An aluminum block, also known as an alu block, is a solid piece of aluminum alloy commonly used in CNC machining and precision manufacturing. It offers excellent strength, low weight, and superb machinability—making it ideal for applications such as mold making, fixtures, and precision parts in aerospace, automotive.

Chalco offers a wide range of aluminum block stock sizes with custom and precision cutting services available. Our cutting tolerances strictly meet various application needs — view full size chart and tolerance details ↓.

Chalco aluminum block – product overview

Available alloys

We offer a wide range of aluminum grades, including: 1050, 1060, 1100, 2024, 2219, 2618, 3003, 5052, 5083, 5754, 5454, 5182, 6061, 6063, 6082, 7050, 7075, 7005, and more.

Dimensions & Customization

Thickness: 8 mm – 600 mm

Width: ≥ 200 mm (or customized)

Length: Up to 16 meters (custom lengths available)

Detailed Size: Fully customizable based on your drawings or samples

Available shapes of aluminum blocks

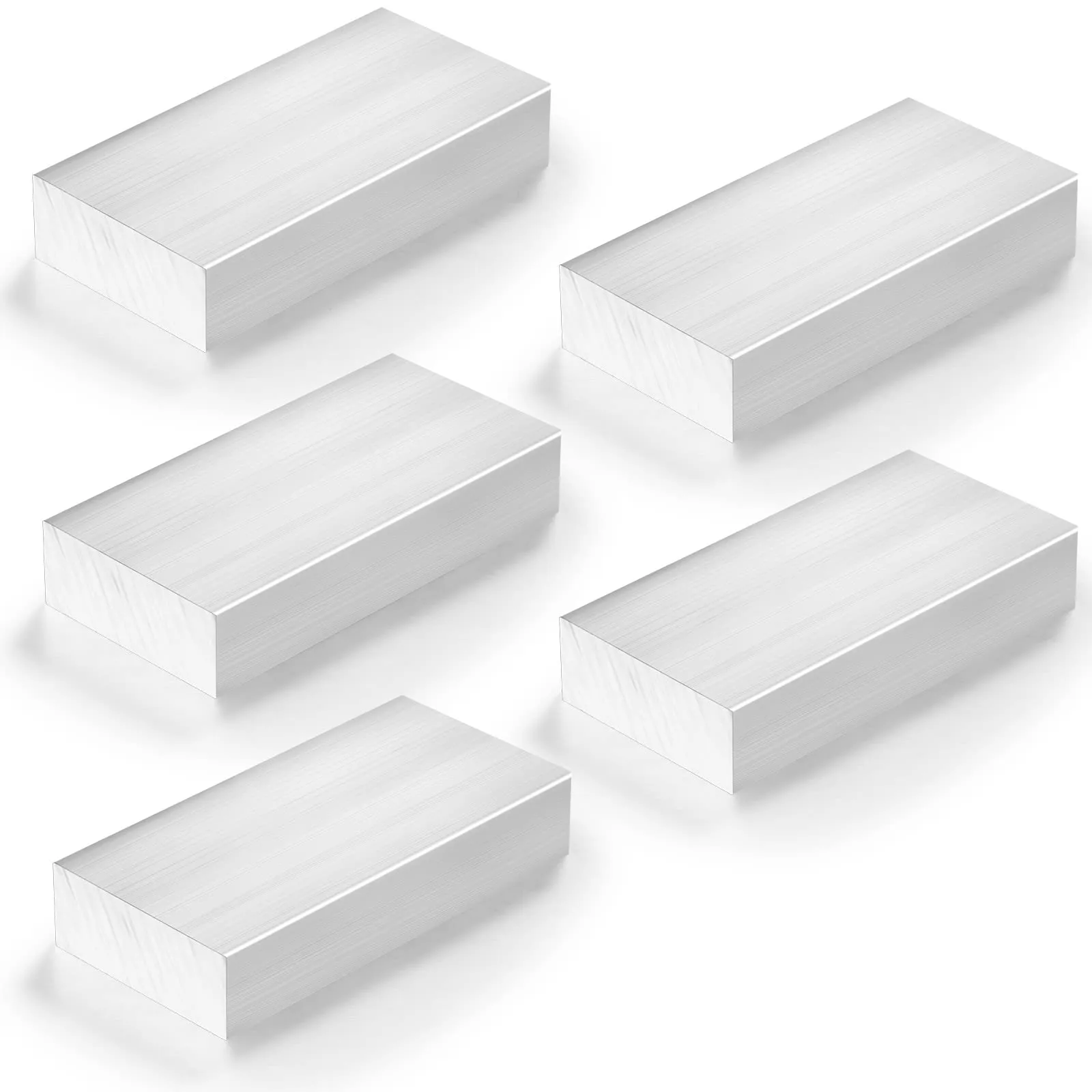

Square Aluminum Block

Square aluminum blocks, often referred to as aluminum cubes, are solid pieces with equal-length sides, commonly used for precision milling, fixture bases, molds, and structural applications. These aluminum cubes are typically made from popular alloys such as 6061, 7075, 2024, and 5083, offering a balance of strength, machinability, and corrosion resistance for both industrial and custom fabrication needs.

Rectangular Aluminum Block

Rectangular aluminum blocks feature a solid, flat-sided shape with unequal length and width, suitable for die bases, machine parts, and structural components. Available in alloys like 6061 and 6082, they provide reliable strength and dimensional stability for a range of industrial uses.

Round Aluminum Block

Round aluminum blocks are solid, cylindrical pieces of aluminum widely used in machining, CNC milling, mold making, automotive components, and aerospace structures. Common alloys include general-purpose 6061, high-strength 7075, aerospace-grade 2024, corrosion-resistant 5083, and structural-grade 6082—each selected based on specific performance and application needs.

Precision Aluminum Block

A precision aluminum block is a solid aluminum alloy with high dimensional accuracy and flatness, typically within ±0.01 mm. It offers better strength, stability, and surface quality than standard blocks, ensuring minimal machining deformation and longer component lifespan.

Instant Quote

Custom-Shaped Aluminum Block

Custom-shaped aluminum blocks are specially machined or cut to meet unique design requirements. Chalco offers customization services across various alloys such as 6061, 7075, and 5083, capable of producing irregular shapes, complex contours, and high-precision parts to support diverse customer applications.

Best-selling aluminum blocks from Chalco

6061 aluminum block

6061 aluminum block is one of the most versatile and cost-effective aluminum alloys, offering excellent machinability, weldability, and medium-to-high strength. It is widely used in both structural and precision machining applications.

Core applications: 6061 aluminum block is ideal for billet machining, automobile bodies, tractor trailer vehicle parts, mechanical components, and mold manufacturing.

If you would like to learn more about 6061 aluminum blocks, please click 6061 aluminum block for more information.

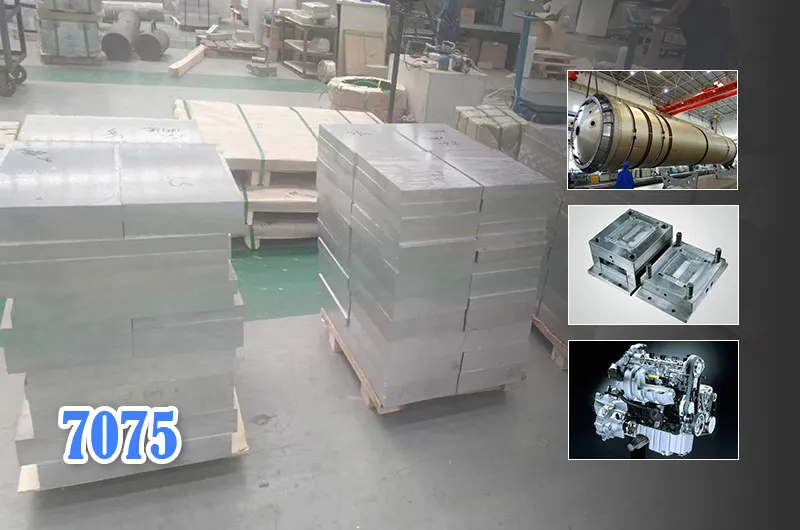

7075 aluminum block

7075 aluminum block is a high-strength, high-hardness alloy belonging to the Al-Zn-Mg-Cu series. As a cold-forging alloy with excellent mechanical properties and good anodic reaction, it is one of the most commonly used materials in the aerospace and defense industries. It offers an outstanding strength-to-weight ratio and is ideal for demanding structural applications.

Core applications: 7075 aluminum block is widely used for billet machining, aerospace components, engine blocks, precision molds, high-performance equipment, and structural parts in the automotive and defense sectors.

If you would like to learn more about 7075 aluminum blocks, please click 7075 aluminum block for more information.

2024 aluminum block

2024 aluminum block is a high-strength Al-Cu-Mg alloy known for its excellent heat resistance and outstanding mechanical properties. As a typical hard aluminum alloy, it features well-balanced composition and can be used for working parts below 150°C. Above 125°C, its strength exceeds that of 7075 aluminum. It offers good formability in hot, annealed, and quenched conditions, with significant improvements after proper heat treatment.

Core applications: 2024 solid square and rectangular aluminum blocks are widely used for billet machining, molds, aircraft frames, propeller structures, trailer wheels, automotive wheels, and other load-bearing components requiring strength and thermal stability.

If you would like to learn more about 2024 aluminum blocks, please click 2024 aluminum block for more information.

In addition to our most popular grades like 6061, 7075, and 2024, Chalco also supplies a wide range of other aluminum alloys to meet diverse industrial needs. Whether you require enhanced corrosion resistance, superior formability, or specific mechanical properties, we have the right solution for your application. Explore more aluminum block alloys

To help you quickly find the right alloy for your application, we've grouped our aluminum blocks by series—from 1000 to 7000—highlighting their key properties and typical uses. Use the links below to navigate directly to the alloy series you're interested in.

Aluminum block manufacturing types: rolled vs. forged

Understanding the manufacturing process of aluminum blocks is essential for selecting the right mechanical properties, machining requirements, and structural strength. Chalco offers two main types of aluminum blocks — rolled and forged — to meet different industrial application needs.

-

Rolled Aluminum Block

Made by hot or cold rolling, with uniform structure and high flatness — ideal for CNC machining and mold bases.

-

Forged Aluminum Block

Produced under high pressure and temperature, with dense grains and superior strength — perfect for aerospace and heavy-duty components.

Rolled aluminum block

Chalco's rolled aluminum blocks are known for their excellent flatness, uniform grain structure, and ease of machining. They are widely used in mold bases, precision-machined components, and structural applications. Common alloys include 1060,5052, 5083, 6061, 6063, 6082 and 7075.

Instant Quote- Thickness: 0.25" – 16"

- Width: 48" – 96"

- Length: ≤158"

Rolled blocks are ideal when you need superior surface quality, dimensional accuracy, and efficient CNC processing.

Forged aluminum block

Forged aluminum blocks are produced under high pressure and temperature, resulting in a dense grain structure and outstanding mechanical strength. They are preferred for applications requiring high load-bearing capacity and fatigue resistance, such as aerospace structures, automotive suspension parts, and defense components. Common alloys include 7075,7050, 2024, 2219, 2618, and 6061-T6.

- Thickness: 4" – 24"

- Width: 24" – 60"

- Length: ≤158"

Choose forged blocks when strength, durability, and toughness are the top priorities in demanding environments.

The key features of Chalco aluminum blocks

Large thickness, stable cutting

Available up to 400 mm thick, Chalco aluminum blocks are ideal for deep-cavity molds and large structural parts. Saw-cutting remains flat and dimensionally stable.

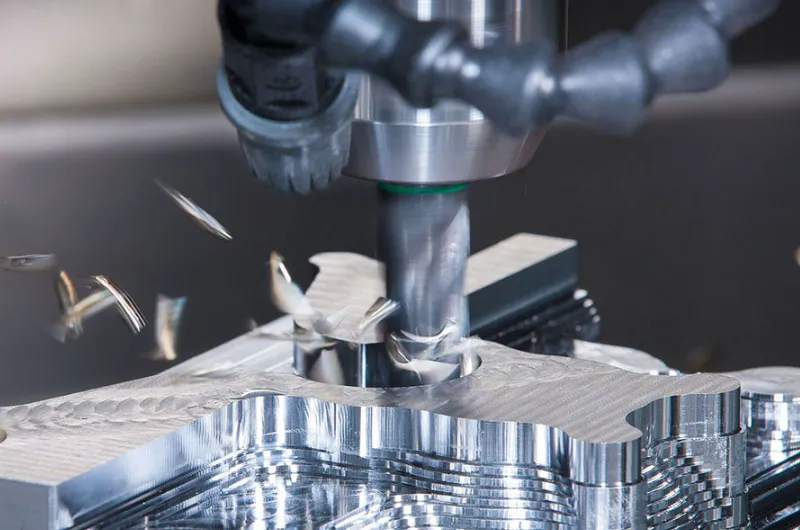

Excellent CNC machinability

With medium hardness and low cutting resistance, Chalco blocks perform well in high-speed CNC machining, offering clean chips and minimal tool sticking.

Multiple tempers available (O / T4 / T6 / T651)

Customizable temper states provide better control over machining stability and distortion, matching diverse application needs.

Low residual stress, high flatness

Blocks are stress-relieved after heat treatment, reducing warpage and maintaining flatness after cutting or machining.

Applications of aluminum block

Aluminum Block for Machining

Ideal for CNC milling, turning, and drilling of complex parts, with excellent machinability and dimensional stability.

Aluminum Block for Milling

Ensures high precision and smooth surface finish in high-speed milling processes, widely used in mold bases and aluminum cylinder block machining.

Aluminum Block for Aerospace Structures

Preferred for structural components that require high strength, low weight, and resistance to stress and temperature fluctuations, such as aluminum engine block components in aircraft systems.

Aluminum Block for Fixtures & Clamps

Offers excellent dimensional stability and machinability, making it ideal for precision jigs, clamps, and aluminum siding mounting block systems.

Aluminum Block for Molds

Suitable for mold bases, inserts, and frame structures requiring thermal balance, and also used in aluminium heater block and aluminium water block manufacturing.

Aluminum Block for Automotive Wheel Hubs

Lightweight and strong, ideal for dynamic-load parts like hubs, brackets, and transmission mounts where aluminum blocks offer both strength and weight efficiency.

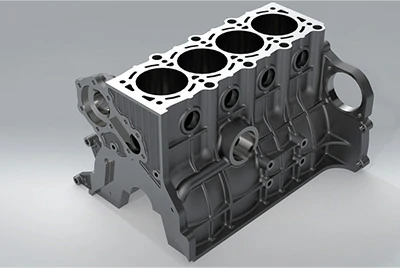

Aluminum Block for Engine Components

Combines structural strength with thermal conductivity, making it ideal for aluminum engine block and aluminum cylinder block production in automotive and motorsport applications.

Chalco CNC sawing and machining

Chalco Aluminum maintains a large stock of aluminum blocks across 1xxx to 7xxx series, with thicknesses ranging from 2 mm to 400 mm. Common in-stock alloys include 1070, 1060, 2024, 2A12, 5052, 5083, 5754, 5A05, 5A06, 6061, 6063, 6082, 7075, 7005, and more.

We offer fast and reliable CNC sawing and aluminum block machining services—ideal for milling, turning, drilling, or custom billet processing. Whether you need standard sizes or complex part machining, Chalco supports just-in-time orders to reduce lead time and inventory pressure.

Instant QuoteMain equipment of aluminum blocks for CNC and aluminum block for milling

Our aluminum block processing capabilities include:

- CNC machining centers

- CNC lathes & conventional lathes

- CNC milling machines & manual milling machines

- Drilling machines

- Internal & external cylindrical grinders

- Centerless grinding machines

Ideal aluminum blocks for CNC precision machining

In CNC precision machining, material stability and purity directly impact the final quality of your parts. Chalco's aluminum blocks—especially our 6061 and 7075 series—are the top choice for CNC workshops, precision mold makers, and high-tech prototyping companies around the world. We understand the critical importance of dimensional accuracy in your project.

Excellent machinability and surface finish: Our aluminum blocks feature a uniform grain structure that ensures smooth cutting, tight dimensional tolerances, and mirror-like surface finishes. This also helps extend your tool life and reduce machining costs.

Exceptional dimensional stability: All blocks undergo rigorous heat treatment and precision pre-stretching to eliminate internal stress. This ensures that the material remains stable—without deformation, warping, or cracking—throughout complex machining processes.

Guaranteed internal purity: Every aluminum block thicker than 10mm is 100% ultrasonically inspected to detect any internal defects. This eliminates the risk of porosity, bubbles, or cracks—protecting your tools and your project from costly material failures.

Recommended machining grades:

- 6061 aluminum block: The all-rounder for general CNC applications. It offers an ideal balance of strength, machinability, and affordability—perfect for mechanical parts, automation components, and functional prototypes.

- 7075 aluminum block: The high-strength choice for demanding parts. When you need steel-like hardness and strength, 7075 is the go-to alloy for aerospace structures, heavy-duty molds, and military-grade equipment.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Chalco aluminum block qualified support

- Sufficient inventory, complete alloy temper specifications, with 100,000 tons of inventory in various alloy temper.

- Customers can place orders at any time and process at any time, which can save customers a lot of time.

- It can be cut arbitrarily according to the requirements of customers, and the cut surface is smooth.

- Aluminum blocks can be pasted with protective film or paper sandwiched between aluminum blocks.

- The surface of the aluminum block is smooth and the cut is free of burrs.

- Cutting is accurate and precise.

FAQ of Aluminum block

What is your MOQ?

For our standard in-stock sizes, there is no minimum order quantity. Even if you need just one piece, we're happy to arrange it for you. For special custom-made dimensions, our sales engineers will discuss the MOQ based on your specific requirements.

How do you calculate the price for a custom-sized block?

The price is mainly composed of three parts: material cost (based on weight and current aluminum price), cutting and processing cost (based on complexity and machining time), and packaging & shipping. Simply send us your drawings and requirements—we'll provide an accurate quote within 24 hours, free of charge.

How to calculate the weight of an aluminum block?

You can estimate the weight using the formula: Weight (kg) = Length (m) × Width (m) × Thickness (m) × 2700 (for most 6xxx series aluminum), or × 2810 for 7075 aluminum. For fast and accurate results, please use our Aluminum Weight Calculator >>

Can I request custom sizes or shapes for aluminum blocks?

Yes, we offer cut-to-size and custom machining services based on your drawings or specifications. Whether you need square, rectangular, or irregular-shaped aluminum blocks, our team can deliver with tight tolerances.

Do your aluminum blocks come with material certificates?

Absolutely. All our aluminum blocks are supplied with full material test reports (MTRs) and certification documents such as EN10204 3.1, ASTM, or other standards upon request.

Can aluminum blocks be welded?

Yes. Alloys like 6061 and 5052 are highly weldable. However, high-strength grades like 7075 and 2024 are generally not recommended for welding due to their susceptibility to cracking unless properly treated.

Do you offer surface treatments such as anodizing?

Yes, we can provide anodizing, sandblasting, or protective film application upon request, especially for 6xxx and 5xxx series alloys.

What is the lead time for standard and custom orders?

Standard sizes are usually shipped within 3–5 working days. For custom orders, lead time depends on material, processing complexity, and quantity—typically 7–15 working days.

Do you ship internationally?

Yes. We ship aluminum blocks worldwide via air, sea, and express services. We can work with your preferred freight forwarder or arrange door-to-door delivery based on Incoterms like FOB, CIF, or DDP.

What is the difference between cast and billet aluminum blocks?

Cast aluminum blocks are made by pouring molten aluminum into molds, suitable for non-critical applications. Billet aluminum blocks are rolled or forged for better strength, density, and machinability—ideal for CNC and structural parts.

How do I place an order or get a quote?

Simply contact our sales team via email or inquiry form. Provide your required alloy, size, quantity, and any processing needs—we'll get back to you within 24 hours with a detailed quote.

Other popular alloy types of aluminum blocks

1000 series aluminum blocks

The 1000 series aluminum blocks are representatives of high-purity aluminum alloys, among which the most common ones are 1050 aluminum blocks, 1060 aluminum blocks and 1100 aluminum blocks. The aluminum content is above 99.0%, and they have excellent corrosion resistance, electrical conductivity and thermal conductivity, as well as excellent processing performance. They are suitable for a variety of deep processing methods, but their strength is relatively low.

-

1050 aluminum block

High-purity aluminum with excellent conductivity and corrosion resistance.

For electrical bases, heat transfer parts, and general machining.

-

1060 aluminum block

99.6% pure aluminum, soft, easy to mill and shape.

Used in chemical equipment, formed plates, and CNC blanks.

-

1100 aluminum block

Commercial grade aluminum with great machinability and weldability.

Ideal for fixture blocks, signage bases, and architectural parts.

2000 series aluminum blocks

2000 series aluminum blocks are primarily alloyed with copper, known for their high strength, excellent fatigue resistance, and good machinability. Grades such as 2024, 2219, 2618, 2124, and 2014 are widely used in aerospace, automotive, and structural components that demand superior mechanical properties and thermal stability. These aluminum blocks are ideal for precision machining, stressed parts, and high-temperature environments where strength-to-weight ratio is critical.

-

2014 aluminum block

2014 aluminum block offers high strength and good machinability, ideal for aerospace, tooling, and high-stress structural components.

-

2618 aluminum block

2618 aluminum block delivers high heat strength and fatigue resistance, ideal for aerospace and performance parts.

-

2219 aluminum block

2219 aluminum block offers excellent weldability and thermal stability, ideal for aerospace structures and cryogenic tanks.

3000 series aluminum blocks

3000 series aluminum blocks are aluminum-manganese alloys known for excellent corrosion resistance, good formability, and moderate strength. Common grades like 3003, 3105, and 3004 are widely used in applications such as construction, packaging, and household appliances due to their versatility and reliable performance.

-

3003 aluminum block

3003 aluminum block features good corrosion resistance and formability, suitable for cookware, signage, and HVAC systems.

-

3004 aluminum block

3004 aluminum block offers higher strength than 3003 with similar workability, commonly used in storage tanks and roofing panels.

-

3105 aluminum block

3105 aluminum block provides excellent corrosion resistance and moderate strength, ideal for architectural and decorative applications.

4000 series aluminum blocks

4000 series aluminum blocks, like 4032, 4047 and 4045, feature high wear resistance, thermal conductivity, and corrosion resistance, making them ideal for engine parts, aerospace components, and heat exchangers.

5000 series aluminum blocks

5000 series aluminum blocks include alloys like 5052, 5083, 5086, 5754, and 5182, known for their excellent corrosion resistance, especially in marine environments, and good weldability and strength.

Instant Quote-

5005 aluminum block

5005 aluminum block is used for milling dashboards, electronic housings, and architectural decorative applications.

-

5052 aluminum block

5052 aluminum block is ideal for machining billets, parts, wheels, molds, fuel tanks, marine panels, and transportation components.

-

5083 aluminum block

5083 aluminum block is used in billet machining for Chevy, Ford, warship plates, aircraft weld panels, pressure vessels, towers, and refrigeration systems.

-

5086 aluminum block

5086 aluminum block is widely used in molds, ships, automobiles, aircraft structures, and cryogenic or transport equipment.

-

5182 aluminum block

5182 aluminum block is suitable for billets and processing car body panels, control units, reinforcements, and brackets.

-

5454 aluminum block

5454 aluminum block is used in wheels, Chevy/Ford parts, marine pipelines, pressure vessels, and oil tank components.

-

5754 aluminum block

5754 aluminum block is commonly applied to car doors, sealing parts, and structural mold components in the automotive industry.

6000 series aluminum blocks

Common 6000 series aluminum blocks include 6061 t6 aluminum blocks, 6063 aluminum blocks, and 6082 aluminum blocks. These alloys are known for their excellent strength, corrosion resistance, and good workability.

Instant Quote-

6063 aluminum block

6063 aluminum block is used for billets, irrigation pipes, truck hubs, and general mechanical parts due to its good formability and surface quality.

-

6082 aluminum block

6082 aluminum block is used for mechanical structures, aircraft components, and industrial mold bases.

7000 series aluminum blocks

In the 7000 series, aside from the widely used 7075 aluminum block, 7005 and 7050 are also among the most popular choices. Known for their high strength, excellent fatigue resistance, and good stress corrosion performance, these alloys are ideal for aerospace structures, transportation parts, and other high-performance engineering applications.

-

7005 aluminum block

Lightweight Al-Zn-Mg-Cu alloy with good weldability and heat treatability.

Used in transport vehicles, truss rods, containers, and large heat exchangers.

-

7050 aluminum block

High-strength aerospace-grade alloy with excellent stress corrosion resistance.

Ideal for aircraft structures, landing gear components, and precision tools.

Can't find the aluminum block you need? Contact us — we'll help you find or customize the right solution.

Aluminum block stock sizes and tolerances

The stock sizes listed below are available for all popular aluminum block alloys, including those used in machining, molds, fixtures, and engine components. We offer custom cut-to-size services based on your exact requirements. For high-precision applications, precision sawing is also available. for a quick quote.

Instant Quote

Standard cutting tolerance: –0" to +1/8"

Precision cutting tolerance: ±0.005"

| Imperial (inches) | Imperial (feet) | Metric (millimeters) |

| 2" × 6" | — | 50.8 mm × 152.4 mm |

| 4" × 4" | — | 101.6 mm × 101.6 mm |

| 6" × 6" | — | 152.4 mm × 152.4 mm |

| 6" × 12" | — | 152.4 mm × 304.8 mm |

| 8" × 8" | — | 203.2 mm × 203.2 mm |

| 12" × 12" | 1' × 1' | 304.8 mm × 304.8 mm |

| 12" × 24" | 1' × 2' | 304.8 mm × 609.6 mm |

| 12" × 48" | 1' × 4' | 304.8 mm × 1219.2 mm |

| 18" × 18" | 1.5' × 1.5' | 457.2 mm × 457.2 mm |

| 24" × 24" | 2' × 2' | 609.6 mm × 609.6 mm |

| 24" × 48" | 2' × 4' | 609.6 mm × 1219.2 mm |

| 36" × 72" | 3' × 6' | 914.4 mm × 1828.8 mm |

| 48" × 48" | 4' × 4' | 1219.2 mm × 1219.2 mm |

| 48" × 96" | 4' × 8' | 1219.2 mm × 2438.4 mm |

| 48" × 120" | 4' × 10' | 1219.2 mm × 3048.0 mm |

| 48" × 144" | 4' × 12' | 1219.2 mm × 3657.6 mm |

| 60" × 144" | 5' × 12' | 1524.0 mm × 3657.6 mm |