Chalco – high quality aluminum pneumatic cylinder tube supplier

Chalco specializes in producing 6063 T5 T6 T832, 6061 T6511 aluminum alloy tubular profiles for pneumatic cylinders, with the advantage of high strength, light weight, accurate and complete dimensions. Anodized surface enhances its wear and corrosion resistance.

- Various standard sizes cylinder tube in stock, hundreds of available standard molds, one-stop comprehensive customized processing;

- Comply with standards such as ISO 6430, ISO 6431, VDMA 24562, ISO 15552, etc.;

- Service enterprises include SMC, FESTO, Airtac, Chelsea, etc.

Specification of Chalco aluminum pneumatic cylinder tube

Alloy: 6063 6061 T5 T6 T6511 T832

Profile shape: Aluminum alloy round tube Aluminum alloy square tube Mickey mouse tube, Aluminum rectangular tube,

Aluminum piston rodTube Length: 1000mm-3000mm

ID accuracy: H9-H11

Processing technology: forging, extrusion, stretching, cutting, drilling, welding or polishing

Tolerance: Click to check [Aluminum Alloy Cylinder Tube Tolerance Table]

Size reference table of Chalco aluminum pneumatic cylinder tube

| Outer diameter of aluminum round tube Φ(mm) | 8, 10, 12, 15, 16, 20, 22, 25, 28, 45, 50, 50.8, 60, 70, 80, 100, 101.1, 150, 177.8, 200, 250, 300, 400, 500, 573, 600, etc. |

| Diameter of mickey mouse cylinder tube Φ(mm) | 32, 40, 50, 63, 80, 100, 125, 160, 200 |

| Dimensions of aluminum square tube (mm) | 8*8, 12*12, 14*14, 20*20, 25*25, 30*30, 50*50, 101.6*101.6, 203.2*203.2, 228*228, 250*250, 350*350 etc. |

| Dimensions of aluminum alloy rectangular tubes (mm) | 18*12, 30*20, 40*20, 40*30, 60*30, 60*40, 70*40, 50*25, 60*40, 50*30, 80*50, 100*50, 100*240, 101.6*203.2, 150*250, 200*300, etc. |

| Cylinder diameter of Piston rod Φ(mm) | 6, 8, 10, 12, 16, 20, 25, 32, 40, 45, 50, 60, 70 etc. |

In addition to the above general sales of pneumatic cylinder aluminum tubes, Chalco also has some other types of aluminum tubes.

If you have the cylinder project and need aluminum tubes, please do not hesitate to contact us. We will try our best to help you.

Instant QuoteChalco hot selling aluminum alloy cylinder tube products

Chalco provides aluminum alloy cylinder tubes that can be used for machining standard cylinders, double acting cylinders, single acting cylinders, Mickey Mouse cylinders, compact cylinders, mini cylinders, guide rod cylinders, double rod cylinders, and more.

More aluminum alloy tubes for cylinder can be customized by contacting us.

