Chalco forged aluminum blocks deliver a dense, defect-free structure with high strength-to-weight performance and excellent machinability — ideal for fatigue-sensitive and impact-loaded parts in aerospace, automotive, precision machinery, and mold bases. As a specialist supplier of forged blocks, including custom forged aluminum block forgings, we provide CNC-ready products in custom sizes, heat treatments, inspection, and documentation to ASTM/AMS/GB/T standards.

- Size/weight: up to 2000×2000×1000 mm · 1 kg–5 t

- CNC 3/4/5-axis; tolerance up to ±0.01 mm; roughness Ra 0.8–3.2 μm

- Processes: open-die / closed-die; grain size ASTM 5–8

- Alloys & tempers: 2024 / 2219 / 5083 / 6061 / 6082 / 7050 / 7075 · O / T4 / T6 / T651 / T73 / H116 / H321

- Surface: sandblasting · blackening · electroplating · anodizing

- Inspections & docs: chemical/mechanical/HT reports · UT/MT/PT · COC

- Service: Quick RFQ · expert DFM · on-demand delivery

Types · Alloys · Applications · Capability · Ordering · Comparison · FAQs

Instant QuoteForged Aluminum Block Types (Blank / Billet / Solid / Cube)

Each forged aluminum block type can be supplied to your exact size and tolerance — see Forged Aluminum Block Capabilities & Sizes.

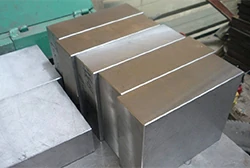

- Forged blank block

Unmachined blank; for secondary/custom processing at your facility.

- Forged billet block

Forged starter stock for further precision machining across industries.

- Forged solid block

High-density solid; for high-load/high-pressure environments (molds, machine parts).

- Forged cube block

Standard cube; for precise sizing/shape requirements (aerospace, precision engineering).

Forged Aluminum Block Alloys (Stock & Custom)

As a specialist in aluminum forging, Chalco delivers dense, defect‑free forged aluminum blocks with stable stress performance and CNC‑ready machinability. We stock mainstream aerospace and engineering alloys and customize sizes, tempers, and documentation to meet demanding applications.

Alloys: 2024 · 2219 · 5083 · 6061 · 6082 · 7050 · 7075

Tempers: O · T4/T6 · T651 · T73/T7451 · H111/H112/H116/H321

Advantages: Dense grain · no porosity · stable under load

Machining: CNC 3/4/5-axis · anodizing

Standards: ASTM B247 · AMS 4127/4134 · GB/T 6892

6061 Forged Aluminum Block (T6 / T651)

Balanced strength; corrosion-resistant; easy machining. Uses: bases, fixtures, mold frames, housings.

7075 Forged Aluminum Block (T6 / T651 / T73)

Ultra-high strength; excellent fatigue. Uses: aerospace/defense, high-load precision parts.

2024 Forged Aluminum Block (T351 / T4 / T6)

High strength; strong fatigue & elevated-temp performance. Uses: aircraft structures, high-load components.

- 6063 forged aluminum block (T5 / T6)

Good surface quality and anodizing appearance; moderate strength. Used for housings, fixtures, heat‑sink bases, and lightweight structures.

- 6082 forged aluminum block (T6 / T651)

High strength among 6xxx with good weldability. Used for structural frames, bridge/automotive chassis parts, and lifting equipment.

- 3003 forged aluminum block (O / H112 / H14)

Non‑heat‑treatable; good corrosion resistance and formability. Used for food/chemical equipment, tanks, and HVAC components.

- 5083 forged al (O / H111 / H116 / H321)

Marine‑grade corrosion resistance with good weldability. Used in shipbuilding, cryogenic/pressure tanks, and marine structures.

- 7050 forged aluminum block (T7451 / T7651)

High strength and toughness with improved stress‑corrosion resistance vs 7075. Suited to thick‑section aerospace structures and landing‑gear components.

- 2219 forged aluminum block (T6 / T62 / T851)

High‑temperature strength and good weldability. Used for aerospace propellant tanks and heat‑exposed structural parts.

Chalco Forged Aluminum Block Applications & Industries Served

Forged aluminum blocks are selected for high‑stress, fatigue‑sensitive, and impact‑loaded parts where dense, defect‑free structure and stable performance are required.

- CNC & Precision Machining

- Aerospace

- Defense

- Automotive & NEV

- Mold & Tooling

- Heavy & Precision Machinery

- Marine & Offshore

- Engines & Powertrains

Forged Aluminum Blocks for CNC & Milling

Dense, defect-free forged aluminum blocks are CNC-ready for precision machining of high-strength bases and housings.

- Tooling/machining plates

- Fixture blocks

- Mounting blocks

- Precision housings & covers

- Complex structural frames

- Adapter/transition plates

- Slide rails & guide blocks

- Mold cavities & inserts

Alloys: 6061-T6/T651 · 6082-T6 · 7075-T651 · See all alloys

Instant Quote

Forged Aluminum Blocks for Aerospace

Aerospace-grade forged aluminum blocks meet AMS/ASTM requirements for high-stress, wide-temperature structures with weight-saving needs.

Material certification support: AMS-S-5000, AMS/ASTM aerospace forging series.

- Fuselage/wing nodes

- Landing-gear brackets

- Bulkhead/rib blocks

- Adapter plates

- Avionics/platform bases

- Satellite fixture blocks

Alloys: 2024-T351 · 7075-T651 · 7050-T7451 · See all alloys

Instant Quote

Forged Aluminum Blocks for Defense Applications

Military & defense aluminium forging meets MIL-grade requirements for high-stress, shock/impact-resistant structures operating in extreme environments, with weight-saving and corrosion-resistance needs.

Material certification support: MIL-S-23284 / MIL-S-46172.

- Armor plates & panel blocks

- Structural support beams

- Missile adapter blocks

- Propulsion brackets

- Radar & antenna bases

- Rugged housings

Alloys: 7050-T7451 · 7075-T651 · 5083-H116 · See all alloys

Instant Quote

Forged Aluminum Blocks for Automotive & NEV

Automotive power & structural forging meets OEM-grade demands for high-stress, high-vibration powertrain and structural parts with weight-saving and thermal-management needs.

- Chassis beams

- Suspension knuckle

- Diff housing

- Caliper bodies

- Battery tray base

- Motor housing

Alloys: 6061-T6 · 6082-T6 · 7075-T651 · See all alloys

Instant Quote

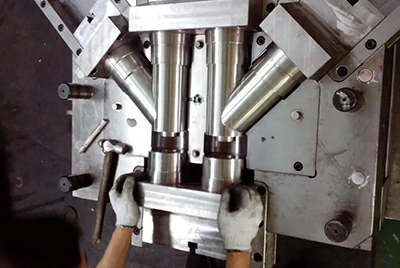

Forged Aluminum Blocks for Mold Manufacturing

Forged aluminum blocks withstand high heat/impact cycles, extending mold life and improving finished-part accuracy.

- Mold frames & bases

- Mold cores

- Cavity inserts

- Guide pins & sleeves

- Cooling-channel inserts

- Die shoes & bolster plates

Alloys: 6061-T6/T651 · 7075-T651 · See all alloys

Instant Quote

Forged Aluminum Blocks for Heavy & Precision Machinery

High-stiffness forged aluminum blocks provide reliable structural support and are suitable for precision assemblies.

- Hydraulic manifold blocks

- Spindle housings & bases

- Robot-arm connection blocks

- Gearbox housings

- Guide rail blocks

- Press platens & bases

Alloys: 6061-T6/T651 · 7075-T651 · See all alloys

Instant Quote

Forged Aluminum Blocks for Marine & Offshore

Corrosion-resistant forged aluminum blocks ensure reliable operation in high-humidity, high-salt environments.

Classification support: ABS Grade 2, DNV, BV, CCS and others.

- Bearing seats & pillow blocks

- Hull frame nodes

- Engine & generator mounts

- Thruster brackets

- Deck equipment bases

- Cryo tank blocks

Alloys: 5083-H116/H321 · 6061-T6 · See all alloys

Instant Quote

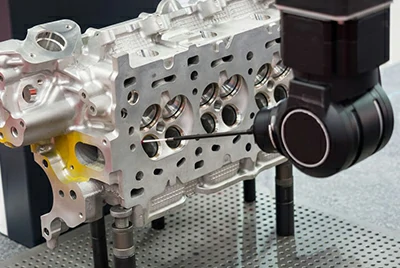

Forged Aluminum Blocks for Engines & Powertrains

Chalco forged aluminum blocks provide high strength, thermal-fatigue resistance and dimensional stability for aerospace, automotive, marine and construction-machinery engines.

- Engine block

- Cylinder head

- Main bearing cap/seat

- Adapter plate / spacer block

- Flywheel housing

- Turbo housing

- Pump/oil-cooler housing

Alloys: 2219-T6/T62 · 7075-T651 · 6061-T6 · See all alloys

Instant Quote

Chalco forging product production and processing capabilities

Forged Aluminum Block — Core Forging & Forming Capabilities

- Forging weight range: 1 kg–5 t

- Maximum forging size: 2000 × 2000 × 1000 mm (L×W×H), custom on request

- Processes: open-die/free forging · closed-die/die forging (supports complex geometries & repeatability)

- Primary alloys: forged aluminum blocks (6061/6082/2024/2219/5083/7050/7075); other metals on request (titanium/steel/copper)

- Post-forging grain size control: ASTM 5–8 to enhance mechanical properties

Forged Aluminum Block — Precision Machining & Surface Treatment

- CNC machining: 3-axis / 4-axis / 5-axis for complex, multi-angle parts

- Dimensional tolerance: up to ±0.01 mm (on request)

- Integrated operations: milling · drilling · tapping · chamfering · contouring

- Surface roughness control: Ra 0.8–3.2 μm

- Surface treatments: sandblasting · blackening · electroplating · anodizing

- On-demand delivery: pre-machined with allowance or finished parts for assembly

Forged Aluminum Block — Project Solutions, Customization & Quality Assurance

- Size customization: L×W×H per drawing/sample; typical size control within ±1 mm; machining allowance reserved as required

- Alloys & materials: standard aerospace/engineering aluminums (e.g., 6061/6082/2024/2219/5083/7050/7075); other metals on request (e.g., 15-5PH, F6NM)

- Heat-treat states: O / T4 / T6 / T651 / T73 / T7451 / T7651 / H112 (alloy-dependent), per AMS / ASTM

- Testing & QA docs: chemical & mechanical reports · hardness · UT/MT/PT · heat-treatment records · COC · third-party on request

- Standards & compliance: ASTM / AMS / GB/T; industry requirements for aerospace/automotive/mold/defense; marine classification (ABS / DNV / BV / CCS) on demand

Ordering & QA for Forged Aluminum Blocks

RFQ Checklist

- Alloy & temper (e.g., 6061-T6/T651, 7075-T651, 2024-T351, 5083-H116)

- Finished size (L×W×H) & machining allowance

- Tolerance & surface (e.g., ±0.01 mm; Ra 0.8–3.2 μm)

- Inspection & docs (ASTM/AMS/GB/T; chemical/mechanical/HT; UT/MT/PT; COC)

- Quantity, packaging, delivery target

Process & Delivery

- Open-die/closed-die forging → heat treatment → CNC → surface → inspection

- Supply options: rough-machined with allowance / CNC-finished ready for assembly

- Packing: corrosion-proof, export crates; sea/air logistics available

Forged Aluminum Block vs Cast/Rolled Aluminum Block

Choose forged aluminum blocks for high-stress, fatigue-sensitive, thick-section parts requiring dense structure and stable performance.

| Item | Forged Aluminum Block | Cast/Rolled Aluminum Block |

|---|---|---|

| Internal | Dense · no porosity | Porosity/segregation risk |

| Fatigue | High | Medium |

| Impact/Toughness | High | Medium |

| Consistency | Grain-flow control | Less controlled |

| Distortion | Lower after HT/machining | Higher risk |

| Cost/Lead | Higher / longer | Lower / shorter |

| Best for | High-stress · fatigue-critical | General CNC bases |

Tip: General CNC bases/fixtures → see Aluminum Block. Need dense, defect-free structure →

Instant QuoteFAQs: Forged Aluminum Blocks

Q1. When should I choose forged aluminum blocks over cast/rolled blocks?

For high-stress, impact or fatigue-sensitive parts, and thick sections needing dense, stable structure.

Q2. What sizes and weights can you supply?

1 kg–5 t; up to 2000 × 2000 × 1000 mm (L×W×H).

Q3. Which alloys and tempers are common?

6061/6082/2024/2219/5083/7050/7075 in O/T4/T6/T651/T73/T7451/H116/H321 (alloy-dependent).

Q4. What machining tolerances and surface roughness are available?

Up to ±0.01 mm and Ra 0.8–3.2 μm with 3/4/5-axis CNC.

Q5. What inspections and documents can you provide?

Chemical/mechanical/HT reports, UT/MT/PT, COC; ASTM/AMS/GB/T compliance; 3rd-party on request.

Q6. Typical lead time?

Depends on alloy/size/HT and machining scope; expedited options available.

Other Forged Metals – Titanium / Steel / Copper Forged Blocks

This page focuses on forged aluminum blocks. We also supply titanium, steel, and copper forged blocks on request for special environments and performance needs.

Titanium Alloy Forged Block – Grades & Standards

High strength-to-weight, heat/corrosion resistance, and biocompatibility for aerospace, chemical, and medical applications.

Instant QuoteAlloy grades: Ti-6Al-4V · Ti-6Al-4V ELI · Ti-5Al-2.5Sn

Mechanical: TS ≥ 895 MPa · excellent fatigue/toughness

Heat treatment: Annealed / STA (solution-treated & aged)

Standards: ASTM B381 · AMS 4928 / 4911

Ti-6Al-4V

High strength and corrosion resistance; aerospace & medical devices.

Ti-6Al-4V ELI

Lower oxygen; preferred for implants & precision parts.

Ti-5Al-2.5Sn

Excellent corrosion resistance; marine & chemical fields.

Steel Forging Blocks – Materials & Standards

High mechanical strength and reliability for heavy-duty aerospace, energy, marine, and automotive uses.

Instant QuoteMaterials: Austenitic · Martensitic · PH · Duplex stainless steels

Mechanical: Yield strength up to ~750 MPa · good fatigue/impact

Standards: ASTM A182 · A105 · A350 · A336/A508/A668/A694/A707/A723

Copper Forging Block – Alloys & Standards

High electrical/thermal conductivity with improved strength for electronics, aerospace, and power distribution.

Instant QuoteAlloys: C11000 · C12200 · C17500 · C18150

Processing: CNC machining · brazing · precision forming

Standards: ASTM B124/B124M · B283 · B134

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote