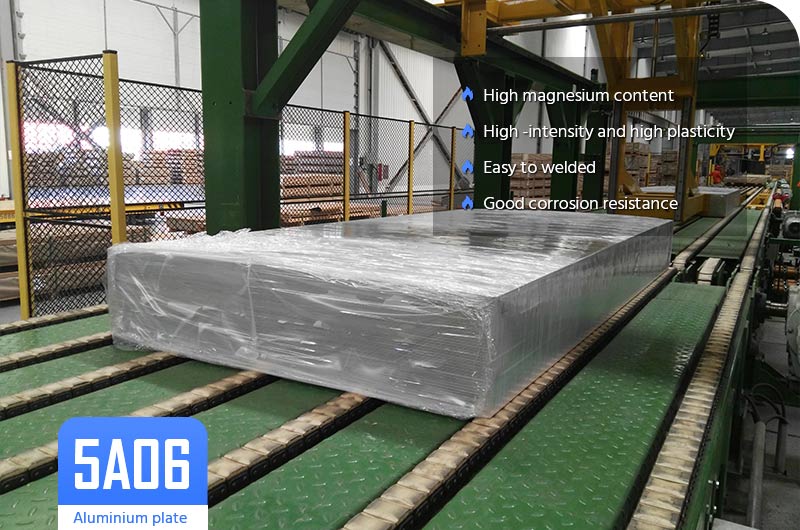

5A06 aluminum alloy is a high-magnesium, non-heat-treatable alloy known for its excellent corrosion resistance, high fatigue strength, and outstanding welding performance. It is widely used in demanding industries such as shipbuilding, military armor systems, fuel tanks, and structural components. Chalco provides high-quality 5A06 aluminum rods in a range of tempers and shapes, helping customers meet rigorous requirements in both mechanical performance and manufacturability.

Product types of Chalco 5A06 aluminum bar

- 5A06 H112 aluminum bar

- 5A06 H116 aluminum bar

- 5A06 O aluminum bar

- 5a06 aluminum round bar

- 5a06 aluminum square bar

- 5a06 aluminum hex bar

- 5a06 al cold drawn bar

- 5a06 aluminum extruded bar

- 5a06 aluminum bar custom

- Precise extrusion and cold drawing processes ensure stable mechanical properties of 5A06 aluminum bars.

- Custom length cutting services reduce material waste.

- Various surface treatments available, including anodizing and polishing.

- Support for precision machining such as turning and milling.

- Strict quality control guarantees consistent product performance.

- Flexible production to accommodate both small and large batch orders.

Chalco 5A06 aluminum round rod stock size list

- Relying on Chalco production line and its subsidiaries, source procurement, lowest price guarantee.

- Chalco has the largest inventory and can allocate its subsidiary's inventory products at any time, seven-day delivery guarantee;

- The quality of large and small batches is the same, and be provided at the lowest price.

Inventory information is being updated in real-time, and the length can be cut. Welcome to click the button to obtain the latest inventory information. Customized sizes can be provided. Click to inquire about how to produce customized products with free mold fees.

Instant Quote| Product | Diameter mm | Diameter inch | Order |

| EN-AW 5A06-H112 | φ8 | 5/16 | Instant Quote |

| EN-AW 5A06-H112 | φ10 | 3/8 | Instant Quote |

| EN-AW 5A06-H112 | φ12 | 7/16 | Instant Quote |

| EN-AW 5A06-H112 | φ14 | 1/2 | Instant Quote |

| EN-AW 5A06-H112 | φ16 | 5/8 | Instant Quote |

| EN-AW 5A06-H112 | φ18 | 11/16 | Instant Quote |

| EN-AW 5A06-H112 | φ20 | 3/4 | Instant Quote |

| EN-AW 5A06-H112 | φ25 | 1 | Instant Quote |

| EN-AW 5A06-H112 | φ30 | 1 3/16 | Instant Quote |

| EN-AW 5A06-H112 | φ35 | 1 3/8 | Instant Quote |

| EN-AW 5A06-H112 | φ40 | 1 9/16 | Instant Quote |

| EN-AW 5A06-H112 | φ45 | 1 3/4 | Instant Quote |

| EN-AW 5A06-H112 | φ50 | 1 15/16 | Instant Quote |

| EN-AW 5A06-H112 | φ55 | 2 5/32 | Instant Quote |

| EN-AW 5A06-H112 | φ60 | 2 3/8 | Instant Quote |

| EN-AW 5A06-H112 | φ65 | 2 9/16 | Instant Quote |

| EN-AW 5A06-H112 | φ70 | 2 3/4 | Instant Quote |

| EN-AW 5A06-H112 | φ75 | 2 15/16 | Instant Quote |

| EN-AW 5A06-H112 | φ80 | 3 1/8 | Instant Quote |

| EN-AW 5A06-H112 | φ85 | 3 3/8 | Instant Quote |

| EN-AW 5A06-H112 | φ90 | 3 9/16 | Instant Quote |

| EN-AW 5A06-H112 | φ95 | 3 3/4 | Instant Quote |

| EN-AW 5A06-H112 | φ100 | 3 15/16 | Instant Quote |

| EN-AW 5A06-H112 | φ105 | 4 1/8 | Instant Quote |

| EN-AW 5A06-H112 | φ110 | 4 5/16 | Instant Quote |

| EN-AW 5A06-H112 | φ115 | 4 1/2 | Instant Quote |

| EN-AW 5A06-H112 | φ120 | 4 3/4 | Instant Quote |

| EN-AW 5A06-H112 | φ130 | 5 1/8 | Instant Quote |

| EN-AW 5A06-H112 | φ140 | 5 1/2 | Instant Quote |

| EN-AW 5A06-H112 | φ150 | 5 7/8 | Instant Quote |

| EN-AW 5A06-H112 | φ160 | 6 1/4 | Instant Quote |

| EN-AW 5A06-H112 | φ170 | 6 11/16 | Instant Quote |

| EN-AW 5A06-H112 | φ180 | 7 1/16 | Instant Quote |

| EN-AW 5A06-H112 | φ190 | 7 1/2 | Instant Quote |

| EN-AW 5A06-H112 | φ195 | 7 21/32 | Instant Quote |

| EN-AW 5A06-H112 | φ200 | 7 7/8 | Instant Quote |

| EN-AW 5A06-H112 | φ205 | 8 1/16 | Instant Quote |

| EN-AW 5A06-H112 | φ210 | 8 1/4 | Instant Quote |

| EN-AW 5A06-H112 | φ220 | 8 21/32 | Instant Quote |

| EN-AW 5A06-H112 | φ230 | 9 1/16 | Instant Quote |

| EN-AW 5A06-H112 | φ240 | 9 7/16 | Instant Quote |

| EN-AW 5A06-H112 | φ250 | 9 13/16 | Instant Quote |

| EN-AW 5A06-H112 | φ260 | 10 1/4 | Instant Quote |

| EN-AW 5A06-H112 | φ265 | 10 7/16 | Instant Quote |

| EN-AW 5A06-H112 | φ270 | 10 5/8 | Instant Quote |

| EN-AW 5A06-H112 | φ280 | 11 | Instant Quote |

| EN-AW 5A06-H112 | φ285 | 11 7/32 | Instant Quote |

| EN-AW 5A06-H112 | φ300 | 11 13/16 | Instant Quote |

| EN-AW 5A06-H112 | φ330 | 13 | Instant Quote |

| EN-AW 5A06-H112 | φ340 | 13 3/8 | Instant Quote |

| EN-AW 5A06-H112 | φ350 | 13 25/32 | Instant Quote |

Technical parameters of 5A06 aluminum alloy

| Chemical Composition | |

| Element | Content (%) |

| Al | Balance |

| Mg | 4.5 – 5.5 |

| Mn | 0.5 – 1.0 |

| Fe | ≤ 0.4 |

| Si | ≤ 0.25 |

| Cu | ≤ 0.1 |

| Zn | ≤ 0.1 |

| Ti | ≤ 0.15 |

| Mechanical Properties | |

| Property | Typical Values (H112) |

| Tensile Strength (Rm) | 265 MPa |

| Yield Strength (Rp0.2) | 115 MPa |

| Elongation (A%) | 14 % |

| Hardness (HB) | 75 |

| Physical Properties | |

| Property | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 570 – 650 °C |

| Thermal Conductivity | ~130 W/m·K |

| Electrical Conductivity | ~34 % IACS |

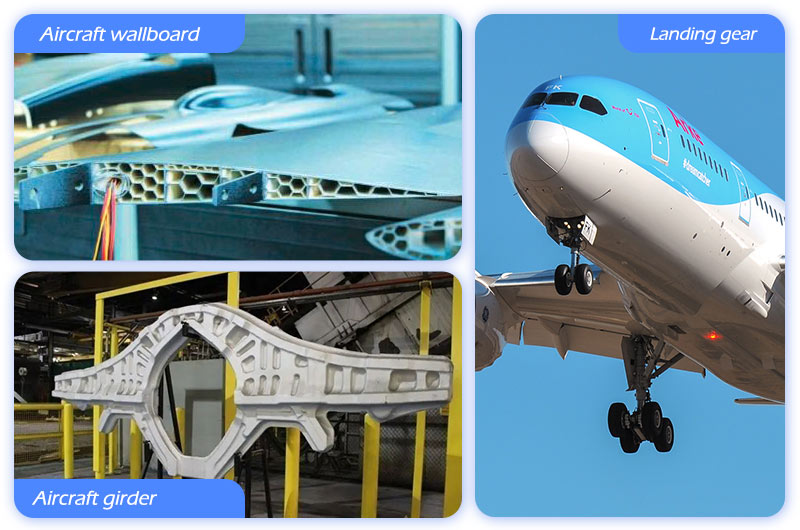

Application of Chalco 5A06 aluminum bar

- 5A06 alloy is commonly used in the manufacturing of welded pipes, welded fuel tanks, and other liquid containers

- 5A06 has high corrosion resistance of the 5000 series aluminum and is commonly used in marine fields and parts of maritime navigation equipment.

- 5A06 aluminum rod has a beautiful anodized surface, which is often used for manufacturing components or rivets that require anodizing treatment.

- 5A06 is a famous military alloy commonly used in the manufacturing of armor plates, high-strength structural components, tanks, etc.

Comparative analysis of 5A06 aluminum bar vs other 5000 series alloys

The 5A06 aluminum alloy, widely used in China, shares many characteristics with other well-known 5000 series alloys globally. To help customers better understand its unique strengths and practical advantages, it is important to compare 5A06 with similar alloys such as 5052, 5083, and 5005. This comparison highlights where 5A06 excels, guiding informed material selection for diverse industrial applications.

| Key Differences and Performance Comparison | |||||

| Alloy | Mg Content (%) | Tensile Strength (MPa) | Corrosion Resistance | Weldability | Typical Applications |

| 5A06 | 4.5 – 5.5 | 265 | Excellent | Good | Marine, Armor, Structural |

| 5052 | 2.5 | 193 | Excellent | Excellent | Marine, Automotive |

| 5083 | 4.5 – 5.5 | 317 | Excellent | Moderate | Shipbuilding, Pressure Vessels |

| 5005 | 0.8 – 1.2 | 150 | Good | Excellent | Architectural, Decorative |

Why we recommond you the 5a06 aluminum bar

- Superior Corrosion Resistance: 5A06 provides excellent resistance especially in marine environments, comparable to or better than many peers.

- Balanced Mechanical Strength: Combines good tensile strength and ductility, ideal for applications requiring toughness and fatigue resistance.

- Military & Structural Grade: Recognized for armor plating and high-strength structural components, highlighting reliability under extreme conditions.

- Good Weldability & Surface Finish: Supports various welding techniques and has a naturally anodizable surface, ideal for both manufacturing and aesthetic requirements.

- Cost-Effective & Readily Available: Thanks to Chalco's large inventory and production scale, 5A06 is competitively priced and supply-stable.

5A06 aluminum bar related recommendations

5A06 aerospace aluminum bar

5A06 marine aluminum round bar

5A06 marine aluminum square bar

5A06 marine Al hexagonal bar

5A06 aluminum plate

5A06 marine aluminum plate

FAQ for purchasing Chalco 5A06 aluminum bar

What standards should 5A06 aluminum rods meet?

Chalco 5A06 aluminum bar complies with standards such as GB/T3190, GB/T3191, BS EN 485-2:200, and strictly controls quality from the source.

Where can I buy the lowest priced 5A06 aluminum bar rod?

FOB price = SMM A00 aluminum ingot price on the day of inquiry + processing fee / exchange rate

FOB price can be US dollar price, Euro price, or Renminbi price, according to customer requirements.

Chalco can customize on demand, some products are in stock, and they will be shipped immediately after placing an order. We look forward to cooperating with you!

Instant QuoteHow to find the best manufacturer of 5A06 aluminum bars?

Chalco, with its complete production line, can produce, cut, and process high-quality 5A06 aluminum bars.

Aluminum rods must go through the following processes: smelting→casting→saw blades→homogenizing aluminum rods→cooling and washing rods→Aluminum rods are put into storage.

Extrusion process: preparation before pressing → extrusion → stretching and straightening →Sawing finished products → framing and trimming.

Instant QuoteWhat are the packaging methods for 5A06 aluminum bars?

- Plastic or kraft paper packages are used to prevent moisture and rain, and ensure that they are clean and free of dirt during transportation

- Install wooden pallets and reinforce them with steel belts to avoid collisions during transportation.

- Export products are packed in wooden boxes and brackets with fumigation marks, and fumigation certificates are provided.

- Pack according to other packaging requirements of customers.

What performance characteristics should be noted when purchasing 5A06 aluminum bars?

- For the Al Mg series of rust resistant aluminum, 5A06 has high fatigue strength, high plasticity, and corrosion resistance.

- It has good machinability in cold work hardening and semi cold work hardening temper, but poor machinability in annealing temper, and can be polished.

- Good welding performance, suitable for atomic hydrogen welding, contact welding with crystallization cracking tendency, and argon arc welding.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote