Are You Looking for a Material That Combines High Strength and Lightweight for Aerospace Structures, MilitaryEquipment, or High-Performance Molds?If so, 7075 Aluminum Block could be the ideal solution you need.

- Steel-Like Strength: Its tensile strength can easily match certain steels while maintaining the lightweightadvantage unique to aluminum.

- Customizable Specifications and Heat Treatments: Available in T6, T651, and T73 tempers, offering flexiblecombinations to meet the demanding requirements of aerospace, military, racing, and mold industries.

- Reliable Quality Assurance: Chalco supplies 7075 Aluminum Block that complies with ASTM B209, AMS-QQ-A-250/12,and EN 485 standards, with options for ultrasonic testing or third-party certification.

If you need to stay "light yet strong" under extreme load conditions, don't miss out on the 7075 Aluminum Block.

Instant Quote- 7075 Hot-Rolled Aluminum Block

The hot rolling process creates a uniform internal structure, ideal for large structuralcomponents and precision machining.

Thickness: 0.25"-16"

Width: 48"-96"

Length: ≤158"

- 7075 Forged Aluminum Block

High-temp forging optimizes grain structure, ideal for high-strength, tough precision parts.

Thickness: 4"-24"

Width: 24"-60"

Length: ≤158"

Specifications of 7075 Aluminum Block

Available Sizes

Chalco offers a variety of 7075 aluminum block sizes, shapes, and precision grades to meet different industrydemands for strength, accuracy, and machinability.

- Thickness: ≤11.8"

- Width: ≤148"

- Length: Customizable

- Popular Sizes: 24" × 48", 48" × 96", 48" × 120", 48" × 144", 60" × 144"

- Standard Tolerance: -0'' to +1/8''

- Precision Tolerance: ±0.005''

Available Shapes

We supply 7075 aluminum blocks in multiple geometric shapes to fit various manufacturing processes and applicationneeds:

7075 Square Aluminum Block

7075 Rectangular Aluminum Block

7075 Round Aluminum Block

Available Product

- Precision 7075 aluminum block

Precision 7075 aluminum blocks offer high-accuracy finishes with ±0.005'' tolerances, ideal forCNC parts, molds, and applications requiring strict precision.

- Large 7075 aluminum block

Large 7075 aluminum blocks can be customized up to 12" thick, serving aerospace, heavyequipment, and large structural applications needing high material volume.

- Small 7075 Aluminum Block

Small 7075 aluminum blocks, available from 1/2" × 1/2", are ideal for sample testing, precisionparts, and small structures. Chalco offers cut-to-size services for fast delivery.

- Aircraft grade 7075 aluminum block

Aircraft-grade 7075 aluminum blocks meet AMS standards, NADCAP certified, and are used infuselages, landing gear, and critical load-bearing parts for their strength and fatigueresistance.

- Custom 7075 aluminum block

Custom 7075 aluminum blocks, processed by laser cutting or waterjet, support complex profiles,perforations, and intricate structures to speed up prototyping and production.

All 7075 aluminum blocks can be customized with cutting, chamfering, drilling, CNC machining, and surfacetreatments. Whether you need small-batch prototypes or bulk orders with fast delivery, Chalco ensures flexible andreliable service. Contact us today to request a sample or get a customized quote!

Instant QuoteTechnical Data of 7075 Aluminum Block

Chemical Composition of 7075 Aluminum Block

Chemical Composition of 7075 Aluminum BlockElements Value Zinc (Zn) 5.1–6.1 Magnesium (Mg) 2.1–2.9 Copper (Cu) 1.2–2.0 Chromium (Cr) 0.18–0.28 Iron (Fe) ≤0.50 Silicon (Si) ≤0.40 Manganese (Mn) ≤0.30 Titanium (Ti) ≤0.20 Other individual impurity elements ≤0.05 Total impurities ≤0.15 Aluminum (Al) Margin  Physical Properties of 7075 Aluminum Block

Physical Properties of 7075 Aluminum BlockPerformance indicators Value Density 0.1 lb/in³(2.81 g/cm³) Elastic modulus 10,400 ksi(71.7 GPa) Shear modulus 3,800–3,900 ksi(26.2–26.9 GPa) Poisson's ratio 0.32 Thermal conductivity 900–1,200 BTU-in/hr-ft²-°F(130–173 W/m·K) Electrical conductivity 33% IACS Specific heat capacity 0.229 BTU/lb-°F(0.96 J/g·°C) Melting point 890–1,180 °F(477–638 °C)  Mechanical Properties of 7075 Aluminum

Mechanical Properties of 7075 AluminumProperty 7075-O 7075-T6 7075-T651 7075-T73 7075-T7351 Ultimate Tensile Strength (ksi) 40 (bare); 39 (clad) 83 (bare); 76 (clad) 80 72.2 73.2 Yield Tensile Strength (ksi) 21 73 (bare); 67 (clad) 67 63.1 63.1 Fatigue Strength (ksi) 18 23 23 20.8 21.8 Shear Strength (ksi) 22 48 (bare); 46 (clad) 48 42.5 43.5 Hardness (Rockwell | Brinell) B17 | 60 B87 | 150 B87 | 150 B82 | 135 B82 | 135 Elongation at Break (%) min. 10% 11% 8.20% 7.10% 7.50%

Heat Treatment Tempers of 7075 Aluminum Block

- 7075-O Aluminum Block

7075-O aluminum block, annealed for softness and ductility, is ideal for forming and heattreatments needing high plasticity over strength.

ASTM B209,AMS 4044,EN 485

- 7075-T6 Aluminum Block

7075-T6 aluminum block, with heat treatment and aging, offers high tensile strength andhardness, ideal for aerospace, molds, sports equipment, and high-load applications.

ASTM B209,AMS 4045,EN 485

- 7075-T651 Aluminum Block

7075-T651 aluminum block, stress-relieved through stretching, offers high strength andstability, ideal for CNC machined and aerospace parts.

ASTM B209,AMS 4045,EN 485

- 7075-T73 Aluminum Block

7075-T73 aluminum block, over-aged for improved corrosion resistance and slightly reducedstrength, is ideal for landing gear, naval equipment, and harsh environments.

ASTM B209,EN 485

- 7075-T7351 Aluminum Block

7075-T7351 aluminum block, stress-relieved from T73, offers improved corrosion resistance, highfatigue life, and is ideal for aerospace structures requiring long-term reliability.

ASTM B209,AMS 4078,EN 485

- 7075-T7451 Aluminum Block

7075-T7451 aluminum block offers great stress corrosion resistance, ideal for aircraft andmarine components needing stability and corrosion resistance.

ASTM B209,EN 485

- 7075-T7651 Aluminum Block

7075-T7651 aluminum block offers high strength and moderate corrosion resistance, ideal forhigh-load structures in challenging environments.

ASTM B209,EN 485

- 7075-T652 Aluminum Block (Forged)

7075-T652 aluminum block is stress-relieved by compression, offering high stability andresistance, ideal for thick parts, molds, and aerospace components.

ASTM B247,AMS 4310

- 7075-T7352 Aluminum Block (Forged)

7075-7075-T7352 aluminum block offers superior corrosion resistance and fatigue performance,commonly used in aerospace hubs, connectors, and primary structures.

ASTM B247,AMS 4147

Performance Overview of 7075 Aluminum Blocks in Different Tempers

To meet the diverse requirements for strength, machinability, and corrosion resistance across industries, 7075aluminum blocks are available in a wide range of heat treatment tempers. The following table summarizes thecharacteristics, applications, and recommended keywords for each temper:

| Tempers | Tensile strength | Extensibility | Processability | Corrosion resistance | Typical application scenarios |

| 7075-O | Lowest | Excellent | Excellent | Medium | Cold processing, deep drawing parts, non-structural support purposes |

| 7075-T6 | Very high | Medium | Good | Poor | High-strength CNC parts, molds, industrial structural parts |

| 7075-T651 | Very high | Low-medium | Excellent (dimensional stability) | Poor | Precision mold bases, aviation structures, processed parts that need to eliminate internal stress |

| 7075-T73 | Medium | Good | Good | Excellent | Aviation skins, military shells, parts with high risk of stress corrosion |

| 7075-T7351 | Medium high | Good | Excellent (dimensional control) | Excellent | Aircraft landing gear, fasteners, structural parts in highly corrosive environments |

| 7075-T7451 | Medium high | Fair | Good | Good | Aircraft cabin frames, aircraft shells, missile parts |

| 7075-T7651 | Extremely high | Low-medium | Good | Good | Military industry, high-load structures, aviation support frames |

| 7075-T7352 | Medium high (forgings) | Fair | Fair | Good | Aviation forgings, pressure-bearing parts, complex curved surfaces |

| 7075-T652 | Very high | Low-medium | Excellent (compression stress relief) | Poor | Thick forgings, aerospace support structures, military modules |

All 7075 aluminum blocks can be heat treated and precision cut according to specified tempers. CNC prototyping,small batch trial production, and export certification materials are fully supported.Welcome to contact Chalco fortechnical support and pricing information.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we willbe your best choice.

Typical Applications of 7075 Aluminum Block

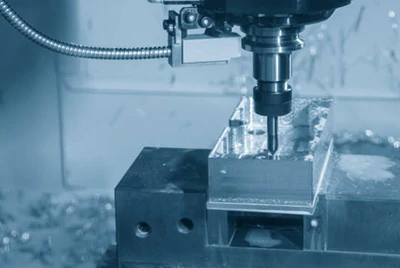

7075 Aluminum Block for CNC Machining

The 7075 Aluminum Block offers excellent cutting performance and dimensional stability, making it anideal choice for CNC machining. States such as T651 help minimize stress deformation while maintainingstrength, making it suitable for manufacturing complex structural components and high-precision parts.

7075 Aluminum Block for Mold Base

7075-T6 or T651 aluminum blocks, known for their high strength and good thermal conductivity, are widelyused in the production of injection molds, die-casting molds, and other high-load mold bases. Their highprocessing efficiency and short molding cycles contribute to enhanced mold lifespan and stability.

7075 Aluminum Block for Aerospace Landing Gear

Aerospace landing gear requires materials with high strength, fatigue resistance, and corrosionresistance. The 7075-T7351 aluminum block meets these stringent standards with its combination of highstrength and stress-corrosion resistance.

7075 Aluminum Block for Motorsports

Racing parts require a balance of weight and strength. The 7075 aluminum block, with steel-like strengthand reduced weight, is perfect for suspension systems, chassis, and engine mounts, offering excellentmachinability for performance optimization.

7075 Aluminum Block for Robotics or Automation

7075 aluminum blocks are perfect for automation equipment and robotic structural components due to theirrigidity, lightweight, and durability. They are used in joints, brackets, actuating parts, and more,significantly improving motion precision and service life.

7075 Aluminum Block for Injection and Die Casting Tooling

The 7075-T6 and T651 aluminum blocks are widely used in precision tools such as die-casting molds, blowmolds, PET bottle molds, and shoe molds, providing excellent thermal conductivity and dimensionalstability, thus extending mold life.

7075 Aluminum Block for Military Applications

With its high strength, corrosion resistance, and impact resistance, the 7075 aluminum block is widelyused in weapon systems, armored mounts, and military equipment structures. It is one of the idealmaterials for military applications.

For further custom solutions tailored to your industry, feel free to contact us. We offer comprehensive technicalsupport, including samples, CNC machining, and heat treatment recommendations.

Certification and Quality Control of 7075 Aluminum Block

As a professional supplier of aerospace-grade aluminum, Chalco strictly follows international aerospace standards toensure each 7075 aluminum block has stable performance, traceable quality, and fully meets the demands of high-endmanufacturing.

Non-Destructive Testing and Defect Control

For thicker specifications and critical applications, Chalco conducts ultrasonic non-destructive testing (NDT) on7075 aluminum blocks to ensure there are no cracks, porosity, or inclusions. We provide EN 10204 3.1/3.2 third-partyinspection reports and can arrange witness testing if needed.

The aerospace-grade 7075-T651, T7351, and T7651 aluminum blocks are NADCAP NDT certified, ensuring suitability forhigh-security applications.

Process Control and Heat Treatment Standards

Our production lines are NADCAP heat treatment certified (HT) to ensure the stability and reliability of processessuch as solution treatment, quenching, and aging. We offer aerospace-grade 7075 aluminum blocks that comply with thefollowing standards:

Instant Quote- AMS 4045 / AMS 4044 / AMS 4078

- ASTM B209 / B221 / B247 / AMS-QQ-A-250/12

- EN 485 / EN 573 / DIN 3.4365

Traceability and Quality System

All 7075 aluminum blocks from Chalco are tracked throughout the entire production process, from raw materials tofinished products. Each batch is traceable to the melt lot, heat treatment cycle, defect inspection records, andquality control reports. Chalco has obtained the following certifications:

- AS 9100 - Aerospace Quality Management System

- ISO 9001 - General Quality Management System

- ISO 14001 - Environmental Management System

We also provide COC certificates, warranty certificates, and third-party inspection reports to assist customers inefficiently completing project audits and acceptance.

Why Choose Chalco as Your 7075 Aluminum Block Supplier?

When selecting high-strength aluminum alloy blocks, both the supplier's expertise and service efficiency arecrucial. Chalco has earned the trust of global customers with its stable product performance, flexible processingand delivery capabilities, and mature customer service.

- Diverse Specifications and Customization: We offer a variety of states such as T6, T651, T7351, and T7651, andprovide shapes including square, round, and custom shapes, meeting the needs of applications such as CNCmachining, molds, and aerospace structures.

- Stable Machinability, Ideal for High-Precision Manufacturing: Using high-quality hot-rolled raw materials andaerospace-grade heat treatment processes, along with grain control and stress relief, our 7075 aluminum blockshave dense structure and stable dimensions, minimizing deformation during machining.

- Sufficient Stock and Fast Delivery: Regular sizes are available in stock for quick delivery, with flexiblescheduling for non-standard products to shorten lead times and meet urgent sample requirements for projects.

- Transparent Pricing and Flexible Purchasing: We support retail, small-batch, and bulk purchasing, with favorablepolicies and a transparent pricing system, balancing cost-effectiveness with the advantages of long-termcooperation.

- One-Stop Service Support: From material selection advice, state recommendations, and sampling to machiningguidance, Chalco offers full-process technical and after-sales support to ensure efficient procurement andworry-free use.

7075 Aluminum Block Procurement Guide

1. Specification and State Selection

Choose the appropriate aluminum block state (e.g., O, T6, T651, T7351, T7651) and shape (square, round, custom)based on the specific application. For aerospace structures, CNC machining parts, or mold applications, it isrecommended to prioritize states with internal stress relief like T651 and T7351. These states ensure both strengthand excellent dimensional stability. Choosing the right size and tolerance can also reduce material waste andmachining costs.

2. Pricing Structure of 7075 Aluminum Blocks

7075 aluminum is a high-strength alloy, and its price is slightly higher than that of general-purpose alloys like6061. The price is primarily influenced by the following factors:

- LME aluminum ingotbase price

- Processing methods (e.g., heat treatment, forging, precision cutting)

- Shape and size (extra-thick or large blocks typically incur higher processing costs)

- Packaging method and transportation distance

It is recommended to define the state and dimensions before procurement and contact Chalco for specific pricinginformation.

Instant Quote3. Quality Standards and Documentation Support

The 7075 aluminum block is commonly used in industries with stringent quality requirements, such as aerospace andmilitary. It must meet standards like ASTM, AMS, and EN. The material supplier should provide complete materialdocumentation, including:

- Original material certification (COC)

- EN 10204 3.1/3.2 inspection reports

- Ultrasonic testing reports

- Heat treatment records

- Dimensional reports

This ensures transparency and traceability of product quality.

4. Stock and Delivery Time

Understand the supplier’s inventory and delivery schedules to ensure that the required aluminum blocks arrive ontime and do not impact your production plan. Reliable supply chain management and timely delivery are critical forensuring the smooth progression of your projects.

5. Export Packaging

For international shipping, high-quality packaging is crucial. Proper packaging materials and professional packagingmethods effectively prevent rust, scratches, deformation, or other damages during transit. The supplier should usemoisture-resistant and corrosion-proof packaging solutions, such as fumigated wooden boxes or wooden pallets, toreduce packaging damage and protect material quality.

6. Loading Solutions

An experienced order-follow-up team can provide flexible loading solutions based on the specifications and quantityof aluminum blocks. Choosing the appropriate container or bulk shipping method for custom loading not only optimizesspace utilization but also helps reduce logistics costs while ensuring the safe and efficient delivery of goods totheir destination.

Further 7075 product selection

7075 Aluminum Block FAQ

What Is the Difference Between 7075-T6 and 7075-T651?

7075-T651 undergoes additional stretching treatment on top of the T6 state to relieve internal stresses, making itmore suitable for thick aluminum blocks or precision machining. This process significantly reduces the risk ofdeformation and warping after machining.

Is 7075 Suitable for CNC Machining?

Yes, 7075 aluminum blocks have excellent cutting performance and are ideal for CNC machining. After T6 or T651 heattreatment, the hardness and strength are significantly enhanced, allowing it to withstand higher cutting forceswhile maintaining good dimensional stability. However, due to its higher hardness, it is important to use the righttools and optimize cutting parameters.

How Is the Corrosion Resistance of 7075?

The corrosion resistance of 7075 is better than that of the 2xxx series, but slightly lower than 6061. Forapplications in moist or marine environments, it is recommended to choose T73 or T76 states, which have bettercorrosion resistance.

Can 7075 Aluminum Blocks Be Welded?

Welding is not recommended for 7075 because the welded area is prone to heat cracking. If welding is necessary,post-weld natural aging can help restore some strength, but it is generally advised to use rivets, bolts, or othermechanical fastening methods instead.

What Is the Minimum Order Quantity (MOQ) for 7075 Aluminum Blocks?

The MOQ can be customized based on size and state. Small batches can be cut, while large batches support customizedproduction. Feel free to contact us for detailed MOQ information and sample support.

Instant QuoteDoes 7075 Easily Deform or Warp During Processing?

If materials like T651, T7351, or T7651 (stress-relieved states) are used, the risk of deformation is minimal. Forthicker blocks, it is recommended to choose materials that have undergone ultrasonic testing to ensure no internaldefects.

What Is the Difference Between 7075 and 6061?

7075 has a higher strength (tensile strength up to 570 MPa) and is suitable for high-load applications, while itsweldability and corrosion resistance are not as good as 6061. If strength is the highest priority, 7075 should beconsidered.

Do Thick Aluminum Blocks Tend to Have Pores or Cracks?

The thick-spec 7075 aluminum blocks supplied by Chalco undergo ultrasonic (UT) testing in compliance with EN 10204standards, ensuring there are no pores, inclusions, or cracks, providing reliable quality.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote