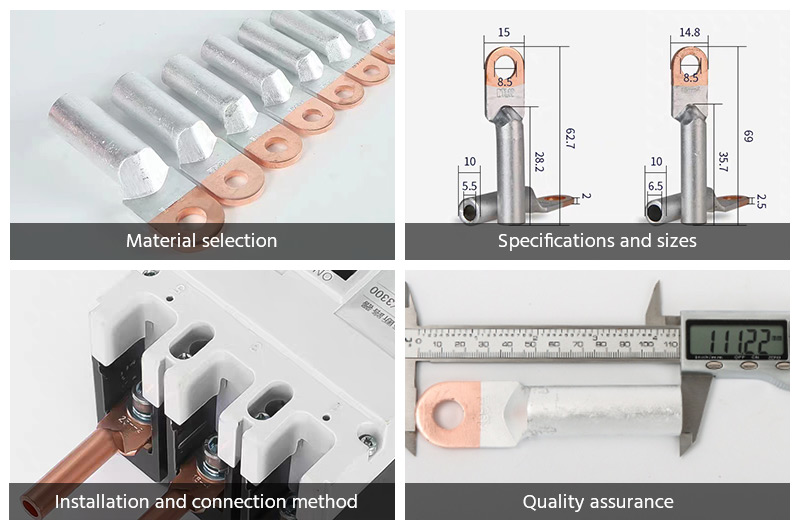

In demanding electrical systems, reliable and corrosion-free connections are essential. As an experienced aluminum manufacturer, Chalco Aluminum offers a one-stop cable termination solution, covering a full range of copper lugs, aluminum lugs, and bimetal cable lugs, and providing integrated support from design and production to installation.

Instant QuoteAll products comply with IEC 61238, UL 486A/B, and GB/T 14315 standards, making them ideal for power transmission, distribution, industrial, construction, and renewable energy applications.

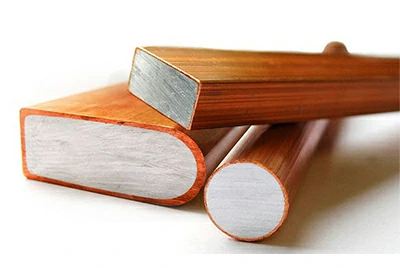

Bimetal Cable Lugs

Bimetal lugs join high-purity copper and aluminum via friction welding, preventing galvanic corrosion. They combine copper’s conductivity with aluminum’s light weight and affordability, ensuring reliable current flow between dissimilar conductors in power, industrial, renewable energy, and rail systems.

Contact us now

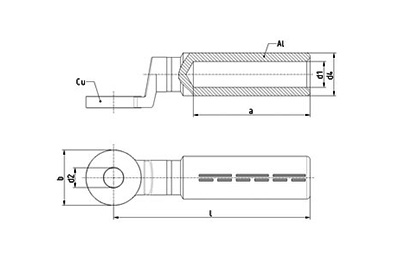

Specifications Performance Parameters

| Applicable Cable Cross Section | 16 mm² – 1600 mm² , covering LV to MV/HV cable sizes. |

| Bolt Hole Diameter | M6 – M24 |

| Materials | Copper part: ETP copper (T2/C11000), purity ≥ 99.9%; Aluminum part: Electrical aluminum (1050/1060/1350 alloys), purity ≥ 99.5% |

| Joining Process | Friction welding: molecular-level metallurgical bond between copper and aluminum for excellent conductivity and strength, preventing galvanic corrosion. |

| Surface Treatment | Copper end: tin plating (≥ 99.9% Sn, thickness 5–10 µm); Aluminum end: pre-filled anti-oxidation compound (breaks oxide layer and seals); some models also tin-plated on aluminum end. |

| Working Temperature Range | –40 °C to +150 °C |

| Rated Voltage | Standard ≤ 1 kV; MV models up to 1–35 kV; HV models above 35 kV |

| Electrical Performance | Low contact resistance for efficient current transmission; Resistivity: Al ~ 2.6 µΩ·cm, Cu ~ 1.74 µΩ·cm; Anti-galvanic corrosion for stable conductivity. |

| Mechanical Properties | Weld strength ≥ 200 MPa, withstands tension and vibration; Excellent vibration resistance; Designed to mitigate aluminum creep for long-term stability. |

| Standard Certifications | IEC 61238-1, UL 486A/B, AS/NZS 4325.1, GB/T 14315, DIN 1712, JIS, RoHS |

Product Type

- Bi Metallic Connector

Safely and reliably connects dissimilar conductors, specifically transitioning between aluminum cables and copper equipment to prevent electrochemical corrosion.

- Bi-Metal Terminals with Copper Ring

Features a pre-fabricated or integrated copper ring on the palm for more secure connection to bolts or studs, ensuring stable current transmission and enhanced mechanical strength.

- Aluminum Tin Copper Plating Type Bi Metallic

The copper palm of these lugs is tin-plated to further enhance corrosion resistance, especially in humid or corrosive environments, and optimize contact performance with copper busbars.

- Square Bimetallic Cable Lugs

These bimetallic lugs feature a square-shaped copper palm, designed for specific equipment with square connection posts or for installations with limited space, offering specific installation convenience.

- Standard Bimetallic Lugs

The most common general-purpose bimetallic lugs, featuring an aluminum barrel for crimping aluminum conductors and a copper palm for connecting to copper equipment, serving as the fundamental choice for dissimilar metal connections.

- Double Hole Crimp Bimetallic Lugs

The copper palm has two bolt holes, providing more stable connections and stronger vibration resistance, often used for heavy-duty or critical electrical equipment requiring high connection reliability.

- Bolted Bimetallic Lugs

Unlike traditional crimp types, bolted lugs secure conductors via bolts, typically supporting a wider range of cable sizes and being reusable, which simplifies installation and maintenance.

- DTL Aluminum To Copper Lug

DTL is a common model or classification for standard bimetallic lugs, specifically referring to those made by friction welding an aluminum barrel to a copper palm, widely used in various power connection scenarios.

Core Features of Bimetal Cable Lugs

Bimetal cable lugs are essentially about safely and effectively connecting dissimilar metal conductors. They achieve this through advanced friction welding technology, which creates a highly conductive, corrosion-resistant metallurgical bond between aluminum and copper. This unique structure completely eliminates the common problem of electrochemical corrosion often found in traditional connections, significantly extending the service life of the connection point.

Furthermore, these lugs ensure superior electrical performance and mechanical strength, effectively reducing resistance and energy loss while withstanding various mechanical stresses. Their design also prioritizes ease of installation, typically being compatible with standard crimping tools. At the same time, they demonstrate excellent environmental adaptability. Ultimately, these characteristics combine to significantly enhance the long-term stability and safety of power systems.

Primary Applications

- Power Transmission & Distribution Systems: Reliable connections between aluminum conductors and copper busbars in overhead lines, underground cables, and substations.

- Switchgear & Control Panels: Secure splicing of aluminum incoming lines to copper busbars or equipment terminals inside switchgear, distribution boards, and control panels.

- Industrial Automation & Manufacturing: Stable connections for aluminum cables to copper components in motors, generators, distribution boxes, and automated production lines.

- Renewable Energy Systems: Critical cable terminations between aluminum conductors and copper components in solar photovoltaic arrays and wind turbine generators.

- Rail Transit & Electric Vehicles: Lightweight connection solutions for high-voltage aluminum cables to copper parts in electric trains and electric vehicles.

- Marine & Offshore Platforms: Tin- or nickel-plated variants suited for high salt-spray and corrosive marine environments.

- Commercial & Residential Buildings: Reliable splicing of aluminum service entrance cables to internal copper branch circuits or equipment terminals in distribution panels.

- Communication & Grounding Systems: Connections between aluminum grounding conductors and copper ground bars or equipment terminals in telecom base stations and data centers.

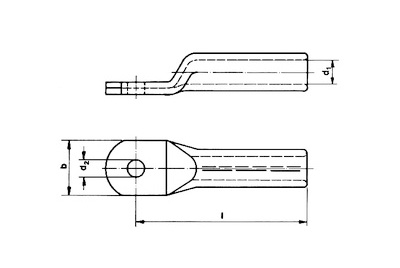

| Conn. bolts dia. | Nominal cross-section mm² | Code | Dimensions mm | Number of crimps | |||||||

| rm/sm | re/se | d1 | a | b | d2 | d4 | l | Al (7 mm) | Al (wide) | ||

| M 8 | 16 | 25 | 12 | 6 | 34 | 24 | 8.5 | 12 | 68 | 4 | 2 |

| M 10 | 16 | 25 | 12 | 6 | 34 | 24 | 10.5 | 12 | 68 | 4 | 2 |

| M 10 | 25 | 35 | 12 | 6.8 | 34 | 24 | 10.5 | 12 | 68 | 4 | 2 |

| M 8 | 25 | 35 | 12 | 6.8 | 34 | 24 | 8.5 | 12 | 68 | 4 | 2 |

| M 12 | 25 | 35 | 12 | 6.8 | 34 | 24 | 13 | 12 | 68 | 4 | 2 |

| M 8 | 35 | 50 | 14 | 8 | 43 | 24 | 8.5 | 14 | 77 | 5 | 2 |

| M 10 | 35 | 50 | 14 | 8 | 43 | 24 | 10.5 | 14 | 77 | 5 | 2 |

| M 12 | 35 | 50 | 14 | 8 | 43 | 24 | 13 | 14 | 77 | 5 | 2 |

| M 8 | 50 | 70 | 16 | 9.8 | 43 | 25 | 8.5 | 16 | 77 | 5 | 2 |

| M 10 | 50 | 70 | 16 | 9.8 | 43 | 25 | 10.5 | 16 | 77 | 5 | 2 |

| M 12 | 50 | 70 | 16 | 9.8 | 43 | 25 | 13 | 16 | 77 | 5 | 2 |

| M 8 | 70 | 95 | 18 | 11.2 | 52 | 25 | 8.5 | 18.5 | 84.5 | 6 | 3 |

| M 10 | 70 | 95 | 18 | 11.2 | 50 | 24 | 10.5 | 18.5 | 85 | 6 | 3 |

| M 12 | 70 | 95 | 18 | 11.2 | 50 | 24 | 13 | 18.5 | 85 | 6 | 3 |

| M 8 | 95 | 120 | 22 | 13.2 | 56 | 30 | 8.5 | 22 | 90.5 | 6 | 3 |

| M 10 | 95 | 120 | 22 | 13.2 | 50.5 | 30 | 10.5 | 22 | 90.5 | 6 | 3 |

| M 12 | 95 | 120 | 22 | 13.2 | 50.5 | 30 | 13 | 22 | 90.5 | 6 | 3 |

| M 16 | 95 | 120 | 22 | 13.2 | 50.5 | 30 | 17 | 22 | 90.5 | 6 | 3 |

| M 8 | 120 | 150 | 22 | 14.7 | 56.5 | 30 | 8.5 | 23 | 92 | 6 | 3 |

| M 10 | 120 | 150 | 22 | 14.7 | 56.5 | 30 | 10.5 | 23 | 92 | 6 | 3 |

| M 12 | 120 | 150 | 22 | 14.7 | 56.5 | 30 | 13 | 23 | 92 | 6 | 3 |

| M 16 | 120 | 150 | 22 | 14.7 | 56.5 | 30 | 17 | 23 | 92 | 6 | 3 |

| M 8 | 150 | 185 | 25 | 16.3 | 62 | 30 | 8.5 | 25 | 104 | 6 | 3 |

| M 10 | 150 | 185 | 12 | 16.3 | 62 | 30 | 10.5 | 25 | 104 | 6 | 3 |

| M 12 | 150 | 185 | 25 | 16.3 | 62 | 30 | 13 | 25 | 104 | 6 | 3 |

| M 16 | 150 | 185 | 25 | 16.3 | 62 | 30 | 17 | 25 | 104 | 6 | 3 |

| M 10 | 185 | 240 | 28 | 18.3 | 62 | 30 | 10.5 | 28.5 | 105.5 | 6 | 3 |

| M 12 | 185 | 240 | 28 | 18.3 | 62 | 35 | 10.5 | 28.5 | 105.5 | 6 | 3 |

| M 16 | 185 | 240 | 28 | 18.3 | 62 | 35 | 17 | 28.5 | 105.5 | 6 | 3 |

| M 20 | 185 | 240 | 28 | 18.3 | 62 | 35 | 21 | 28.5 | 105.5 | 6 | 3 |

| M 8 | 185 | 240 | 28 | 18.3 | 62 | 30 | 8.5 | 28.5 | 105 | 6 | 3 |

| M 10 | 240 | 300 | 32 | 21 | 70 | 35 | 10.5 | 32 | 118.5 | 8 | 3 |

| M 12 | 240 | 300 | 32 | 21 | 72 | 35 | 13 | 32 | 118.5 | 8 | 3 |

| M 16 | 240 | 300 | 32 | 21 | 72 | 35 | 17 | 32 | 118.5 | 8 | 3 |

| M 20 | 240 | 300 | 32 | 21 | 72 | 35 | 21 | 32 | 118.5 | 8 | 3 |

| M 10 | 300 | -- | 34 | 23.3 | 72 | 36 | 10.5 | 34 | 124 | 8 | 3 |

| M 12 | 300 | -- | 34 | 23.3 | 72 | 36 | 13 | 34 | 124 | 8 | 3 |

| M 16 | 300 | -- | 34 | 23.3 | 72 | 36 | 17 | 34 | 124 | 8 | 3 |

| M 20 | 300 | -- | 34 | 23.3 | 72 | 40 | 21 | 34 | 124 | 8 | 3 |

| M 12 | 400 | -- | 38 | 26 | 100 | 40 | 13 | 38.5 | 150.5 | -- | 4 |

| M 16 | 400 | - | 38 | - | 100 | 40 | 17 | 38.5 | 150.5 | - | 4 |

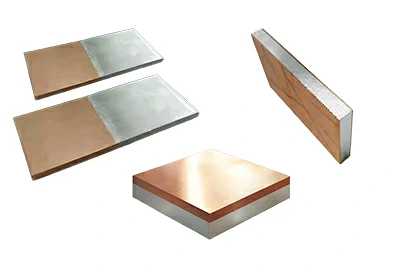

One-Stop Copper-Aluminum Composite Material Solutions

Chalco Aluminum offers a full range of copper-aluminum composite products, including copper-aluminum composite plates, copper-clad aluminum busbars, copper-clad aluminum cables, copper-aluminum composite strips, copper-aluminum composite gaskets, and copper-clad aluminum foil. Our composites feature excellent interfacial strength, high conductivity, and superior corrosion resistance, making them ideal for power, transportation, electronics, and renewable energy applications.

Instant Quote

Copper Clad Aluminum Plate

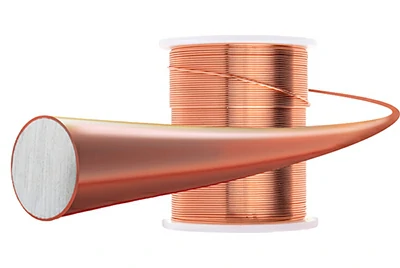

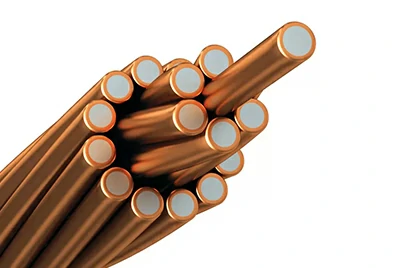

Copper Clad Aluminum Wire (CCA)

Copper Clad Aluminium Busbar CCA

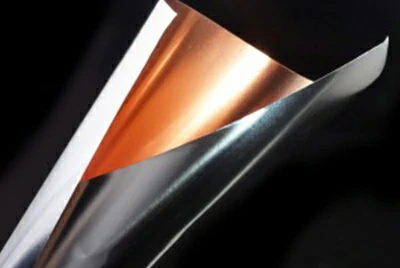

Copper Clad Aluminum Strip

Copper Clad Aluminum Cable

Copper Clad Aluminum Foil

Aluminum Lugs

Aluminum lugs are electrical connectors for aluminum or bi-metal cables. Made from high-purity aluminum, they are lighter and more cost-effective than copper lugs. Pre-filled with anti-oxidation compound and tin-plated, they resist oxidation and cold flow. Widely used in low to medium-high voltage systems across power, industry, construction, transport, and renewable energy.

Contact us now

Specifications Performance Parameters

| Applicable Cable Cross Section | 16 mm² – 1000 mm² (AWG 6–1000 kcmil) |

| Rated Current Capacity | 75 A – 1500 A |

| Bolt Hole Diameter | M6 – M24 (some up to M30/M36) |

| Material | 1000 High‑purity aluminum(Purity ≥ 99.5%)High Strength Alloy(6061‑T6 / 6082‑T6) |

| Surface Treatment | Tin Plating: ≥99.9% Tin, Thickness 5–10 µm Nickel Plating: Enhanced corrosion resistance, Thickness 0.5–2.5 µm |

| Working Temperature Range | –55 °C to +155 °C (standard); High‑temp models up to +150 °C peak |

| Rated Voltage | ≤ 1000 V (LV); selected models support 11–33 kV (MV/HV) |

| Electrical Resistivity | ≤ 2.87 µΩ·cm (@ 20 °C) |

| Tensile Strength | 150 MPa – 310 MPa(6082 T6 - 310MPa) |

| Elongation | 10% – 23% |

| Salt Spray Resistance | ≥ 500 hrs (standard); up to ≥ 2000 hrs for high-corrosion versions |

| Main Standard Certifications | IEC 61238‑1 ANSI C119.4 UL 486A/B AS/NZS 4681 ASTM B117 / ISO 9227 (salt‑spray) |

Various types of aluminum lugs

- Standard Aluminum Lugs

General-purpose aluminum lugs for common electrical connections.

- Long Barrel Aluminum Lugs

Extended barrel for enhanced mechanical strength and improved electrical contact.

- Single Hole Crimp Aluminum Lugs

Designed with one bolt hole for straightforward connections to a single stud or busbar.

- Double Hole Crimp Aluminum Lugs

Features two bolt holes for increased stability and redundancy in critical connections.

Key Features

1. Aluminum lugs are made from high‑purity aluminum alloy, offering approximately 50% cost savings compared to copper lugs and significantly reducing weight for easier transport and installation.

2. The lugs are tin‑plated and pre‑filled with an anti‑oxidation compound; their thickened barrel and precise inner diameter, when used with the correct crimping tool, effectively prevent creep and ensure long‑term connection reliability.

3. While aluminum's conductivity is lower than copper, optimized cross‑sectional design ensures high current‑carrying capacity, and aluminum’s excellent thermal conductivity helps dissipate heat, minimizing hotspot risks under heavy load or high ambient temperatures.

Typical Applications

- Used in power distribution systems for low, medium, and high voltage aluminum cable terminations in utility and industrial installations.

- Employed in commercial and industrial building power circuits, including automation panels and main feeders.

- Ideal for renewable energy installations in solar farms, wind farms, and energy storage systems utilizing large-gauge aluminum cables.

- Applied in transportation and rail sectors, such as lightweight cable bundles in electric vehicles and railcars.

- Suitable for marine and saline environments when equipped with tin/nickel plating and corrosion-resistant design.

- Used in mining and heavy industry for durable and reliable power connections in rugged equipment.

| Conn. bolts dia. | Nominal cross-section mm² | Code | Dimensions mm | Number of crimps | |||||||

| rm/sm | re/se | d1 | a | b | d2 | d4 | l | Al (7 mm) | Al (wide) | ||

| M 6 | 10 | 16 | 10 | 5 | 32 | 16 | 6.5 | 10 | 52 | 4 | 2 |

| M 8 | 10 | 16 | 10 | 5 | 32 | 18 | 8.5 | 10 | 52 | 4 | 2 |

| M 8 | 16 | 25 | 12 | 5.8 | 32 | 18 | 8.5 | 12 | 52 | 4 | 2 |

| M 10 | 16 | 25 | 12 | 5.8 | 32 | 18 | 10.5 | 12 | 52 | 4 | 2 |

| M 8 | 25 | 35 | 12 | 6.8 | 38 | 18 | 8.5 | 12 | 60 | 4 | 2 |

| M 10 | 25 | 35 | 12 | 6.8 | 38 | 18 | 10.5 | 12 | 60 | 4 | 2 |

| M 10 | 35 | 50 | 14 | 8.2 | 42 | 21 | 10.5 | 14 | 67 | 5 | 2 |

| M 12 | 35 | 50 | 14 | 8.2 | 42 | 21 | 13 | 14 | 67 | 5 | 2 |

| M 10 | 50 | 70 | 16 | 9.8 | 45 | 25 | 10.5 | 16 | 72 | 5 | 2 |

| M 12 | 50 | 70 | 16 | 9.8 | 45 | 25 | 13 | 16 | 72 | 5 | 2 |

| M 10 | 70 | 95 | 18 | 11.2 | 55 | 28 | 10.5 | 18.5 | 86 | 6 | 3 |

| M 12 | 70 | 95 | 18 | 11.2 | 55 | 28 | 13 | 18.5 | 86 | 6 | 3 |

| M 10 | 95 | 120 | 22 | 13.2 | 55 | 32 | 10.5 | 22 | 90 | 6 | 3 |

| M 12 | 95 | 120 | 22 | 13.2 | 55 | 32 | 13 | 22 | 90 | 6 | 3 |

| M 16 | 95 | 120 | 22 | 13.2 | 55 | 34 | 17 | 22 | 90 | 6 | 3 |

| M 12 | 120 | 150 | 22 | 14.7 | 55 | 32 | 13 | 23 | 91 | 6 | 3 |

| M 16 | 120 | 150 | 22 | 14.7 | 55 | 34 | 17 | 23 | 91 | 6 | 3 |

| M 12 | 150 | 185 | 25 | 16.5 | 63 | 35 | 13 | 25 | 103 | 6 | 3 |

| M 16 | 150 | 185 | 25 | 16.5 | 63 | 35 | 17 | 25 | 103 | 6 | 3 |

| M 16 | 240 | 300 | 32 | 21.3 | 70 | 45 | 17 | 32 | 116 | 8 | 3 |

| M 12 | 185 | 240 | 28 | 18.5 | 65 | 40 | 13 | 28 | 106 | 6 | 3 |

| M 16 | 185 | 240 | 28 | 18.5 | 65 | 40 | 17 | 28 | 106 | 6 | 3 |

| M 20 | 240 | 300 | 32 | 21.3 | 70 | 45 | 21 | 32 | 116 | 8 | 3 |

| M 20 | 185 | 240 | 28 | 18.5 | 65 | 40 | 21 | 28.5 | 106 | 6 | 3 |

| M 16 | 300 | -- | 34 | 23.6 | 75 | 49 | 17 | 34 | 124 | 8 | 3 |

| M 20 | 300 | -- | 34 | 23.6 | 75 | 49 | 21 | 34 | 124 | 8 | 3 |

| M 12 | 240 | 300 | 32 | 21.3 | 70 | 45 | 13 | 32 | 116 | 8 | 3 |

| M 16 | 400 | -- | 38 | 26 | 95 | 58 | 17 | 38.5 | 165 | -- | 4 |

| M 20 | 400 | -- | 38 | 26 | 95 | 58 | 21 | 38.5 | 165 | -- | 4 |

Copper Lugs

Copper lugs are critical components in electrical connection systems, securely and efficiently joining copper cables to electrical equipment or busbars. As terminal connectors, they ensure reliable, safe current transmission with minimal contact resistance, supporting crimping, welding, or bolted connections.

Contact us now

Specifications & Performance Parameters

| Applicable Cable Cross Section | 1.5 mm² – 1000 mm² |

| Bolt Hole Diameter | M4 – M24 |

| Material | Electrolytic Copper C11000, Purity ≥ 99.9%, Oxygen Content ≤ 30 ppm |

| Surface Treatment | Tin Plating: 99.9% Tin, Thickness 5–10 µm Nickel Plating: Enhanced Corrosion Resistance, Thickness 0.5–1 µm |

| Working Temperature Range | –55 °C to +155 °C |

| Rated Voltage | ≤ 1000 V (Low Voltage); Some models support up to 35 kV |

| Electrical Conductivity | 99.7–99.9% IACS |

| Electrical Resistivity | ≈ 1.72 µΩ·cm |

| Tensile Strength | ≥ 200 MPa |

| Elongation | ≥ 40% |

| Main Standard Certifications | IEC 61238-1 UL 486A/B AS/NZS 4325 Part 1 |

Key Features

- Manufactured from ≥99.9% IACS high-purity electrolytic copper, ensuring superior conductivity and minimal resistance for maximum power transmission efficiency.

- Professionally surface-treated (tin or nickel plating) to prevent oxidation and corrosion, significantly extending service life in harsh environments and enhancing long-term connection stability.

- Processed via cold pressing or forging for outstanding tensile and vibration resistance, ensuring durable and reliable connections in high-load, high-vibration applications.

- High thermal conductivity of copper effectively dissipates heat from connection points, reducing failure risk from heat buildup and improving system safety.

- Supports multiple installation methods including crimping, welding, and bolted connections, offering high flexibility for various project requirements and installation conditions.

Various types of copper lugs

Standard Tubular Copper Lugs

The most common type, versatile for everyday electrical wiring connections.

Long Barrel Copper Lugs

Feature a longer barrel for enhanced mechanical strength and lower resistance, commonly used in heavy-duty or high-voltage applications.

Angled Copper Lugs (45°/90°)

Designed with an angled palm for easier installation in confined spaces or where specific cable routing is required.

Two-Hole / Multi-Hole Copper Lugs

Equipped with two or more bolt holes for more secure connections to busbars or large equipment.

Bell-Mouth Copper Lugs

Feature a flared barrel entrance for easy insertion of multi-strand cables, preventing fraying.

Fork Lugs / Spade Lugs

U-shaped terminal ends allow for connection or disconnection without fully removing the bolt, ideal for quick maintenance.

Primary Applications

- Power Transmission & Distribution Systems: Connecting busbars, circuit breakers, transformers, rectifiers, and more.

- Industrial Equipment: Providing highly stable electrical connections for motors, generators, distribution boxes, control panels, and other industrial machinery.

- Renewable Energy Systems: Essential for cable connections in solar photovoltaic arrays and wind turbine generators.

- Automotive & Battery Systems: Used for battery terminals, automotive power generation systems, and heavy-duty vehicle electrical connections.

- Marine & Offshore Platforms: Tin-plated variants are particularly suited for high-salt spray and corrosive marine environments.

- Rail Transit & High Voltage Engineering: Applicable for medium to high voltage (MV/HV) specific uses, typically ranging from 1.5–1200 mm² and 6.6–33 kV.

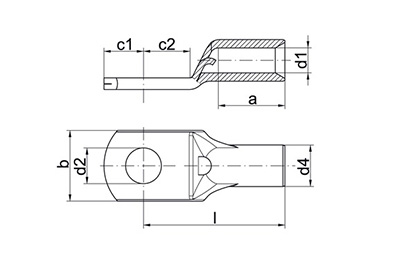

| Nominalcross-sectionmm² | Conn.boltsdia. | Dimensionsmm | |||||||

| d1 | a | b | d2 | d4 | c1 | c2 | l | ||

| 0.75 | M3 | 1.3 | 6 | 6 | 3.2 | 2.8 | 3.25 | 4 | 12 |

| 0.75 | M4 | 1.3 | 6 | 6.5 | 4.3 | 2.8 | 4 | 5 | 13 |

| 0.75 | M5 | 1.3 | 6 | 7.5 | 5.3 | 2.8 | 4.75 | 5.5 | 14 |

| 1.5 | M3 | 1.8 | 6 | 6.5 | 3.2 | 3.3 | 3.25 | 4 | 12 |

| 1.5 | M4 | 1.8 | 6 | 6.5 | 4.3 | 3.3 | 4 | 5 | 13 |

| 1.5 | M5 | 1.8 | 6 | 7.5 | 5.3 | 3.3 | 4.75 | 5.5 | 14 |

| 1.5 | M6 | 1.8 | 6 | 9 | 6.4 | 3.3 | 6.5 | 6.5 | 16 |

| 2.5 | M3 | 2.3 | 6 | 7.5 | 3.2 | 4.2 | 3.25 | 4 | 12 |

| 2.5 | M4 | 2.3 | 6 | 7.5 | 4.3 | 4.2 | 4 | 5 | 13 |

| 2.5 | M5 | 2.3 | 6 | 8.5 | 5.3 | 4.2 | 4.75 | 5.5 | 14 |

| 2.5 | M6 | 2.3 | 6 | 9.5 | 6.5 | 4.2 | 6.5 | 6.5 | 16 |

| 2.5 | M8 | 2.3 | 6 | 13 | 8.4 | 4.2 | 7.75 | 9.5 | 20 |

| 4 | M4 | 3 | 8 | 8.5 | 4.3 | 5 | 4.75 | 5.5 | 17 |

| 4 | M5 | 3 | 8 | 9 | 5.3 | 5 | 4.75 | 6 | 17 |

| 4 | M6 | 3 | 8 | 10 | 6.4 | 5 | 6.5 | 6.5 | 19 |

| 4 | M8 | 3 | 8 | 13 | 8.4 | 5 | 8.5 | 9.5 | 22 |

| 6 | M4 | 4 | 9 | 9.5 | 4.3 | 6 | 5 | 5.5 | 18 |

| 6 | M5 | 4 | 9 | 9.5 | 5.3 | 6 | 6 | 6 | 19 |

| 6 | M6 | 4 | 9 | 10 | 6.4 | 6 | 7 | 6.5 | 19 |

| 6 | M8 | 4 | 9 | 14 | 8.5 | 6 | 8.5 | 9.5 | 22 |

FAQs

What’s the fundamental difference between copper terminals, aluminum terminals, and bimetallic (copper-aluminum) terminals? Why are all three types needed?

Copper, aluminum, and bimetallic terminals differ in conductivity, oxidation resistance, mechanical strength, thermal expansion, and electrochemical potential.

Copper terminals offer excellent conductivity (IACS 100%), high strength, and superior oxidation resistance.

Aluminum terminals are lighter and more cost-effective, suitable for aluminum cables, but prone to surface oxidation.

Bimetallic terminals solve copper-aluminum transition issues, preventing galvanic corrosion in mixed systems, commonly used where aluminum cables connect to copper busbars.

Why is it not recommended to connect aluminum cables with copper terminals, or copper conductors with aluminum terminals?

Direct copper-aluminum contact causes galvanic corrosion due to significant potential difference, especially under moisture or current flow. This leads to overheating, contact degradation, or failure.

Use bimetallic terminals or apply anti-oxidant paste and full insulation sealing where necessary. Compliance with standards like DIN 46267 and IEC 61238-1 is also essential.

How do bimetallic terminals prevent corrosion? Are they more reliable than pure copper or aluminum terminals?

Bimetallic terminals are produced through explosion welding, friction welding, or cold pressing, forming a permanent, low-resistance bond between copper and aluminum.

They outperform aluminum terminals in corrosion resistance and electrical stability, though may be slightly less durable than pure copper in extreme environments. Ideal for copper bus to aluminum cable connections.

Can aluminum terminals be used with copper conductors?

No. Aluminum terminals should only be used with aluminum conductors. Connecting aluminum terminals to copper conductors may cause:

Galvanic corrosion

Thermal mismatch causing loosening under thermal cycling

Increased contact resistance leading to overheating

Bimetallic terminals are the recommended solution for copper-aluminum transitions.

In engineering projects, how do you match cables and terminals?

Terminal materials must match cable materials for safe, long-term performance. General rules:

Use copper terminals for copper cables.

Use aluminum terminals for aluminum cables connected to aluminum busbars.

For aluminum cable to copper busbar, use bimetallic terminals.

For rare cases like copper cable to aluminum busbar, also use bimetallic terminals or specialized adapters.

Are bimetallic terminals suitable for high-voltage applications?

Yes, bimetallic terminals are commonly used in low and medium-voltage systems (0.6/1kV to 35kV), and can be customized for higher voltage levels.

Ensure they pass type tests (e.g., IEC 61238-1) and meet insulation and clearance requirements. Widely used in substations, compact transformer stations, and solar AC/DC transitions.

What surface treatments are available for terminals? Which is best for aluminum types?

Common surface treatments include:

Tin plating improves corrosion resistance and contact reliability.

Silver plating is used in high-reliability, high-temperature environments like aerospace.

Anodizing (for aluminum) enhances oxidation resistance but may slightly reduce conductivity.

For aluminum terminals, tin plating is most widely adopted, often combined with anti-oxidant compounds in humid or marine environments.

How to verify that a terminal has been installed correctly? What are common mistakes?

Proper installation requires:

- Correct crimping tools and dies

- Proper crimp position with clear markings

- No cracks, bulging, or damage

- Secure transition at copper-aluminum joints (for bimetallic types)

Typical mistakes include:

- Using mismatched crimping tools

- Connecting copper and aluminum directly without a bimetallic solution

- Poor surface cleaning and oxidation treatment

- Improper handling of stranded conductors, leading to heat buildup

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote