In silver brazing, besides selecting the appropriate silver solder (electrode, wire, ring), the flux is equally crucial. Flux effectively removes oxides from the metal surface, promotes solder wetting and flow, thereby ensuring the strength and density of the weld. Depending on different processes and application requirements, flux materials are mainly divided into two categories:

Description: It exists in powder, paste or liquid form, does not contain metal fillers, and needs to be used with silver solder or welding wire.

Applications: Suitable for industrial applications such as HVAC ducts, stainless steel parts, and carbide cutting tools.

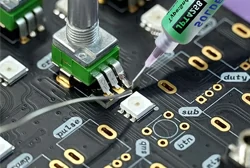

Description: It is made of silver alloy powder and flux premixed and is usually packaged in syringes or bottles.

Applications: It is easy to use and can be precisely applied. It is widely used for precision soldering of jewelry, electronic components and small parts.

As a full-system brazing flux supplier, Chalco provides a complete alloy range of brazing auxiliaries, covered within our broad brazing flux portfolio. In addition to silver solder flux and paste products, we also offer dedicated aluminum brazing flux solutions to support different alloys and processing conditions. If you need guidance on choosing the right flux system, our team is ready to assist.

Silver Solder Flux

Silver solder flux is an essential auxiliary material in the silver soldering process. It is commonly available in powder, paste, or liquid form and must be used in conjunction with silver solder rods, solder wires, or solder rings.

Common types of Silver Solder Flux:

- White Flux (General Purpose White Paste): Activation temperature range 500–800 ℃, easy to clean residue, suitable for general welding needs such as HVAC copper pipes and stainless steel valves, corresponding to StaySilv White Brazing Flux.

- Black Flux (High Temperature Black Paste): Activation temperature range up to 850–900 ℃, suitable for welding stainless steel, cemented carbide and high nickel alloys, corresponding to black flux for silver brazing.

Silver Solder Flux Industry Compatibility Overview

- HVAC & Refrigeration

- Industrial Piping

- Tool Manufacturing

- Stainless & Nickel Parts

- Aerospace & Heavy Industry

- MRO / Repair

Silver Solder Flux Technology Highlights

- Wide temperature range: The general-purpose type covers 500–700 ℃, and the high-temperature type can reach above 850 ℃, meeting the welding needs from copper pipes to stainless steel and hard alloys.

- Compatible with a variety of materials: copper and copper alloys, stainless steel, nickel alloys, hard alloys, etc.

- Good cleaning properties: The residue is soluble in hot water, making it easy to clean and treat the surface.

- Process compatibility: Applicable to common processes such as flame, induction, and in-furnace heating.

- Standardized quality: Performance meets AWS A5.31 / ISO 9454 requirements and is comparable to mainstream international systems such as Easy-Flo®, Stay-Silv®, and Comweld.

Silver Solder Flux Product Types

-

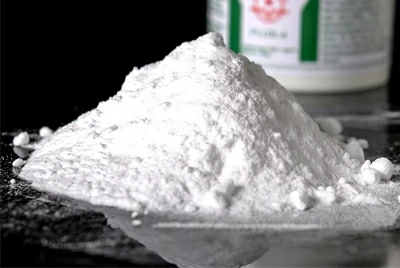

Flux Powder

Description: Suitable for furnace brazing or mass production of workpieces.

Usage: It can be mixed with water to form a paste for application.

-

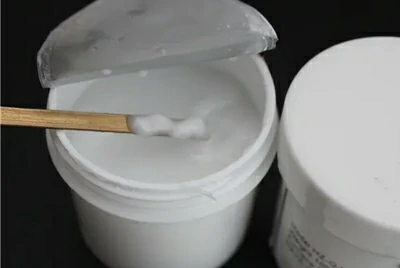

Flux Paste

Description: Facilitates uniform coating and reduces powder loss.

Applications: Commonly used in flame brazing and induction brazing.

-

Liquid Flux

Description: Can be directly dipped or sprayed as needed.

Applications: Suitable for assembly line operations and continuous brazing processes.

-

Description: Welding rods are pre-coated with flux for convenience.

Applications: Ideal for on-site installation, maintenance and manual flame brazing.

Silver Solder Paste

Silver solder paste is a paste-like material premixed with silver alloy powder and flux. It contains both filler metal and oxide film remover, enabling brazing in a single operation. Common packaging forms are syringes or bottles, facilitating application and precise dosage control, making it ideal for small-part processes and precision assembly.

Silver Solder Paste Industry Compatibility Overview

- Jewelry

- Electronics

- Stainless & Nickel

- Repair / DIY

- Medical

- Optical / Instruments

Silver Solder Paste Technical Highlights

- Alloy and flux integrated, simplifying the process.

- Syringe application allows for precise operation and reduces waste.

- The weld seam is smooth and dense, which facilitates subsequent polishing or electroplating.

- Stable formula ensures consistent solder joint quality.

- Diverse packaging options to meet different needs

Silver Solder Paste Product Types

-

Low Temp Silver Solder Paste

Suitable for heat-sensitive components such as jewelry repair and electronic devices.

-

High Temp Silver Solder Paste

Suitable for high-strength workpieces such as stainless steel and cemented carbide.

-

Hard Silver Solder Paste

For stainless steel, high-nickel alloys and wear-resistant tools, providing strong bonding and high heat resistance.

-

Tin Silver Solder Paste

Tin-silver alloy base, with good wettability and conductivity, used in electronics, precision parts and low-temp soldering.

-

Sterling Silver Solder Paste

Special for jewelry and sterling silver, bright solder joints with minimal discoloration.

-

General-Purpose Silver Solder Paste

Easy to use and adaptable to a wide range of base materials.

Technical Specifications of Chalco silver solder flux & paste

Our silver soldering flux and silver soldering paste undergo rigorous process design and quality testing, and possess the following technical parameters:

Operating temperature range: 500–925 ℃, meeting the needs from low-temperature jewelry repair to high-temperature stainless steel and hard alloy welding.

Compatible base materials: copper and copper alloys, stainless steel, nickel alloys, cemented carbide (not recommended for aluminum, magnesium, and titanium).

Compliance Standards: Complies with AWS A5.31 / ISO 9454 flux classification standards. The silver solder paste corresponds to common silver-based solder standards AWS A5.8 / ISO 17672 (such as BAg-7 / Ag156).

Residue handling: White general-purpose residue can be cleaned directly with hot water. High-temperature residue has strong temperature resistance, so it is recommended to remove it promptly after welding to avoid corrosion.

Process compatibility: Applicable to various welding methods such as flame, induction, and furnace heating.

Environmental protection and safety: Low halogen, low smoke, RoHS and REACH compliant, suitable for environmentally sensitive applications.

Chalco silver solder flux & paste Supply capability

Chalco not only offers standardized products, but also provides flexible customization to meet customer needs:

-

Packaging Specifications

Flux powder/paste: 50 g, 250 g, 500 g bottles

Silver solder paste: 10 g / 30 g syringe packaging, 100 g / 250 g bottle packaging

Liquid flux: 250 ml, 500 ml, 1 L

-

OEM & Customization

Custom options: Adjustable viscosity, operating temperature range, and silver powder content.

We offer customized formulas to meet specific process requirements.

-

Delivery Advantages

Supply: Sufficient stock available, fast shipping supported.

Samples: Free samples are available for testing.

We can flexibly support both small-batch trial orders and large-batch supply.

Flux vs Paste Comparison & Selection Guide

| Project | Silver Solder Flux | Silver Solder Paste |

| Composition | pure flux | Silver powder + flux (premixed) |

| Form | Powder/Paste/Liquid/Coated Welding Electrodes | syringes/bottles |

| How to use | It requires the use of silver solder rods, solder wires, and solder rings. | It can be used alone and completes welding in one operation. |

| Suitable industries | HVAC, industrial piping, tool manufacturing, stainless steel and heavy industry | Jewelry, electronic components, small stainless steel parts, repair and DIY |

| Main advantages | Wide temperature range coverage, strong adaptability, and easy residue cleaning | Easy to operate, aesthetically pleasing welds, precise application, and reduced waste. |

FAQ (Frequently Asked Questions)

Q1: Is flux always necessary for silver brazing?

A: Yes. Flux removes the oxide layer on the surface of the base metal, ensuring good wetting of the solder. Otherwise, slag inclusions or incomplete welds are likely to occur.

Q2: What is the difference between Silver Solder Flux and Silver Solder Paste?

A: Flux is a simple flux and needs to be used with soldering rods/wires; Paste is a premix of silver powder and flux, which can be used directly for soldering.

Q3: How to choose between low-temperature and high-temperature products?

A: Low-temperature products are recommended for heat-sensitive components (jewelry, electronic devices); high-temperature products are recommended for high-strength base materials such as stainless steel and hard alloys.

Q4: Does the welding residue need to be cleaned?

A: Cleaning is recommended. White, general-purpose residue can be dissolved directly in hot water. High-temperature residue is more heat-resistant and needs to be cleaned promptly after welding to prevent corrosion.

* Chalco has a complete silver soldering material supply chain, providing both standardized products and customized solutions for customers.

Contact us now to get a silver soldering flux and solder paste solution tailored to your process.

Free sample request; supports small-batch testing and large-volume orders.

24-hour quotes, quick response to your procurement needs

Let Chalco provide stronger and more reliable support for your welding processes.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote