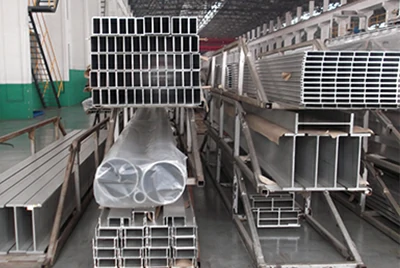

6061 Aluminum Rectangular Tubing is widely used in engineering structures, machinery frames, automotive components, and aerospace equipment due to its high strength, lightweight, excellent weldability, and corrosion resistance.

Instant QuoteAs an industry-leading rectangular aluminum tube manufacturer, Chalco offers multiple heat treatment tempers (T6 / T6511), a variety of wall thickness options, surface treatments (anodizing / coating), and precision cutting services with a tolerance of ± 0.5 mm, meeting your diverse needs from lightweight structures to heavy-load systems.

View our 6061 Rectangular Aluminum Tubing stock size table now.

Why Choose 6061 Aluminum Rectangular Tubing

Heat Treatment Tempers

6061-T6 Aluminum Rectangular Tubing

6061-T6 Aluminum Rectangular TubingSolution heat–treated and artificially aged for exceptional strength and hardness (tensile ≥ 290 MPa, yield ≥ 240 MPa). Ideal for aerospace brackets, automotive components, and structural engineering.

ASTM B221 AMS 4113Preservative 6061-T6511 Aluminum Rectangular Tubing

6061-T6511 Aluminum Rectangular TubingBuilt on the T6 temper with an added stress-relief process to enhance extrusion precision and dimensional stability. Suited for applications demanding tight post-machining tolerances, such as fixtures, CNC machine frames, and drive systems.

ASTM B221 AMS 4173

Mechanical Properties

| Tensile Strength | 290-310 MPa |

| Yield Strength | 240-276 MPa |

| Fatigue Strength | 97 MPa |

| Shear Strength | 207 MPa |

| Elongation | 8–12% |

| Brinell Hardness | 95 HB |

Compared to 6063, tensile strength increases by over 20%; versus 7075, cost-effectiveness is higher and corrosion resistance is superior.

Specifications Of 6061 Rectangular Aluminum Tubing

Specification

- ASTM B221

- AMS QQ-A-200/8

- EN 755

- ASTM B210

- WW-T-700/6

Standard Size Range

| Metric range (mm) | Imperial range (inch) | |

| Width | 12.7 – 300 | 0.5" – 12" |

| Height | 12.7 – 200 | 0.5" – 8" |

| Wall | 1.5 – 12.0 | 0.058" – 0.5" |

| Length | ≤ 6000(customizable) | ≤ 24ft (customizable) |

Process And Treatment Capabilities

- Manufacturing Process: Standard extruded; supports custom seamless construction

- Surface Treatments: Anodizing (anodic film thickness up to 50 μm) / Powder coating / Brushing / Electrophoretic coating

- Secondary Processing Options: Cut-to-length / CNC machining / Perforation / Chamfering / Weld beveling / Polishing

Special Customization Capabilities

Chalco maintains over 1,000 existing die sets covering more than 95 % of mainstream profiles—no new tooling required for immediate production. For non-standard sections, large rectangular profiles (up to 350 mm outer dimension), unique wall thicknesses, or tight tolerance requirements, we offer rapid die-making and prototyping with sample delivery in as little as 15 working days—providing true one-stop development from drawing to finished 6061 aluminum rectangular tubing.

Instant Quote

6061 Aluminum Rectangular Tubing Stock Sheet

6061 T6 aluminum rectangular tubing Stock Sheet

Specification: ASTM B221,AMS 4113

| Details | Is it in stock | Optional processing |

| 0.5" × 1" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching |

| 0.75" × 1" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching |

| 0.75" × 1.5" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching |

| 1" × 1.5" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching / CNC |

| 1" × 2" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching / CNC |

| 1.5" × 2" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching / CNC |

| 1.5" × 3" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching / CNC |

| 1.75" × 3" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / Punching / CNC |

| 2" × 3" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / CNC / Welding |

| 2" × 4" × 0.125" 6061 T6 aluminum rectangular tubing | In Stock | Cutting / CNC / Welding |

| 2" × 6" × 0.188" 6061 T6 aluminum rectangular tubing | Custom | Cutting / CNC / Chamfering |

| 2" × 8" × 0.25" 6061 T6 aluminum rectangular tubing | Custom | Cutting / CNC / Chamfering |

| 2" × 10" × 0.25" 6061 T6 aluminum rectangular tubing | Custom | Cutting / CNC / Chamfering |

| 3" × 6" × 0.188" 6061 T6 aluminum rectangular tubing | Custom | Cutting / CNC / Chamfering |

| 4" × 6" × 0.25" 6061 T6 aluminum rectangular tubing | Custom | Cutting / CNC / Chamfering |

| 4" × 8" × 0.125" 6061 T6 aluminum rectangular tubing | Custom | Cutting / CNC / Chamfering |

6061-T6511 Aluminum Rectangular Tubing Hot Selling Sizes

Specification: ASTM B221, AMS 4173

| Details | Is it in stock | Optional processing |

| 1" × 2" × 0.125" 6061 T6511 aluminum rectangular tubing | In Stock | Cutting / CNC |

| 1.5" × 3" × 0.125" 6061 T6511 aluminum rectangular tubing | In Stock | Cutting / Chamfering / CNC |

| 2" × 4" × 0.25" 6061 T6511 aluminum rectangular tubing | In Stock | Cutting / Punching / CNC |

| 2" × 6" × 0.25" 6061 T6511 aluminum rectangular tubing | In Stock | Cutting / CNC |

| 4" × 6" × 0.25" 6061 T6511 aluminum rectangular tubing | In Stock | Cutting / Welding / CNC |

| 2" × 8" × 0.25" 6061 T6511 aluminum rectangular tubing | Custom | Cutting / CNC |

| 4" × 8" × 0.25" 6061 T6511 aluminum rectangular tubing | Custom | Cutting / CNC |

For detailed in-stock inventory, sample requests, or project support recommendations, please contact us now. The Chalco engineering team will provide fast response and professional assistance.

Instant QuoteProduct Types of 6061 Aluminum Rectangular Tubing

To meet the diverse demands of different industries in terms of strength, appearance, and machinability, Chalco offers a wide range of 6061 aluminum rectangular tubing types:

Thin Wall 6061 Aluminum Rectangular Tubing

Wall Thickness≤ 1/8" (3.2 mm),Lightweight, excellent formability, easy to bend and punch, cost-effective for fixed-length customization

Applications: Display racks, lightbox frames, hand tool housings, decorative structures

Structural 6061 Rectangular Tube

Medium to thick wall design, high strength and fatigue resistance, suitable for MIG/TIG welding, ideal for load-bearing structures

Applications:Industrial frameworks, robotic arms, conveyor tracks, engineering platforms

Seamless 6061 Rectangular Tubing

Drawn seamless structure without welds, uniform mechanical properties, better fatigue life and sealing performance

Applications: High-pressure systems, aerospace fixtures, lab equipment

Telescoping 6061 Rectangular Tubing

Precision tolerance control, matching inner and outer tube dimensions for smooth sliding fit, ideal for adjustable structures

Applications: Lift supports, modular systems, movable components

Anodized 6061 Aluminum Rectangular Tubing

Aesthetic surface finish, anodic film thickness up to 50 μm, oxidation- and scratch-resistant, long-lasting color

Applications: Building façades, window & door systems, decorative profiles

For selection guidance or to request a sample catalog, please contact the Chalco engineering team — we’ll help you choose the most suitable tubing type and structural solution.

Instant QuoteTypical Applications of 6061 Rectangular Aluminum Tubing

6061 rectangular aluminum tubing is widely used across various industries thanks to its excellent strength-to-weight ratio, outstanding weldability, and superior corrosion resistance. Below is an overview of common application scenarios categorized by industry, along with recommended specifications:

Aerospace Applications of 6061 Rectangular Tubing

Wall Thickness: ≥ 0.125"

Common Sizes: 1"×2", 2"×4"

Key Advantages: Lightweight with high strength / Excellent fatigue resistance / Superior weather resistance

Typical Uses: Aircraft fuselage frames, landing gear supports, ground test platforms, tool racks

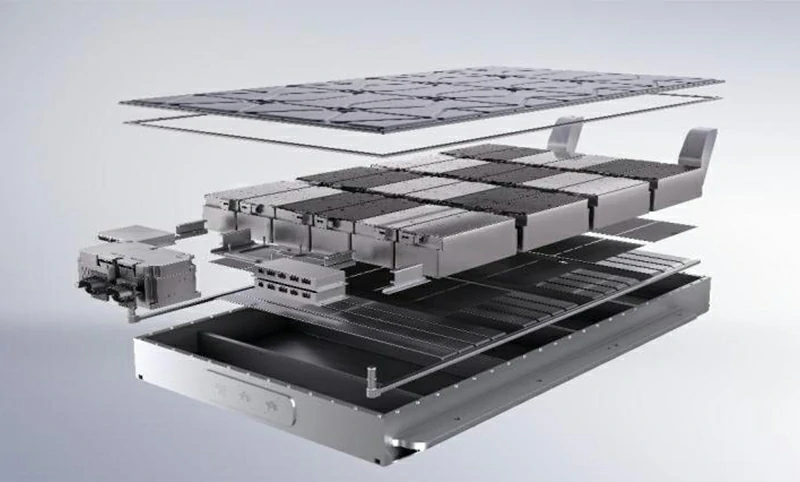

Automotive Applications of 6061 Rectangular Tubing

Wall Thickness: 0.125"–0.25"

Common Sizes: 1.5"×2", 3"×1.5", 3"×2"

Key Advantages: Combines strength with light weight / Impact resistance / Easy to form and fabricate

Typical Uses: Battery mounts, roof frames, shock-absorbing beams, bumper reinforcements

Machinery & Equipment Applications of 6061 Rectangular Tubing

Temper: T6 / T6511

Common Sizes: 4"×2", 6"×2", 6"×4"

Key Advantages: High rigidity / Easy to drill and weld / Supports precision machining

Typical Uses: Machine enclosures, conveyor frames, structural arms, assembly platforms

Marine Applications of 6061 Rectangular Tubing

Wall Thickness: ≥ 0.188"

Common Sizes: 3"×6"

Surface Treatment: Anodized

Key Advantages: Excellent corrosion resistance / Compatible with anodizing

Typical Uses: Hull reinforcement structures, flotation tube frames, electrical enclosures, marine ladders and platforms

Construction Applications of 6061 Rectangular Tubing

Common Sizes: 2"×1", 3"×2", 4"×2"

Surface Treatment: Anodizing, powder coating, polishing

Key Advantages: Aesthetic appearance / Easy to finish / High installation efficiency

Typical Uses: Curtain wall supports, door and window frames, decorative columns, railing systems, bridge components

If you need tailored recommendations based on your specific industry or application scenario, please feel free to contact the Chalco Engineering Team for expert support and solution matching.

Instant Quote

Surface Finishing & Machining Services

To meet the diverse demands for aesthetics, corrosion resistance, and assembly efficiency across industries, Chalco offers a range of standardized and custom surface finishing and post-processing services for 6061 aluminum rectangular tubing:

Surface Treatment Options

Anodizing: Available in silver, black, gold, etc., with film thickness from 10–50 μm; enhances corrosion resistance and decorative appeal.

Powder Coating: Offers matte or glossy finishes; ideal for outdoor exposure and high-humidity environments.

Electrophoretic Coating: Improves adhesion and salt spray resistance; suited for marine engineering projects.

Brushed Mill Finish: Natural, aesthetic look; perfect for light decorative structures.

Machining Capabilities

Cut‐to‐Length Cutting: Standard tolerance ± 0.5 mm, customizable to ± 0.2 mm.

CNC Milling: Supports complex hole patterns, slots, and high-precision component machining.

Punching / Drilling / Chamfering / Polishing: Adapts to various installation and assembly requirements.

Weld Beveling / V‐Groove Preparation: Facilitates structural joins and enhances weld strength.

For volume assembly processing, we offer drawing‐based machining, batch prototyping, and consolidated delivery.

Contact our technical team for more details on machining capabilities or to request samples.

Instant Quote6061 Rectangular vs. Square vs. Round Tubing

When selecting material, 6061 rectangular, square, and round tubing each offer unique advantages. Chalco provides all three product lines to meet various structural design and installation requirements. For comparative samples or tailored section‐shape recommendations, please refer to our dedicated product pages.

| Rectangular tube | Square tube | Round tube | |

| Structural directionality | Clear force direction, excellent bending rigidity | Balanced support, suitable for symmetrical structure | Applicable to multi-directional load and pressure scenarios |

| Installation connection | Easier to drill and weld for flat connection | Also easy to weld and dock | Difference in round surface connection, auxiliary clamps are required |

| Space utilization | Can be attached to walls and corners, saving structural space | Slightly larger footprint | Lowest space utilization |

| Appearance aesthetics | Moderate | Hard lines | Round shape |

| Manufacturing cost | Moderate cost | High mold utilization, slightly lower | High extrusion efficiency, more economical batch |

| Typical application areas | Engineering frame, rack, load bracket | Architectural profiles, shelves, guardrail systems | Fluid systems, sports equipment, frame rods, etc. |

FAQs

What Is The Minimum Order Quantity For 6061 Aluminum Rectangular Tubing? Do You Support Small Batches?

Chalco maintains stock of 6061-T6 tubing; standard MOQ for stocked sizes is 200 kg, with fast prototyping support for smaller samples. Custom products typically require a 1-ton MOQ, but we can flexibly accommodate trial runs and small-to-medium batch orders.

What Is The Typical Price Of 6061 Aluminum Rectangular Tubing?

Pricing for 6061 aluminum rectangular tubing varies by size, wall thickness, temper, and order quantity. Typical range is $2.5–$12.5/ft. Chalco offers tailored quotes—please submit your specifications for a rapid price estimate.

Is The Structural Strength Of 6061 Rectangular Tubing Sufficient To Replace Steel?

In T6 temper, 6061 rectangular tubing achieves tensile strength ≥ 290 MPa and yield strength ≥ 240 MPa, making it suitable for load-bearing frames and equipment supports. With proper wall thickness and design support, it can serve as a lightweight alternative to carbon steel in transportation, construction, and equipment manufacturing.

Is 6061 Rectangular Tubing Suitable For Humid Or Corrosive Environments?

Yes. 6061 has a natural oxide layer that resists atmospheric, moisture, and mild chemical corrosion. For salt spray or marine conditions, we recommend anodizing or powder coating, or consider using 5083 alloy for enhanced corrosion resistance.

What Advantages Does 6061 Have Over 6063 Rectangular Tubing?

Compared to 6063, 6061 offers higher strength and greater structural rigidity, making it ideal for load-bearing and mechanical applications. 6063 Rectangular Tubing is better suited for decorative, lightweight structures with stringent surface-finish requirements. For projects involving CNC machining, welding, or structural support, 6061 is the preferred choice.

Does 6061 Rectangular Tubing Support Surface Treatments Like Anodizing Or Electrophoresis?

Yes. Chalco provides anodizing (up to 50 μm), black electrophoretic coating, powder coating, and other finishes to enhance corrosion resistance and aesthetic appeal, meeting demands in architecture, marine, and high-end equipment applications.

Can You Custom-Size 6061 Rectangular Tubing According To My Drawings?

Absolutely. With over 1,000 die sets covering most profiles, Chalco can produce standard sizes immediately. For non-standard dimensions, special wall thicknesses, or unique profiles, we offer quick die-making and sample runs with 15–20 working day turnaround.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote