | 11 | 36.482 | 12500T |

| 19.37" | 492 | 6 | 24.734 | 12500T |

| 19.45" | 494 | 7 | 28.916 | 12500T |

| 19.69" | 500 | 10 | 41.563 | 12500T |

| 20.67" | 525 | 10 | 43.684 | 12500T |

| 29.92" | 760 | 12 | 75.119 | 22500T |

Supported standards: EN 755 and GB 5237.1; AA / ASTM on request. Small OD can be cold drawn to final size. Final delivery is based on the approved process sheet and EN 10204 3.1 material certificate.

6082-O / T6 / T6511 Aluminum Round Tube Die Table

6082 is a high-strength 6xxx alloy suitable for load-bearing structures and equipment frames. It remains stable even in larger OD ranges.

Applicable standards: EN 755, ASTM B210, ASTM B211, GB/T 14846 (high precision), GB 5237.1 (high precision).

The table below shows the dedicated 6082 aluminum round tube dies library, including in-stock tooling for large OD (up to Ø495 mm). If you need tighter tolerance or have downstream machining, please note it in your RFQ.

| OD(in) | OD(mm) | Thickness(mm) | Linear Weight (kg/m) | Extrusion Press Capacity (T) |

| 3/4" | 19 | 4 | 0.509 | 660T |

| 3/4" | 19.05 | 1.63 | 0.24 | 500T |

| 3/4" | 19.05 | 1.63 | 0.24 | 500T |

| 3/4" | 19.05 | 2.03 | 0.293 | 500T |

| 3/4" | 19.05 | 3.25 | 0.436 | 660T |

| 0.77" | 19.5 | 3.25 | 0.448 | 660T |

| 0.79" | 20 | 5.5 | 0.676 | 880T |

| 0.81" | 20.7 | 4.25 | 0.593 | 660T |

| 0.83" | 21 | 5.4 | 0.715 | 880T |

| 0.87" | 22 | 3 | 0.483 | 660T |

| 0.87" | 22 | 5.9 | 0.806 | 660T |

| 0.89" | 22.5 | 4.25 | 0.658 | 880T |

| 0.94" | 24 | 7.5 | 1.05 | 880T |

| 1" | 25.4 | 1.63 | 0.328 | 660T |

| 1" | 25.4 | 2.5 | 0.486 | 660T |

| 1" | 25.4 | 3.25 | 0.611 | 880T |

| 1.06" | 27 | 8.4 | 1.325 | 1250T |

| 1.13" | 28.58 | 1.8 | 0.409 | 660T |

| 1.18" | 30 | 3 | 0.687 | 880T |

| 1.18" | 30 | 9 | 1.603 | 1250T |

| 1.18" | 30 | 9.7 | 1.67 | 1250T |

| 1.18" | 30 | 10.7 | 1.752 | 1250T |

| 1.22" | 31 | 6.6 | 1.366 | 1250T |

| 1.22" | 31 | 6.75 | 1.388 | 1250T |

| 1-1/4" | 31.75 | 1.63 | 0.415 | 660T |

| 1-1/4" | 31.75 | 2.64 | 0.652 | 880T |

| 1-1/4" | 31.75 | 3.25 | 0.786 | 880T |

| 1-1/4" | 32 | 2.5 | 0.626 | 880T |

| 1-1/4" | 32 | 5.5 | 1.236 | 1250T |

| 1.3" | 33 | 6.5 | 1.461 | 1250T |

| 1.33" | 33.7 | 3.38 | 0.869 | 880T |

| 1.34" | 34 | 7.3 | 1.653 | 1250T |

| 1.34" | 34 | 8.05 | 1.772 | 500T |

| 1.38" | 34.925 | 3.25 | 0.873 | 880T |

| 1.38" | 35 | 10 | 2.121 | 1800T |

| 1.42" | 36 | 2 | 0.577 | 880T |

| 1.42" | 36 | 9.25 | 2.099 | 1800T |

| 1.44" | 36.5 | 3 | 0.852 | 880T |

| 1-1/2" | 38 | 3.5 | 1.024 | 880T |

| 1-1/2" | 38 | 9 | 2.214 | 1800T |

| 1-1/2" | 38 | 11 | 2.519 | 2000T |

| 1-1/2" | 38.1 | 3.25 | 0.961 | 880T |

| 1-1/2" | 38.1 | 4.5 | 1.283 | 1250T |

| 1.57" | 40 | 3.3 | 1.027 | 1250T |

| 1.57" | 40 | 5 | 1.484 | 1250T |

| 1.61" | 41 | 1.75 | 0.583 | 880T |

| 1.63" | 41.28 | 3.25 | 1.048 | 880T |

| 1.63" | 41.5 | 1.75 | 0.59 | 880T |

| 1-3/4" | 44.45 | 1.63 | 0.591 | 660T |

| 1.76" | 44.8 | 1.8 | 0.657 | 880T |

| 1.79" | 45.5 | 1.75 | 0.649 | 880T |

| 1.8" | 45.8 | 4 | 1.418 | 1250T |

| 1.9" | 48.3 | 4.05 | 1.52 | 1250T |

| 1.91" | 48.42 | 4.47 | 1.666 | 1250T |

| 1.97" | 50 | 5 | 1.909 | 2000T |

| 1.97" | 50 | 6 | 2.239 | 1800T |

| 1.97" | 50 | 7 | 2.553 | 2000T |

| 1.97" | 50 | 7 | 2.553 | 2000T |

| 1.97" | 50 | 8 | 2.85 | 2000T |

| 1.97" | 50 | 15 | 4.453 | 3150T |

| 2" | 50.7 | 1.8 | 0.747 | 880T |

| 2" | 50.8 | 1.55 | 0.648 | 880T |

| 2" | 50.8 | 1.63 | 0.678 | 880T |

| 2" | 50.8 | 1.8 | 0.748 | 880T |

| 2" | 50.8 | 2.5 | 1.024 | 880T |

| 2" | 50.8 | 3.25 | 1.311 | 1250T |

| 2" | 50.8 | 6.35 | 2.394 | 2000T |

| 2" | 50.8 | 9.525 | 3.335 | 2750T |

| 2" | 51 | 10.5 | 3.607 | 2000T |

| 2.17" | 55 | 8 | 3.189 | 2000T |

| 2.17" | 55 | 10 | 3.817 | 2750T |

| 2.2" | 56 | 2.25 | 1.026 | 1250T |

| 2-1/4" | 57.15 | 3.25 | 1.486 | 1250T |

| 2-1/4" | 57.15 | 9.525 | 3.848 | 2750T |

| 2.3" | 58.4 | 2 | 0.957 | 880T |

| 2.32" | 59 | 15.5 | 5.719 | 3600T |

| 2.36" | 60 | 8 | 3.529 | 2000T |

| 2.36" | 60 | 20 | 6.786 | 3600T |

| 2-1/2" | 63.5 | 6.35 | 3.078 | 2000T |

| 2-1/2" | 63.5 | 12.7 | 5.472 | 3150T |

| 2.52" | 64 | 16.5 | 6.648 | 3150T |

| 2.56" | 65 | 3.5 | 1.826 | 1800T |

| 2.56" | 65 | 15 | 6.362 | 3600T |

| 2-3/4" | 70 | 15 | 6.998 | 3150T |

| 2-3/4" | 70 | 20 | 8.482 | 3600T |

| 2.95" | 75 | 4 | 2.409 | 2000T |

| 2.95" | 75 | 4 | 2.409 | 2000T |

| 2.95" | 75 | 13 | 6.837 | 3600T |

| 2.95" | 75 | 15 | 7.634 | 3600T |

| 3" | 76.2 | 1.6 | 1.012 | 1250T |

| 3" | 76.2 | 1.63 | 1.031 | 1250T |

| 3" | 76.2 | 3.25 | 2.012 | 1250T |

| 3" | 76.2 | 9.525 | 5.387 | 3600T |

| 3" | 76.2 | 12.7 | 6.841 | 3600T |

| 3" | 76.2 | 19.05 | 9.235 | 3600T |

| 3.15" | 80 | 12.5 | 7.157 | 3600T |

| 3.15" | 80 | 25 | 11.663 | 7500T |

| 3.31" | 84 | 20.5 | 11.042 | 3600T |

| 3-1/2" | 88.9 | 3.25 | 2.361 | 2000T |

| 3-1/2" | 88.9 | 6.35 | 4.446 | 2750T |

| 3-1/2" | 88.9 | 12.7 | 8.209 | 3600T |

| 3-1/2" | 88.9 | 12.7 | 8.209 | 3600T |

| 3.54" | 90 | 4 | 2.918 | 2000T |

| 3.54" | 90 | 32 | 15.743 | 3150T |

| 3-3/4" | 95 | 5 | 3.817 | 2750T |

| 3.94" | 100 | 25 | 15.904 | 3600T |

| 4" | 101.6 | 1.6 | 1.357 | 1250T |

| 4" | 101.6 | 12.7 | 9.577 | 7500T |

| 4.29" | 109 | 8 | 6.854 | 3600T |

| 4.33" | 110 | 15 | 12.087 | 7500T |

| 4.33" | 110 | 30 | 20.358 | 7500T |

| 4.47" | 113.5 | 20 | 15.862 | 3150T |

| 4-1/2" | 114.3 | 3.25 | 3.061 | 2750T |

| 4-1/2" | 114.3 | 6.35 | 5.814 | 3600T |

| 4.53" | 115 | 6 | 5.547 | 2750T |

| 4.72" | 120 | 25 | 20.145 | 7500T |

| 4.72" | 120 | 26 | 20.731 | 7500T |

| 4.72" | 120 | 30 | 22.902 | 7500T |

| 4.92" | 125 | 10 | 9.755 | 3600T |

| 5" | 127 | 3.25 | 3.412 | 2750T |

| 5.12" | 130 | 10 | 10.179 | 3600T |

| 5.12" | 130 | 20 | 18.661 | 7500T |

| 5.12" | 130 | 30 | 25.447 | 7500T |

| 5.31" | 135 | 5 | 5.513 | 2750T |

| 5.31" | 135 | 17.5 | 17.442 | 5500T |

| 5.31" | 135 | 17.5 | 17.442 | 5500T |

| 6" | 152.4 | 22.22 | 24.536 | 7500T |

| 6.3" | 160 | 18 | 21.681 | 3150T |

| 6.3" | 160 | 20 | 23.75 | 7500T |

| 6.3" | 160 | 30 | 33.081 | 7500T |

| 6.46" | 164 | 15 | 18.958 | 3150T |

| 6-1/2" | 165.1 | 6.35 | 8.551 | 3600T |

| 6.69" | 170 | 10 | 13.572 | 7500T |

| 6.69" | 170 | 15 | 19.721 | 7500T |

| 6.69" | 170 | 30 | 35.626 | 7500T |

| 7.09" | 180 | 20 | 27.143 | 7500T |

| 7.09" | 180 | 30 | 38.17 | 7500T |

| 7.09" | 180 | 40 | 47.501 | 12500T |

| 7.28" | 185 | 10 | 14.844 | 7500T |

| 7.87" | 200 | 6 | 9.873 | 5500T |

| 7.87" | 200 | 15 | 23.538 | 7500T |

| 7.87" | 200 | 25 | 37.11 | 7500T |

| 7.87" | 200 | 30 | 43.26 | 12500T |

| 7.87" | 200 | 40 | 54.287 | 12500T |

| 8.27" | 210 | 10 | 16.965 | 5500T |

| 8.27" | 210 | 20 | 32.233 | 7500T |

| 8.66" | 220 | 20 | 33.929 | 7500T |

| 8.66" | 220 | 25 | 41.351 | 12500T |

| 8.66" | 220 | 30 | 48.349 | 12500T |

| 9.06" | 230 | 10 | 18.661 | 7500T |

| 9.06" | 230 | 15 | 27.355 | 7500T |

| 9.06" | 230 | 20 | 35.626 | 7500T |

| 9.13" | 232 | 38.5 | 63.191 | 12500T |

| 9.21" | 234 | 34.5 | 58.382 | 22500T |

| 9.45" | 240 | 15 | 28.628 | 7500T |

| 9.45" | 240 | 30 | 53.438 | 12500T |

| 9.84" | 250 | 20 | 39.019 | 12500T |

| 9.84" | 250 | 30 | 55.983 | 12500T |

| 9.84" | 250 | 50 | 84.823 | 12500T |

| 10" | 254 | 25.5 | 49.424 | 12500T |

| 10.24" | 260 | 30 | 58.528 | 12500T |

| 10.24" | 260 | 30 | 58.528 | 12500T |

| 10.39" | 264 | 7 | 15.26 | 7500T |

| 11.02" | 280 | 10 | 22.902 | 7500T |

| 11.02" | 280 | 30 | 63.617 | 12500T |

| 11.81" | 300 | 10 | 24.599 | 7500T |

| 11.81" | 300 | 20 | 47.501 | 12500T |

| 11.81" | 300 | 30 | 68.707 | 12500T |

| 11.81" | 300 | 50 | 106.029 | 22500T |

| 11.81" | 300 | 50 | 106.029 | 22500T |

| 11.93" | 303 | 26.5 | 62.152 | 12500T |

| 12.2" | 310 | 30 | 71.99 | 12500T |

| 12.6" | 320 | 50 | 114.511 | 12500T |

| 13.78" | 350 | 10 | 28.84 | 12500T |

| 13.78" | 350 | 25 | 68.919 | 22500T |

| 13.78" | 350 | 50 | 127.235 | 22500T |

| 14" | 355.6 | 25.4 | 71.142 | 22500T |

| 14.17" | 360 | 40 | 108.573 | 22500T |

| 14.57" | 370 | 15 | 45.168 | 12500T |

| 14.96" | 380 | 40 | 115.359 | 22500T |

| 15-3/4" | 400 | 30 | 94.154 | 22500T |

| 19.4" | 492.8 | 11.4 | 46.551 | 12500T |

| 19.49" | 495 | 12.5 | 51.159 | 12500T |

Can't Find an Exact Match?

- Near-Match Sizing: If your target size is within ±0.2–0.5 mm (OD / ID) or ±0.2–0.3 mm (WT), we can often hit it by cold drawing to final size or by minor die adjustments.

- Open a New Die: We can open a new die quickly. Typical sample timing is 3–5 days; production 7–14 days. For volume orders, die cost can be rebated or offset (details confirmed in quotation / contract).

- Engineer Review Within 2 Hours: Send a PDF / DWG and we will return 1–3 feasible options, with tolerance / lead time / cost.

We can produce to EN 755, GB 5237.1 (high precision), or AA / ASTM as required. Different alloys and processes affect tolerance and surface finish. Final delivery follows the approved process sheet and EN 10204 3.1 material certificate.

Once the size is confirmed, you only need to choose the alloy, required tolerance, desired surface finish, and whether secondary processing is needed. After that, we can lock in lead time and cost. The default configuration covers most orders; high-precision parts and visible / cosmetic parts can be upgraded on request. Not sure which option fits? Send an RFQ — an engineer will reply within 2 hours.

Other Alloy Aluminum Round Tube

Beyond 6061 / 6063 / 6082, we also supply aluminum round tube in 3003, 5052, 5083, 2024, 7075 and more.Many common sizes can be matched directly to existing dies / in-stock tooling. For detailed alloy information, click to view.

Processing · Surface · Secondary Operations

Processing & Quality

To ensure assembly fit and consistency, we control key steps in extrusion and post-processing. The default setup covers most orders and can be upgraded according to your drawing.

- Baseline Control: straightness ≤ 0.2 mm/m; roundness / concentricity kept stable; extrusion surface Ra ≤ 3.2 μm.

- Tolerance Execution: OD / WT per EN 755 / ASTM B211 or per drawing; small OD can be cold drawn to final size for tighter tolerance.

- Optional Upgrades: cold drawing to final size | NDT (eddy current / ultrasonic) | tighter tolerance on critical sections | heat-treatment stability / straightening.

- Inspection & Documentation: first-piece / in-process / final inspection; EN 10204 3.1 material certificate with shipment; dimensional / mechanical data, NDT report, coating thickness / color report (if required).

Surface Finishing

To meet different goals for corrosion resistance and visual grade, we offer the following standard finishing options. We can color-match to your sample / RAL / Pantone and record the requirement in the process sheet.

- Anodizing: improves corrosion resistance and film hardness; 6063 offers more consistent appearance, suitable for façade systems and outdoor structures.

- Powder Coating: RAL / Pantone color match; good weather resistance, suitable for equipment covers and structural parts.

- Electrophoretic Coating: decorative + corrosion protection; smooth, refined surface, used for high-appearance parts.

- Polishing / Brushing / Sandblasting: mirror, fine matte, or coarse texture finish; suitable for display, furniture, and any visible application.

Anodizing

Powder Coating

Polishing

Secondary Processing

We handle critical steps in-house to control size, fit, and schedule. Prototype and mass production are both supported.

- Cut-to-Length: optional chamfering / deburring; length per drawing.

- CNC Tube Bending: single or multi-radius, U / L shapes, custom curves; tooling can be developed for repeatability.

- End Forming (Expansion / Reduction): flare, bevel, chamfer, etc., for fit-up and sealed welding.

- CNC / Drilling / Tapping / Slotting: hole location and tolerance follow your 2D / 3D drawing.

- Welding: TIG / MIG / brazing; leak test or strength test available on request.

- Assembly & Protective Packaging: end caps, film wrap, bundling / palletizing to reduce handling damage.

Featured Case Studies

Case 01 | HVAC OEM · Manifold / Connection Tube

Customer: HVAC manufacturer in the U.K.

Application: Heat exchanger manifolds and connection tubes

Spec: 6063-T5, 3/4" (19.05 mm) × 1.2 mm

Die / Tolerance: Matched an in-stock die (3/4"); cold drawing to final size, OD ±0.10 mm, roundness ≤0.15 mm, straightness ≤0.2 mm/m

Surface: End expansion + chamfer, brazing-ready (no coating)

Result: Sample approved in 3 days, first order 2 tons; no die cost, ~10 days faster than opening a new die, ~8% cost reduction

Case 02 | Fitness Equipment Brand · Post / Sleeve Fit Area

Customer: U.S. fitness equipment brand

Application: Structural post and sleeve fit section

Spec: 6061-T6, 2" (50.8 mm) × 3.0 mm

Die / Tolerance: Matched 2" die; critical fit section was finish-sized, OD +0 / -0.10 mm (80 mm section), concentricity ≤0.15 mm

Surface: Black powder coat RAL 9005; hole locations CNC drilled / tapped

Result: Sample in 4 days, production in 10 days; no die cost, 99.6% assembly pass rate, ~6% total cost reduction

Case 03 | Façade Contractor · Railing / Post (Visible Part)

Customer: Large façade contractor in Singapore

Application: Façade members and railing posts

Spec: 6063-T5, 1-1/2" (38.1 mm) × 2.0 mm

Die / Tolerance: Matched existing die; appearance-grade window (straightness ≤0.2 mm/m, roundness stable)

Surface: 15 μm anodizing, matte silver; in-lot color variation controlled

Result: Sample in 4 days, first order 8 tons; faster on-site install vs. alternative design, ~20% project lead time reduction

More Die Libraries

We maintain a large in-house die / tooling library beyond aluminum round tube, covering bar, profiles, structural shapes, and microchannel tube.

Below are quick links to commonly requested product tooling tables. You can review specs and send an RFQ directly.

Packaging & Logistics

- Protection & Reinforcement: end caps + scratch protection film / kraft paper; bundled and separated with spacers; wooden crate / pallet reinforcement (suitable for sea or air shipment).

- Labeling & Traceability: each bundle / box is labeled / marked with alloy, size, length, heat / batch number, quantity; QR code traceability supported.

- Shipping Documents: Commercial Invoice, Packing List, Bill of Lading / Air Waybill, EN 10204 3.1; Certificate of Origin, dimensional / mechanical report, NDT report, coating thickness / color report available on request.

- Trade Terms: EXW / FOB / CIF / DDP (we can assist with customs clearance and final delivery).

- Cargo Insurance: cargo insurance can be arranged; any exception is documented with photos / video first.

- Shipment Record (available on request): packing photos, loading photos, sealing photos.

FAQ

What if my size is not an exact match?

We first try to match an in-stock die. If the difference is within ±0.2–0.5 mm (OD / ID) or ±0.2–0.3 mm (WT), we can usually meet it by cold drawing to final size or by minor die adjustment. If not, we can open a new die quickly.

How is die ownership and confidentiality handled?

We use only our own in-stock / dedicated dies and do not share tooling with third parties. NDA can be signed; drawings and specs stay within the project team.

Can you meet my tolerance? How do you keep it consistent in mass production?

The baseline tolerance window is shown on this page. Custom tolerance is available (small OD can be cold drawn to final size). For production, we run first-piece / in-process / final inspection and record critical dimensions to ensure consistency.

Which standards and certificates can you supply? Can you provide inspection reports?

EN 755 and GB 5237.1 (high precision); AA / ASTM on request. Each shipment can include EN 10204 3.1. Dimensional / mechanical data, NDT (eddy current / ultrasonic), coating thickness / color reports are available if required.

What about MOQ, sampling, and lead time?

MOQ is flexible. Typical timing is 3–5 days for samples and 7–14 days for production, depending on the drawing and scheduling.

How fast can you open a new die, and can the die cost be returned?

Typical new die sampling takes 3–5 days. For volume orders, die cost can be rebated or offset (details defined in the quotation terms).

Can you color-match the surface finish? How is color variation controlled?

Yes. We can color-match to your sample / color code. Film thickness / gloss / color delta are written into the process sheet, and in-lot color variation is controlled. For visible parts, 6063 is preferred.

How do I get a quote as fast as possible?

Send PDF / DWG, OD / WT / length, alloy and temper, quantity, surface requirement, and tolerance request. An engineer will reply within 2 hours with the proposal and timeline.