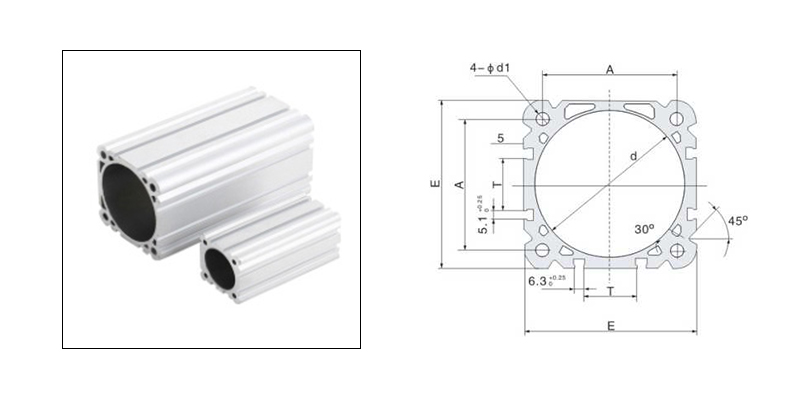

DNC square cylinder tube

| d | E | A | T | 4 – Φd1 |

| Φ32 | 44x44 | 32.5x32.5 | 8.2 | Φ5.1 |

| Φ40 | 51x51 | 38x38 | 11 | Φ5.1 |

| Φ50 | 64x64 | 46.5x46.5 | 17 | Φ6.7 |

| Φ63 | 75x75 | 56.5x56.5 | 26 | Φ6.7 |

| Φ80 | 93x93 | 72x72 | 28 | Φ8.7 |

| Φ100 | 111x111 | 89x89 | 35 | Φ8.7 |

| Φ125 | 134x134 | 110x110 | 55 | Φ10.3 |

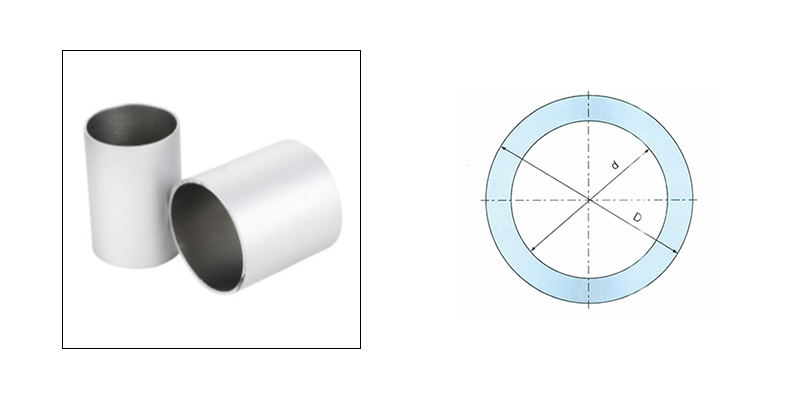

SC round cylinder tube

| Bore (d) | Outer (D) | Thickness | Bore (d) | Outer (D) | Thickness |

| Φ16 | Φ20 | 2 | Φ70 | Φ75 | 2.5 |

| Φ20 | Φ25 | 2.5 | Φ80 | Φ86 | 3 |

| Φ25 | Φ29 | 2 | Φ100 | Φ104 | 2 |

| Φ32 | Φ37 | 2.5 | Φ100 | Φ106 | 3 |

| Φ40 | Φ44 | 2 | Φ125 | Φ133 | 4 |

| Φ45 | Φ50 | 2.5 | Φ140 | Φ150 | 5 |

| Φ48 | Φ60 | 6 | Φ150 | Φ160 | 5 |

| Φ49 | Φ76 | 13.5 | Φ160 | Φ170 | 5 |

| Φ50 | Φ54 | 2 | Φ180 | Φ190 | 5 |

| Φ55 | Φ60.5 | 2.75 | Φ200 | Φ210 | 5 |

| Φ63 | Φ68 | 2.5 | Φ250 | Φ262 | 6 |

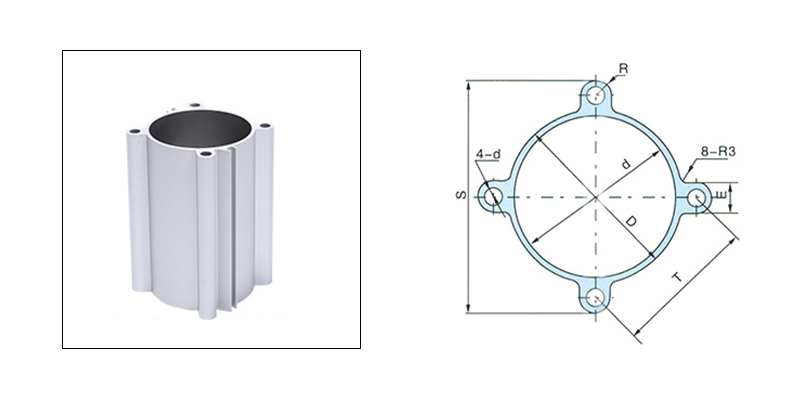

SI mickey mouse cylinder tube

| d | D | T | S | E | 4-d |

| Φ32 | Φ32 | 32.5x32.5 | 55.3x55.3 | 10 | Φ5.2 |

| Φ40 | Φ44.5 | 38x38 | 65x65 | 10 | Φ5.2 |

| Φ50 | Φ55.3 | 46.5x46.5 | 81.8x81.8 | 12 | Φ7.4 |

| Φ63 | Φ68 | 56.5x56.5 | 93.5x93.5 | 12 | Φ6.8 |

| Φ80 | Φ85.8 | 72x72 | 117x117 | 14 | Φ8.7 |

| Φ100 | Φ106 | 89x89 | 145x145 | 15 | Φ8.7 |

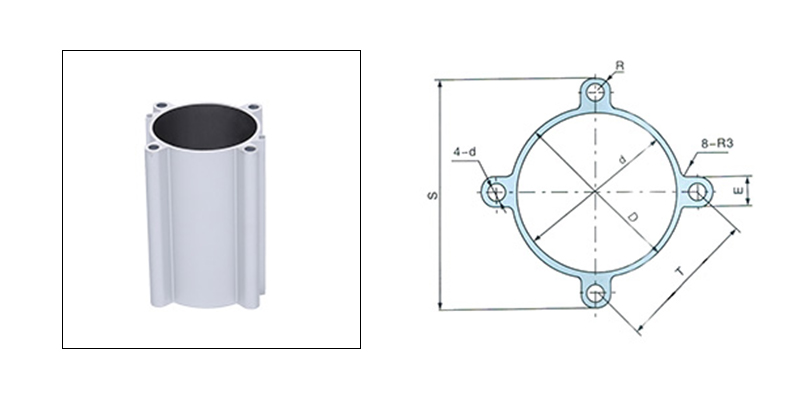

SU mickey mouse cylinder tube

| d | D | T | S | E | 4-d |

| Φ32 | Φ36.5 | 33x33 | 55.3x55.3 | 10 | Φ5.2 |

| Φ40 | Φ44.5 | 37x37 | 65x65 | 10 | Φ5.2 |

| Φ50 | Φ55.3 | 47x47 | 81.8x81.8 | 12 | Φ5.2 |

| Φ63 | Φ68 | 56x56 | 93.5x93.5 | 12 | Φ6.8 |

| Φ80 | Φ85.8 | 70x70 | 117x117 | 14 | Φ8.7 |

| Φ100 | Φ106 | 84x84 | 145x145 | 15 | Φ8.7 |

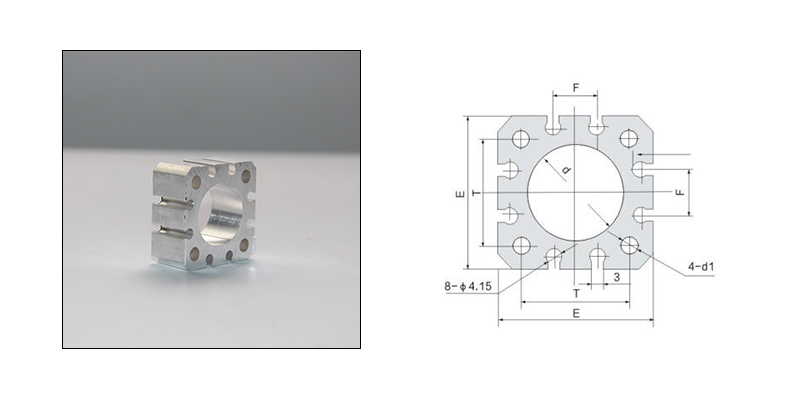

Compact cylinder

| d | 4-d1 | E | T | F |

| Φ12 | 3.6 | 25 | 15.5 | - |

| Φ16 | 3.6 | 29 | 20 | 7 |

| Φ20 | 5.5 | 36 | 25.5 | 11 |

| Φ25 | 5.6 | 40 | 28 | 11 |

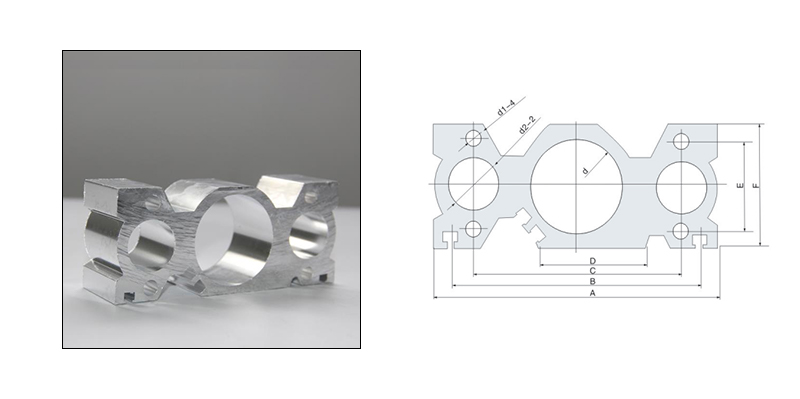

Guide rod cylinder tube

| d | d2-2 | A | B | C | D | E |

| Φ12 | Φ9.4 | 58 | - | 40 | 12.4 | 18 |

| Φ16 | Φ11.5 | 64 | - | 42 | 11.6 | 22 |

| Φ20 | Φ13 | 74 | - | 52 | 18.6 | 26 |

| Φ25 | Φ17.5 | 88 | - | 62 | 19.1 | 32 |

| Φ32 | Φ20 | 114 | 98 | 80 | 33.1 | 38 |

| Φ40 | Φ20 | 124 | 108 | 90 | 46 | 38 |

| Φ50 | Φ27 | 140 | 124 | 100 | 58 | 44 |

| Φ63 | Φ27 | 150 | 134 | 110 | 65.8 | 44 |

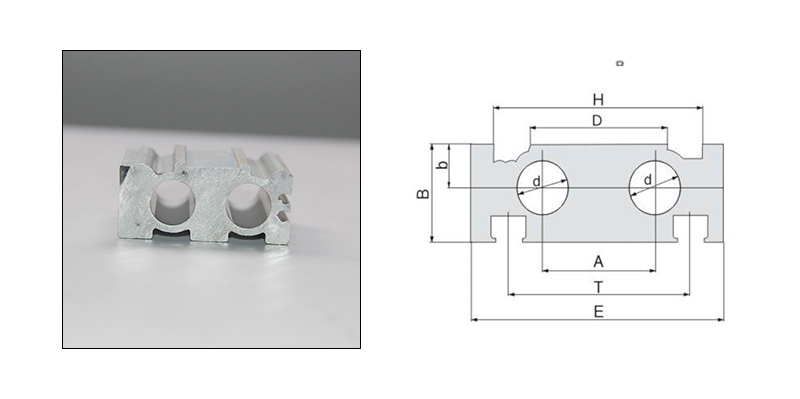

Dual rod air cylinder aluminum tube

| d | E | A | T | B | b | D | H |

| Φ10 | 46 | 20 | 33.8 | 17 | 7.1 | 25.8 | 38 |

| Φ15 | 58 | 25 | 41.2 | 20 | 10 | 33.4 | - |

| Φ20 | 64 | 28 | 53 | 25 | 12.5 | 37.5 | 52.5 |

| Φ25 | 80 | 35 | 64 | 30 | 15 | 45.5 | 67 |

| Φ32 | 98 | 48 | 76 | 38 | 19 |

For more pneumatic cylinder tube sizes and product types, you may click the detailed [Cylinder Tube Dimension Table] or contact us for assistance.

Advantages of Chalco pneumatic cylinder tube

- Low friction for reduced seal wear, so you won't have to worry about replacements.

- Designed to withstand the most caustic of environments, so you can use them just about anywhere.

- Combats denting with impingement resistance, so they'll last longer and save you money.

- Non-conductive, meaning they are the safer option.

Manufacturing Capabilities of Chalco Aluminum Pneumatic Cylinder Tubes

With decades of aluminum extrusion and precision machining experience, Chalco provides complete in-house manufacturing capabilities for pneumatic cylinder tubes, ensuring stable quality, fast delivery and consistent performance for medium to large-volume actuator manufacturers.

- Extrusion capability: Round, square, rectangular and Mickey Mouse profiles; outer diameter up to Φ600 mm.

- Mold capability: Hundreds of existing dies; rapid development for customized cylinder profiles with short lead time.

- Machining capability: CNC cutting, drilling, slotting, milling, grooving, welding, polishing and deep machining.

- Precision control: Straightness ≤0.1 mm/m; concentricity ≤0.05 mm; dimensional consistency for automatic assembly.

- Surface treatment: Standard anodizing, hard anodizing, micro-arc oxidation, custom colors available.

- Length capability: Standard 1000–3000 mm; long-length customization available upon request.

- Production capacity: Industrial-scale extrusion and finishing lines supporting stable batch supply for OEM actuator plants.

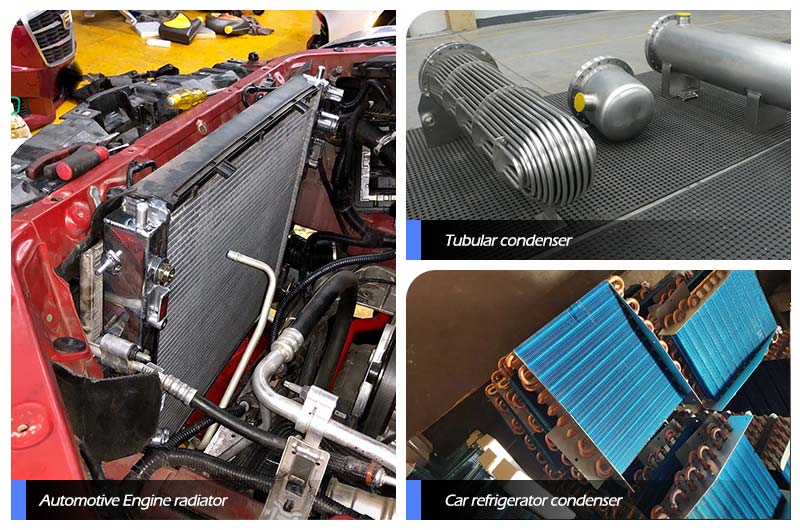

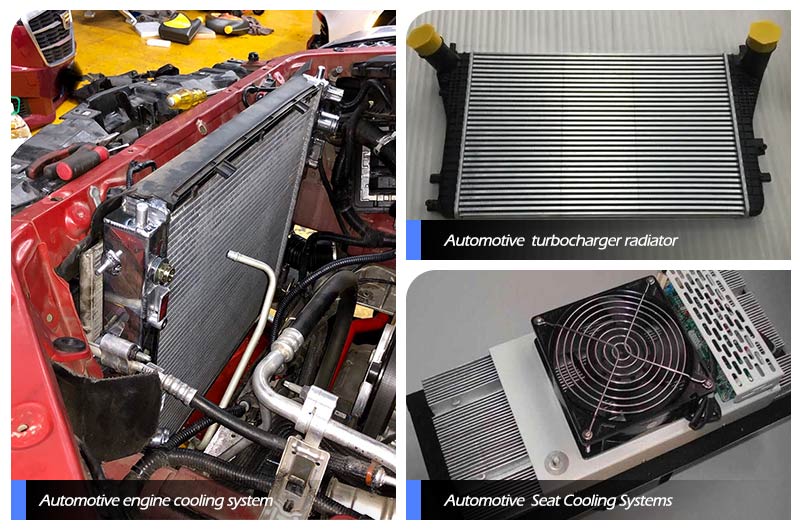

Chalco other tube extrusion profile products

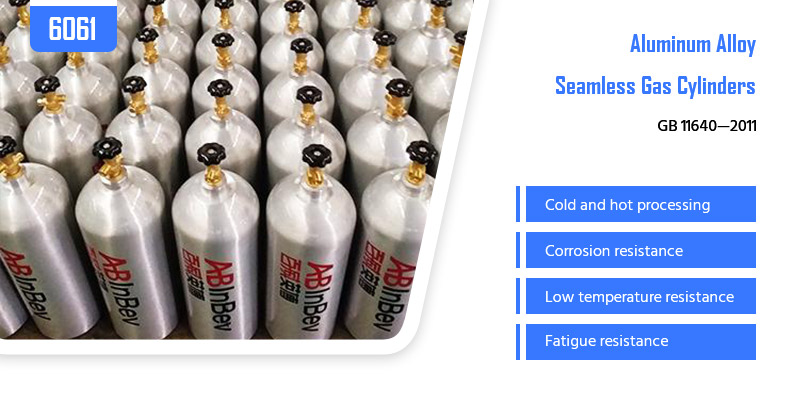

Tubes for Gas Cylinders and Fire Extinguishers

Tubes for Pressure Vessel

Finned Tubes for Heat Exchangers

Clad Aluminium HF Welded Tubes

Micro-channel Aluminum Flat Tubes

Tubular buspipe

Quality & Inspection of Chalco Aluminum Pneumatic Cylinder Tubes

To ensure reliable performance in pneumatic systems, Chalco implements strict quality control from billet casting to finished cylinder tubes. Each batch is tested for chemical composition, mechanical properties, dimensional accuracy and surface quality.

- Chemical composition analysis: Spectrometer testing to ensure 6063 / 6061 alloys meet international standards.

- Mechanical properties: Tensile strength, yield strength and elongation tested according to EN / ASTM standards.

- Dimensional inspection: ID, OD, wall thickness and length fully checked; bore tolerance controlled within H9–H11.

- Straightness & concentricity: Straightness and run-out inspection to guarantee smooth piston movement and sealing performance.

- Surface quality: Anodizing thickness, hardness and roughness (Ra) checked to ensure wear and corrosion resistance.

- Leakage & pressure resistance (if required): Sample pieces can be tested under working pressure to verify safety margin.

- Traceability: Each batch is labeled with alloy, temper, production date and inspection records for full traceability.

Application Fields of Chalco Aluminum Pneumatic Cylinder Tubes

Automation & Assembly Equipment: Widely used in automated production lines, pick-and-place units, conveying systems, indexing tables, robot grippers and general pneumatic actuators.

Packaging Machinery: Applied in sealing machines, labeling machines, filling systems, carton forming, and other high-speed packaging lines requiring lightweight, corrosion-resistant cylinder components.

Machine Tools & Industrial Equipment: Suitable for clamping, positioning, feeding and auxiliary motion control in CNC machines, metal processing equipment and precision manufacturing modules.

Transportation & Logistics Systems: Used in sorting machines, shuttle conveyors, palletizers, AGV/AMR lifting modules and other automated logistics equipment.

Medical & Food-grade Automation: Aluminum cylinder tubes are corrosion-resistant, clean and lightweight, making them ideal for pharmaceutical automation, laboratory equipment, food processing and beverage machinery.

Other pneumatic applications: Textile machinery, printing equipment, HVAC control systems, woodworking equipment and customized pneumatic motion platforms.

Instant QuoteChemical component of Chalco aluminum pneumatic cylinder tube

| Element | 6063 | 6061 | ||

| Min. | Max. | Min. | Max. | |

| Si | 0.2 | 0.6 | 0.40 | 0.8 |

| Fe | - | 0.35 | - | 0.7 |

| Mn | - | 0.9 | - | 0.15 |

| Mg | - | 0.1 | 0.8 | 1.2 |

| Cr | - | 0.1 | 0.04 | 0.35 |

| Zn | - | 0.1 | - | 0.25 |

| Ti | - | 0.05 | - | 0.15 |

| Others each | - | 0.15 | - | 0.05 |

| Other total | - | - | - | 0.15 |

| Al | Rest | Rest | ||

Tolerance of Chalco aluminum pneumatic cylinder tube

| Grade of tolerance Dia mm Φ | H | |||

| H7 | H8 | H9 | H10 | |

| 3mm |

+0.010 0 |

+0.014 0 |

+0.025 0 |

+0.040 0 |

| 3mm-6mm |

+0.012 0 |

+0.018 0 |

+0.030 0 |

+0.048 0 |

| 6mm-10mm |

+0.015 0 |

+0.022 0 |

+0.036 0 |

+0.058 0 |

| 10mm-18mm |

+0.018 0 |

+0.027 0 |

+0.043 0 |

+0.070 0 |

| 18mm-30mm |

+0.021 0 |

+0.033 0 |

+0.052 0 |

+0.084 0 |

| 30mm-50mm |

+0.025 0 |

+0.039 0 |

+0.062 0 |

+0.100 0 |

| 50mm-80mm |

+0.030 0 |

+0.046 0 |

+0.074 0 |

+0.120 0 |

| 80mm-120mm |

+0.035 0 |

+0.054 0 |

+0.087 0 |

+0.140 0 |

| 120mm-180mm |

+0.040 0 |

+0.063 0 |

+0.100 0 |

+0.160 0 |

| 180mm-250mm |

+0.046 0 |

+0.072 0 |

+0.115 0 |

+0.185 0 |

| 250mm-315mm |

+0.052 0 |

+0.081 0 |

+0.130 0 |

+0.210 0 |

| 315mm-400mm |

+0.057 0 |

+0.089 0 |

+0.140 0 |

+0.230 0 |

| 400mm-500mm |

+0.063 0 |

+0.097 0 |

+0.155 0 |

+0.250 0 |

FAQ of Aluminum Pneumatic Cylinder Tubes

1. What alloys are commonly used for pneumatic cylinder tubes?

Chalco mainly uses 6063 T5/T6/T832 and 6061 T6/T6511 aluminum alloys, which offer excellent strength, machinability and anodizing performance.

2. Can you produce customized cylinder tube profiles?

Yes. Besides standard round, square and Mickey Mouse profiles, we can customize special shapes according to your drawings or samples, with fast mold development.

3. What is the dimensional tolerance for ID and OD?

ID tolerance is controlled within H9–H11; OD and wall thickness follow ISO/VDMA or customer-specific tolerance requirements.

4. Do you provide anodizing or hard anodizing?

Yes. Standard clear anodizing, hard anodizing, micro-arc oxidation and custom color anodizing are available depending on your application.

5. What is your typical production length?

Standard length ranges from 1000 mm to 3000 mm. Custom long or short lengths can be provided on request.

6. What is the MOQ for pneumatic cylinder tubes?

For standard sizes, MOQ is low and some specifications are available in stock. Customized profiles require mold opening and minimum order quantities.

7. Can you assist with machining operations?

Yes. We offer CNC cutting, drilling, slotting, grooving, welding and other deep machining services for semi-finished cylinder components.

8. How do you ensure quality consistency?

Each batch undergoes chemical composition analysis, dimensional inspection, straightness and concentricity checks, anodizing thickness testing, and full traceability records.

9. What is the typical lead time?

Standard sizes are usually shipped within 7–10 days. Custom extrusions or special machining orders require 15–30 days depending on complexity.

10. Can you provide samples for testing?

Yes. Small cut samples or short tubes can be supplied for fit and performance testing before mass production.

If you have a pneumatic cylinder project or need support selecting suitable tube specifications, please feel free to contact us.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote