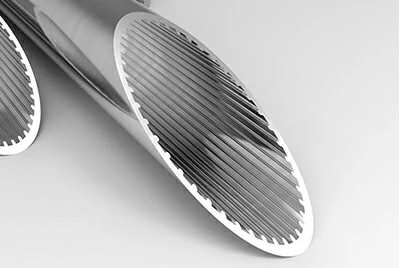

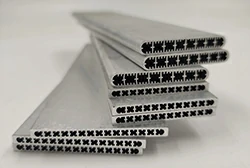

Also known as internal toothed tube, the aluminum inner grooved tube features straight or spiral grooves on the inner wall to enhance heat transfer. It is widely used in air conditioners, heat pumps, refrigerators, and automotive cooling systems.

Compared to smooth tubes, inner grooved tubes offer higher heat exchange efficiency and enable more compact system designs. As a lightweight alternative to copper, aluminum offers lower cost, easier processing, and good strength, weldability, and corrosion resistance—making it an ideal choice for modern cooling and thermal systems.

Instant QuoteChalco specializes in aluminum heat transfer solutions, providing full services from alloy composition, groove design, to zinc coating and anti-corrosion treatments, helping customers build efficient and sustainable thermal systems.

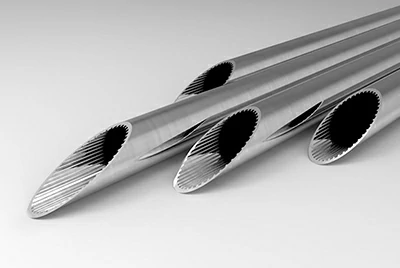

Types of Inner Grooved Aluminum Tubes

Straight Groove Tubes

Feature regular internal grooves with high processing efficiency. Suitable for high fin-density condensers and evaporators. They ensure good formability, stable heat transfer, and cost-effectiveness.

Contact us now

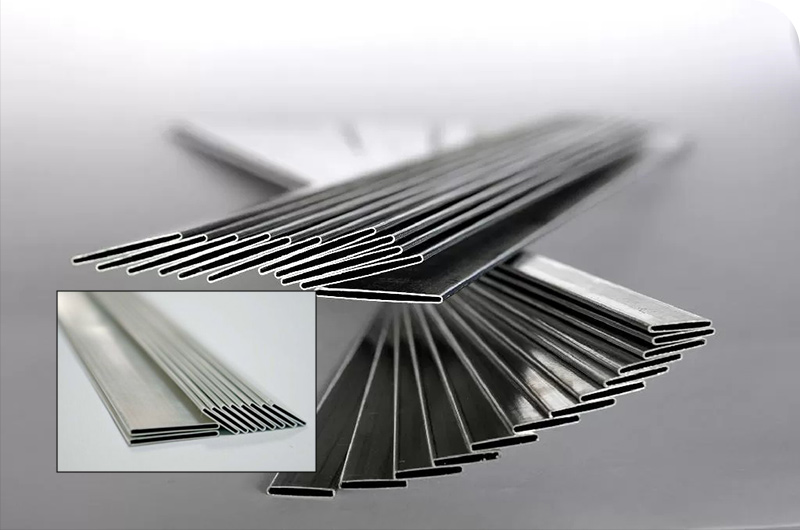

Spiral Groove Tubes

The spiral grooves create stronger fluid turbulence, significantly improving the internal heat transfer coefficient. They typically deliver 1.5–2× higher performance than smooth tubes and are ideal for energy-saving heat pumps and compact condensers.

Contact us nowGroove designs can also be customized based on refrigerant type and application conditions to achieve better system efficiency and reduce refrigerant consumption.

Instant QuoteSpecifications of Inner Grooved Tube

| Alloy | 1060/3003/3103/3003N |

| Outer diameter | 6.15-16mm(5.0,7.0,7.94,9.52,12.7mm) |

| Wall thickness | 0.4-2mm |

| Groove height | 0.05-0.33mm |

| Number of teeth | 38-60 |

| Helix angle | 5-27° |

| Tooth top angle | 30°-135° |

| Supply method | Coiled/straight tube |

| Standard | ASTM B483, ASTM B210, ASTM B221, EN 754-7, EN 1396 |

For humid or high-corrosion environments, Chalco offers zinc coating solutions to greatly enhance corrosion resistance and extend service life in marine or industrial salt spray conditions.

Instant QuoteAdvantages of Aluminum Inner Grooved Tube

The aluminum inner grooved tube offers both design and manufacturing efficiency, along with material benefits that make it ideal for modern high-performance heat exchange systems:

- High Heat Transfer Efficiency: Precision grooves (tooth height 0.05–0.33 mm) on the inner wall increase surface area and fluid turbulence, delivering much better thermal performance than smooth tubes.

- Lightweight & Energy-Saving: Aluminum weighs about 1/3 of copper, reducing system weight—ideal for EVs, home appliances, and AC compressors.

- Lower Cost: Aluminum offers 40%–60% lower cost compared to copper, thanks to cheaper raw materials and easier processing.

- Excellent Formability: High ductility allows for flaring, bending, punching, and precision cutting, supporting automated assembly.

- Strong Corrosion Resistance: With a natural oxide layer plus anodizing or zinc coating, aluminum performs well in humid, salt-spray, and mild chemical environments.

- High Precision & Surface Quality: Advanced cold drawing and finishing ensure groove consistency, clean surfaces, and good weldability.

- Eco-Friendly & Recyclable: Aluminum is 100% recyclable, aligning with sustainability and green supply chain policies.

Compared to copper, aluminum inner grooved tubes not only improve system efficiency but also offer a more cost-effective, lightweight, and scalable solution.

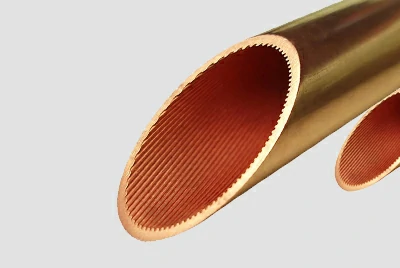

Aluminum vs. Copper Inner Grooved Tubes

| Category | Aluminum Inner Grooved Tubes | Copper Inner Grooved Tubes |

| Thermal Conductivity | ~237 W/m·K; optimized groove design narrows the gap with copper in most scenarios | ~398 W/m·K; better for extreme heat transfer needs |

| Material Cost | Lower and more stable; overall cost reduced by 40–60% | High and volatile material cost |

| Weight | 1/3 the weight of copper; ideal for lightweight systems | Heavy; adds load, unsuitable for mobile or wall-mounted systems |

| Processing Efficiency | Easy to form, bend, and automate | Harder to process; needs specialized equipment |

| Corrosion Resistance | Good with anodizing or zinc coating; durable in industrial/civil settings | Naturally strong corrosion resistance; suitable for extreme environments |

While copper tubes are still used in extreme conditions, aluminum inner grooved tubes have become the mainstream choice for most heat transfer systems due to their balanced performance, cost efficiency, and lightweight advantage.

Typical Applications of Aluminum Inner Grooved Tube

HVAC Systems

Aluminum inner grooved tubes are widely used in air conditioners and heat pump systems. Their light weight reduces equipment load and refrigerant volume. The grooved design also improves energy efficiency, offering a cost-effective alternative to copper tubes.

Home Appliances & Heat Pumps

Used in heat pump water heaters, refrigerators, and freezers, aluminum grooved tubes fit compact layouts due to their small diameter and high formability. They support anodizing and zinc coating for humid and corrosive environments.

New Energy Vehicle Thermal Systems

Aluminum inner grooved tubes are ideal for battery, motor, and vehicle A/C cooling. They offer lightweight design, efficient heat transfer, and support custom welding and shaping, making them perfect for EV thermal management.

Industrial Cooling & Energy Storage

Used in condensers and cooling modules, aluminum tubes provide stable heat conductivity and corrosion resistance. Optional zinc-coated grooves ensure long-term performance in high humidity and salt-spray environments.

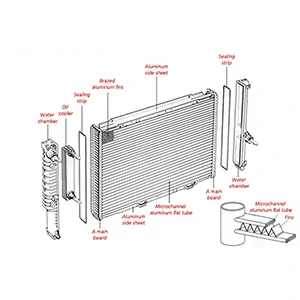

Aluminum Solutions from Chalco for Thermal Management

Aluminum Heat Transfer Solutions

Chalco offers brazing clad materials, HFW tubes, header tubes, and stamping parts with a one-stop supply chain from casting to assembly, providing solutions in structure, cladding, and process design.

Contact us now

Micro-channel Aluminum Tubes

Aluminum Condenser Header Pipe

Aluminium Tube Coil

Aluminum Capillary Tube

Aluminum Finned Tubes

Aluminum Tubes For Heat Exchangers

Aluminum Fin Stock

Aluminum Brazing Sheet

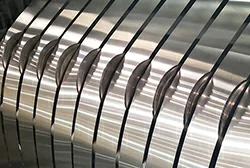

Brazing Aluminum Strip

For tailored solutions in thermal aluminum materials, contact the Chalco engineering team. We provide alloy design, structural optimization, and process integration to support your project needs.

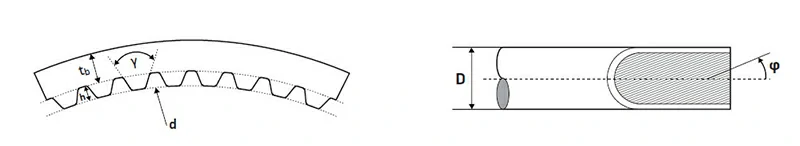

Instant QuoteInner Grooved Tube Size Range

| Outer diameter D (mm) | Bottom thickness tb (mm) | Groove depth h (mm) | Vertex angle γ (degrees) | Lead angle φ (degrees) | Number of grooves n |

| 5,00 | 0,20-0,23 | 0.12-0.15 | 11-40 | 18-40 | 40-58 |

| 6,35 | 0,23-0,27 | 0,15-0,16 | 12-40 | 18-28 | 45-54 |

| 7,00 | 0,21-0,27 | 0,10-0,24 | 10-53 | 15-40 | 50-70 |

| 7,94 – 8,00 | 0,23-0,41 | 0,12-0,22 | 12-42 | 18-43 | 50-80 |

| 9,52 | 0,27-0,45 | 0.15-0.25 | 20-90 | 15-30 | 55-85 |

| 11,90-12,00 | 0,32-0,40 | 0,17-0,25 | 15-55 | 16-30 | 70-98 |

| 12,70 | 0,32-0,41 | 0,23-0,25 | 30-58 | 18-30 | 70-75 |

| 15.00 – 15.90 | 0.35-0.50 | 0,25-0,35 | 30-53 | 18-30 | 30-75 |

Precise structural control comes from strong manufacturing and service capabilities. Chalco provides end-to-end support from design to delivery.

Instant QuoteChalco's Manufacturing & Custom Services

As a professional aluminum tube manufacturer, Chalco delivers one-stop solutions for inner grooved tube projects:

Integrated Production Process

Complete in-house processes—from alloy casting, groove mold extrusion, cold drawing, heat treatment, surface coating to end machining—ensuring batch consistency and stable performance.

Precision Groove Customization

Chalco is equipped with specialized spiral and straight-groove dies, supporting customization of groove depth (0.05–0.33 mm), helix angle (5°–27°), and tooth count (38–60). These parameters can be fully adjusted to match different refrigerants and system designs.

Instant QuoteAdvanced Surface Treatments

Available options include anodizing, zinc coating, and anti-corrosion spraying for long-term performance in corrosive, humid, and chemical environments.

Full Set of End Machining Services

Offers flaring, punching, slotting, sealing, and expanding, allowing fast system integration and improved assembly efficiency.

Smart Testing & Clean Control

Equipped with ultrasonic cleaning, infrared cutting, non-destructive testing, and secondary inspection, ensuring each tube's cleanliness and structural integrity.

Flexible Supply Options

Available in flat coil or straight cut lengths, perfect for automated feeding and on-site processing in modern assembly lines.

FAQs

Can aluminum inner grooved tubes match the heat transfer performance of copper?

Yes. While copper has higher thermal conductivity, optimized aluminum groove designs (tooth height, count, and angle) now offer comparable performance in most HVAC, home appliance, and EV systems.

Are aluminum tubes reliable in corrosive environments like salt spray or high humidity?

Chalco offers anodizing, zinc coating, and multi-layer protection. Grooved tubes can pass ASTM B117 tests with 1000–2000 hours of salt spray resistance—suitable for coastal, kitchen, and outdoor condenser use.

Can Chalco support custom designs for different heat exchanger structures?

Yes. We provide full customization on outer diameter, groove shape, wall thickness, and end machining. Whether replacing copper or starting a new project, we can quickly adjust designs and tooling.

Instant QuoteIs deeper groove depth or more grooves always better?

Not necessarily. Groove design depends on refrigerant type, flow rate, and cooling conditions. Chalco engineers provide thermal modeling to recommend optimal groove depth and count—not just maximize them blindly.

Do you offer coiled tubes for automated production lines?

Yes. We supply flat coils and cut-to-length tubes, compatible with automatic feeders and cutters—ideal for microchannel condensers and high-density evaporators.

How do these tubes perform in new energy vehicles?

EV systems require lightweight, efficient cooling, and airtight sealing. Chalco's aluminum tubes are widely used in e-motor radiators, liquid cooling plates, and heat pumps, with options like flaring, expanding, and zinc coating for both durability and weight savings.

Do you provide samples? What's the MOQ and lead time?

Yes. We offer custom samples and low MOQ (starting at 100–200 meters). Standard lead time is 7–15 days. For custom items, schedule depends on mold availability and design complexity.

Want to learn more about aluminum inner grooved tubes—performance, selection, or customization?

Contact Chalco to request samples, quotes, or technical support. We're here to deliver efficient and reliable solutions for your thermal systems.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote