Small aluminum tubing refers to high-precision aluminum tubes with an outer diameter typically ranging from 4.8mm to 20mm, widely used in automotive, electronics, medical, aerospace, and industrial control sectors. For micro-scale applications such as aluminum capillary tubes, customization is available with outer diameters as small as 1mm.

Chalco offers small diameter aluminum tubes across the 1000 to 7000 series aluminum alloys, featuring lightweight, easy formability, high precision, and excellent corrosion resistance. We support extrusion, cold drawing, anodizing, sealing, slotting, welding, and other processing methods to deliver one-stop solutions from raw materials to finished assemblies.

Instant QuoteCategories of Small Aluminum Tubing

Chalco provides a diverse range of small aluminum tubing products, which can be classified by alloy series, structural form, surface treatment, and functional applications, tailored to meet the needs of various industries:

Extruded for excellent straightness and stability, these tubes are used in mechanical support and structural connections, such as tent poles, folding chairs, trekking poles, fishing rods, and telescopic flagpoles.

Alloys: 6061, 6063, 7075, 3003

Drawn Precision Aluminum Tubes

Cold-drawn for superior dimensional consistency and finish, these tubes are ideal for medical devices, electronics, pneumatic components, and printer drums where high precision and cleanliness are essential.

Alloys: 6061-T6, 6063, 3003, 3103, 5083, 7075

Precision micro thin-walled tubes (OD ≥1mm, wall 0.25–0.5mm), ideal for subcutaneous injection needles, oxygen systems, electronic cooling, and precision instruments requiring tight tolerances and cleanliness.

Alloys: 1060, 1050, 1100, 3003, 3103

Supplied in coils (OD 5–16mm), ideal for HVAC, medical, and heat pump systems requiring flexible, long-distance routing. Coil form improves auto-feeding and tight-space installation over straight tubing.

With an outer diameter ≤ φ10mm and wall thickness as low as 0.25mm, these tubes offer excellent formability and lightweight benefits. They are widely used in medical catheters, electronics cooling channels, and instrument pipelines that require precision and tight bending radii.

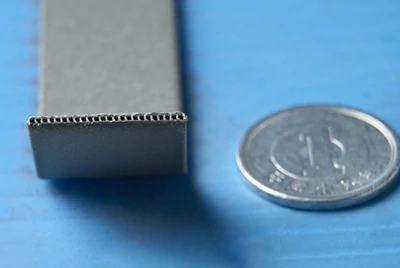

Made via ultra-precision extrusion, these tubes feature internal microchannels for enhanced heat transfer and strength—ideal for EV cooling and compact AC systems. Typically from 1000/3000 series with optional zinc or brazing flux coatings.

Surface-treated for improved corrosion resistance and appearance, these tubes are perfect for furniture accessories, trekking poles, and telescopic components that require durability and aesthetics. Available in multi-color anodizing, electrophoresis, powder coating, and polishing finishes.

Chalco provides customized small aluminum tubing solutions with diverse structures, alloys, finishes, and support for non-standard sizes, tempers, and packaging. From heat transfer to lightweight frames and precision assemblies, we deliver the ideal tubing for your application.

Contact us for tailored solutions and competitive pricing.

Instant QuoteSpecifications of Small Aluminum Tubing

| Outer Diameter | φ4.8 mm – φ20 mm |

| Wall Thickness | 0.25 mm – 0.5 mm |

| Length | 10 mm – 6000 mm |

| Alloy | 1060, 1100, 3003, 3103, 5052, 6061, 6063, 7001,7005,7075, etc. |

| Temper | O, H14, H18, H24, T5, T6, etc. |

| Supply Form | Straight strips and coils of fixed length |

Hot selling size of Small Aluminum Tubing

12mm Small aluminum tubing

13mm Small aluminum tubing

14mm Small aluminum tubing

15mm Small aluminum tubing

17mm Small aluminum tubing

20mm Small aluminum tubing

Interested in more size options for small aluminum tubes? Get in touch with us today.

Instant QuoteCore Advantages of Small Aluminum Tubing

- Lightweight Design:Aluminum weighs only one-third of copper or stainless steel, significantly reducing equipment weight—ideal for EVs, medical devices, and outdoor systems requiring lightweight materials.

- Excellent Corrosion Resistance:Its natural oxide layer, enhanced by anodizing or galvanizing, offers stability in humidity, salt mist, and mild corrosive environments—suitable for refrigerants, gases, and outdoor use.

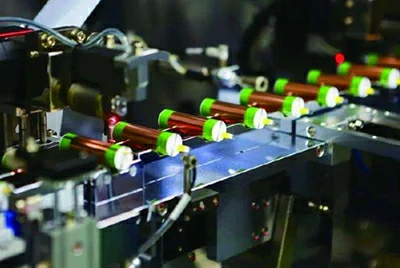

- Superior Processability:Aluminum’s ductility and weldability allow for bending, flanging, expanding, punching, and brazing. It supports integrated manufacturing and automated assembly line production.

- High Precision & Cleanliness:Cold drawing and extrusion ensure ±0.05mm tolerances with smooth surfaces. Clean packaging meets the standards of medical, lab, and sensor applications.

- Strong Compatibility & Flexible Supply:Available in straight tubes, coils, thin-walled, small-diameter, and custom shapes. Compatible with most connectors for easy integration and replacement.

- Eco-Friendly & Recyclable:100% recyclable with low carbon emissions. Complies with ESG, RoHS, and REACH standards globally.

Small diameter aluminum tubing delivers lightweight, cost-effective performance in heat exchangers, fluid control, and weight-sensitive applications.

Typical Application Fields of Small Aluminum Tubing

Due to its lightweight, excellent machinability, and heat transfer performance, small diameter aluminum tubing is widely used in various systems that require compact structures, high efficiency, and good formability. Below are typical industries and representative applications:

Automotive & New Energy Vehicles

Used in fuel, brake, coolant, and refrigerant lines, with focus on light weight, strength, and corrosion resistance.

Products: φ6–φ12 drawn precision tubes, pre-galvanized small aluminum tubes, liquid cooling capillary tubes

Alloys: 3003, 6061-T6, 7075-T73

HVAC & Appliances

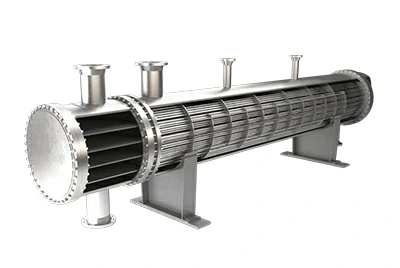

Used in condensers, evaporators, and cooling circuits, with excellent heat transfer, corrosion resistance, and formability.

Products: Small diameter coil tubing, micro-channel aluminum tubes, internally threaded capillary tubes

Alloys: 3003, 3103, 1060; anodized finish

Medical & Lab Equipment

Used in medical and lab equipment requiring cleanliness, precision, and smooth surfaces.

Products: Capillary tubes, thin-walled anodized aluminum tubes

Alloys: 1100, 3003, 6061; optional mirror polishing

Electronics & Thermal Management

Used in 5G, LED, and heat exchange systems requiring high thermal conductivity and workability.

Products: Anodized heat dissipation tubes, small diameter precision round tubes

Alloys: 6063-T5, 6061-T6

Outdoor & Consumer Products

Used in poles, chairs, and other lightweight structures requiring strength, bend resistance, and visual appeal.

Products: Colored anodized extruded tubes, thin-walled round tubes

Alloys: 6061, 7001, 7005, 6082

Manufacturing Capabilities & Surface Finishing Services

As a fully integrated aluminum manufacturer, Chalco provides end-to-end services—from aluminum ingot casting, extrusion, cold drawing, to custom machining and surface finishing—ensuring that our small diameter aluminum tubing meets structural, performance, and aesthetic requirements.

Precision Forming & Machining Capabilities

- Small Diameter Extrusion: Supports extruding tubes from φ5–φ20mm, with dies for round, oval, square, and multi-channel profiles.

- Cold Drawing Finishing: Improves dimensional accuracy and surface smoothness, ideal for precision-fit applications.

- Coiled Tubing & Straightness Control: Ensures consistent coiling and precise diameter/straightness for automated feed systems.

- End-forming Services: Includes flaring, punching, expanding, reducing, grooving, and sealing for easier integration.

Surface Finishing Options

- Anodizing: Enhances corrosion resistance and surface hardness, available in decorative colors (silver, black, champagne, red/blue, etc.), suitable for outdoor or electronic enclosures.

- Chemical Polishing / Electrophoretic Coating: Ideal for high-gloss and scratch-resistant applications like aesthetic medical devices and consumer parts.

- Sandblasting / Brushed / Mirror Finish: Meets industrial or visual design needs.

- Internal & External Zinc Coating: Provides added corrosion protection in humid, salty, or harsh environments.

With automated production, a strict quality system, and a wide range of mold resources, Chalco delivers efficient, consistent, and high-precision custom solutions for your small aluminum tubing projects.

Instant QuoteFAQs

What is the minimum outer diameter available for small aluminum tubes? What are the common uses?

Chalco can produce tubing as small as φ4.8mm, widely used in medical devices, microfluidics, and lab sampling. Even at small sizes, tubes maintain strong dimensional stability and mechanical strength, ideal for clean and space-limited setups.

How do you ensure precision and cleanliness in small aluminum tubes?

We use cold drawing + reshaping for dimensional control, achieving tolerances within ±0.05mm. Tubes are ultrasonically cleaned, degreased, and dried, then sealed, suitable for ventilators, electronics, and lab-grade equipment.

What secondary processing can be done? Will it crack?

We offer flaring, punching, end-sealing, expanding, reducing, and bending. Chalco tailors the heat treatment and forming method based on diameter, wall thickness, and alloy condition to prevent cracking from work hardening.

Which products are best for cooling or refrigerant systems?

We recommend small diameter coil tubing or micro-channel flat tubes in φ6–12mm, commonly used in HVAC, EV battery cooling, and liquid cooling loops. Options include internal threading, micro-grooves, and zinc coatings to boost heat transfer and corrosion resistance.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote