In automotive, HVAC, industrial refrigeration, and new energy sectors, efficient thermal transfer systems are essential for equipment stability and energy efficiency. Whether through conduction, dissipation, or heat exchange, the ability to rapidly transfer heat is fundamental to the performance of condensers, intercoolers, evaporators, and oil coolers. Compared to copper and stainless steel, aluminum has become the preferred material due to its lightweight, high thermal conductivity, corrosion resistance, and excellent formability.

Instant QuoteChalco offers a full product range covering brazing clad materials, HFW pipe, condenser header tubes, and thermal stamping components, supported by a one-stop industrial chain from aluminum ingot casting to module assembly. We deliver integrated solutions including structural customization, alloy cladding, process design, and performance validation, meeting diverse needs for thermal efficiency, weight reduction, and cost optimization.

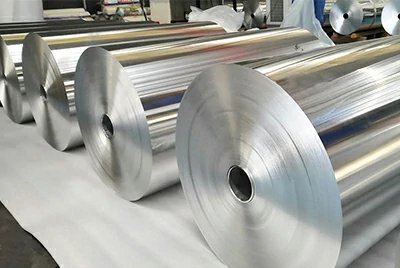

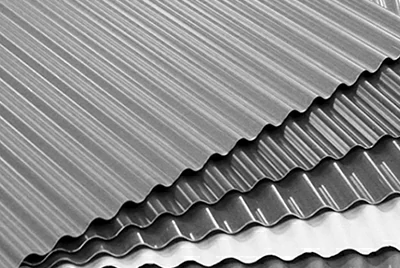

Brazing Clad Aluminum Materials

Brazing clad aluminum materials are one of the most essential and foundational components in thermal systems. They are widely used in the construction of heat exchanger plates, fins, housings, and liquid-cooled module structures.

Chalco supplies a full range of brazing aluminum sheets, clad coils, and brazing foils. We support customized composite structures such as single-layer, double-layer, and Zn-enhanced cladding, compatible with various brazing methods including vacuum brazing, furnace brazing, and salt bath brazing.

Aluminum Brazing Sheet

These plates use high-Si content cladding alloys like 4045 or 4343, combined with 3003 or 6061 high-conductivity cores, formed via composite rolling. Available in single-side or double-side cladding structures, they are ideal for large liquid-cooled panels and plate-type heat exchangers.

Contact us nowCommon Alloy Structures

- Single Clad: 4045/3003, 4343/3003

- Double Clad: 4045/3003/7072, 4343/3003/7072

- Optional Zn layer for enhanced corrosion resistance (adjustable Zn content)

Specifications

| Thickness | 0.8-6.35 mm |

| Width | ≤1500 mm |

| Coverage | 4%–18% (customizable) |

| Covering method | Single-sided / double-sided composite |

| Temper | O, H14, H24, H18 |

Battery Cooling Plate

Base Plate for Plate Heat Exchangers

High-Efficiency Condenser Panels

Aluminum Brazing Coil Strip

Brazing clad coils are primarily used for tube manufacturing (e.g., HFW header tubes) or continuous stamping of heat exchanger components. Chalco supports high-speed slitting, narrow strip control, and automated recoiling, compatible with fully automated tube mills and high-speed stamping lines.

Contact us nowCommon Alloy Structures

Single Clad: 4343/3003, 4045/3105

Double Clad: 4343/3003/7072, 4045/3003/7072

Specifications

| Thickness | 0.3–2.5 mm |

| Width | 20–800 mm |

| Coverage | 8%–15% (customizable) |

| Roll Weight | 100–2000 kg |

Application

HFW Aluminum Header Tubes

Stamped Aluminum Shell Parts

Structural Strip for Heat Exchangers

Aluminum Fin Stock

Fin stock is a critical material for increasing the heat exchange surface area in aluminum heat exchangers. As the lightest and most surface-intensive thermal component, it plays a vital role in improving efficiency. Clad fin stock not only enhances brazing performance, but also significantly improves corrosion resistance.

Contact us nowChalco offers customized fin shapes, including embossed, slotted, perforated, and corrugated fins, suitable for both automotive and industrial applications.

Common Alloy Structures

- Bare Fin Stock: 3003, 3102, 8011

- Clad Fin Strip: 4045/3003, 4343/3105

- Zn-Enhanced Cladding: 4045/3003/7072

Specifications

| Thickness | 0.06–0.20 mm |

| Width | 50–600 mm |

| State | H14, H18, O |

| Surface Treatment | Anodized/sprayed |

Typical application

Condenser / Intercooler Fins (Automotive)

Commercial HVAC Radiators

Energy Storage Cooling Modules

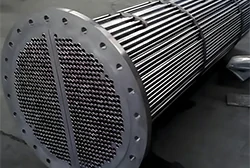

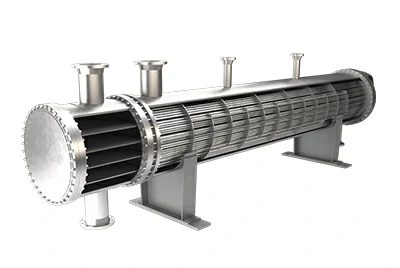

Fluid Conduction Tubes

Fluid conduction pipes are indispensable structural components in heat transfer systems. They are responsible for the flow and distribution of refrigerants, coolants and other media. They are widely used in condensers, intercoolers, evaporators, oil coolers, battery thermal management systems and other modules. Chalco has complete production and deep processing capabilities for high-frequency welded pipes, microchannel flat pipes, reducing flared pipes and pre-punched pipes, supporting large-scale continuous pipe making and complex geometry customization.

High-Frequency Welded Pipe

Manufactured from clad aluminum strip using roll forming and high-frequency welding, these tubes are ideal for a wide variety of collector configurations—round, D-shaped, square, or stepped joints. They offer excellent brazability, pressure resistance, and dimensional consistency.

Contact us nowCommon Alloy Structure

- Core: 3003, 3105

- Cladding: 4045, 4343, 7072 (optional Zn layer for corrosion resistance)

- Structure: Single clad / Double clad / Double clad + Zn

Product Shapes

| Type | Cross-sectional shape | Features and Applications |

| Round tube | Φ9–61 mm | Applied to traditional condensers, oil coolers, commercial air conditioners and other systems |

| D-type tube | Oblate mixed | Increase heat exchange area, suitable for vehicle-mounted condensers, heat pump modules, etc. |

| Square tube | 10×10 mm+ | Higher assembly density, used for compact modules or flat space structures |

| Reducing tube | One end contracted | Used to distribute flow, connect systems of different calibers, strong adaptability |

Size

| Outer diameter | 9–61 mm |

| Wall thickness | 1.0–3.0 mm |

| Length | 300–5000 mm |

| Temper | H14,O,T |

Typical Applications

- Parallel flow condenser header tubes

- Main collectors in EV heat pump modules

- Shaped inlets for electric drive cooling systems

- Multi-port distributors in industrial chillers

Aluminum Microchannel Tubes (MPE Tubes)

Multi-Port Extruded (MPE) Tubes are formed by extruding aluminum billets with internal microchannels, significantly increasing heat transfer within a compact volume. These tubes are widely used in high-efficiency radiators, EV battery cooling plates, and liquid-cooled electronics systems requiring both thermal performance and compact design.

Contact us nowCommon Alloys

- Base: 6063, 3003, 6061 (high strength)

- Optional Cladding: 4045, 7072 (enhanced brazability/corrosion resistance)

- Tempers: T5, T6, O

Structures & Dimensions

| Dimensions | 8×1.0 mm - 60×3.0 mm |

| Number of channels | 3-60 holes |

| Wall thickness | 0.25–5 mm |

| Surface treatment | anodized / coated / mechanically polished |

Typical Applications

- Liquid cooling plates for EV power batteries

- Core layers of high-efficiency intercoolers / oil coolers

- Cooling systems for solar inverters / data centers

- Microchannel condenser/evaporator modules

Radiator Aluminum Flat Tubes

Featuring a wide rectangular profile, these tubes support high flow rates and low-pressure drop applications. They are typically used in engine radiators and oil cooling systems, and are suitable for integrated brazing with fins or modules.

Contact us now

Alloy Options

3003, 6060, 6061, supports brazed cladding structures

Tempers: H14, T6, O

Dimensions: Customizable

Size:

| Width | 10–60 mm |

| Thickness | 1.0–3.5 mm |

| Length | 3/6m, customizable |

Typical Applications

- Main channels of water-cooled radiators

- Engine oil cooler core tubes

- Industrial hydraulic heat dissipation systems

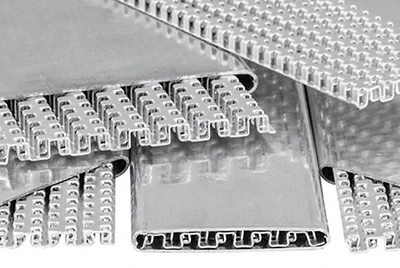

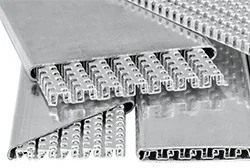

Serrated Fin Flat Tubes

Using high-frequency welding, aluminum strips are pre-punched with louvers or holes to create integrated turbulent fin structures. Compared to smooth tubes, these offer greater surface area and higher heat transfer rates, ideal for high-efficiency heat pumps, automotive A/C condensers, and EV intercoolers.

Contact us nowAlloy Structure

- Core: 3003, 3105

- Cladding: 4045, 4343, 7072

- Structure: Single clad / Double clad (Zn-enhanced corrosion protection available)

Dimensions

| Outer diameter | 6–16 mm |

| Wall thickness | 0.5–1.5 mm |

| Winding diameter | 200–1000 mm |

| Other | Supports small radius processing, single/multi-disc design |

- Header tubes for parallel-flow condensers

- Heat pump cooling modules in EVs

- High-throughput intercoolers for electric vehicles

- Precision thermal management for electronics

Coiled Aluminum Tubes

Formed using serpentine bending or spiral coiling, these tubes are well-suited for compact or multi-loop heat dissipation applications, such as refrigerators, freezers, and air-cooled modules.

Contact us nowAlloy Options: 3003, 8011, 6061

Tempers: O, H14 (excellent formability for coiling)

Dimensions

| Outer diameter | 6–16 mm |

| Wall thickness | 0.5–1.5 mm |

| Winding diameter | 200–1000 mm |

| Other | Supports small radius processing, single/multi-disc design |

Typical Applications

- Refrigerant tubes in refrigerator evaporators

- Indoor unit coil sections in air conditioning systems

- Industrial cold storage coil systems

Precision Fabricated Tube Components (Punching / Bending / Flaring)

To support manifold connection, welding positioning, and module pre-assembly, Chalco provides a wide range of secondary processing services, including pre-punched designs, multi-axis bending, and flared ends. These services are tailored for lightweight assembly in HVAC and EV thermal management modules.

Contact us now

Customization Capabilities

- Wall punching (round, slotted)

- Multi-diameter flared ends (compatible with rubber seals or brazed joints)

- Multi-axis bending (90°/180°)

- End designs: tapered, flanged, flat ends

Typical Applications

- Integrated sections of in-vehicle heat pump condensers

- Main connector tubes in energy storage liquid cooling systems

- Multi-port refrigerant routing for cold chain modules

- Pre-assembled modules for quick plug/weld joints

Chalco provides a full portfolio of aluminum tubing solutions, including welded tubes, extruded profiles, heat exchanger tubes, and precision-machined parts. With integrated capabilities from clad material production to finished components, we meet demanding requirements for high thermal conductivity, corrosion resistance, and mechanical strength—ideal for applications ranging from passenger vehicle thermal systems to industrial heat exchange modules.

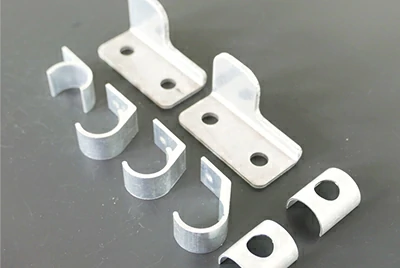

Instant QuoteStamped Heat Transfer Components

Stamped parts are essential structural-functional components in heat transfer systems. They are widely used in condensers, intercoolers, liquid cooling systems, and energy storage modules to enable heat conduction, encapsulation, support, channel forming, or modular integration. Chalco offers integrated solutions from materials to final structures, with full capabilities in coil stamping, precision die tooling, coating, electroplating, crimping, and TIG welding.

Air Side Plates & End Covers

These components serve as module frames or sealing structures, typically stamped from 1.0–3.0mm medium-thick aluminum sheets (3003, 5052, 6061). They often include perforations, slots, or flanged designs to provide reliable structural strength and forming consistency.

Contact us now

Common Features

- Crimped fin side plates

- Bolt holes or snap-fit designs

- Optional powder coating, electrophoresis, or anodizing

Application Systems

- Air conditioning condenser frames

- Enclosure beams for industrial/commercial heat exchangers

- Side covers for energy storage or inverter heat sinks

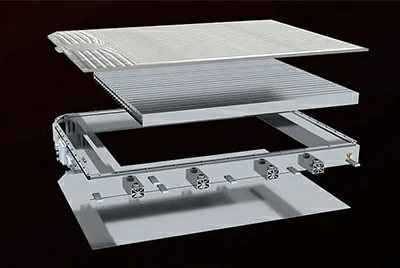

Stamped End Caps / Enclosures

These components encapsulate the ends of liquid cold plates or thermal modules, often integrated with microchannels or brazed structures. Chalco supports complete processing including stamping, bending, welding, and polishing, along with O-ring grooves, pre-punched holes, and sealing structures.

Contact us now

Typical Structures

- Flat end caps (1.0–2.5 mm thick)

- U-shaped / domed module enclosures

- Compatible with TIG welding, spot welding, and heat sink rib machining

Application Scenarios

- End enclosures for liquid-cooled battery packs

- Connection segments for condenser/evaporator modules

- Integrated covers for thermal energy storage systems

Corrugated Channel Sheets

Used to form flow channels inside plate heat exchangers or liquid cold plates, these sheets are stamped from aluminum strips into corrugated profiles, allowing for fluid routing and heat transfer area expansion. They are typically assembled via brazing.

Contact us now

Process Advantages

- Controlled embossing depth for optimized refrigerant flow

- Continuous roll stamping with high efficiency and precision

- Supports brazing-compatible alloys and micro-serrated structures

Typical Applications

- Core layers for flat cold plates

- Heat exchanger cores in PV/inverter modules

- Flow guides in microchannel modules

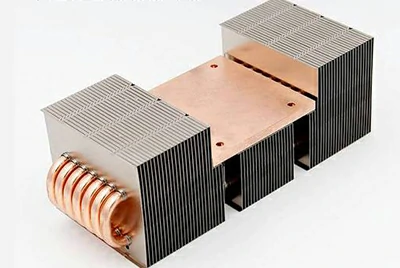

Integrated Formed Parts

These parts combine multiple functions into a single aluminum stamping, such as heat sinks + connection interfaces, or channel covers + support ribs. CNC machining or automated welding is often used to enhance assembly efficiency and thermal performance.

Contact us now

Capabilities

- Large-format multi-station die stamping (up to 1500mm wide)

- One-step forming for cavities and plug-in structures

- Integrated spot welding, laser welding, and flanged nut assembly

Typical Applications

- Heat sink housings for industrial inverters

- Modular power cooling assemblies

- Bottom plates for electric drive thermal management

Aluminum Condenser Header Pipe

Stamped header tubes feature customized punched openings and adjustable spacing, ideal for quick integration with condensers and microchannel tubes.

Contact us nowCommon Alloys & Structures

- Alloys: 3003, 3105 (with cladding options)

- Process: Stamping + Stretching + Flanging/Roll-forming

- Shapes: Toothed, corrugated, angled cuts, and more custom options

Typical Applications

- Headers for microchannel condensers

- Intermediate connectors for heating/cooling modules

- Compact HVAC sub-module enclosures

Chalco offers a complete range of stamped aluminum components for heat exchange systems, covering thermal enhancement, sealing, fluid channel forming, and multi-functional integration. We support various alloy types and tempers, custom die development, and assembly with compatible welding technologies.

Instant QuoteApplication Scenarios & Solutions

Chalco delivers end-to-end aluminum-based solutions tailored to heat transfer systems across a range of industries including automotive & NEVs, HVAC, industrial refrigeration, energy & power electronics, and appliances & consumer electronics. Our products are widely used in condensers, evaporators, intercoolers, cold plates, and oil coolers, helping clients boost thermal efficiency, reduce system weight, increase durability, and lower total costs.

Automotive & NEV Thermal Management Systems

Heat management in vehicles, especially New Energy Vehicles (NEVs), covers modules like battery cooling, heat pump air-conditioning, intercoolers, and e-drive heat sinks. These systems demand high heat transfer efficiency, lightweight materials, and integrated structures. Customizability, weld compatibility, and corrosion resistance are crucial, along with strength, low leakage, and thermal expansion compatibility.

Chalco Solutions

Product Types: D-shaped header tubes, pre-punched flat tubes, brazing materials for cold plates, stamped fins and end covers

Recommended Alloys: 3003 + 7072 (dual-layer), 4045 cladding, 6061 microchannel tubes

Typical Systems: Onboard condensers, intercoolers, battery cold plates, e-drive coolers, energy storage cooling modules

HVAC (Heating, Ventilation & Air Conditioning) Systems

HVAC systems are used in residential air conditioners, commercial heat pumps, and building ventilation units, often operating in humid, corrosive, and high-frequency load conditions. These systems require thermal conductivity, corrosion resistance, structural stability, and efficient assembly. Standardized components like header tubes, fins, and stamped covers demand material consistency and mass-production readiness.

Chalco Solutions

- Product Types: HF-welded round tubes, fin stock, sealing plates, dual-clad aluminum strips

- Recommended Alloys: 3003-H14 fins, 4045+7072 clad strips, 8011 anodized aluminum

- Typical Systems: AC condensers, outdoor units, VRF modules, air-source heat pump units

Industrial Cooling & Equipment Heat Dissipation

In industrial refrigeration, heavy-duty equipment, and automated systems, components operate under high temperatures, heavy loads, or continuous duty cycles. Applications like cold storage condensers, refrigeration dryers, and compressor intercoolers need custom profiles and non-standard fittings that provide design flexibility, long-term corrosion resistance, and high-pressure endurance—making aluminum the preferred material.

Chalco Solutions

- Product Types: High-pressure flat tubes, pre-punched headers, flat cold plates, heat sink covers and housings

- Recommended Alloys: 6061-T6 microchannel tubes, 3003+Zn dual-clad strips, 5052 pressure-resistant sealing plates

- Typical Systems: Cold room evaporators, industrial chillers, large intercoolers, liquid cooling systems for equipment

Energy & Power Electronics Thermal Management

Applications in PV, energy storage, wind power, power control, and 5G communication demand high thermal conductivity, precise structural integration, and long-term corrosion resistance. As power density increases and modules miniaturize, there's rising demand for custom aluminum composites, microchannel structures, and thin-wall extrusions—balancing thermal performance with strength.

Chalco Solutions

- Product Types: Brazed composite plates, microchannel tubes, stamped heat sink bases, structural housings

- Recommended Alloys: 3003+4045/7072 trilayer sheets, 6061 cold plate materials, 6063 multi-channel micro-profiles

- Typical Systems: Energy storage PCS modules, inverter cold plates, wind turbine power electronics cooling, 5G cabinet heat exchangers

Commercial Appliances & Consumer Electronics Radiators

Heat exchange components in home appliances, kitchen equipment, and consumer electronics are used in refrigerators, dryers, water heaters, dispensers, and LED cooling modules. These systems require lightweight, cost-effective, and aesthetically consistent materials that meet mass production needs. Small-scale evaporators, coils, and enclosures must support high-frequency welding, form consistency, and corrosion resistance.

Chalco Solutions

- Product Types: Aluminum coils for piping, standard fin coils, stamped heat sink plates, brazed composite coils

- Recommended Alloys: 3003-O, 8011-H18, 4343/4045 composites

- Typical Systems: Water heaters, heat pump dryers, refrigerator condensers, electronic device heat dissipation covers

Chalco's Manufacturing Capabilities & Quality Assurance

As a system supplier of aluminum for thermal transfer applications, Chalco provides integrated manufacturing capabilities covering clad rolling, high-frequency welding, precision cold forming, structural stamping, surface treatment, and quality inspection. We are committed to offering stable, customizable, and high-performance aluminum solutions to heat exchanger manufacturers.

One-Stop Manufacturing Platform Covering the Full Process Chain

With over 20 years of experience in the brazed heat exchanger industry, Chalco leverages industry-leading equipment in cladding, welding, and forming to deliver quick-response, large-scale production from raw materials to functional components:

- Clad Rolling System: Supports three-layer online cladding (e.g., 4045/3003/7072) with high cladding uniformity and coating rate control within ±1%, ideal for brazing sheets, coils, and foils.

- High-Frequency Welding System: Equipped with German HFW tube production lines to produce round, D-shaped, square, and transition header tubes. Maximum OD reaches Ø61mm with wall thickness tolerance of ±0.05mm.

- Custom Cold Drawing Equipment: Specializes in necking, flaring, pre-punching, and non-standard interface production, supporting the integration trend of condenser and evaporator piping.

- Large CNC Stamping Lines: Enables mass production of fins, side plates, and end plates, integrating grooving, flanging, and bending processes in one line.

- Surface Treatment & Cleaning System: Includes automated ultrasonic cleaning, high-temperature drying, and anodizing, ensuring component cleanliness, coating compatibility, and corrosion resistance.

- Welding Support Lines: Equipped with dual-head dip brazing and localized brazing systems to support sub-assembly level pre-assembly requirements.

Strict Quality Control and Compliance

Chalco places consistency and traceability at the core of quality management, implementing multi-level inspections from raw material intake to final product delivery:

- Dimensional Accuracy Inspection: Full-process digital measurement systems with ±0.02mm precision.

- Weld Quality Monitoring: Uses AI weld recognition + infrared thermography for real-time defect detection.

- Offline NDT: Equipped with secondary ultrasonic flaw detectors to identify inclusions, microcracks, and pores.

- Physical, Chemical & Corrosion Testing: Includes metallographic analysis, thermal conductivity tests, ASTM B117 salt spray (1000h+), and thermal cycling fatigue tests.

- International Standards Compliance: Products meet ASTM B491, B210, B313, B547, EN 573, QC/T 816, and can provide RoHS, REACH, and LCA certifications.

Value-Added Services & System-Level Delivery

Chalco is more than a material supplier—we act as a system-level partner for heat exchanger manufacturers by offering:

- Integrated aluminum processing + stamping + welding solutions

- One-stop services for product packaging, assembly, and logistics

- Technical documentation, process support, and scheduled follow-ups

- Rapid prototyping and custom orders, with MOQ as low as 100 meters

With our technology + productivity + customer-oriented approach, Chalco is committed to being a reliable aluminum solution provider for global thermal system customers.

Instant QuoteChalco – Your Trusted Partner in Thermal Aluminum Systems

As thermal exchange structures grow more complex and customer demands evolve, Chalco strives to become not just a material provider, but also a system-savvy, design-collaborative, and delivery-secure partner. Here's why leading customers choose Chalco:

Material Expertise with System Insight

Chalco deeply understands the performance attributes of various thermal management aluminum alloys and the specific requirements of modules like condensers, evaporators, liquid cold plates, and cooling housings. We help clients with alloy selection, wall thickness optimization, and welding compatibility analysis in early design phases to ensure a solid technical foundation.

Cross-Industry Experience with OEM Support

Our products are widely used across automotive, new energy, HVAC, industrial cooling, and consumer electronics. We have established robust partnerships with top-tier OEMs, demonstrating proven performance and delivery stability.

Key Customers Include:

- Automotive & New Energy: Tesla, BYD, SVOLT, CATL

- HVAC & Refrigeration: Gree, Midea, Sanhua

- Industrial Equipment & Wind Power: HAIZE, Schneider Electric

- Consumer Electronics: Johnson Electric, TCL

Flexible Solutions for Custom & Small-Batch Orders

We understand that SMEs and pilot projects often face challenges such as long lead times and high customization thresholds. Chalco’s APS-based flexible scheduling system supports:

- MOQ: 100 meters

- Sampling lead time: 7–10 days

- Quick realization of non-standard interfaces / punching / structural customizations

- Simulation + welding validation data packages provided

Our small-batch customers enjoy the same high-quality service as large projects.

Brand Strength & Reliable Delivery

As a core enterprise in China's non-ferrous metal industry, Chalco has earned a strong reputation and brand trust in the aluminum for thermal applications segment. We adhere to long-term cooperation, controllable processes, and full traceability as our delivery standards—ensuring every project is worth trusting.

Co-Creation for Competitive Advantage

We believe that our customers' success is our success. Chalco is committed not only to material supply but also to collaborative R&D, structural optimization, cost balancing, and regulatory compliance—empowering our customers with competitive and sustainable thermal solutions.

Choosing Chalco means choosing more than a supplier—you're choosing a strategic aluminum partner who understands systems, values long-term collaboration, and is committed to shared growth.

Aluminum vs. Copper: A Thermal Transfer Comparison

When selecting materials for heat exchangers, aluminum and copper are two primary options. While copper is known for its excellent thermal conductivity, aluminum is now the preferred choice in automotive, HVAC, energy storage, and home appliances due to its:

| Comparative dimensions | Aluminum | Copper |

| Thermal conductivity | Thermal conductivity is about 237 W/m·K | Thermal conductivity is about 390 W/m·K |

| Density and weight | 2.7 g/cm³, with significant lightweight advantages | 8.96 g/cm³, and the weight is about 3.3 times that of aluminum |

| Cost control | Low raw material cost, lower processing energy consumption (about 35% lower) | Raw material prices fluctuate greatly, and processing costs are high |

| Processing and molding capabilities | Suitable for high-frequency welding, composite rolling, cold drawing, stamping and other processes | Good formability, but the welding process is more complicated and the equipment cost is high |

| Corrosion resistance | Natural oxide film + coating layer (4045/7072, etc.) + anodizing treatment, can cope with salt spray/high humidity environment | It has its own corrosion resistance, but it is prone to galvanic corrosion (contact with aluminum parts) |

| System compatibility | Stronger integration with modern brazing process, microchannel structure, special-shaped flat tube | More compatible with traditional fin tube structure, but the assembly method is complicated |

| Sustainable development | Recyclable rate >95%, support LCA carbon footprint management and ESG audit | High recycling energy consumption and high carbon emissions |

| Supply chain stability | Abundant global reserves and relatively stable prices | Affected by geopolitical and economic fluctuations |

Copper still fits niche high-end applications with extreme thermal requirements (e.g., superconducting cooling, military-grade heat pipes). However, in most modern systems, aluminum outperforms in total value.

Chalco's aluminum thermal management materials have successfully replaced copper in automotive condensers, liquid cooling systems, radiator modules, HVAC outdoor units, and intercoolers.

Contact Chalco today for professional technical support and customized quotations.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote