8011 aluminum foil is a commonly used aluminum alloy foil known for its excellent ductility, corrosion resistance, and lightweight properties. It is an ideal material for food packaging, pharmaceutical packaging, and foil containers. Available in various thicknesses and widths, it features both shiny and matte surfaces, making it widely used in household, industrial, and medical applications.

8011 aluminum foil introduction

Alloy: 8011

Standards: AMS-QQ-A-1876, ASTM B479

Dyne Value: 30–52

Temper: F, O, H14, H16, H18, H19, H22, H24, H26, H28

Thickness Range: 0.00018" – 0.064" / 0.008 – 0.025 mm / Commonly used: 9μm – 20μm (Tolerance ±3%)

Width Range: 0.375" – 60" / 100 – 1220 mm / Commonly used: 150 – 500 mm

Core Inner Diameter: 75 mm, 76 mm, 150 mm, 152 mm

Core Material: Aluminum or Steel

Tensile Strength: 55 – 110 N/mm²

Elongation: ≥ 1.8%

Wettability: A / A+

Common types of 8011 aluminum foil

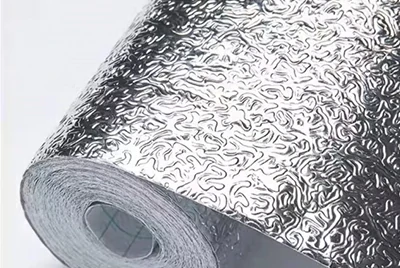

8011 aluminum bare foil

8011 aluminum bare foil is uncoated, untreated aluminum foil with a clean, metallic surface. It is ideal for laminating, printing, or coating, and widely used in food, pharma, and industrial packaging.

Contact us now

Patterns such as grids or diamonds are embossed onto the surface of 8011 aluminum foil to enhance its strength, anti-slip properties, and decorative appeal. It is commonly used in foil lids, baking liners, and premium packaging applications.

Contact us now8011 coated aluminum foil

The surface is coated with PE, PP, lacquer, or epoxy resin to enhance its corrosion resistance and heat-sealing properties. It is widely used in pharmaceutical blister packs, heat seal films, and flexible packaging.

Contact us now

8011 lacquered aluminum foil

A heat-seal lacquer is applied to the surface of 8011 aluminum foil, making it suitable for applications that require heat sealing with plastic, paper, or other substrates—such as bubble tea sealing films, pharmaceutical blisters, and food cup lids.

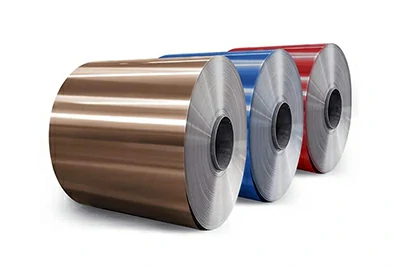

8011 color coated aluminum foil

A colored coating such as polyester, PVDF (fluorocarbon), or polyurethane is sprayed onto the surface of 8011 aluminum foil. It features uniform color and strong adhesion, making it widely used in appliance back panels, labels, and decorative applications.

8011 hydrophilic aluminum foil

The surface is specially treated to be hydrophilic, preventing water from forming droplets. It is widely used in air conditioner fins and heat exchangers to improve condensation efficiency and prevent frosting and water accumulation.

8011 hydrophobic aluminum foil

The surface has water-repellent properties, causing water droplets to slide off quickly without sticking. It is commonly used in specialized HVAC (heating, ventilation, and air conditioning) applications, offering anti-corrosion and anti-fouling benefits that extend system lifespan.

8011 double-sided bright aluminum foil

Produced using a double-sided rolling process, both sides of the foil have a mirror-like finish. It is ideal for high-end packaging, electronic shielding, and reflective materials where superior appearance is required.

Contact us now8011 one-side bright / one-side matte aluminum foil

Featuring one bright side and one matte side, this is the most common type of 8011 aluminum foil. The bright side enhances visual appeal, while the matte side is suitable for heat sealing or lamination. It is widely used in food packaging, meal trays, and household foil.

Features of 8011 aluminum foil

Higher iron and silicon content for enhanced strength

8011 aluminum alloy contains trace amounts of iron (Fe) and silicon (Si), giving it better tensile strength and ductility compared to pure aluminum foils like 1235 or 1050. This makes it ideal for forming demanding packaging containers such as foil trays and food lids.

Cost-effective with a balance of softness and strength

Compared to high-end pharmaceutical foils like 8021, 8011 offers a good balance of performance and lower cost, making it suitable for large-scale and high-frequency use.

Compatible with multiple surface treatments

8011 aluminum foil supports a wide range of post-processing techniques, including lacquering, coating, printing, and embossing. It shows excellent adaptability in applications such as household foil, sealing films, food container lids, and pharmaceutical packaging.

Flexible supply in various tempers

Available in multiple tempers, 8011 foil can meet different application needs—from soft forming and high-strength pressing to heat sealing requirements.

Excellent wettability for pharmaceutical and laminated packaging

With strong surface wettability (typically rated A / A+), 8011 aluminum foil is ideal for gluing and lamination processes, particularly excelling in blister packs and flexible composite layers.

Advantages of Chalco 8011 aluminum foil

As one of China's leading aluminum processing enterprises, Chalco's 8011 aluminum foil stands out with its excellent physical properties, superior surface quality, and stable processing performance. It performs exceptionally well in various applications, including pharmaceutical packaging, food packaging, bottle cap materials, and air conditioner heat exchangers.

Instant QuoteExcellent mechanical performance

Depending on the annealing temper (O, H18, H22, etc.), Chalco offers high-strength 8011 aluminum foil suitable for various applications:

- Tensile strength up to 125 MPa

- Elongation up to 10%, ideal for deep drawing, lamination, and embossing

- Stable yield strength ensures reliable bottle cap sealing and high forming efficiency

High dimensional accuracy with strict tolerance control

Equipped with advanced rolling and slitting equipment, Chalco ensures precise control of thickness and width deviations:

- Thickness tolerance within ±2%

- Width deviation less than ±0.1 mm

- Custom specifications available from 0.006 mm to 0.2 mm

Outstanding surface quality

With dual assurance from automated inspection systems and manual rechecking, Chalco delivers premium surface finishes:

- High surface gloss with mirror brightness exceeding 85%

- Low pinhole count—final product can achieve 0 pinholes/m² (diameter < 0.3 mm)

- Free from oil stains, black spots, wrinkles, and foreign inclusions

High dyne level and strong adhesion

Through precise corona treatment and degreasing processes, Chalco significantly enhances surface tension:

- Dyne value up to 52 dyn/cm—well above industry standards

- Greatly improves adhesion for coating, lamination, and printing, preventing delamination and peeling

Thorough degreasing for process compatibility

Chalco uses advanced continuous annealing and degreasing technology:

- Residual oil as low as < 0.005 mg/cm²

- Ensures bubble-free and peel-resistant surfaces in downstream processes, compatible with various adhesive systems

Stable coil quality

- Neatly trimmed edges with burrs controlled to < 20μm

- Proper winding tension and flat end faces without collapsed edges

- Available with 76 mm and 152 mm steel or paper cores, compatible with various equipment

Applications of 8011 aluminum foil

8011 Aluminum Foil for Air Conditioner

Used for air conditioner fins (hydrophilic/hydrophobic foil), it offers excellent thermal conductivity, corrosion resistance, and formability, helping to improve heat exchange efficiency and extend equipment lifespan.

Used as a composite material for building roof insulation layers, it can reflect sunlight and reduce heat transfer. It also offers moisture resistance, flame retardancy, and aging resistance, making it widely used in thermal insulation rolls.

8011 Aluminum Foil for Heat Seal

Used in food and pharmaceutical sealing films, such as yogurt lids, aluminum-plastic films, and blister pack sealing layers. It offers excellent heat-sealing and barrier properties and is commonly supplied in lacquered or laminated form.

8011 Aluminum Foil for Cigarette Packaging

Used as inner lining paper in cigarette packaging (cigarette gold foil), it provides excellent light-blocking, moisture resistance, and printability, helping to preserve the flavor and enhance the appearance of cigarettes.

8011 Aluminum Foil for Bottle Caps

Suitable for sealing caps of wine, pharmaceutical, and cosmetic bottles, it offers excellent stamping performance, sealing ability, and corrosion resistance, and is available in both plain and coated surface finishes.

8011 Aluminum Foil for Lithium-Ion Battery

As part of battery packaging materials, 8011 aluminum foil can be used for battery case covers or outer sealing layers. It offers chemical resistance, strong sealing performance, and excellent formability for deep drawing and stamping.

8011 Aluminum Foil for Food Containers

Widely used in aluminum foil food containers, takeaway boxes, and baking trays, it is food-grade safe and suitable for both high-temperature heating and freezing.

Chemical composition of 8011 aluminum foil

| Element | Composition (%) |

| Al | Remainder |

| Si | 0.50 – 0.90 |

| Fe | 0.60 – 1.00 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.20 |

| Mg | ≤ 0.050 |

| Cr | ≤ 0.050 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.080 |

Recommended products related to 8011 aluminum foil

8011 aluminum foil FAQ

What is the price of 8011 aluminum foil?

The price of 8011 aluminum foil varies significantly depending on the following factors:

- Current aluminum ingot price (LME or Shanghai spot)

- Product thickness, width, and temper

- Need for coating, lamination, or surface treatment

- Order quantity and delivery schedule

In general, Chalco provides quotations based on real-time market conditions and customer requirements. Both short-term and long-term pricing options are available. Please contact us for a same-day quote tailored to your needs.

Instant QuoteWhat color options are available for coated 8011 aluminum foil?

Coated 8011 aluminum foil is available in a variety of colors, including:

- Standard colors such as silver, black, red, blue, gold, green, and brown

- Custom colors based on Pantone codes provided by the customer

- Options for single-sided or double-sided coating, as well as matte, glossy, or embossed finishes

Color-coated aluminum foil is widely used in bottle caps, decorative materials, and food packaging. Chalco uses eco-friendly coatings with strong adhesion, excellent heat resistance, and long-lasting color that won't fade or peel.

What are the coating materials and properties of color-coated 8011 aluminum foil?

Common coating types include:

- PE (Polyester Coating): Cost-effective, suitable for general packaging

- PVDF (Fluorocarbon Coating): Excellent weather resistance, ideal for outdoor use

- Epoxy Coating: Widely used for food and pharmaceutical contact layers

Chalco uses eco-friendly coatings that offer outstanding adhesion, corrosion resistance, and high-temperature durability.

Can 8011 aluminum foil be stretched or stamped? Will it crack?

Yes, it can. 8011 aluminum foil in O or H14 temper has good ductility and crack resistance, making it suitable for deep drawing, sealing caps, edge folding, and other complex forming processes. Chalco offers high-ductility materials that are professionally tested to ensure no cracking during forming.

How is aluminum foil packaged to prevent damage or oxidation during transport?

Chalco provides multi-layer protective packaging, including:

- Plastic film wrapping for moisture resistance

- Desiccant plus kraft paper lining

- Securing with solid wood pallets or wooden crates

- Strapping for stable and tight sealing

This ensures the aluminum foil remains free from oxidation, edge damage, and deformation during transportation.

Can Chalco provide small rolls or slitting services?

Yes. Chalco is equipped with precision slitting equipment and can offer:

- Narrow roll slitting (width as narrow as 20 mm)

- Custom length slitting by meters

- Small package supply (e.g., 10kg/roll, 20kg/roll)

These services are ideal for lab use, sampling, and small-batch production.

Does Chalco provide technical documents or usage recommendations?

Yes, Chalco can provide customers with:

- Processing guidelines for aluminum foil

- Heat sealing recommendations

- Compatibility test data

- Environmental compliance reports such as MSDS, RoHS, and REACH

Why choose Chalco as your 8011 aluminum foil supplier?

Advanced production equipment and technical strength

Chalco operates world-class aluminum foil production lines, using high-precision cold rolling mills and annealing furnaces to ensure excellent thickness control and surface quality. With strict process control, our products meet international standards in both mechanical properties and surface finishes.

Free sample support

We provide free samples for customer testing, helping you evaluate product performance before placing an order.

Instant QuoteFlexible customization services

From thickness, width, alloy temper to surface treatments, Chalco offers tailored solutions based on your specific needs. We support various coating colors and embossed patterns to suit different industry applications.

Strict quality inspection and certification

Every batch of 8011 aluminum foil is delivered with a complete quality inspection report. Our testing includes chemical composition analysis, tensile testing, and more. All products comply with international certifications such as RoHS and FDA, ensuring environmental and health standards are met.

Competitive pricing and discount policies

Chalco offers competitive prices and bulk discounts, helping you reduce costs without compromising on quality. Our flexible pricing and delivery terms (FOB, CIF, etc.) make your purchasing process more efficient and convenient.

Comprehensive after-sales service and technical support

From order confirmation to delivery, Chalco provides full tracking and responsive support. If you encounter any issues, our technical team and customer service will offer timely solutions to ensure smooth operation.

Integrated solutions

Whether you're in food packaging, pharmaceutical packaging, or home appliances, Chalco provides comprehensive aluminum foil solutions. We offer expert application advice to help you optimize production, improve product quality, and reduce costs.