2618 and 2618A are high-strength, heat-treatable aluminum-copper-magnesium alloys engineered to maintain excellent mechanical properties at elevated temperatures. These alloys combine superior strength, good machinability, and reliable fatigue resistance, making them ideal for aerospace, motorsports, and high-performance industrial applications.

Chalco specializes in producing premium 2618/2618A aluminum bars that meet stringent aerospace standards such as DTD 5014A, MSRR 8018, and AMS 4132. We offer customized solutions and dedicated technical support to ensure you receive the optimal material for your demanding projects. Contact us today to discuss your specific requirements.

Specification of Chalco 2618 aluminum bar rod

Chalco provide high quality 2618 and 2618A aluminum bar rod products in T1, T6, T351, T851, T62, T6511, T8, T8511, F etc, temper, and the quality can strictly follow the Spacifications below:

AIR 9049, EN3553, AMS4132, NFA 50-702, BS L100, BS EN 573, BS EN 755, BS EN 754

2618/2618A T6 aluminum bar: DTD 717A, DTD 731B, DTD 745A, DTD 5084A

2618/2618A T351 T851 aluminum bar: AIR 9048.640, EN 2123

2618/2618A T651 aluminum bar: AIR 9048.640, WS 3.1924

2618/2618A T6511 Aaluminum bar rod: EN 3553, DTD, 5014, DTD, 5014A

Other certification such as EN 10204 3.1, Third Party Inspection, Buyer Inspection, Mill Test Certificate... also can be procvided according to the customer requirement to ensure tue quality.

Instant Quote

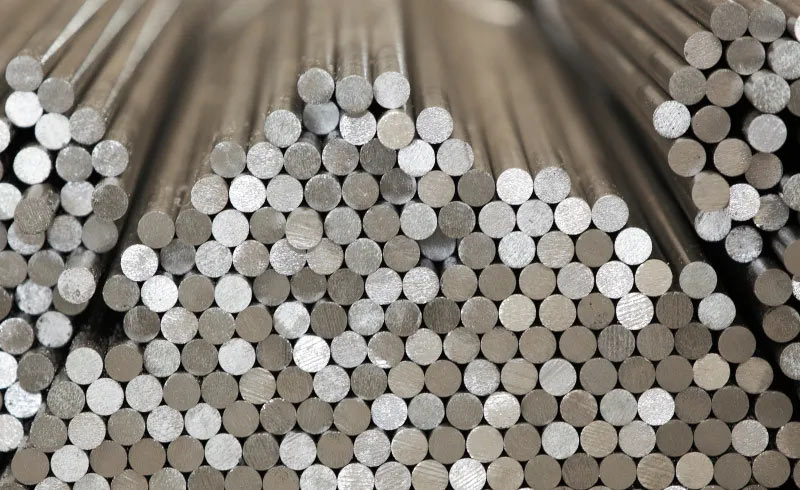

Chalco hot selling 2618 2618A aluminum bar rod products

| Forged aluminum square bar rod | Forged aluminum round bar rod | ||

| Maximum weight | ≤ 9T | Maximum weight | ≤8T |

| Width | ≤ 2000mm | Diameter | ≤ 800mm |

| Height | ≤ 500mm | - | - |

| Length | ≤ 7000mm | Length | ≤ 7000mm |

| Available temper: O, F, H112, T3, T4, T5, T6, T62, T652, T73, T74, T7452, T852, etc. | |||

| Executive standard: GBn223, YS/T479, ASTM B247, AMS series standards | |||

- 2618 2618A alumunum CF bar

- 2618 2618A aluminum extruded bar

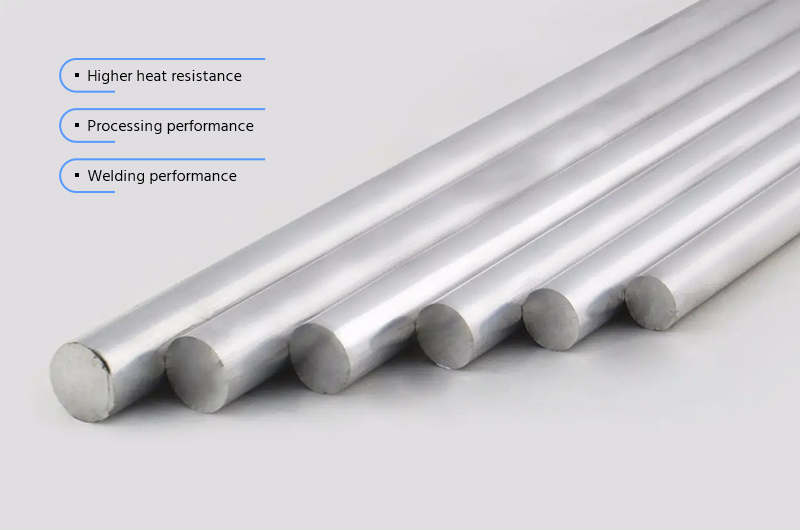

- 2618 2618A aluminum round bar

- 2618 2618A aluminum square bar

- 2618 2618A aluminum flat bar

- 2618 2618A aluminum hex bar

Chalco 2618 2618A aluminum bar rod alloy series

- 2618 T6 aluminum bar

High strength and hardness, suitable for aerospace and high-performance structural applications.

- 2618 T61 aluminum bar

Offer enhanced strength and toughness, ideal for high-pressure applications.

- 2618 T651 aluminum bar

Exceptional strength and corrosion resistance, used in aerospace structures and marine components.

- 2618 T351 aluminum bar

Good machinability and moderate strength, commonly used in automotive and mechanical components.

- 2618 T851 aluminum bar

High strength and excellent stress corrosion cracking resistance, suitable for aerospace and marine.

- 2618 T62 aluminum bar

Superior machinability, used in automotive components and fasteners...

All listed tempers apply to both 2618 and 2618A alloys, meeting various industry demands. Contact Chalco today to discuss your specific needs and get customized solutions for your project.

Instant QuoteTechnical parameters of 2618/2618A aluminum bar rod

| Chemical Composition (wt%) | |||

| Element | 2618 Range (%) | 2618A Range (%) | Notes |

| Copper (Cu) | 2.4 – 3.5 | 2.7 – 3.3 | 2618A has slightly narrower Cu range |

| Magnesium (Mg) | 0.2 – 0.8 | 0.2 – 0.8 | |

| Iron (Fe) | ≤ 0.7 | ≤ 0.7 | |

| Nickel (Ni) | 1.7 – 2.3 | 1.7 – 2.3 | |

| Silicon (Si) | ≤ 0.2 | ≤ 0.2 | |

| Manganese (Mn) | 0.2 – 0.9 | 0.2 – 0.9 | |

| Zinc (Zn) | ≤ 0.1 | ≤ 0.1 | |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.15 | |

| Aluminum (Al) | Balance | Balance | |

| Mechanical Properties by Temper (Heat Treatment) | |||

| Temper (Heat Treatment) | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation (%) |

| 2618-T6 / T6511 | 375 | 315 | 6 |

| 2618-T8 / T8511 | 385 | 325 | 5 |

| 2618-T1 / T62 | 365 | 305 | 5 |

| Physical Properties | ||

| Property | Typical Value | Unit |

| Density | 2.78 | g/cm³ |

| Melting Point | 640 – 650 | °C |

| Thermal Conductivity | 120 | W/(m·K) |

| Electrical Conductivity | ~25 | % IACS |

| Coefficient of Thermal Expansion | 23.5 × 10⁻⁶ | 1/°C |

Note

- Parameters are based on industry standards like AMS 4132 and DIN; actual values may vary by manufacturer and heat treatment.

- Mechanical properties mainly reference the T6 temper; other tempers differ accordingly.

- 2618A is an optimized variant of 2618 with a narrower copper range for more consistent performance.

- This info helps you better understand the alloys and choose the right material for your application.

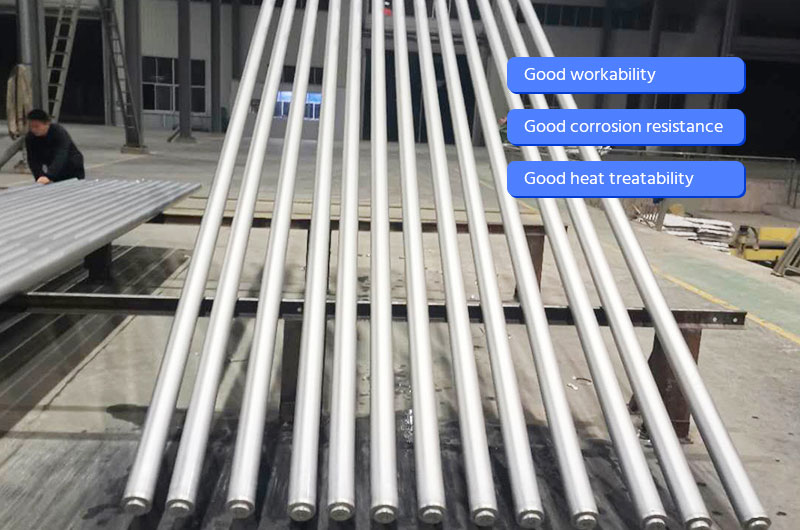

The typical features of Chalco 2618 2618A aluminum bar rod

- Chalco 2618 aluminum rods has high heat resistance;

- Chalco 2618 aluminum bar has good thermoplasticity and pressure workability;

- After crystallization, Chalco 2618 aluminum bar rod has a small critical deformation degree of coarse grains (2-4%);

- Chalco 2618 aluminum rods have good process performance during casting and pressure processing (whether it is forging, extrusion or rolling).

- Copper content croader range (2.4–3.5%)

- High strength, moderate variability

- Suitable for 200–250°C

- Good machinability

- Moderate elongation (~5-6%)

- Aerospace pistons, rotating parts, automotive

- Batch dependent variability

- Copper content Narrower, more controlled range (2.7–3.3%)

- Slightly higher strength, more stable

- Similar heat resistance, improved stability

- Consistent machinability

- Similar elongation with better uniformity

- Aerospace components, precision mechanical parts

- More uniform and reliable performance

The application of EN AW2618 aluminum bar rod

Both 2618 and 2618A aluminum bars are widely used in high-strength, heat-resistant applications such as aerospace, automotive, and mechanical industries. While they share many common uses, there are slight differences in their application focus due to 2618A’s improved composition and performance stability.

- 2618 Aluminum Bar: Commonly used for aerospace pistons, cylinder heads, and high-performance automotive parts that require good strength and heat resistance.

- 2618A Aluminum Bar: Often selected for precision aerospace components and critical mechanical parts where consistent performance and tighter tolerances are essential.

2618 & 2618A aluminum bar rod for High-Temperature Use

2618: excellent thermal stability for engine parts and heat-exposed components (AMS 4132, DTD 5014)

2618A: provides enhanced heat resistance and uniformity for critical aerospace parts (AMS 4132, DTD 5014A)

2618 & 2618A aluminum bar rod for Aerospace

2618: used in lightweight, strong structural and engine components (AMS 4132, AIR 9049)

2618A: suits precision aerospace parts needing tight tolerances and reliability (AMS 4132, DTD 5014A)

2618 & 2618A aluminum bar rod for Forging

2618: features good ductility and strength for forged components (AMS 4132)

2618A: offers improved uniformity, ideal for reliable forged parts (AMS 4132)

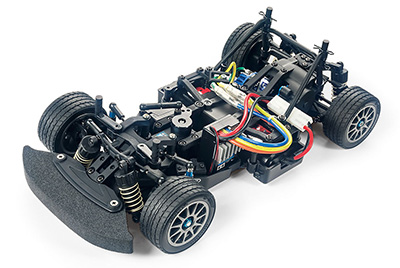

2618 & 2618A aluminum bar rod for Pistons

2618: popular in high-performance and racing pistons for its strength and heat endurance (AMS 4132)

2618A: preferred for pistons requiring consistent strength and corrosion resistance (AMS 4132)

2618 & 2618A aluminum bar rod for Automotive

2618: applied in engine and high-stress parts (AMS 4132)

2618A: used for precision, durable automotive components (AMS 4132)

2618 & 2618A aluminum bar rod for Military Applications

2618: favored for aerospace and defense parts needing strength and heat resistance (AMS 4132)

2618A: chosen for critical defense components demanding uniformity and reliability (AMS 4132)

2618 aluminum bar rod molds (cold dimensions)

| Mold | ||

| Ø 160 mm | Ø 178 mm | Ø 201 mm |

| Ø 215 mm | Ø 227 mm | Ø 252 mm |

| Ø 280 mm | Ø 314 mm | Ø 350 mm |

| Ø 372 mm | Ø 425 mm | Ø 435 mm |

| Ø 518 mm | Ø 607 mm | Ø 682 mm |

| Ø 750 mm* | Ø 930 mm | Ø 1150 mm* |

Purchasing guidance of 2618 aluminum bar

Comparison of 2618 aluminum alloy with some commonly used alloys

- 2024 vs. 2618: 2024 aluminum alloy is known for its high strength and good fatigue resistance, making it a popular choice for aerospace structures. However, its heat resistance is lower than that of 2618. The 2618 alloy offers better creep resistance, making it more suitable for high-temperature applications such as engine components.

- 7075 vs. 2618: 7075 is one of the highest-strength aluminum alloys, commonly used in aerospace and structural applications requiring high strength. However, 7075's performance at high temperatures is inferior, as it tends to lose strength under heat. In contrast, 2618 has better high-temperature stability and creep resistance, making it ideal for high-heat applications like pistons.

- 4032 vs. 2618: 4032 is also a popular aluminum alloy for pistons due to its low thermal expansion and good wear resistance. While 2618 has higher strength at elevated temperatures, 4032 is preferred for applications needing dimensional stability under temperature changes. The choice often depends on specific requirements for thermal expansion in high-temperature uses.

- 6061 vs. 2618: 6061 is a versatile alloy with good machinability and corrosion resistance, but it lacks the strength and heat resistance of 2618. While 6061 is widely used for structural purposes, 2618's superior high-temperature performance makes it better suited for applications that demand high strength under thermal stress.

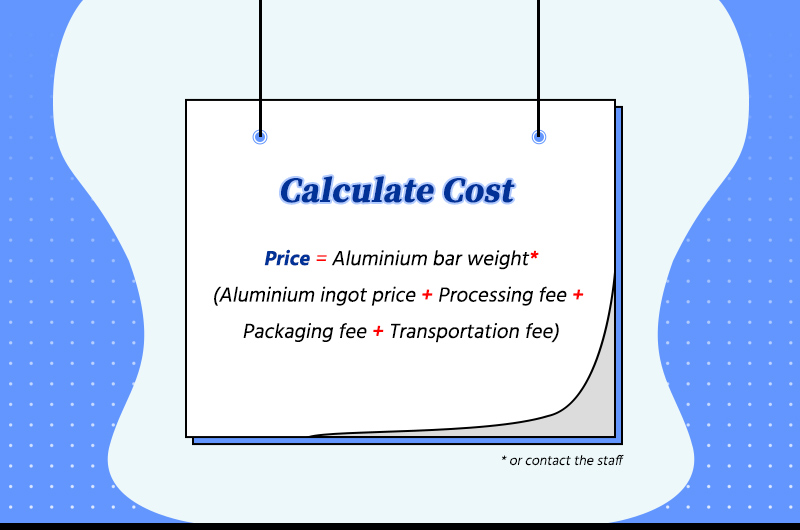

The price composition of Chalco 2618 aluminum bar

FOB price of 2618 aluminum bar rod /cold drawn aluminum rod bars 2618/2618 forged aluminum bar rod= SMM A00 aluminum ingot price on the day of inquiry + processing fee / exchange rate

Notes:

Aluminum ingot price is SMM A00 aluminum ingot price

FOB price can be US dollar price, Euro price, or Renminbi price, according to customer requirements.

Aluminum alloy 2618 F aluminum bar rod, Aluminium alloy 2618 T6 round bar rod are the 2 most ordered tempers by customers

Instant Quote

How to find a reliable supplier for 2816 aluminum?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting future challenges.

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

We have passed the AS9100 certification required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Instant Quote

Chalco 2618 aluminum bar products related recomendations

2618 aerospace aluminum bar

2618 aerospace forgings

2618 aerospace aluminum plate

2024 aluminum bar

7075 aluminum bar

6061 aluminum bar

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote