In modern engineering where lightweight, high strength, and corrosion resistance are essential, Structural Aluminum Tubing has become a key material across industries like construction, industrial equipment, and new energy systems. It weighs only one-third of steel and offers excellent oxidation resistance without the need for extra rust protection—achieving strong load-bearing capacity while ensuring lightweight and long-term stability.

Curious about how structural aluminum tubing compares to pipes or steel tubes?

Unlike standard aluminum tubes, structural aluminum tubing focuses more on mechanical strength and load support than pressure resistance. It's widely used in non-pressurized applications such as frames, beams, and support systems.

As a global leader in aluminum manufacturing, Chalco offers structural aluminum tubing that meets ASTM B429, B221, and other standards. We support a wide range of alloy and dimension customizations, meeting strict demands for strength, lightweight, and precision assembly.

Versatile Profile Designs for Complex Engineering Needs

Round Structural Tubing

Round Structural Tubing OD: 12.7 mm – 152.4 mm (0.5" – 6")

WA: 1.2 mm – 6.35 mm (0.049" – 0.25")

Length: 6m / customizable

Offers excellent bending and torsional stiffness, ideal for railings, handrails, curved structures, and joints that require strong deformation resistance and even force distribution. The round shape is perfect for cold bending and roll forming, making it a flexible choice for varied applications.

Square Structural Tubing

Square Structural Tubing Size: 25.4 mm – 101.6 mm (1" – 4")

Wall Thickness: 1.2 mm – 6.0 mm

Length: 6m / customizable

Known for its high torsional strength and flat surface connections, it’s widely used in machine frames, solar brackets, energy storage cabinets, and equipment supports. Its clean corners allow easy welding, assembly, and modular designs, making it a go-to in industrial manufacturing.

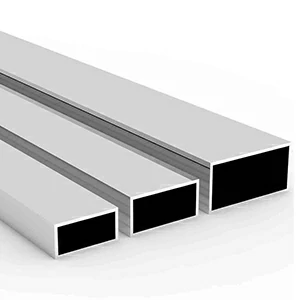

Rectangular Structural Tubing

Rectangular Structural Tubing Side A: 25.4 mm – 152.4 mm (1" – 6")

Side B: 12.7 mm – 101.6 mm (1/2" – 4")

Wall Thickness: 1.2 mm – 6.0 mm

Length: 6m / customizable

When load strength is needed in a specific direction, rectangular tubing is a better fit. Especially the Aluminum Rectangular Hollow Section (RHS), which is commonly used in curtain wall frames, industrial doors/windows, equipment enclosures, vehicle platforms, and solar beam supports.

Hexagonal Structural Tubing

Hexagonal Structural Tubing Across Flats: 6 mm - 150 mm (1/4" - 6")

Wall Thickness: 1.0 mm - 12.0 mm (0.039" - 0.5")

Length: 6m / Customizable

Hex aluminum tubes are ideal for applications requiring multi-face connections, lightweight structure, or distinctive assembly geometry. The hexagonal profile allows for easy multi-angle welding and fitting, commonly used in bicycle components, outdoor gear, decorative profiles, model frameworks, and tool handles.

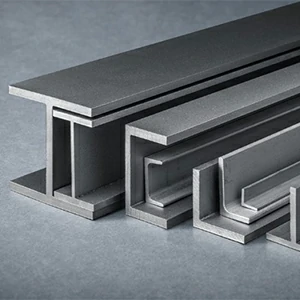

Custom Structural Profiles

Custom Structural Profiles Chalco can manufacture custom profiles like T-shaped, C-shaped, U-shaped, H-beam, I-beam, and rail types per your drawings. We offer flexibility in wall thickness, strength grades, and surface finishes—ideal for heavy equipment frames, track systems, and non-standard building nodes in complex structural applications.

Custom Structural Profiles

Aluminum T bar

Aluminum Angles

Aluminum Beams

Aluminum U Channel

Aluminum Hat Channel

Aluminium Z Section

Aluminum F Channel

Aluminum J Channel

Aluminium Y Section

Contact Chalco today for engineering selection advice and custom structural tubing solutions—helping you build strong, lightweight support systems with ease.

Instant QuoteDimensional Tolerances & Certifications of Structural Aluminum Tubing

As a professional Structural Aluminum Tubing manufacturer, Chalco strictly follows international standards and holds multiple quality certifications to ensure precision, strength, corrosion resistance, and full traceability across global markets.

Precision & Tolerance Standards

Chalco complies with ASTM B429, ASTM B221, and EN 755, guaranteeing consistent dimensions and structural reliability.

- OD / side tolerance: ±0.05 mm – ±0.2 mm (based on size grade)

- Wall thickness tolerance: ±10%

- Diagonal deviation / straightness: <0.8‰ (within standard lengths)

- Surface roughness: Ra ≤ 1.6 μm (after drawing and polishing)

- Ovality control: Ensures precise fit for round tubing

Standard Compliance

Our structural aluminum tubing meets the following standards, widely used in engineering and industrial assembly:

- ASTM B429/B429M – For 6061 and 6063 tubes in structural and mechanical use

- ASTM B221/B221M – General spec for extruded aluminum tubes, bars, and shapes

- EN 755-2 / EN 755-8 – European dimensional and tolerance standards

Certified Quality Systems

To ensure consistency and reliability, Chalco has established a complete quality and traceability system:

- ISO 9001 – Quality management

- ISO 14001 – Environmental compliance

- AS9100 – Aerospace quality system (for select alloys)

- RoHS / REACH – Safe for export, free of hazardous substances

- Optional documents: MTC, mechanical tests, chemical analysis, export inspection

Optional Testing & Traceability Services

Upon request, Chalco offers value-added tests for enhanced product confidence:

- Laser dimensional reports

- Weld NDT (for seamed tubes in load-bearing use)

- Surface roughness & finish consistency

- Metallographic inspection (for high-end applications)

Need tubes that meet specific project standards? Contact us for certified samples, comparison charts, and detailed reports.

Instant QuotePopular Alloy Grades for Structural Aluminum Tubing

Chalco offers a wide range of structural aluminum tubes in 6000, 5000, and 7000 series alloys. Each grade has unique strength, corrosion resistance, weldability, and machinability—suitable for buildings, machinery, electronics, and new energy applications.

6061 Structural Aluminum Tubing

Temper: T6 / T651 / T4

Tensile Strength: 310 MPa | Yield Strength: 276 MPa

Balanced in strength and workability, ideal for load-bearing frames, EV structures, displays, and general equipment. Known as the go-to structural aluminum alloy.

6063 Architectural Aluminum Tubing

Temper: T5 / T6

Tensile Strength: 240 MPa

Excellent extrudability and weldability with a smooth finish. Perfect for windows, railings, curtain walls, and light-duty frames.

High-Strength Structural Aluminum Tubing Options

6082 Structural Aluminum Tubing (Medium to High Strength)

6082 Structural Aluminum Tubing (Medium to High Strength) Temper: T6

Tensile Strength: 330 MPa (higher than 6061)

Excellent structural stability. Ideal for large frames and heavy-load structures. Common in European-standard projects.

5052 Aluminum Tubing (Lightweight & Corrosion-Resistant)

5052 Aluminum Tubing (Lightweight & Corrosion-Resistant) Temper: H32 / H112 / O

Tensile Strength: 215 MPa

Good ductility and strong resistance to seawater and industrial corrosion. Best for humid, outdoor, or visually exposed environments. Used in light brackets, housings, and decorative structures.

5083 Aluminum Tubing (Heavy-Duty & Corrosion-Resistant)

5083 Aluminum Tubing (Heavy-Duty & Corrosion-Resistant) Temper: H111 / H112 / O

Tensile Strength: up to 290 MPa

Higher strength than 5052 and excellent salt spray resistance. Suitable for long-term outdoor use, such as ship pipelines, marine platforms, and heavy-duty frames.

7075 Aluminum Tubing (Aerospace & Ultra-High Strength)

7075 Aluminum Tubing (Aerospace & Ultra-High Strength) Temper: T6 / T651

Tensile Strength: up to 570 MPa | Yield Strength: 505 MPa

Offers outstanding strength and fatigue resistance. Lower corrosion resistance—recommended with anodizing or coating. Ideal for aerospace parts, protective structures, and military equipment frames.

2024 Aluminum Tubing (High Strength & Fatigue-Resistant)

2024 Aluminum Tubing (High Strength & Fatigue-Resistant) Temper: T3 / T4

Tensile Strength: 470 MPa

Combines strength and impact resistance. Less corrosion-resistant than 6000 series—requires anodizing or coating. Commonly used in transport frames, lightweight arms, and structural fasteners.

Not Sure Which Alloy to Choose?

| Alloy | Recommended processes | Typical uses |

| 6061-T6 | Seamless extrusion + anodizing | Building support, equipment frame, mechanical structure |

| 6063-T5 | Seamless extrusion + spraying | Door and window frame, display structure, advertising bracket |

| 5083-O/H112 | Seamless extrusion + anti-corrosion coating | Ship structure, outdoor support, corrosion-resistant equipment rack |

| 5052-H32 | Seamless extrusion + bending | Lighting bracket, traffic railing, lightweight support |

| 2024-T4 | Seamless cold drawing + precision machining | Aviation rack, load-bearing component, compact connection system |

| 7075-T6 | Seamless extrusion + surface strengthening | High-load structure, military bracket, drone frame |

Chalco can help you select the best structural aluminum tubing alloy and temper based on your project’s load, environment, and performance needs.

Instant QuoteStructural Aluminum Tubing Typical Applications & Industry Solutions

As industries pursue lightweight and efficient designs, Structural Aluminum Tubing plays a key role with its high strength-to-weight ratio, excellent corrosion resistance, and strong fabrication adaptability. Chalco offers versatile tubing solutions—covering various shapes, alloys, and processes—widely used in the following sectors:

Architectural Structures & Curtain Wall Systems

Applications: Curtain wall frames, sunroom beams, glass railing frames, scaffolding, canopies, adjustable supports

Recommended Alloys:

- 6061-T6 aluminum rectangular tube: Ideal for main frames in curtain walls and claddings

- 6063-T5/T6 aluminum rectangular beam: Great surface quality for door & window frameworks

- 6082-T6 aluminum scaffolding tubing: Handles high loads in facade and truss systems

- 5052-H32 structural aluminum tubing: Lightweight and corrosion-resistant for roof trusses and outdoor support

Industrial Equipment & Automation Structures

Applications: Conveyor supports, robotic arms, tooling fixtures, testing machine frames

Recommended Alloys:

- 6061-T6 machine frames: Common for tables and conveyor structures

- 6082-T6 rectangular tubing: Higher strength for robotic arms and automated frames

- 3003-H14 round tubing: For lightweight supports in flexible systems

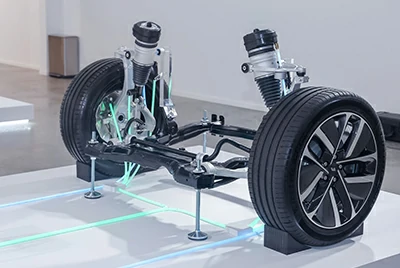

Automotive Manufacturing

Applications: Battery mounts, subframes, A/C housings, chassis connectors

Recommended Alloys:

- 6061-T6 square tubing: Balanced strength and cost, used in EV battery frames and roof beams

- 6082-T6 aluminum beam: Suitable for torque-intensive parts like subframes

- 7075-T6 aluminum tubing: For high-performance vehicles and race car frames

Renewable Energy & Solar Structures

Applications: PV mounting systems, inverter frames, wind turbine housings

Recommended Alloys:

- 6101-T6/T61 conductive bus pipe: Structural + conductive, ideal for power frames

- 6063-T5 hollow rectangular tube: Widely used in residential and commercial solar racking

Display & Modular Structures

Applications: Expo stands, stage lighting frames, backdrops, sign frames, mobile shelves

Recommended Alloys:

- 6063-T5 square tube for machine frames: Smooth surface for coatings or anodizing

- 3003-H14 modular frame: Mid-strength and cost-effective for non-load-bearing decorative structures

Marine & Shipbuilding Structures

Applications: Cabin frames, railings, external supports, port structures, docks, floating bridges

Recommended Alloys:

- 5083-H116 round tubing: Excellent saltwater resistance for marine applications

- 5052-H34 rectangular tube: Used in cabin interiors and structural connectors

Chalco provides high-performance aluminum tubing solutions tailored to your needs. Whether you need lightweight, corrosion-resistant, or easy-to-assemble materials, we offer custom alloy selection, precise dimensions, and fast delivery. Contact us now for tailored solutions and technical support!

Instant QuoteStructural Aluminum Tubing: Processes & Technical Advantages

The manufacturing method of aluminum tubing significantly affects its mechanical strength, surface finish, and stability. Chalco provides integrated production from extrusion to deep processing, offering full solutions for building frameworks, machinery structures, and clean energy systems.

Extrusion

The most common method, available as seamless or welded tubes.

Welded Tubing (Porthole Extrusion)

Welded Tubing (Porthole Extrusion) Made with porthole or bridge dies; ideal for 6061, 6063 alloys. Hollow structures are formed by internal mandrels and re-welding.

Cost-effective, efficient, and suitable for non-critical applications like curtain walls, displays, and decorative frames.

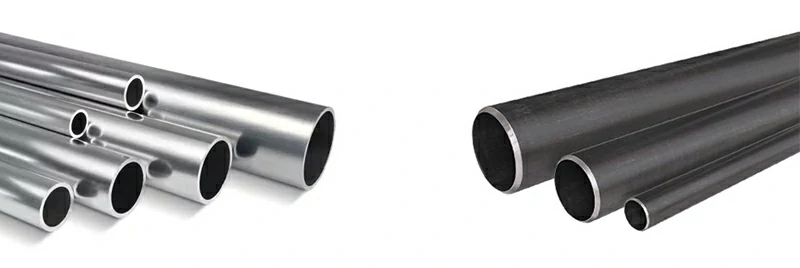

Seamless Tubing

Seamless Tubing Made by piercing solid billets. No welds = better uniformity.

Perfect for high-strength applications such as automation, aerospace, or precision frames. Common alloys include 6061-T6, 2024-T4, 7075-T6.

Cold Drawn Aluminum Tube

Used to improve precision and surface quality, especially for:

- Precision tubes

- Small-diameter tubing

- Rails, supports, lightweight machine structures

Benefits: ±0.05 mm tolerance, smooth finish, and improved strength via grain refinement during drawing.

Deep Processing (CNC, Welding, Bending)

Chalco offers cutting, drilling, welding, bending, anodizing, and electrophoretic coating services to ensure that aluminum tubing can be directly used in final structural systems, reducing on-site processing costs.

Chalco offers full machining services:

- Cutting: ±0.2 mm length tolerance

- Bending: U, S, spiral shapes

- End finishing: Chamfering, expanding, reducing

- CNC: Drilling, tapping, milling

- Welding: Flanges, joint assemblies

Surface Treatments

To enhance weather resistance, appearance, and adaptability across various applications, Chalco provides a range of surface treatment options for structural aluminum tubing.

- Anodizing: Boosts corrosion resistance and hardness—ideal for outdoor and curtain wall use

- Powder Coating: Adds color, texture, and extra protection

- Electrophoresis Coating: Decorative and corrosion-resistant, for premium applications

- Polishing & Brushing: Improves look—used in displays, exhibition frames, etc.

From extrusion to surface finish, Chalco offers complete one-stop aluminum tubing solutions. Submit your drawings today for expert support.

Instant QuoteHow does Structural Aluminum Tubing compare to steel?

| Aluminum tube | Steel pipes | |

| Weight | Light (about 1/3 of steel), easy to carry and install | Heavy, installation requires hoisting |

| Corrosion resistance | Natural oxide film protection, no need for additional galvanizing/painting | Rust-prone, requires galvanizing or spraying for protection |

| Strength | Medium to high strength, high strength/weight ratio | Higher absolute strength, suitable for extreme loads |

| Processability | Easy to extrude, cut, form, and weld | High strength but more difficult to process |

| Appearance | Smooth surface, can be anodized | Requires additional spraying to improve appearance |

| Cost | Slightly higher unit price, low overall installation and maintenance cost | Cheap material, but high maintenance cost |

If you prioritize lightweight, corrosion resistance, and easy installation, aluminum is a better fit—especially in architectural, transportation, and decorative frameworks.

Instant QuoteWhat's the difference between Structural Tubing, Tube, and Pipe?

| Structural Aluminum Tubing | Aluminum Tube | Aluminum Pipe | |

| Main purpose | Load-bearing structures, mechanical frames, building supports | General purpose structure, decoration, light load frame | Fluid/gas transportation, pressure-bearing system |

| Focus | Strength, dimensional tolerances, structural stability | Cost, appearance, processing flexibility | Inner diameter, pressure bearing capacity, sealing |

| Definition method | OD + wall thickness (precise tolerances) | Outer diameter + wall thickness (moderate tolerance) | Nominal diameter (NPS) + Schedule (wall thickness grade) |

| Standard specification | ASTM B429 / EN 755, etc. | ASTM B221 / B483, etc. | ASTM B241 / MIL-DTL-25995, etc. |

| Applicable areas | Buildings, equipment frames, brackets, solar systems, etc. | Furniture, radiators, fences, decoration | Chemical pipelines, HVAC, drainage systems, etc. |

They serve different needs. Choose based on application, load, and installation to balance performance and cost.

Instant QuoteFAQs

Should I choose seamless or welded tubing?

Depends on the use:

- For general frameworks (e.g., curtain walls): welded tubes are sufficient and cost-efficient

- For high-strength or dynamic loads (e.g., robots, aerospace): use seamless tubes for better durability

Chalco offers both types, tailored to your project.

Can aluminum tubing be welded?

Yes. We recommend 6061-T6, 6063-T5 with TIG/MIG welding. Use proper filler (e.g., ER4045) and shielding gas (argon). Preheating is advised to reduce defects.

How to cut, connect, and maintain aluminum tubing?

- Cutting: Use alloy saw blades, band saws with lubricant, or plasma. Deburr after cutting

- Connecting: Options include bolts, welding, inserts, or adhesives (e.g., WSD-9099 for metal-glass)

- Maintenance: Check for loose joints or corrosion. Clean with neutral cleaners, avoid harsh chemicals

Can structural aluminum tubing be bent?

Yes, depending on alloy and thickness:

- 6061-T6 aluminum tube: Needs annealing (T4/T0) before bending and post-treatment

- 6063, 5052 aluminum tube: Better for medium-radius cold bends

Use proper dies and bend radii to avoid cracks—especially with welded tubing.

Chalco offers custom precision bending on request.

Can I request samples or technical support?

Absolutely! Chalco provides:

- Free samples (standard sizes)

- Alloy & drawing consultations

- Material reports, RoHS, ISO, ASTM certifications

- One-on-one engineering support

Contact us today for quotes and expert assistance!

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote