If you are looking for a versatile and reliable material, whether you're a machinist, engineer, or hobbyist, 6061 aluminum blocks will be your ideal choice.

6061 aluminum alloy is renowned for its high strength, excellent corrosion resistance, and superb workability, making it the first choice for projects such as CNC machining, milling, and turning. This alloy, composed of magnesium and silicon, is not only easy to cut and shape, but also benefits from significantly enhanced performance through heat treatment. It is widely used in industries such as aerospace, automotive manufacturing, and shipbuilding.Quick Quote

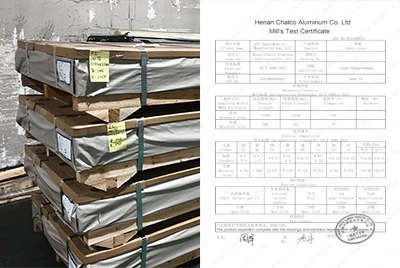

By choosing Chalco, you will receive high-quality materials that meet the requirements of ASTM B209, AMS-QQ-A-250/11, and EN 485 standards. We can also provide custom cutting according to your specific needs to meet the requirements of your project.

-

6061 Hot-Rolled Aluminum Block

The rolled aluminum block has a uniform internal structure, making it ideal for large structural components and precision machining.

Thickness: 0.25" - 16"

Width: 48" - 96"

Length: ≤158"

-

6061 Forged Aluminum Block

The high-temperature forged aluminum block has an optimized grain structure, widely used in precision industries requiring high strength and toughness.

Thickness: 4" - 24"

Width: 24" - 60"

Length: ≤158"

Chalco Provides Various Shapes of 6061 Aluminum Blocks

6061 Round Aluminum Block

Our aluminum round blocks can be made by cutting aluminum plates into circles (Aluminum Plate Circle Cut), saw-cutting aluminum rods, or forging aluminum discs. Round aluminum blocks are suitable for projects that require cylindrical materials, providing a solid foundation for subsequent CNC machining or other precision manufacturing.

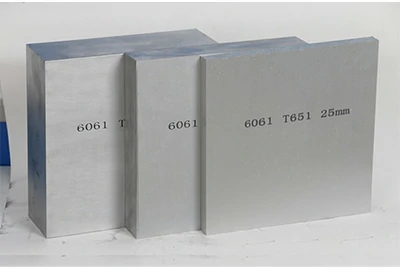

6061 Square Aluminum Block

By saw-cutting thick aluminum plates, we can produce a variety of aluminum square blocks. These blocks can be made from cast aluminum plates, rolled aluminum plates, or forged aluminum plates. Square aluminum blocks are ideal for industrial applications requiring stable shapes and high strength, such as mold making, machinery part production, etc.

6061 Flat Aluminum Block

Flat aluminum blocks are usually thinner and are made by cutting rolled aluminum plates. Their thin characteristics make them excellent for applications requiring flat, uniform thickness plates, such as fixture making, panel production, and precision structural components.

6061 Rectangular Aluminum Block

Similar to square aluminum blocks, rectangular aluminum blocks are mainly made by saw-cutting thick plates. They have straight edges and flat surfaces, suitable for industrial and manufacturing applications that require high strength and precise dimensions, such as frame supports and mechanical parts.

6061 Precision Aluminum Block

Precision aluminum blocks have strict dimension control and excellent tolerance requirements (+/- .005"). We provide materials that meet high-precision standards, ideal for projects with stringent size and surface quality requirements, such as mold and fixture manufacturing.

6061 Custom-Shaped Aluminum Block

According to specific customer requirements, we can customize aluminum blocks in various shapes and sizes. Whether it’s a specific geometric structure or a unique dimension, we offer tailored solutions through our personalized service.

Chalco not only provides material supply but also offers a range of processing services. With our professional sawing and CNC machining capabilities, we can perform basic CNC machining to ensure that the 6061 aluminum blocks you purchase are accurately cut and meet your project requirements. Through our comprehensive services, you can obtain the required aluminum material and processing support in one stop, helping your project run smoothly.Quick Quote

6061 Aluminum Block Specifications and Dimensions

When choosing the right 6061 aluminum block, understanding the common sizes and tolerance ranges is crucial. The common sizes we offer include:

| Imperial (inches) | Imperial (feet) | Metric (millimeters) |

| 12" x 12" | 1' x 1' | 304.8 mm x 304.8 mm |

| 12" x 24" | 1' x 2' | 304.8 mm x 609.6 mm |

| 12" x 48" | 1' x 4' | 304.8 mm x 1219.2 mm |

| 24" x 24" | 2' x 2' | 609.6 mm x 609.6 mm |

| 24" x 48" | 2' x 4' | 609.6 mm x 1219.2 mm |

| 48" x 48" | 4' x 4' | 1219.2 mm x 1219.2 mm |

| 48" x 96" | 4' x 8' | 1219.2 mm x 2438.4 mm |

| 48" x 120" | 4' x 10' | 1219.2 mm x 3048.0 mm |

| 48" x 144" | 4' x 12' | 1219.2 mm x 3657.6 mm |

| 60" x 144" | 5' x 12' | 1524.0 mm x 3657.6 mm |

We can custom-cut according to customer needs, and for high-demand applications, we also offer precision cutting. The specific tolerances are as follows:

- Standard Cutting Tolerance: -0" to +1/8"

- Precision Cutting Tolerance: ±0.005"

Based on these size and tolerance requirements, Chalco can supply various specifications of 6061 aluminum blocks to meet the needs of different applications. Our products cover multiple heat treatment conditions, including O, T4, T6, and T651, each with unique performance advantages and applicable scenarios. Below is a brief overview of the characteristics and standards of these four different conditions:

-

6061 O aluminum block AMS 4025, ASTM B209, AMS-QQ-A-250/11

6061 O aluminum block AMS 4025, ASTM B209, AMS-QQ-A-250/11The O condition is an annealed soft state with lower tensile strength but excellent ductility, ideal for high formability applications.

Good Ductility Good Formability -

6061 T4 aluminum block AMS 4026, ASTM B209, AMS-QQ-A-250/11

6061 T4 aluminum block AMS 4026, ASTM B209, AMS-QQ-A-250/11T4 condition undergoes heat treatment and aging, offering lower cost and good formability, ideal for loose tolerance applications.

Lower Cost High Elongation Good Formability -

6061 T6 aluminum block AMS 4027, ASTM B209, AMS-QQ-A-250/11

6061 T6 aluminum block AMS 4027, ASTM B209, AMS-QQ-A-250/11The T6 condition, achieved through artificial aging, offers high tensile and yield strength, ideal for high-strength, machinable applications.

High Strength Suitable for Machining -

6061 T651 aluminum block AMS 4027, ASTM B209, AMS-QQ-A-250/11

6061 T651 aluminum block AMS 4027, ASTM B209, AMS-QQ-A-250/11T651, based on T6 with stretching to relieve stresses, offers high strength, stable dimensions, and minimal deformation.

High Strength Good Stability Minimal Processing Deformation

Physical properties of 6061 Aluminum Block

| O | T4 | T6 | T651 | |

| Density | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 |

| Ultimate Tensile Strength | 18 ksi | 35 ksi | 45 ksi | 46 ksi |

| Yield Tensile Strength | 8 ksi | 21 ksi | 40 ksi | 39 ksi |

| Fatigue Strength | 9 ksi | 14 ksi | 14 ksi | 14 ksi |

| Shear Strength | 12 ksi | 24 ksi | 30 ksi | 30 ksi |

| Shear Modulus | 3, 800 ksi | 3, 800 ksi | 3, 800 ksi | 3, 800 ksi |

| Hardness Rockwell | Brinell | N/A | 30 | B27 | 65 | B60 | 95 | B58.5 | 93 |

| Elongation at Break Percentage | 25% | 22% | 12% | 11% |

| Modulus of Elasticity | 10, 000 ksi | 10, 000 ksi | 10, 000 ksi | 10, 000 ksi |

| Poisson's Ratio | 0.33 | 0.33 | 0.33 | 0.33 |

| Machinability Percentage | 30% | 50% | 50% | 50% |

| Melting Point | 1, 080-1, 205 °F | 1, 080-1, 205 °F | 1, 080-1, 205 °F | 1, 080-1, 205 °F |

| Specific Heat | 2.14 x 10^-1 BTU/lb-°F | 2.14 x 10^-1 BTU/lb-°F | 2.14 x 10^-1 BTU/lb-°F | 2.14 x 10^-1 BTU/lb-°F |

| Thermal Conductivity | 1, 250 BTU-in/hr-ft^2-°F | 1, 070 BTU-in/hr-ft^2-°F | 1, 160 BTU-in/hr-ft^2-°F | 1, 160 BTU-in/hr-ft^2-°F |

| Electrical Conductivity | 43% IACS | 43% IACS | 43% IACS | 43% IACS |

Features of 6061 Aluminum Block

6061 aluminum alloy is one of the most commonly used materials in the manufacturing industry due to its excellent overall performance, particularly in CNC machining. Its main features include:

- High Strength and Lightweight: The 6061 aluminum block offers high strength and excellent weight-to-strength ratio, making it ideal for applications in industries such as aerospace and automotive, where lightweight and high-strength structures are crucial. It also maintains stability and precision during CNC machining.

- Excellent Machinability: This aluminum alloy is easy to cut, mill, and turn, making it perfect for CNC machining. Its good machinability allows for the efficient and repeatable manufacturing of complex and precise parts.

- Heat Treatment Capability: 6061 aluminum can be further enhanced through solution heat treatment and aging, improving its mechanical properties. Heat treatment before and after machining enhances material stability and strength, ensuring dimensional accuracy and product quality during the CNC machining process.

- Good Weldability and Corrosion Resistance: During the assembly process after CNC machining, 6061 aluminum blocks are easy to weld and offer excellent corrosion resistance, ensuring the long-term durability of the product.

- Moderate Ductility: While its formability is limited, 6061 aluminum demonstrates good toughness when some bending or shaping is required. However, during CNC machining, the focus is generally more on its high precision machining capabilities rather than large-scale forming.

These characteristics make 6061 aluminum block the ideal choice for CNC machining, enabling the efficient manufacturing of complex and precise components while providing reliable mechanical properties and corrosion resistance.

Applications of 6061 Aluminum Block

6061 Aluminum Block for Machining

The 6061 aluminum block is the preferred material for machining due to its high strength, excellent machinability, and corrosion resistance. It is suitable for various processes such as CNC milling, turning, and drilling, allowing for the easy production of complex and precise components, especially those requiring high dimensional stability and surface finish.

6061 Aluminum Block for Milling

The 6061 aluminum block used for milling provides a stable and uniform material, ensuring dimensional accuracy and surface quality during high-precision milling processes. Its excellent machinability and low cutting force make it the ideal choice for complex mold parts and precision components.

6061 Aluminum Block for Molds

In mold manufacturing, 6061 aluminum blocks are the ideal choice due to their outstanding mechanical properties and machinability. High strength and good weldability allow mold frames and cores to withstand high stresses while maintaining precise dimensions and durability.

6061 Aluminum Block for Fixtures/Clamps

The 6061 aluminum block is popular for fixtures and clamps due to its dimensional stability and corrosion resistance. They can be precisely machined into complex geometries via CNC machining, ensuring high precision and repeatable positioning capabilities for fixtures, improving production efficiency.

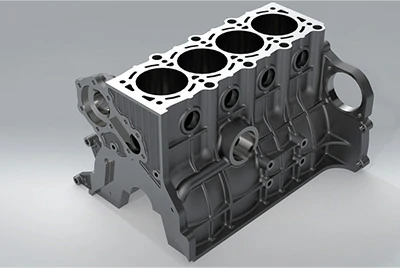

6061 Aluminum Block for Engine Blocks

After heat treatment, 6061 aluminum blocks offer high strength and excellent thermal conductivity, making them ideal for engine blocks. Its machinability enables the precise fabrication of complex engine block structures via CNC machining, while also reducing the overall weight.

6061 Aluminum Block for Automotive Wheel Hubs

Automotive wheel hubs require both lightweight and high strength, and the 6061 aluminum block provides the ideal material choice. Its higher strength and toughness ensure stability and safety under dynamic loads, while its excellent machinability enables the realization of complex designs.

6061 Forged Block for Aerospace Structural Parts

The forged 6061 aluminum block, processed through heat treatment and forging, offers exceptional strength and toughness, making it ideal for aerospace structural parts. It performs excellently in high-stress and high-temperature environments, with good weldability and machining properties.

What Can We Provide as a High-Quality Aluminum Block Supplier?

- High-Quality Products:We produce 6061 aluminum blocks using high-quality hot-rolled raw materials and strict heat treatment processes to ensure high strength, excellent formability, and superior machinability, making them especially suitable for CNC machining.

- Excellent Roughness and Precision Control:Through advanced hot-rolling technology and inspection equipment (such as three-stage emulsified spraying and IMS thickness gauges), we achieve refined grain structure, precise thickness, and high surface quality, improving product consistency and machining stability.

- Fast Delivery Time:We maintain a large stock of standard sizes, and for special sizes with uniform specifications, we can quickly cut and ensure fast shipping and on-time delivery to meet customers' urgent demands, reducing the order-to-delivery cycle.

- Price Advantage:By offering flexible procurement options, large-scale production, and efficient supply chain management, we provide transparent pricing and significant cost advantages, supporting both retail and bulk purchases with preferential policies.

- Comprehensive Quality Testing:We conduct stringent testing using methods such as ultrasonic, metallographic, and radiographic inspections, and also support third-party testing. This ensures accurate chemical composition, defect-free internal structure, and dimensional accuracy in compliance with ISO and other international standards, providing a full quality guarantee.

- Customer Service:We offer comprehensive services from technical consultation to sample testing and after-sales support. With a responsive team and extensive experience, we ensure customer satisfaction through a complete service system.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Further 6061 Product Selection

6061 Aluminum Block Procurement Guide

1. Specifications and Dimensions

Choose the appropriate aluminum block shape, condition (such as O, T4, T6, T651), and size based on specific application requirements to ensure compliance with design needs and usage scenarios. Proper selection of dimensions and tolerances not only enhances machining efficiency but also reduces material waste and subsequent processing costs.

2. Aluminum Block Price

When purchasing 6061 aluminum blocks, the price is typically composed of the base metal market price (such as the London Metal Exchange LME price), plus processing fees, packaging fees, and shipping costs. It is recommended to contact us for a detailed breakdown of the pricing structure to accurately assess the total cost and make an effective budget.Quick Quote

3. Quality Standards and Documentation Support

Ensure that the 6061 aluminum blocks purchased meet the relevant international quality standards (such as ASTM B209, AMS, etc.) to guarantee the material's mechanical properties, corrosion resistance, and machinability. The supplier should be able to provide detailed quality inspection reports, including material certificates, laboratory test reports, specification guides, commercial invoices, and warranties, ensuring the transparency and traceability of each batch's quality.

4. Inventory and Delivery Time

Understand the supplier's inventory status and delivery schedule to ensure that the required aluminum blocks arrive on time, without affecting your production plans. Reliable supply chain management and timely delivery are crucial to ensuring the smooth progress of the project.

5. Export Packaging

For international shipping, high-quality packaging is crucial. Premium packaging materials and professional packing experience effectively prevent aluminum blocks from rusting, scratching, deforming, or suffering other damages during transit. The supplier should use moisture-proof, corrosion-resistant packaging solutions, such as fumigated wooden boxes, wooden pallets, etc., to reduce packaging damage rates and protect material quality.

6. Loading Solutions

An experienced order follow-up team can provide flexible and diverse loading solutions. The appropriate container or bulk transport method will be selected based on the specifications and quantity of aluminum blocks. Custom loading plans not only optimize space utilization but also effectively reduce logistics costs and ensure the safe and efficient arrival of goods at the destination.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote