High Frequency Welded Aluminum Pipe (HFW Pipe) is an aluminum alloy tube produced through high-frequency induction welding. Compared with seamless extruded and welded pipe, HFW aluminum pipes offer key advantages:

- High efficiency: Welding speeds of 20–150 m/min, suitable for mass production;

- Flexible sizing: Outer diameter φ8–300mm, wall thickness 0.3–6mm, supports custom profiles (D-shape, oval, etc.);

- Lower cost: Up to 40%–60% cheaper than seamless tubes, with ≥95% material utilization.

With their cost-performance and process compatibility, HFW tubes are replacing brazed and some seamless tubes in HVAC headers, EV battery cooling, solar thermal systems, and refrigeration modules, becoming a core solution for industrial thermal flow.

Instant QuoteHFW Aluminum Pipe Shape Options

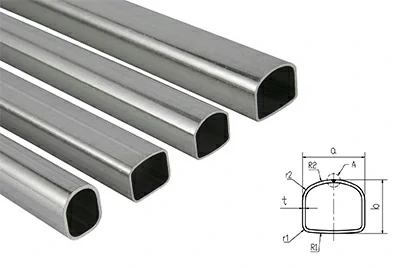

The cross-sectional design of HFW aluminum pipes directly impacts their heat transfer performance, strength, and system compatibility. Chalco offers a wide range of profiles—round, oval, D-type, flat turbulent—for use in HVAC, EV thermal systems, cooling modules, and other high-efficiency heat exchange applications.

Instant QuoteRound HFW Aluminum Pipe

Symmetrical section with low flow resistance, easy to weld or connect with fittings. Common in intercooler lines, HVAC mains, refrigerant pipes, and battery branch cooling.

Alloys: 3003, 3105, 4343/3003

OD: φ8 – φ60mm

Wall Thickness: 0.3 – 3.0mm

D-Type HFW Aluminum Pipe

Flat side fits closely with fins, increasing contact area by 30–50%. Optimizes flow distribution and reduces pressure drop. Common in parallel-flow evaporators and solar thermal collectors.

Alloy: 4343/3003

Size: D15.5×14mm – D32×23mm

Oval HFW Aluminum Pipe

Larger surface area at the same cross section boosts heat transfer by 15–20%, with low airflow resistance—ideal for compact heat exchangers like parallel-flow condensers and EV battery manifolds.

Alloys: 4343/3003, 4045/3003, 3005

Major Axis: 18 – 35mm

Minor Axis: 4 – 10mm

Wall Thickness: 0.3 – 1.2mm

Rectangular HFW Aluminum Pipe

Offers higher strength and better deformation resistance than round tubes. Ideal for modular systems such as intercoolers and oil coolers.

Alloys: 4343/3003, 4045/3003, 4047/3003

Size: 15×30mm – 15×64mm

Wall Thickness: 0.8 – 3.0mm

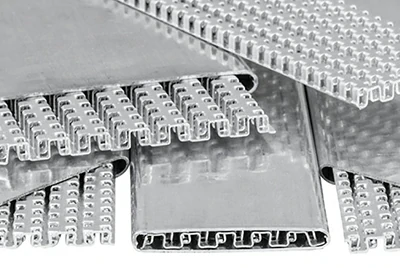

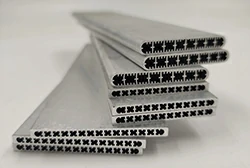

Flat HFW Aluminum Pipe

Ultra-thin walls for lightweight and high-efficiency heat dissipation. Multi-channel design increases surface area, suitable for radiator modules and data center liquid cooling.

Alloys: 4004/3003, 7072/3003

Size: 2×16mm – 2×34mm

Wall Thickness: 0.26 – 0.30mm

Multi-Chamber / Dual-Chamber HFW Pipe

Multi-channel tubes increase heat exchange area and structural stability. Formed with precision tooling, can integrate multi-stage turbulent zones.

Alloys: 7072/3003, 4343/3003, 4047/3005

Applications: battery cold plates, AC evaporators, hydrogen fuel cooling systems

Flat Turbulent HFW Aluminum Pipe

Features internal corrugations or turbulators that enhance heat transfer. Inner structure is roll-formed during welding—no post-processing required.

Alloys: 4343/3003, 4045/3003, 4343/3005

Applications: thick-wall oil coolers, high-efficiency heat exchangers, air coolers

Choosing the right cross-section is key to performance. Chalco offers customized shapes and alloys tailored to your system pressure, heat transfer needs, and assembly requirements, delivering the optimal balance of efficiency and strength.

Instant QuoteHFW Aluminum Pipe Alloy Selection Guide

HFW Aluminum Pipe demand excellent conductivity, weldability, and brazing compatibility. Chalco offers a full range of homogeneous and clad aluminum strip materials to meet performance needs in heat exchangers, cooling systems, and structural tubing.

Homogeneous Alloy Tube (Single Alloy HFW Material)

Ideal for non-brazing applications where cost-efficiency and simple structure are priorities.

- 3003 Aluminum Strip

A manganese alloy with good formability and corrosion resistance. Widely used in manifold pipes, appliance tubing, and structural connectors.

- 3005 Aluminum Strip

Slightly stronger than 3003, with moderate Mg content. Suitable for light-duty structural parts like intercooler tubes and high-temperature heat sinks.

- 3105 Aluminum Strip

Offers higher strength and compression resistance. Used for large-size or load-bearing parts like ventilation ducts, solar frames, and AC tubing.

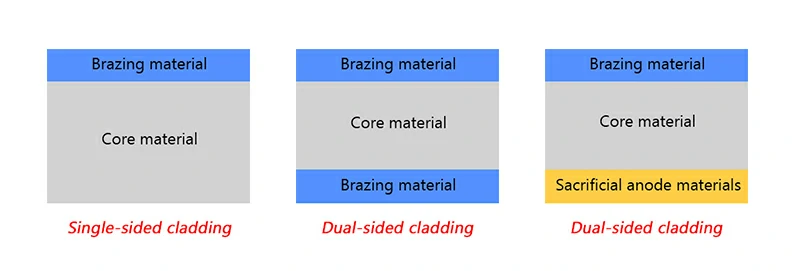

Clad Aluminum Welded Tube (Composite Alloy Material)

Clad aluminum is the mainstream choice for HFW heat exchanger tubes, combining strength, brazing compatibility, and corrosion resistance.

Instant Quote

- 4343/3003 Clad Aluminum Strip

The most widely used composite. Excellent brazability. Common in HVAC condensers, EV battery cold plates.

- 4045/3003 Clad Aluminum Strip

Higher Si content and lower melting point (~577°C) improves brazing flow. Used for AC connecting pipes, heat exchanger headers.

- 7072/3003 Clad Aluminum Strip

Improves pitting resistance, suitable for humid or corrosive environments. Used in marine heat exchangers, coastal cooling systems.

- 4004/3003 Clad Aluminum Strip

Moderate Si, ideal for thicker brazing parts with good film uniformity. Used in parallel-flow evaporators, condensing modules.

- 4047/3003 Clad Aluminum Strip

Eutectic Al-12Si with a 577°C melting point and excellent fluidity. Suitable for vacuum brazing, precision cooling manifolds.

- 4047/3005 Clad Aluminum Strip

Strong diffusion and thermal resistance. Fits complex flow systems like D-type turbulent tubes and oil cooler manifolds.

- 4343/3005 Clad Aluminum Strip

Higher strength option for medium-duty heat exchange systems, such as high-end EV battery plates and solar heat collectors.

- 7072/3003/4343 Multi-Layer Clad Strip

Triple-layer structure with corrosion resistance, brazability, and strength. Ideal for battery manifold tubes in aggressive environments.

- 4343/3003/4343 Dual Clad Strip

Double cladding ensures post-weld stability, especially for high-strength brazed components like manifolds.

Different applications require specific alloy properties for optimal performance. Whether you prioritize brazing compatibility, corrosion resistance, or mechanical strength, Chalco delivers process-validated material solutions. Share your drawings or application scenarios, and we'll help you select the right material for efficient mass production.

Instant QuoteHigh-Frequency Welded Aluminum Tube Application Solutions

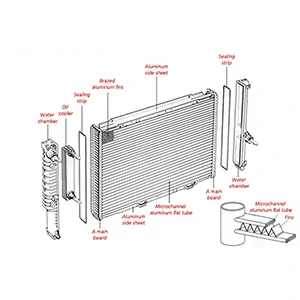

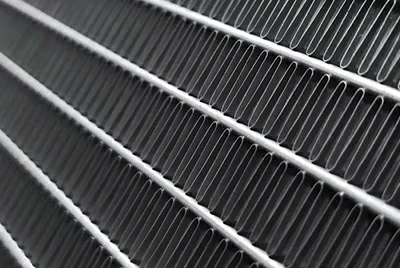

HVAC & Heat Exchange Systems Solutions

In HVAC systems and various types of heat exchangers, high-frequency welded aluminum tubes are widely used due to their thin wall structure, excellent thermal conductivity, and brazing compatibility. They are ideal for condenser manifolds, evaporator headers, and air-conditioning heat exchanger modules, serving medium to low-pressure thermal flow applications such as central air conditioning, refrigeration compressors, and appliance thermal management.

- Condenser and evaporator header tubes

- Multi-channel high-efficiency heat exchanger modules

- Ventilation circuits for central air conditioning and refrigeration systems

Recommended Product Selection

- Oval Flat Brazed Tube

4045/3003, 4343/3003

22×2×0.28mm

16×2×0.3mm

- Multi-channel Micro Cooling Tube

7072/3003, 3003

φ10×0.5mm

24×2×0.3mm (20± channels)

- D-shape HFW Tube (Main Header)

4343/3003

D26×23mm

D32×23mm

Technical Support

- Excellent brazing compatibility: Cladded with 4343/4045 for furnace brazing and fin-integrated assemblies

- Surface treatment: Supports anodizing and electrophoretic coating for humid/corrosive environments

- Customization: D-shape → multi-channel → header connector → integrated fin assembly for modular HVAC systems

Automotive Thermal Management Solutions

Thanks to their lightweight, high thermal conductivity, and complex profile forming capabilities, high-frequency welded aluminum tubes are increasingly used in automotive heat exchangers, intercoolers, and oil cooler modules, gradually replacing traditional copper pipes and brazed structures.

- Battery cooling manifolds and microchannel fluid systems

- Intercooler and oil cooler systems

- Connection and loop pipes for thermal management modules

Recommended Product Selection

- Flat Composite Tube

4343/3003, 4045/3003

16×2×0.3mm

25×4×0.4mm

- Rectangular HFW Tube

3005, 4343/3003

30×10×0.8mm

- Turbulent Flow Flat Tube

4047/3003, 4343/3005

32×2×0.35mm

Multi-channel

Technical Support

- Brazing compatibility: 4343/4045 cladding supports protective atmosphere furnace brazing

- Leak testing: Supports 100% helium testing with leak rate ≤1×10⁻⁶ Pa·m³/s

- Surface treatment: Options include anodizing, electrophoresis, and polishing for enhanced corrosion resistance

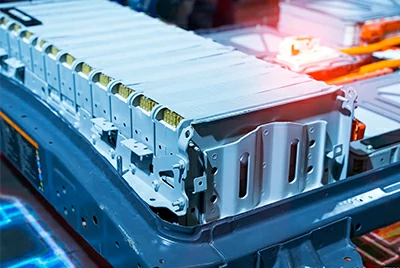

New Energy Battery Cooling System Solutions

In new energy vehicles and energy storage systems, high-frequency welded aluminum tubes are critical components in battery liquid cooling plates, cooling manifolds, and integrated thermal systems. They offer high thermal conductivity, lightweight structure, and brazing compatibility, with customizable shapes and flow paths suited for various thermal density and space constraints.

- Battery module cooling manifolds

- Manifold and branch pipes in liquid cooling plates

- Integrated flow paths in thermal management systems

Recommended Product Selection

- Microchannel Brazed Flat Tube

4045/3003, 4343/3003

16×2×0.3mm

25×2.5×0.4mm

- Flat Manifold Tube

4343/3003, 7072/3003

24×4×0.5mm

30×4×0.5mm

- Shaped Connection Tube (D/Snake)

4343/3005, 4047/3003

D26×23mm

Custom sections

Technical Support

- High gas-tightness: Leak rate ≤1×10⁻⁶ Pa·m³/s, supports dual helium and pressure testing

- Electrolyte corrosion resistance: Anodized or inner cladding with 7072 (Al-Zn) for extended durability

- Modular interface optimization: One-piece manifolds with microchannel sections simplify liquid cooling assembly

Industrial Heat Exchange Solutions

In fields like industrial equipment, energy systems, and process manufacturing, equipment demands higher cooling efficiency, pressure resistance, and structural integration. Chalco's high-frequency welded aluminum tubes offer high strength and thermal performance, widely used in hydraulic oil coolers, laser cooling modules, and heat exchanger bundles—especially when replacing copper or stainless steel.

- Hydraulic system cooling tube groups

- Water/oil cooling systems in electromechanical devices

- Heat exchanger tube bundles and condenser modules

Recommended Product Selection

- Square/Rectangular HFW Tube

4045/3003, 3005, 5052

40×8.08×0.45mm

30×12×0.8mm

- Corrosion-Resistant Structural Tube

4343/3003, 7072/3003

φ16×1.0mm

D20×15mm

- Corrugated/Turbulent Internal Tube

4047/3003, 4343/3005

28×2.5×0.35mm

Multi-channel

Technical Support

- Pressure compatibility: Supports 6–10 MPa; structural simulation and fatigue testing available

- Weld quality assurance: Weld strength reaches 90–95% of base metal, with inline eddy current flaw detection (≤0.3mm)

- Internal turbulence customization: Boosts heat transfer efficiency by 20%+, ideal for high-flux equipment

- Surface finishing options: Anodizing, electrophoretic coating, and paint compatibility for corrosive environments

Chalco offers full-spectrum high-frequency welded aluminum tube solutions covering material design, structural customization, and process compatibility, widely serving the core thermal management needs of automotive, HVAC, heat exchange, and industrial equipment sectors.

If you require assistance with material selection, structural design, or performance validation, our technical team provides one-on-one support and precise recommendations.

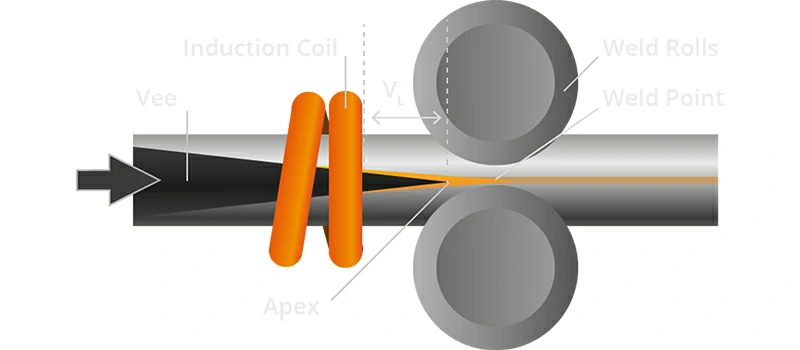

Instant QuoteHFW Aluminum Pipe Manufacturing Process

High-Frequency Welded Aluminum Tubes (HFW Pipes) are manufactured through a continuous aluminum strip roll forming process combined with high-frequency induction welding, integrated shaping, and post-treatment. This enables high-efficiency and consistent welding quality. Below is an overview of the standard production workflow:

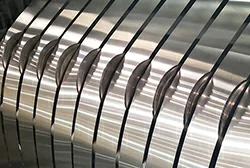

Aluminum Strip Preparation & Pretreatment

We use 3003, 3105, and 4343/3003 clad aluminum strips. Strips undergo chemical degreasing and edge milling to ensure the welding area is free from oxide layers and impurities. Strip dimensions are calculated based on the final pipe diameter.

Roll Forming

The strip is gradually rolled into a tube through 10–15 passes, with roller gap tolerance controlled within ±0.02mm to ensure consistent forming. Suitable for round, oval, D-shaped, and rectangular cross-sections.

High-Frequency Induction Welding

High-frequency current (100–400kHz) is applied to the tube edges to rapidly heat them to a molten state. Simultaneously, 0.5–1.5MPa mechanical pressure is applied to achieve metallurgical bonding of the seam.

Weld Seam Treatment & Sizing

An in-line carbide scraper removes internal burrs (residual height ≤0.1mm). Air or fan cooling is used to avoid residual stress. A sizing machine ensures outer diameter tolerance of ±0.05mm and straightness ≤1mm/m.

Surface Treatment & End Machining

Depending on customer needs, tubes can undergo anodizing, electrophoretic coating, or sealing treatment, with anodic film thickness controlled between 15–25μm and salt spray resistance ≥1000 hours. Cutting is done via laser or flying saw, and end machining includes chamfering, flaring, and other custom interfaces for improved assembly efficiency.

Chalco's Quality Control & Inspection System

To ensure weld strength, air tightness, and dimensional consistency, Chalco employs comprehensive testing equipment and real-time process monitoring.

Weld Quality Inspection

| Testing methods | Function description | Standard requirements |

| Eddy current testing | Real-time detection of surface cracks and lack of fusion defects | Defect size ≤ 0.3mm (ISO 10893-7) |

| Ultrasonic testing | Inspection of internal inclusions and incomplete penetration | Applicable to wall thickness ≥ 3mm (ASTM E317) |

| X-ray testing | High-precision perspective of weld defects | Used for high reliability projects such as battery cooling |

Dimensional & Mechanical Testing

- Dimensional accuracy: Laser diameter gauge ensures ±0.05mm outer diameter and wall thickness control

- Ovality/Straightness: Controlled within ≤0.5% / ≤1mm/m

- Mechanical performance: Weld strength ≥ 90% of base metal, hardness variation ≤ 10HV

Air Tightness & Corrosion Resistance Testing

- Hydrostatic Test: 1.5x working pressure, hold for 30 minutes, no leakage

- Helium Leak Detection: Sensitivity ≤ 1×10⁻⁶ Pa·m³/s

- Salt Spray Test: Anodized tubes ≥ 1000 hours per ASTM B117

Chalco operates a fully integrated production line from strip processing to finished HFW tube delivery, ensuring each batch meets international standards in weld integrity, precision, and application compatibility. We welcome custom inquiries regarding welding technology, testing capabilities, or product specifications.

Instant QuoteChalco's Other Aluminum Solutions for Thermal Management

Aluminum Heat Transfer Solutions

Chalco offers brazing clad materials, HFW tubes, header tubes, and stamping parts with a one-stop supply chain from casting to assembly, providing solutions in structure, cladding, and process design.

Contact us now

Multi-port design, excellent thermal conductivity and compact structure. EV cooling plates, data center liquid cooling modules.

Internal helical grooves increase fluid turbulence and heat exchange. HVAC condensers, evaporators.

Clad alloys like 4343/3003, 7072/3003 for vacuum or protective atmosphere brazing. Condensers, evaporators, heat exchangers.

Aluminum Condenser Header Pipe

Distributes refrigerant or coolant evenly in condensers and evaporators, ensuring efficient heat exchange.

Flexible aluminum tubing designed for compact installation in HVAC and refrigeration systems.

Precision small-diameter tubes used for refrigerant throttling in HVAC and cooling systems.

Aluminum tubes with extended fins to enhance heat dissipation for HVAC, radiators, and heat exchangers.

Thin aluminum sheets with excellent formability and corrosion resistance for fins in heat exchangers and condensers.

Clad aluminum sheets engineered for brazing, widely used in automotive heat exchangers and HVAC components.

For tailored solutions in thermal aluminum materials, contact the Chalco engineering team. We provide alloy design, structural optimization, and process integration to support your project needs.

Instant QuoteFAQs

How to choose the right alloy for HFW Aluminum Pipe?

- 3003: Cost-effective, good corrosion resistance. Suitable for condenser headers and HVAC ducts.

- 4343/3003 clad strip: Ideal for in-furnace brazing systems, used in A/C evaporators and battery cooling plates.

- 7072/3003 clad strip: For marine or high-corrosion environments, offers sacrificial anode protection.

What to do if thin-wall HFW Aluminum Pipe (<1mm) burn through during welding?

Thin walls are sensitive to heat. Solutions:

- Switch to laser welding or pulsed TIG to reduce heat-affected zone by ~40%

- Use copper liners or external mist cooling, keeping temperature ≤100°C

Why is the weld strength only 80% of base metal after HFW?

Likely due to insufficient heat or pressure. Recommendations:

- Increase current frequency by 10kHz per 0.1mm wall thickness

- Set extrusion pressure to 1.0–1.2mm

- Add plasma cleaning before welding for a cleaner surface

Our HFW tubes fail early in salt spray tests – any solution?

This often relates to material or post-treatment issues. Suggested:

- Use Zn-layered 7072/3003 clad strips

- Apply anodizing + sealing for up to 2x corrosion resistance

- Design the weld zone to avoid standing water exposure

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteHigh-Frequency Welded Tube Size Chart

Round High-Frequency Welded Tube Size Chart

| Round Collector | OD/a(mm) | Wall Thickness/t(mm) |

| P20x1.15 | 20±0.1 | 1.15 |

| P20x1.2 | 20±0.1 | 1.2 |

| P20x1.5 | 20±0.1 | 1.5 |

| P20x1.12 | 20±0.1 | 1.12 |

| P28x1.0 | 20±0.1 | 1.3 |

| P28x1.6 | 28±0.12 | 1.6 |

| P33.4×1.5 | 33.40-0.2 | 1.5 |

| P30x1.2 | 30+0.20 | 1.2 |

| P30x1.5 | 30±0.05 | 1.5 |

| P30x1.6 | 30±0.1 | 1.6 |

| P19x1.3 | 19±0.05 | 1.3 |

| P15.88×1 | 15.88±0.2 | 1 |

| P19x1.2 | 19 | 1.2 |

| P31.6×1.5 | 31.6±0.2 | 1.5 |

| P25x1.3 | 25±0.1 | 1.3 |

| P38x2 | 38±0.15 | 2 |

| P22x1.3 | 19±0.05 | 1.2 |

| P26x1.9 | 26±0.08 | 1.9 |

| P25x1.8 | 25±0.08 | 1.8 |

| P23x1.7 | 23±0.08 | 1.7 |

| P20.4×1.7 | 20.4±0.1 | 1.7 |

D-Shaped High-Frequency Welded Tube Size Chart

| D-type collector | Dimensions(mm) | ||

| Width(a) | Height(b) | Material Wall Thickness(t) | |

| PD20.4×18 | 20.4±0.1 | 18±0.1 | 1.2 |

| PD20x18 | 20±0.1 | 18±0.1 | 1 |

| PD20.4×18.5 | 20.4±0.05 | 18.5±0.05 | 1 |

| PD25.5×19 | 25.5±0.1 | 19±0.05 | 1.2 |

| PD15.1×12.7 | 15.1±0.05 | 12.7±0.05 | 1.2 |

| PD16×16 | 16 | 16 | 1.2 |

| PD18×19 | 18 | 19 | 1 |

| PD18×22 | 18 | 22 | 1.5 |

| PD20×17 | 20 | 17 | 1 |

| PD21.4×19.4 | 21.4 | 19.4 | 1 |

| PD21×18 | 21 | 18 | 1 |

| PD21×19.5 | 21 | 19.5 | 1 |

| PD23.35×22.4 | 23.35 | 22.4 | 1.6 |

| PD25.5×19 | 25.5 | 19 | 1.2 |

| PD26×22.4 | 26 | 22.4 | 1.2 |

| PD32×18 | 32 | 18 | 1.2 |

| 32 | 18 | 1.8 | |

| PD32×23 | 32 | 23 | 1.2 |

| PD38×27 | 38 | 27 | 2 |

| PD44×19 | 44 | 19 | 1 |