6951 aluminum alloy is an Al-Mg core material supplied in sheet, coil, strip, and foil form, widely used in clad brazing for automotive and industrial heat exchangers. Compared with 3003, it offers higher strength, better fatigue resistance, and improved lightweight performance, making it an ideal choice for radiators, condensers, and evaporators.

Optimized for clad brazing • Non-heat-treatable Al-Mg alloy • Superior fatigue and strength-to-weight performance

Chalco 6951 aluminum composite core material product types

Chalco supplies 6951 aluminum alloy in sheet, coil, strip, and foil forms to meet diverse brazing applications.

-

Brazing Sheet

Thickness: 0.2mm–3.0mm

Width: As specified

Length: As specified

Features: Baffles and core material for plate-fin heat exchangers, mainly supplied as clad sheets for reliable brazing performance.

-

Thickness: 0.2mm–3.0mm

Width: As specified

Length: Coil length as required

Features: Continuous coil, suitable for mass production and automated processing.

-

Thickness: 0.1mm–0.5mm

Width: As specified

Length: As specified

Features: Precision strip, widely used in fin forming and continuous stamping.

-

Thickness: 0.08mm–0.15mm

Width: As specified

Length: As specified

Features: Ultra-thin foil designed for lightweight fins and efficient heat transfer structures.

This multi-faceted supply model is suitable for both specialized industrial projects and large-scale production of automotive heat exchangers. Chalco also offers 6951 aluminum bar rod products, providing integrated material support for structural components and precision-machined parts.

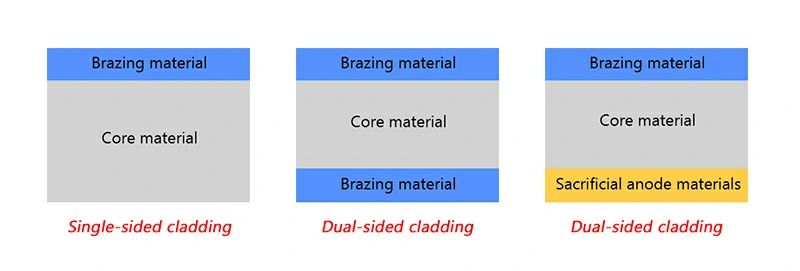

Chalco 6951 aluminum clad brazing sheet coil options

Clad brazing sheet with a 6951 core delivers strength, durability, and reliable brazing performance for automotive, HVAC, and industrial heat exchangers. When combined with 4045 or 4343 clad layers—and optional 7072 for corrosion protection—it enables lower brazing temperatures, consistent joint quality, and long service life.

Chalco provides flexible supply options, including single- or double-sided cladding, multi-layer composites, and sheet, coil, strip, or foil formats, meeting the needs of R&D, pilot runs, and mass production.

| Core Alloy | Cladding Alloy | Typical Application | Recommended Brazing Temp (℃) | Key Benefit |

| 6951 | 4004 | High-strength heat exchangers (alternative to 3003 systems) | 598–602 | Higher strength, improved fatigue life vs. 3003 |

| 6951 | 4045 | Automotive radiators and condensers | 582–604 | Wide brazing window, stable joint quality |

| 6951 + 7072 | 4343 / 4045 | Marine & industrial exchangers in highly corrosive environments | 590–610 | Sacrificial 7072 layer, outstanding corrosion resistance |

| 6951 (multi-layer) | 4004 + 4045 | High-performance industrial heat exchange equipment | 580–605 (config.-dependent) | Balance of weldability and corrosion resistance for demanding environments |

Advantages of Chalco 6951 composite brazing plate sheet coil

Precisely matched brazing temperature: With 4004 or 4045 cladding, stable brazing can be achieved (vacuum or CAB) within 582–602 °C, avoiding base metal overburning or weld defects.

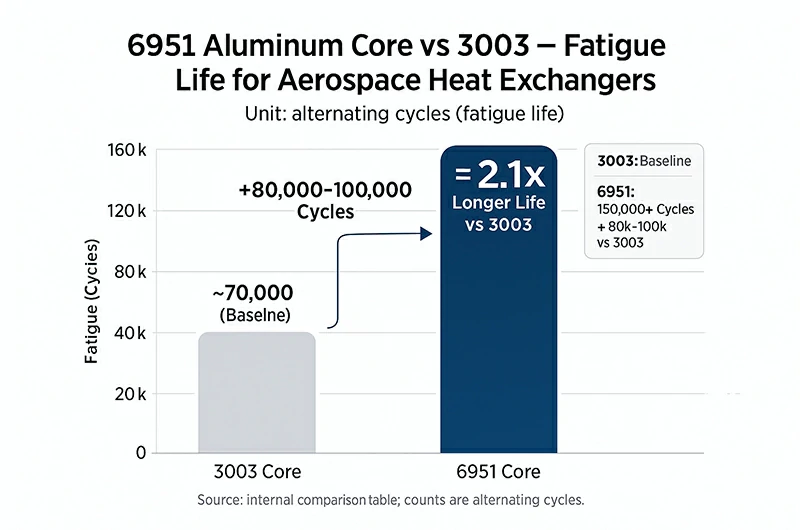

Enhanced strength and fatigue resistance: Compared with 3003, 6951 provides higher strength and longer fatigue life, ensuring more durable heat exchanger performance.

Reliable corrosion protection: Optional 7072 sacrificial layer effectively resists corrosion in salt spray and humid environments, ideal for marine and energy equipment.

Broad applications with flexible customization: From automotive mass production to industrial and marine systems requiring corrosion resistance, Chalco offers tailored clad sheet, coil, strip, and foil solutions.

Chalco 6951 aluminum brazing products applications and cooperation areas

Chalco 6951 aluminum alloy brazing products, with excellent strength, fatigue resistance, and weldability, are widely used in automotive, marine, HVAC, and industrial heat exchange equipment. Through diverse clad composite structures and product forms (sheet, coil, strip, and foil), we provide efficient, reliable, and customizable solutions for different application needs.

Aerospace Research & Validation – Plate-Fin Heat Exchangers

In aircraft environmental control and engine cooling systems, heat exchangers face high temperatures, pressure pulsations, and strict weight limits. 6951 aluminum sheet and coil are ideal for plate-fin partitions and fins, offering longer life and lighter weight.

Contact us now

Recommended solution: 6951 + 4004 / 6951 + 4045 clad brazing sheet

Advantages and highlights: Stable brazing window (598–602 °C); joint strength significantly improved after post-weld heat treatment; tests show fatigue life increased by 80,000–100,000 cycles compared with 3003 alloy.

Application of 6951 aluminum alloy composite brazing plate in aerospace heat exchangers – Material composition table

| Part | Alloy grade | Specifications (mm) |

| Partition | 6951 + 4004 | 0.6 |

| Fins | 6951 | 0.15 |

| Seal plate | 3003 | 6.0 |

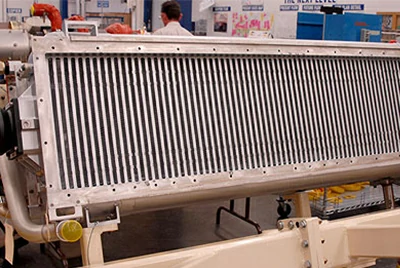

Automotive Radiators & Condensers

Automotive cooling systems require materials that balance heat dissipation efficiency, lightweight construction, and high-volume production stability. 6951 aluminum provides an efficient and cost-effective brazing material for automotive radiators, condensers, and EGR coolers.

Contact us now

Recommended solution: 6951 + 4045 clad coil / strip / foil

Advantages: A wider brazing temperature window (582–604°C) makes it suitable for continuous production; coils, strips, and ultra-thin foils (≤0.15 mm) meet the needs of automated stamping and large-scale manufacturing.

6951 Aluminum Alloy Brazing Coil/Strip/Foil Applications in Automotive Heat Exchangers – Supply Form

| Form | Typical thickness | Application process | Features |

| Coil | 0.2–3.0 mm | Continuous stamping | Suitable for mass production |

| Strip | 0.1–0.5 mm | Precision stamping/fin forming | Uniform thickness and stable molding |

| Foil | 0.08–0.15 mm | CAB brazing fins | Lightweight and efficient heat dissipation |

Marine & Industrial Cooling Systems

Heat exchangers in marine power, chemical, and energy equipment are often exposed to salt spray, heat and humidity, or corrosive media. 6951 aluminum is particularly suitable for marine coolers, marine equipment, and industrial heat exchangers in highly corrosive environments.

Contact us now

Recommended solution: 6951 + 7072 + 4343 multi-clad brazing sheet

Advantages and highlights: The 7072 sacrificial layer significantly improves corrosion resistance and effectively resists pitting and crevice corrosion in long-term service.

6951 Multilayer Composite Brazing Plate Applications in Marine and Industrial Cooling Systems – Coating Combination Table

| Composite structure | Cladding characteristics | Corrosion resistance performance | Typical Applications |

| 6951 + 7072 + 4343 | 7072 sacrificial layer + 4343 brazing layer | Excellent performance in salt spray and hot and humid environments | Ship coolers, marine equipment |

| 6951 + 4045 | Low melting point coating | Standard industrial cooling systems | Industrial cooling systems |

High-Performance Industrial Heat Exchangers

High-end heat exchange equipment in power, machinery, energy, and other fields requires a balance between strength, weldability, and corrosion resistance. 6951 aluminum provides flexible and reliable material solutions for power coolers, precision machinery, and chemical heat exchange systems.

Contact us now

Recommended solution: 6951 multi-layer clad (4004 + 4045)

Advantages and highlights: The multi-layer composite structure can flexibly customize the coating ratio and plate thickness, which not only ensures the stability of the welding process but also enhances the long-term service performance.

Application of 6951 aluminum alloy composite brazing plate in high-performance industrial heat exchange equipment – Customization Capabilities

| Customizable content | Scope | Advantages |

| Covering ratio | 5–15% (adjustable) | Flexible selection according to welding window |

| Thickness range | 0.2–3.0 mm | Meet different equipment structures |

| form | Sheet/ Coil/ Strip/ Foil | Adapting R&D and mass production |

By recommending 6951 clad brazing sheet/foil/strip/coil combinations tailored to specific industry applications, Chalco offers complete solutions encompassing aerospace-grade high-strength, automotive mass production, marine corrosion protection, and flexible industrial customization. This not only enhances material selection but also comprehensively improves project lifespan, reliability, and production efficiency.

Why choose Chalco 6951 aluminum alloy brazing material

Full-process manufacturing: smelting, rolling, cladding, heat treatment, and testing in-house.

Proven reliability: vacuum/CAB brazing applications in automotive and aerospace heat exchangers.

Certified quality: batch traceability with ASTM, EN, GB/T compliance and EN 10204 3.1 certificates.

Flexible supply: sheet, coil, strip, foil formats for both R&D and mass production.

6951 vs 3003 – Core Alloy Comparison in Brazed Heat Exchangers

In brazed plate-fin heat exchangers, the choice of core alloy directly affects strength, fatigue life, and long-term reliability. While 3003 (Al-Mn) has long been used as a conventional core material due to its good brazability and corrosion resistance, it suffers from low strength and limited fatigue performance. 6951 (Al-Mg-Si), by contrast, is a heat-treatable alloy that can be strengthened through solution treatment and artificial aging after brazing, delivering superior mechanical properties and durability.

| Core Material | Fatigue life (number of alternating cycles) | Improvement |

|---|---|---|

| 3003 core | ~70,000 times | Benchmark |

| 6951 Core | 150,000+ times | +80,000–100,000 times |

Key Advantages of 6951 over 3003

- Higher strength after brazing and post-heat treatment

- Significantly longer fatigue life (+80,000–100,000 cycles)

- Better suited for lightweight and long-life heat exchanger applications

Frequently Asked Questions (FAQ)

Q: What cladding combinations are available?

A: Common configurations include 6951+4004, 6951+4045, 6951+7072+4343, and multi-layer composite structures to adapt to different application scenarios.

Q: Can you supply coils and strips to support continuous production?

A: Yes. We offer coil and strip versions, suitable for automated stamping and continuous production lines in the automotive industry.

Q: What is the recommended vacuum brazing temperature?

A: The recommended temperature for 6951+4004 clad is 598–602°C. The recommended temperature for 6951+4045 clad is 582–604°C.

Contact Chalco now

If you are looking for high performance 6951 aluminum alloy brazing sheet, coil, strip or foil , Chalco has aerospace proven composite solutions.

Contact us for a quick quote and technical support to learn how to improve your heat transfer system performance with 6951 clad brazing sheets.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote