Aluminum blanks are pre-cut aluminum pieces supplied in standard or custom shapes for downstream processing. They serve as a versatile base material for applications such as sublimation printing, metal stamping, engraving, and CNC milling, and are widely used across signage, packaging, industrial components, and consumer products.

Depending on the processing method and industry terminology, these blanks may be referred to as aluminum circles, discs, slugs, or blocks. Chalco offers all of these in 6061 aluminum and other alloys, with customizable dimensions, surface finishes, and forming capabilities to meet specific end-use requirements.

Aluminum Blank Technical Specifications

Chalco aluminum blanks are available in a wide range of dimensions and finishes to meet various processing needs. Below are the standard and customizable technical specifications:

- Diameter: 20mm – 116mm (standard), up to 2000mm for custom blanks

- Thickness: 0.5mm – 15.0mm (standard), up to 150mm for block-type blanks

- Flatness: ≤0.10mm for disc blanks under 300mm diameter

- Tempers: O / T4 / T5 / T6 based on forming and machining requirements

- Surface Finishes: Mill finish, tumbled, brushed, mirror polished, anodized, PE/PVDF coated

- Tolerance Standards: EN 570 / ASTM B209

- Chemical Standards: EN 573-3 for alloy composition

- Mechanical Testing: ASTM E8 / EN 485-2 for tensile and elongation properties

Aluminum Blank Shapes & Product Types Available – 6061 Aluminum Circle, Disc, Slug, and Block

Chalco offers precision aluminum blanks in a wide range of shapes and thicknesses to meet the needs of stamping, milling, engraving, extrusion, and sublimation processes. Our blanks are available in standard and customized profiles including round, square, rectangular, oval, flat, domed, and conical, with optional hole punching or edge shaping for specific applications.

In different industries or processing contexts, aluminum blanks may also be referred to by more specialized names. At Chalco, we classify and supply four common types of aluminum blanks:

Ideal for stamping, sublimation printing, and decorative engraving. Smooth surface and consistent thickness for reliable performance.

Used for CNC milling, signage, and structural parts requiring excellent flatness and pressure resistance.

Compact blanks designed for deep drawing, impact extrusion, and forming of aerosol cans and auto parts.

Precision-milled blocks ideal for mold bases, jigs, fixtures, and CNC-machined structural components.

Application-Based 6061 Aluminum Blank Types

Chalco's 6061 aluminum blanks are engineered to serve a wide range of industries and end-use scenarios. Whether you need blanks for high-precision CNC machining, colorful sublimation printing, or deep drawing for structural components, our products are available in tailored shapes and surface finishes to meet your needs.

From sublimation aluminum blanks for custom gifts and signage, to stamping and impact extrusion blanks for industrial forming, and engraving blanks for precision marking and machining—Chalco provides reliable solutions in circle, disc, slug, and block formats. Explore the options below to find the ideal blank type for your next project.

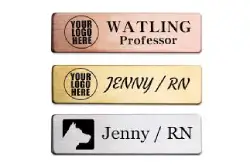

Instant QuoteSublimation Aluminum Blanks

Chalco's sublimation blanks are pre-treated with a special coating for dye sublimation printing, making them ideal for personalized photo panels, signs, nameplates, and promotional items.

Recommended shapes: Circle and disc blanks with smooth or coated surfaces.

Preferred alloys: 6061 (for strength and stability), 1050, 1100 (for better coating adhesion).

Sublimation Blanks Printing Sample

Round Sublimation Blanks

Anodized Aluminum Circle Blanks

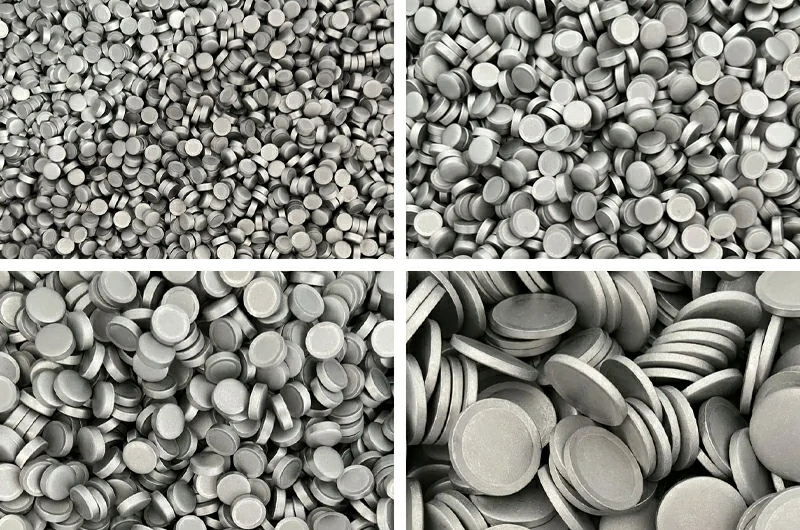

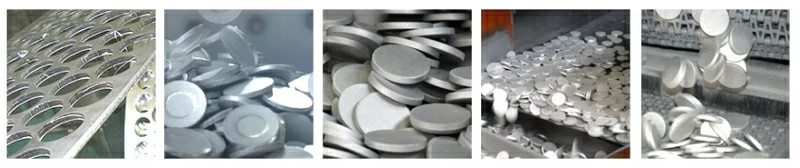

Stamping & Impact Extrusion Blanks

Designed for deep drawing, cold forming, and high-speed stamping processes, these blanks are widely used in aerosol cans, automotive housings, and battery components.

Recommended shapes: Slug and disc blanks with clean edges and consistent flatness.

Preferred alloys: 6061 (for strength and pressure applications), 3003, 1070 (for high formability).

Aluminum Slug for Deep Drawing

Extruded Aerosol Can Body

Battery Components

Engraving & Milling Blanks

Chalco offers precision-ground aluminum blanks ideal for CNC machining, laser engraving, and part prototyping. These blanks provide excellent dimensional stability and surface quality.

Recommended shapes: Disc and block blanks.

Preferred alloys: 6061 (for precision machining), 2024 (for fatigue-resistance), 5083 (for corrosion resistance).

Aluminum Block for CNC

Engraving Panel Application

Round Disc Blank for Milling

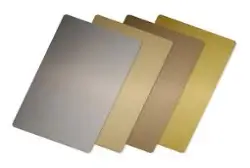

Anodized Decorative Blanks

These blanks are pre-anodized or supplied in anodizable grades for applications such as decorative panels, signage, jewelry, and craft engraving.

Recommended shapes: Circle, slug, and bracelet blanks.

Preferred alloys: 6061 (for color consistency and durability), 5052, 1100 (for easier anodizing).

Anodized Decorative Plate

Laser Engraved Tag

Color Anodized Aluminum Blank

Punched & Concave Aluminum Blanks

Chalco offers customized punched and concave-shaped aluminum blanks to meet the needs of complex part geometries and functional surface requirements. These blanks feature through-holes, recessed surfaces, or special edge profiles tailored for precise assembly, electronic modules, and heat-sensitive housings.

Recommended shapes: Circle, disc, rectangular, or oval blanks with holes, recesses, or edge features.

Preferred alloys: 6061 (for strength and structural consistency), 1100, 3003 (for easier forming or coating).

Surface Finish Options for 6061 Aluminum Blanks

Anodizing & Color Coating

Creates a corrosion-resistant, durable oxide layer. Available in multiple colors and gloss levels, ideal for decorative, consumer, or electronic applications.

Bright Finish

Achieved by mechanical or chemical polishing, offering high reflectivity and smoothness. Popular in lighting, cosmetics, and visual branding.

Tumbled

Barrel-tumbling process that smooths edges, removes burrs, and improves handling for stamping and forming applications.

Shot Blasting / Sandblasting

Provides uniform roughness and oxide removal, enhancing paint, adhesive, or coating adhesion. Ideal for functional blanks and pre-treatment steps.

PE / PVDF Coating

Optional fluorocarbon or polyester coatings for architectural or weather-exposed applications. High UV resistance and chemical durability.

Teflon Coating

Non-stick, high-temperature resistant coating ideal for technical and industrial aluminum blanks requiring surface lubricity or chemical resistance.

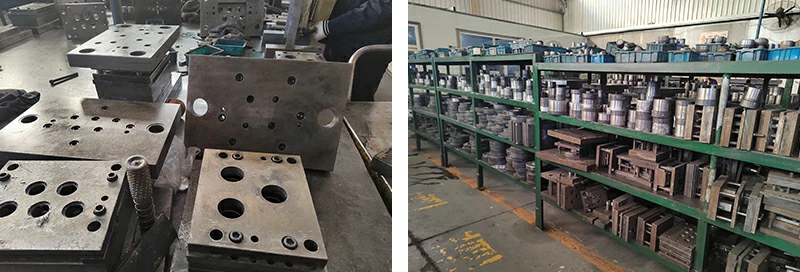

Technical Specifications & Processing Capabilities

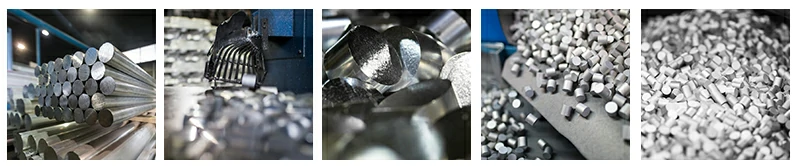

Chalco provides comprehensive aluminum blank processing services from alloying to final finishing. Our process ensures high material integrity, consistent dimensions, and tight tolerance control for every 6061 aluminum blank.

Melting & Alloying: High-purity aluminum is melted and alloyed under controlled conditions to ensure precise composition and cleanliness.

Casting & Hot Rolling: The molten aluminum is rotary cast and hot-rolled into coils, forming the base for billets or blanks.

Cold Rolling & Laser Measurement: Cold rolling ensures target thickness, while laser sensors measure and control dimensional tolerance in real-time.

Precision Sawing: Aluminum rods are sawn into blank slugs using high-efficiency CNC saws, ensuring clean edges and accurate diameter control.

Stamping & Annealing: High-speed stamping forms final shapes. Annealing adjusts hardness and improves ductility for deep drawing or forming processes.

Surface Finishing: Options include tumbling, shot blasting, or polishing to achieve desired appearance and improve coating or anodizing adhesion.

Packing & Warehousing: Final blanks are cleaned, packaged, and stored in a sealed environment to avoid contamination and ensure safe delivery.

All Chalco aluminum blanks comply with EN 573-3 (chemical composition), EN 570 (dimensional tolerance), and ASTM B209 standards. Mechanical testing is performed per ASTM E8 or EN 485-2. Full traceability is available with heat number, production batch, and inspection documentation.

Instant Quote

Quality Control for Chalco Aluminum Blanks Products

Ensuring high quality and consistency is a top priority in Chalco's aluminum blank production. Through a comprehensive set of quality control procedures, we deliver products that meet the demanding standards of the automotive, electronics, and packaging industries.

1. Alloy Consistency & Metallurgical Purity

- Strict chemical composition monitoring to maintain alloy uniformity across batches.

- Metallurgical contamination control through weight-based material verification.

2. Dimensional & Weight Accuracy

- Laser measurement tools ensure precise diameter, thickness, and tolerance control.

- Each blank is weight-graded to eliminate variances and maintain specification accuracy.

3. Surface Finish & Defect Screening

- Visual and automated inspection detects surface imperfections like cracks or scratches.

- Microscopic and X-ray analysis ensures the blank surface meets both aesthetic and functional standards.

4. Heat Treatment & Mechanical Testing

- Uniform furnace control during annealing enhances mechanical properties and formability.

- Each batch undergoes tensile and hardness tests to verify strength and durability.

5. Waste Reduction & Process Optimization

- Advanced grading systems reduce scrap and boost production efficiency.

- Precise process control minimizes material consumption and supports sustainability.

6. Automated & Data-Driven Quality Systems

- Real-time monitoring via automated inspection systems for stable quality control.

- SPC-based data analytics drive continuous improvement in both production and quality assurance.

Need help choosing the right alloy for your aluminum blanks? Contact our engineering team for application-specific recommendations or custom alloy solutions.

6061 Aluminum Blank – Advantages & Alloy Alternatives

While aluminum blanks are commonly made from soft, highly formable alloys such as 1050, 1100, or 3003 for ease of stamping and coating, 6061 aluminum offers a unique balance of strength, machinability, and corrosion resistance that makes it an excellent choice for more demanding applications.

Thanks to its excellent dimensional stability, good weldability, and heat-treatable strength, 6061 is ideal for blanks used in CNC machining, structural components, tooling bases, and engraved plates. It's especially valuable when blanks need to hold tight tolerances or be used in load-bearing or outdoor environments.

At Chalco, we provide 6061 aluminum blanks in circle, disc, slug, and block shapes, available in standard or custom sizes to suit both decorative and industrial uses.

Other hot selling aluminum blank products in Chalco

- 1050 / 1100 aluminum blank – Soft and highly ductile; ideal for sublimation, decorative blanks, and light stamping with excellent surface coating performance.

- 3003 aluminum blank – Moderate strength with excellent formability; suitable for deep drawing and medium-duty blanking applications.

- 5052 aluminum blank – Good corrosion resistance and moderate strength; commonly used for anodized or outdoor-use blanks.

- 1070 / 1085 aluminum blank – High purity with excellent reflectivity; recommended for high-gloss or lighting-related blank applications.

Technical details table of chalco aluminum slug products

| Tolerances on Diameter of Sawn Aluminum Blanks | |

| Aluminum Blank Diameter (mm) | Tolerances (mm) |

| 3 - 6 | 0 - 0.07 |

| 6 - 10 | 0 - 0.09 |

| 10 - 18 | 0 - 0.11 |

| 18 - 30 | 0 - 0.13 |

| 30 - 50 | 0 - 0.16 |

| 50 - 65 | 0 - 0.50 |

| 65 - 80 | 0 - 0.60 |

| 80 - 130 | 0 - 0.90 |

| Tolerances on Length and Width of Rectangular Aluminum Blanks | |

| Length and Width (mm) | Tolerances (mm) |

| ≤10 | ±0.05 |

| 10 - 20 | ±0.08 |

| 20 - 40 | ±0.10 |

| 40 - 60 | ±0.12 |

| 60 - 120 | ±0.14 |

| 120 - 150 | ±0.17 |

| 150 - 200 | ±0.20 |

| Tolerances on Thickness of Rectangular Aluminum Blanks | |

| Blank Thickness (mm) | Tolerances (mm) |

| ≤2.8 | ±0.03 |

| 2.8 - 6.5 | ±0.05 |

| 6.5 - 8.5 | ±0.07 |

| 8.5 - 10.5 | ±0.10 |

| 10.5 - 15 | ±0.14 |

| 15 - 20 | ±0.18 |

| 20 - 25 | ±0.22 |

| 25 - 30 | ±0.26 |

| 30 - 40 | ±0.30 |

| Tolerances on Thickness of Sawn Aluminum Blanks | ||||

| Diameter or Width (mm) | Tolerances for Thicknesses (mm) | |||

| 7 - 10 | 10 - 20 | 20 - 40 | 40 - 70 | |

| ≤15 | ±0.15 | ±0.15 | ±0.15 | ±0.20 |

| 15 - 30 | ±0.15 | ±0.20 | ±0.20 | ±0.25 |

| 30 - 70 | ±0.15 | ±0.20 | ±0.25 | ±0.30 |

| 70 - 100 | ±0.30 | ±0.35 | ±0.40 | ±0.45 |

| 100 - 130 | ±0.40 | ±0.45 | ±0.50 | ±0.60 |

Aluminum slug market prospects and sustainable development direction of Chalco slug products

Aluminum slug market prospects and development analysis

- Growing market demand: Aluminum slugs are widely used in industries such as automobiles, food and beverages, personal care, pharmaceuticals, paints and coatings, and electrical appliances. Especially in the automotive and consumer goods sectors, demand continues to grow.

- Diversified material sources: Common aluminum slugs on the market use different types of aluminum alloys and recycled aluminum raw materials (such as PCR, PIR, and green primary aluminum), which helps reduce dependence on natural aluminum resources and promote environmental protection and resource recycling.

- Technological innovation improves production efficiency: The production process of aluminum slugs is increasingly advanced, from efficient stamping technology to fine surface treatment technology, which has significantly improved the quality and production efficiency of aluminum slugs.

- Expansion of application areas: The rising demand for aluminum slugs in aerosol containers, automotive parts, electronic products and other fields has further promoted the expansion of the aluminum slug market.

Chalco aluminum slug's sustainable development strategy

- Use of recycled aluminum: Chalco actively uses PCR (post-consumer recycled aluminum) and PIR (post-industrial recycled aluminum) raw materials to reduce dependence on natural aluminum resources and promote the development of a circular economy.

- Efficient and environmentally friendly production process: By optimizing the production process of aluminum slugs, from smelting and casting to stamping and surface treatment, Chalco ensures that every link meets strict environmental requirements, reducing resource waste and carbon emissions in production.

- Low-carbon emission technology: We apply low-carbon emission production technology to improve energy efficiency and reduce environmental impact during the production process.

- Improve product recyclability: Chalco continues to innovate designs to make aluminum slugs more recyclable, in line with the global trend of green environmental protection.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote